Insulation batt with integral air vent

a technology of air vents and insulation batts, which is applied in the field of insulation products, can solve the problems of poor air circulation and installers who may inadvertently fail to install vents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

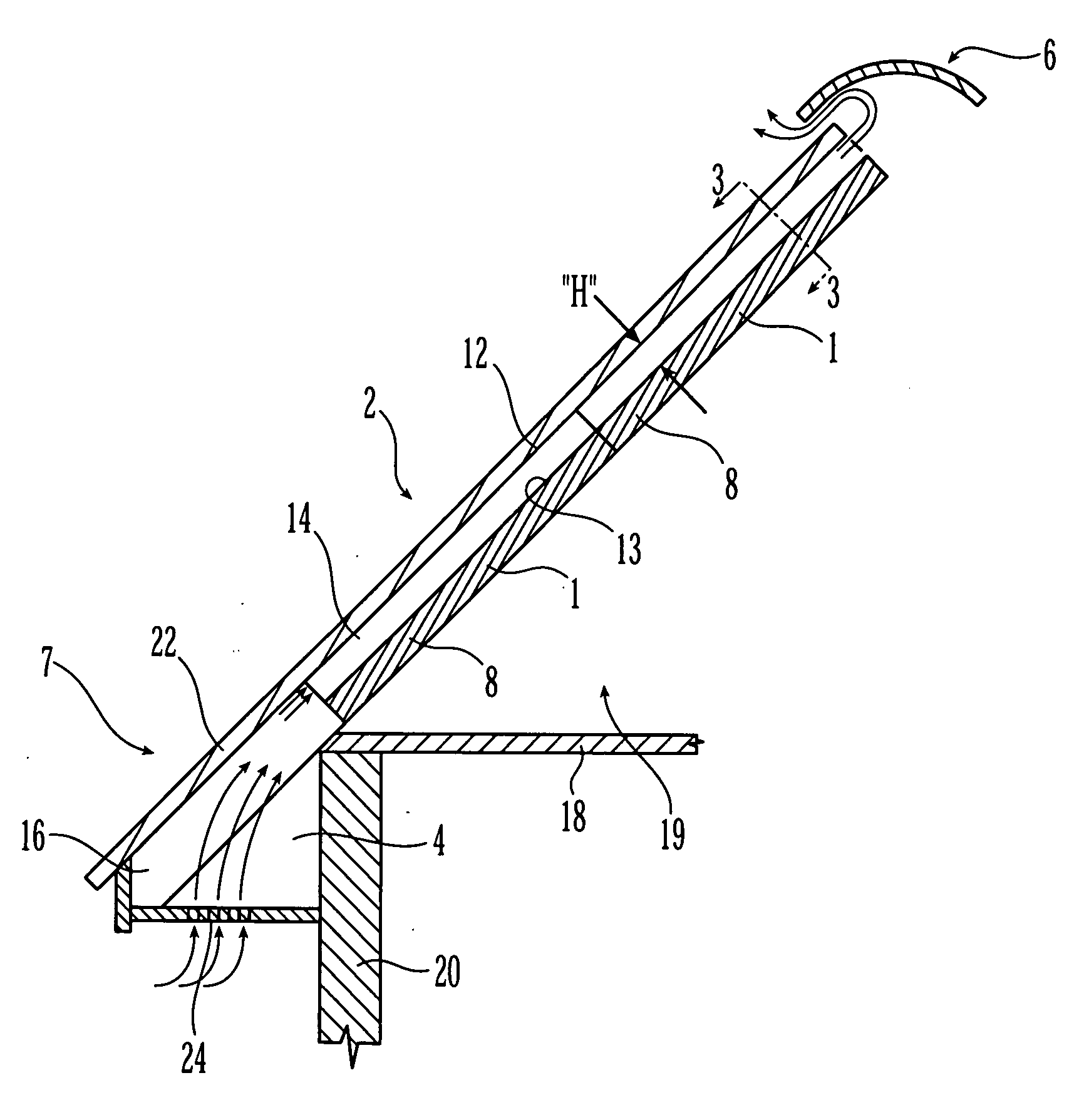

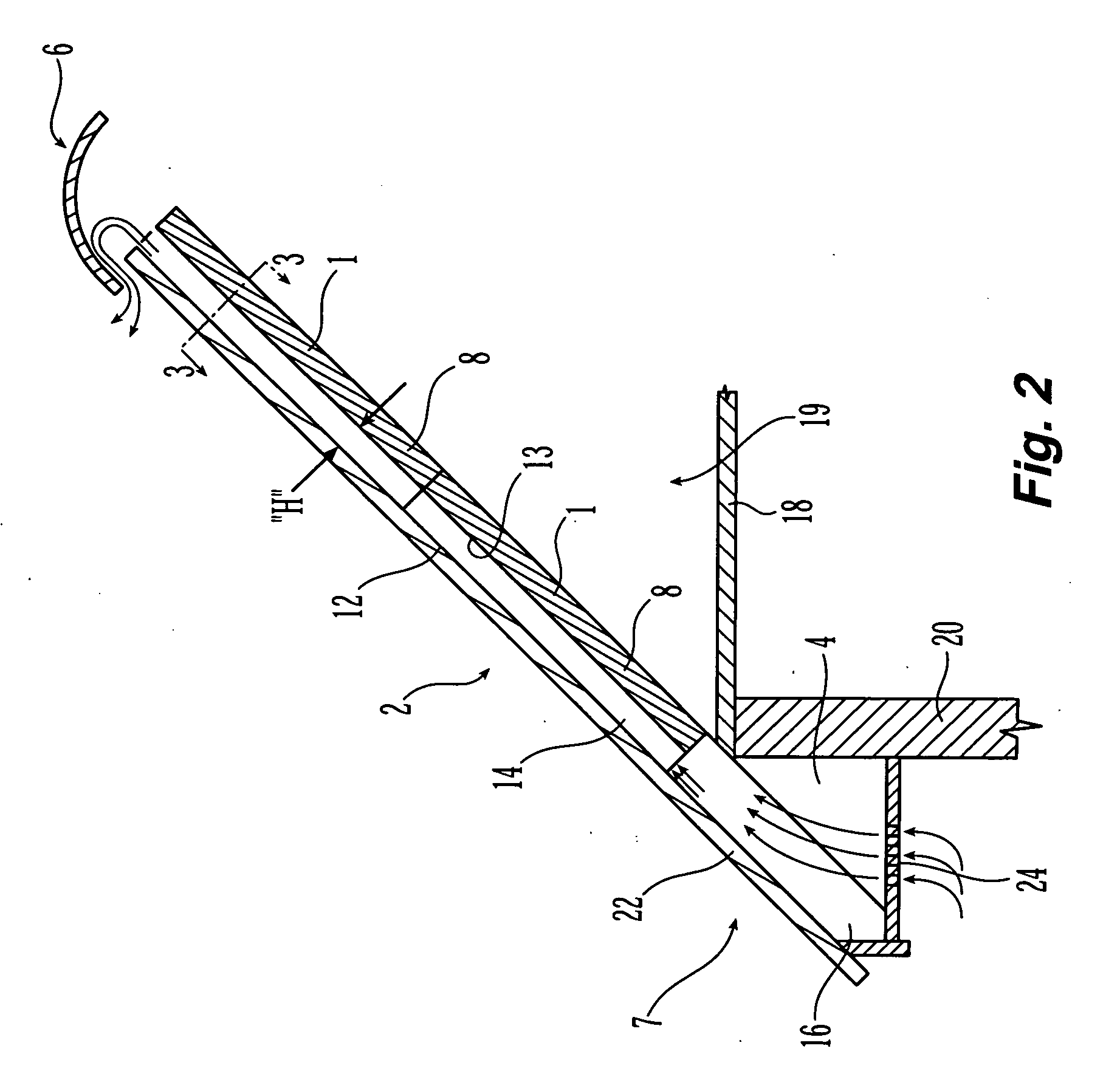

[0019]This invention is directed to attic air vents used under the roof of a building to ventilate air from a soffit area to an attic space. The invention is particularly advantageous for use in cathedral ceiling applications in which pre-formed insulation batts are placed between roof rafters. Pre-formed insulation batts can be self-retaining, meaning they are manufactured to have a width that is about ¼″ to about ½″ wider than the distance between adjacent roof rafters. The resulting friction-fit between the batts and roof rafters eliminates the need for stapling or other mechanical fastenings. One problem with such self-retaining insulation batts is that without careful installation they can be pressed up too close to the roof, thereby cutting off air flow from the soffit to the roof peak.

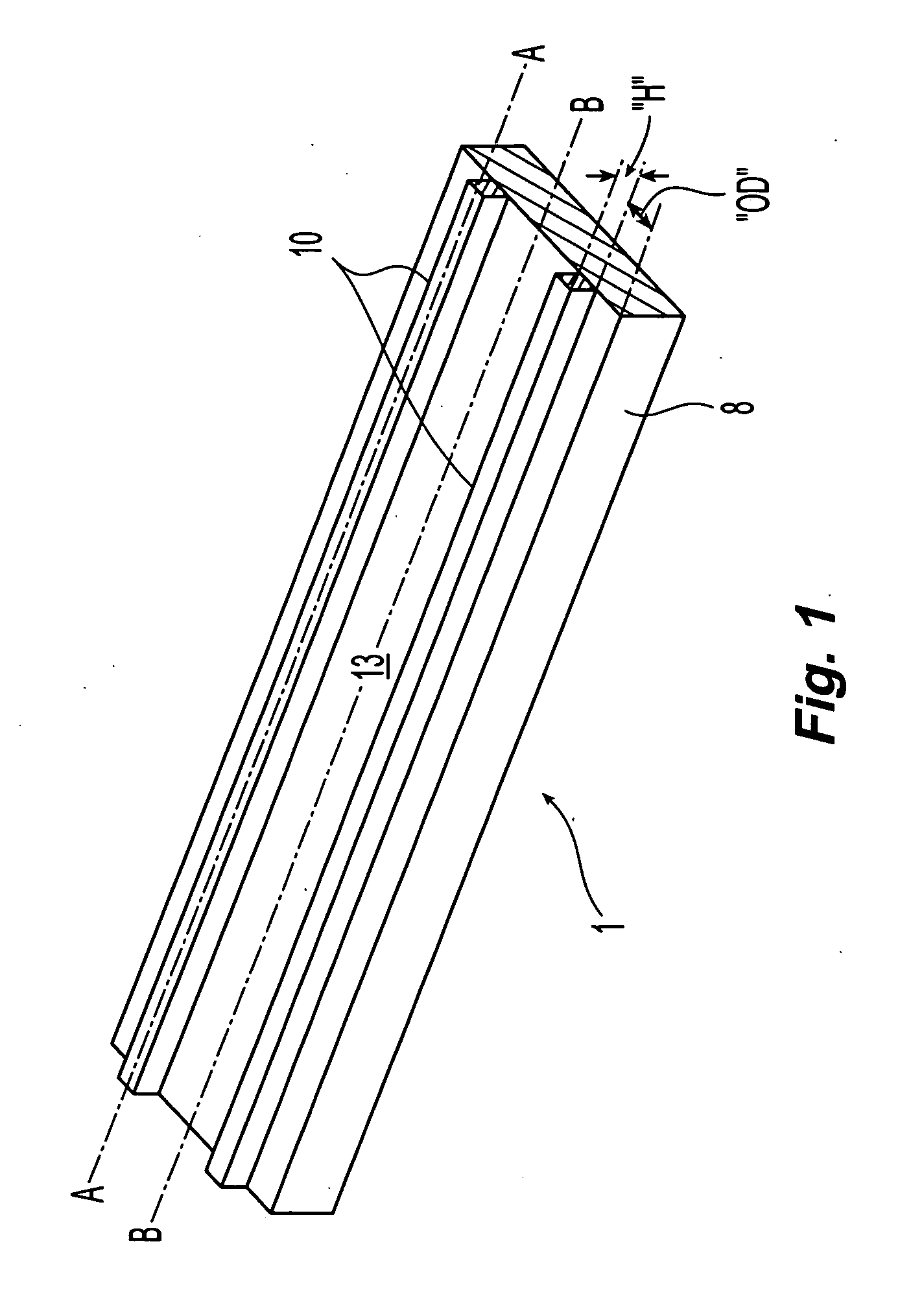

[0020]In accordance with the Figures, and particularly FIGS. 1 and 2, there is shown a preferred insulation batt 1 for ventilating air under a roof 2 between a soffit area 4 of the roof and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com