Friction generator

A triboelectric generator and electrode layer technology, applied in the direction of triboelectric generators, etc., can solve the problems of restricting the development and application of generator output power, and achieve the effects of large output power, high output power and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

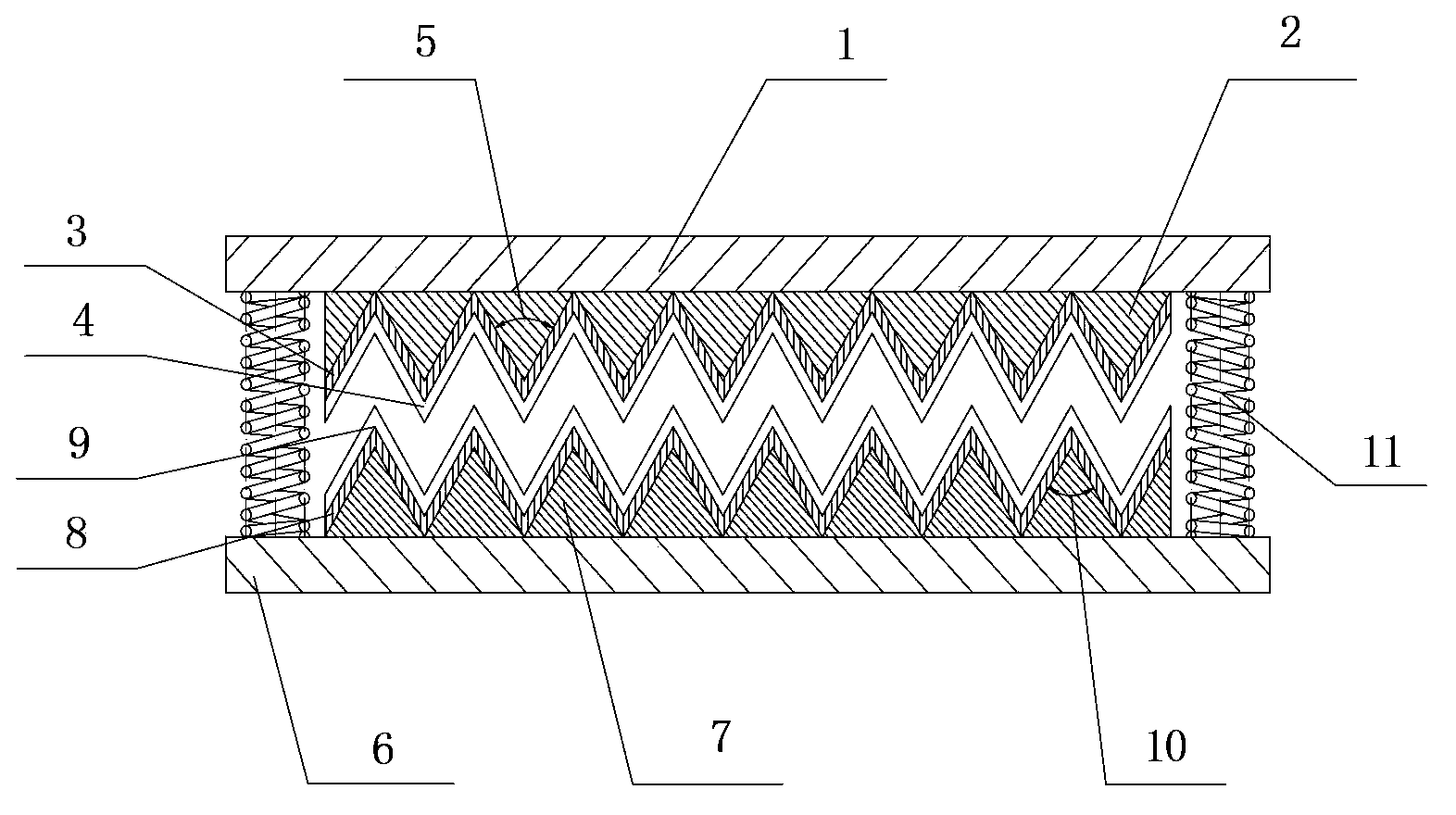

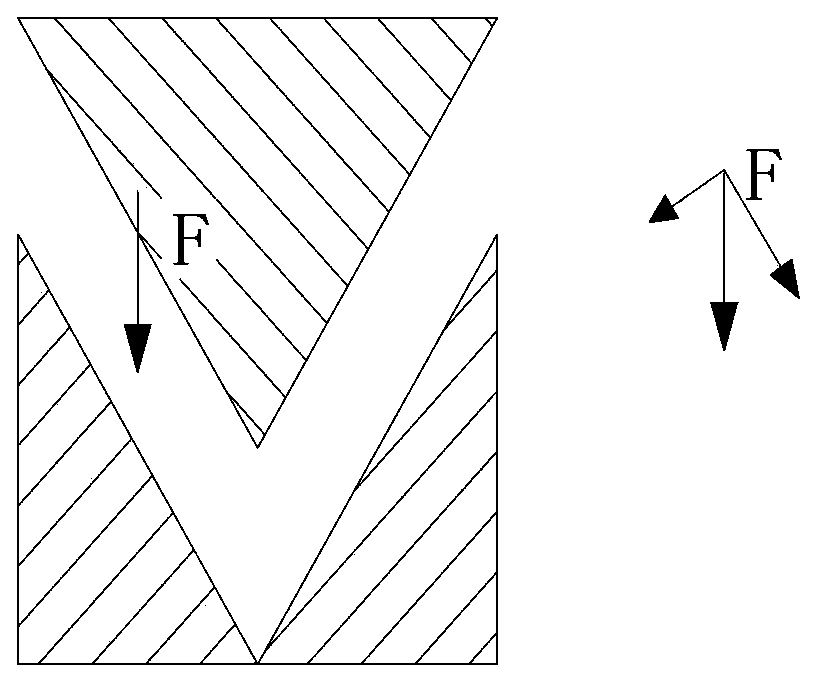

[0064] Such as figure 1 Triboelectric generator

[0065] (1) Take two square acrylic plates as the first substrate and the second substrate, the size of which is 10cm*10cm*1cm, and drill four holes in the four corners of the two square substrates for installing springs.

[0066] (2) Bonding the sponge to the first substrate prepared in step (1), the shape of the sponge protrusion is a regular pyramid (that is, the dihedral angle between the bottom surface of the regular pyramid and the sides of the regular pyramid is 60 degrees) , the size of the bottom surface of the regular square pyramid is 2mm*2cm, and the regular square pyramids are arranged in sequence with common sides; the acrylic is bonded to the second substrate prepared in step (1), and the shape of the acrylic depression is a regular square pyramid, and the regular square pyramid The dihedral angle between the bottom surface and the sides of the quadrangular pyramid is 62 degrees, and the side length of the bottom...

Embodiment 2

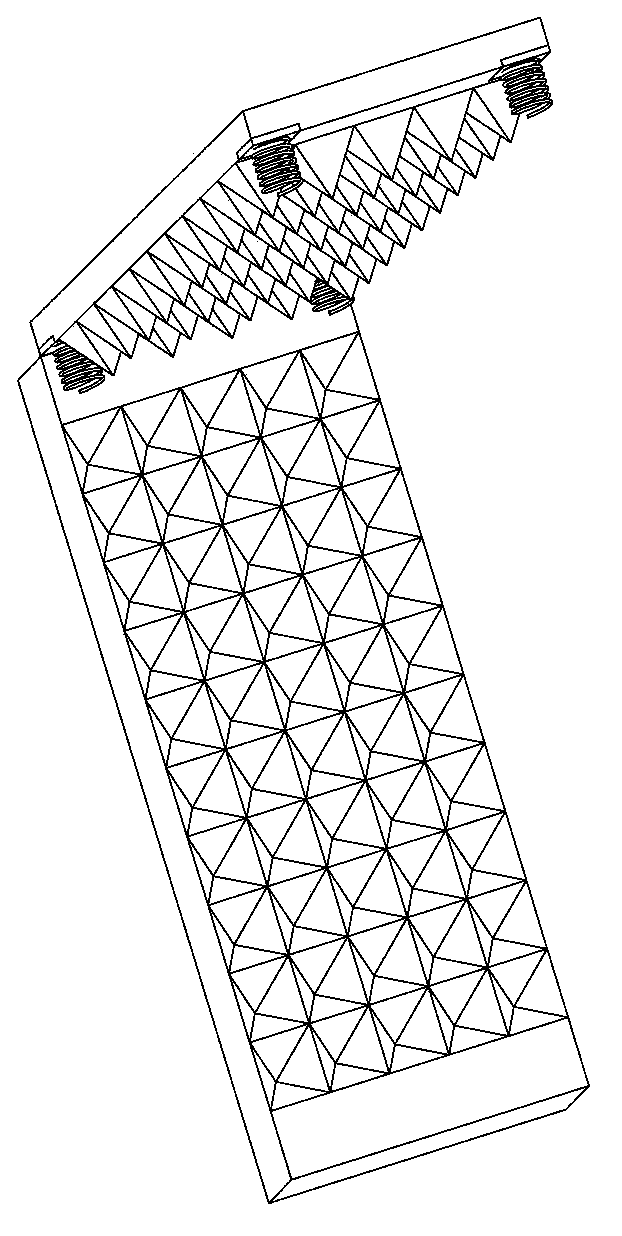

[0070] Such as Figure 3a with Figure 3b The friction generator is prepared as shown, wherein, Figure 3a is the three-dimensional view of the prepared triboelectric generator, Figure 3b Plan view of the prepared triboelectric generator.

[0071] (1) Take two square acrylic plates as the first substrate and the second substrate, the size of which is 10cm*10cm*1cm, and drill four holes in the four corners of the two square substrates for installing springs.

[0072] (2) Bonding the sponge to the first substrate prepared in step (1), the shape of the sponge protrusion is a regular triangular prism, wherein the dihedral angle between the surface of the first substrate and the side of the regular triangular prism is 120 degrees , the base length of the regular triangular prism cross-section triangle is 2 mm, and the regular triangular prisms are arranged in sequence with common sides; the acrylic is bonded to the second substrate prepared in step (1), and the shape of the acr...

Embodiment 3

[0076] Such as Figure 4a with Figure 4b The friction generator is prepared as shown, wherein, Figure 4a is the three-dimensional view of the prepared triboelectric generator, Figure 4b Plan view of the prepared triboelectric generator.

[0077] (1) Take two square acrylic plates as the first substrate and the second substrate, the size of which is 10cm*10cm*1cm, and drill four holes in the four corners of the two square substrates for installing springs.

[0078] (2) Bond the sponge to the first substrate prepared in step (1). The shape of the sponge protrusion is a cuboid (the length, width and height of the cuboid are 3mm*3mm*6mm), distributed in an array, and two adjacent cuboids The distance between them is square, and its size is 2.5mm*2.5mm; the acrylic is bonded to the second substrate prepared in step (1), and the shape of the acrylic protrusion is also a cuboid (the length, width and height of the cuboid are 2.5mm *2.5mm*6mm), array distribution, the interval ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com