Separator for separating envelopes from a stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

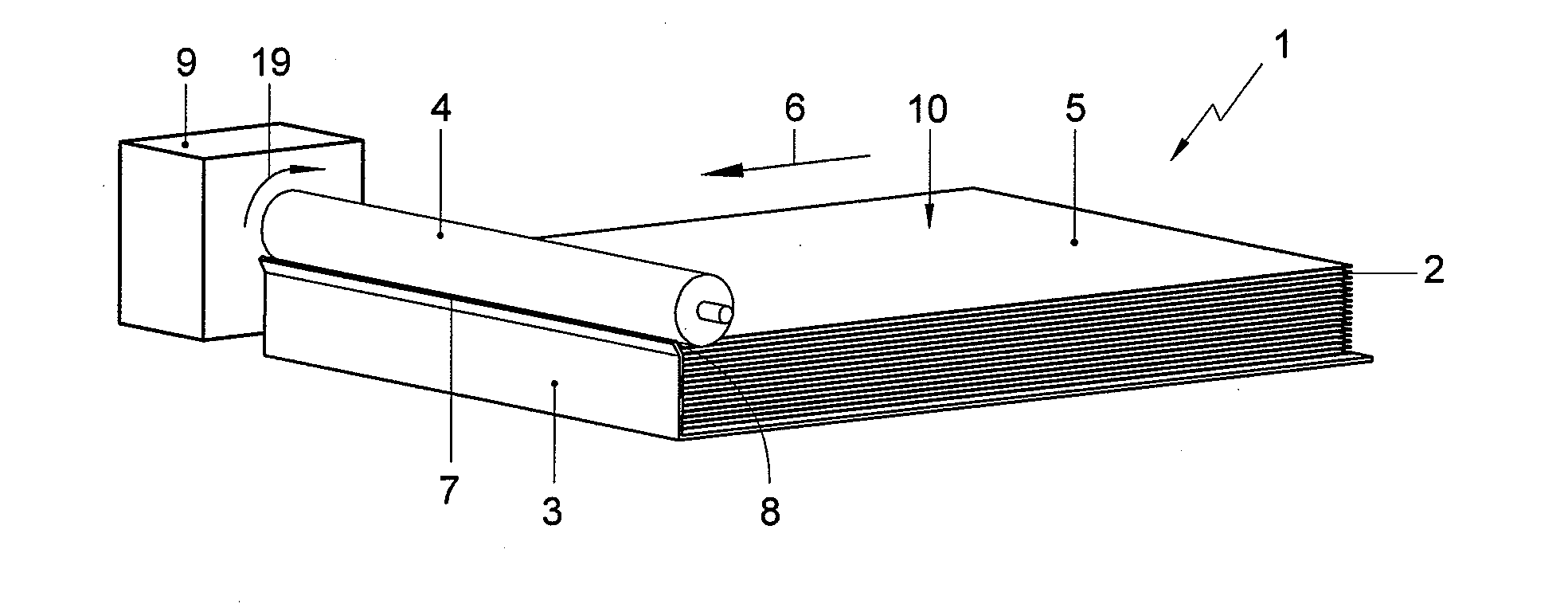

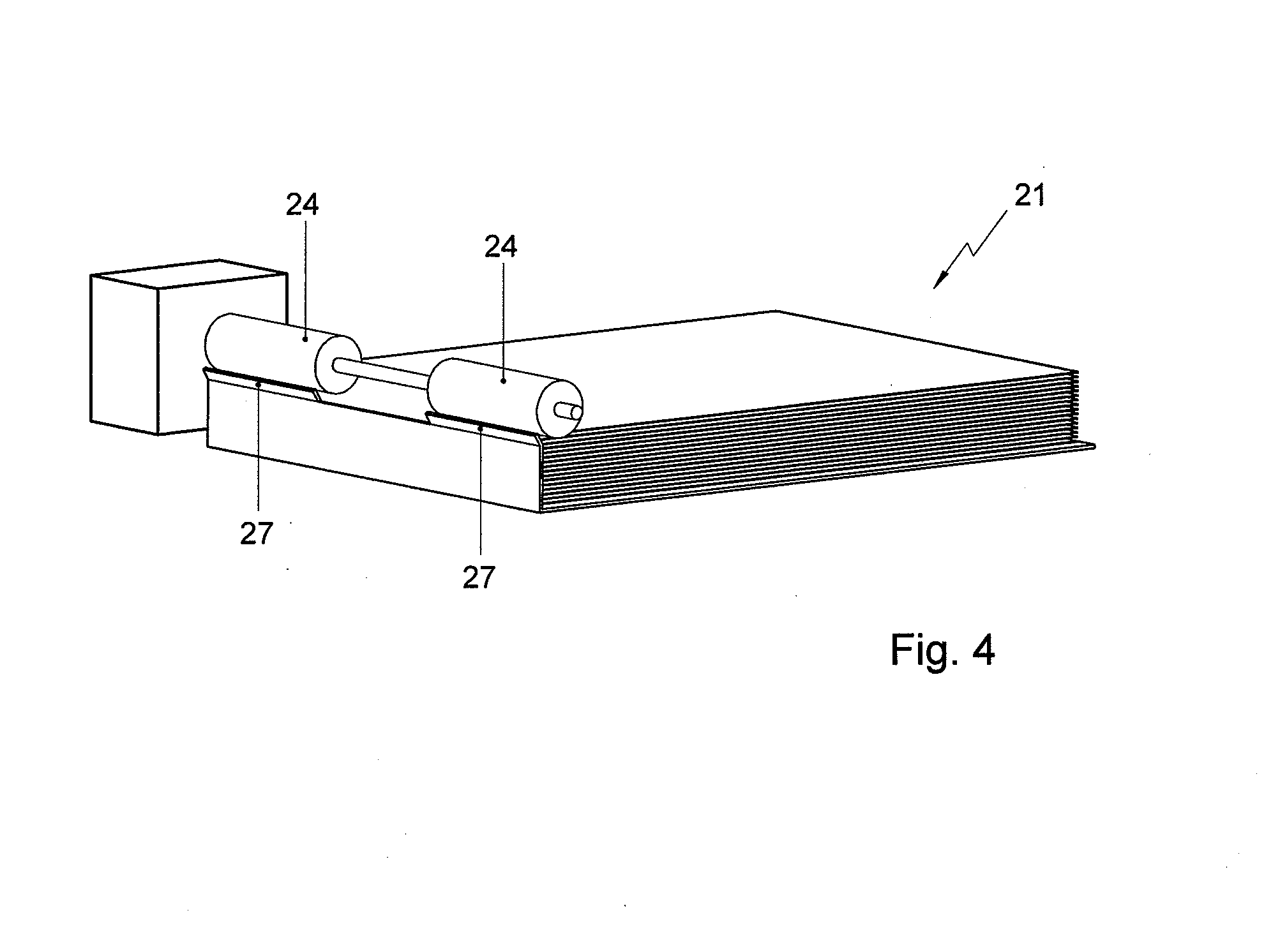

[0012]The invention is first described with reference to the example shown in FIGS. 1-3.

[0013]The separator 1 according to the present example is equipped with a holder 3 for holding a stack of envelopes 2 with an outer envelope 5 in a separating position, a feeding roller 4 and a deflecting surface 7. The feeding roller 4 and the deflecting surface 7 bound a feeding path having a width, and starting at the separating position.

[0014]The holder 3 supports the stack 2 of envelopes to be separated. The holder 3 has lateral guides 11 (not shown in FIG. 1) for maintaining the envelopes positioned by contacting lateral edges of the envelopes. The guides 11 are adjustable in the lateral direction by rotating a threaded spindle 12, for adapting the mutual distance between the guides 11 to envelopes of different sizes. Stops 13 define the maximum outer position of the guides 11.

[0015]The stack of envelopes 2 is positioned with one edge against a front (downstream) wall of the holder 3 for al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com