Material Containment System

a technology of containment system and material, which is applied in the direction of container/bottle construction, rigid containers, packaging, etc., can solve the problems of reducing order fulfillment rates, increasing the likelihood of imbalances, and affecting the commercial implementation of sub-atmospheric pressure gas packages. , to achieve the effect of enhancing the safety of fluids, and enhancing the safety of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

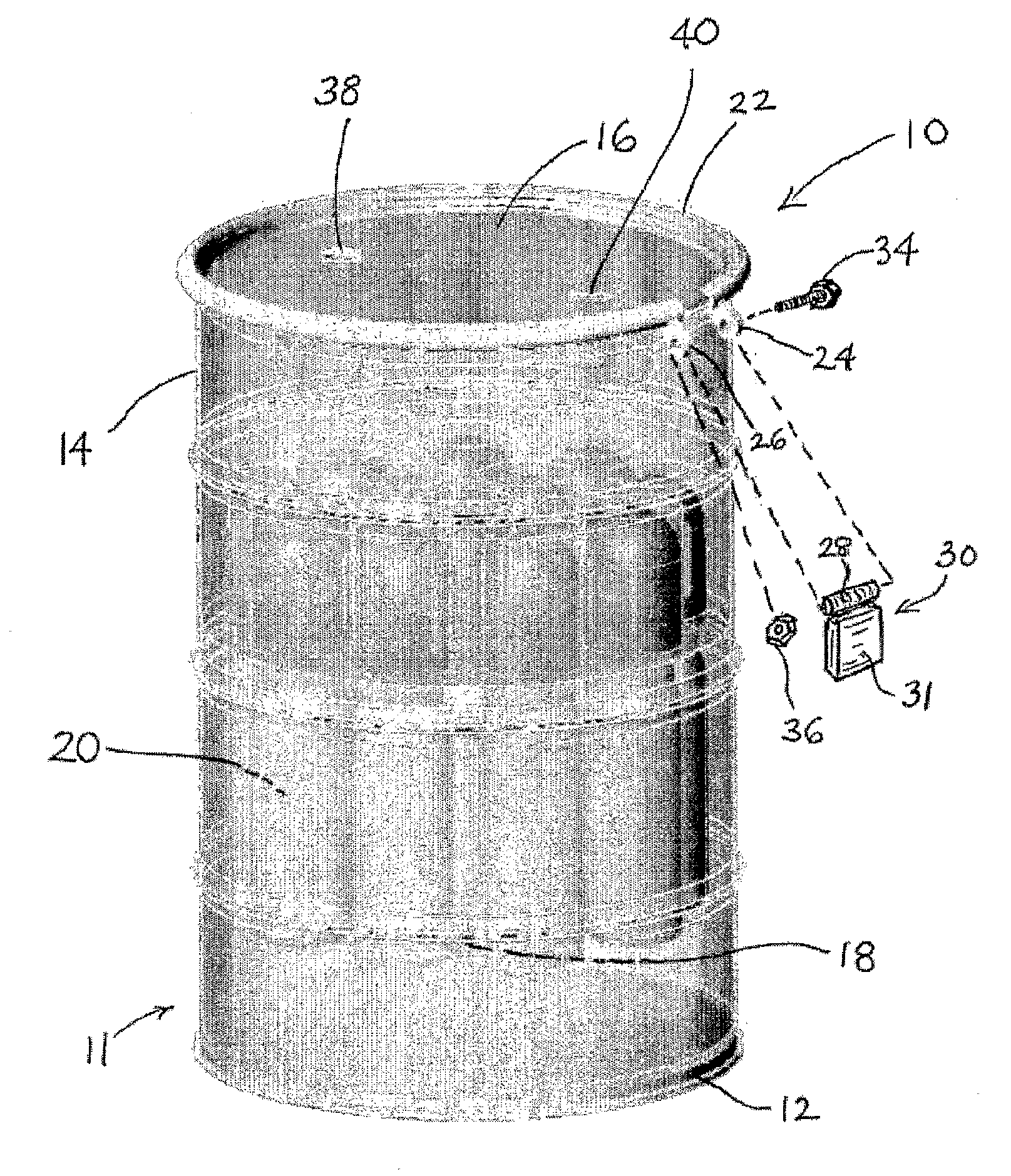

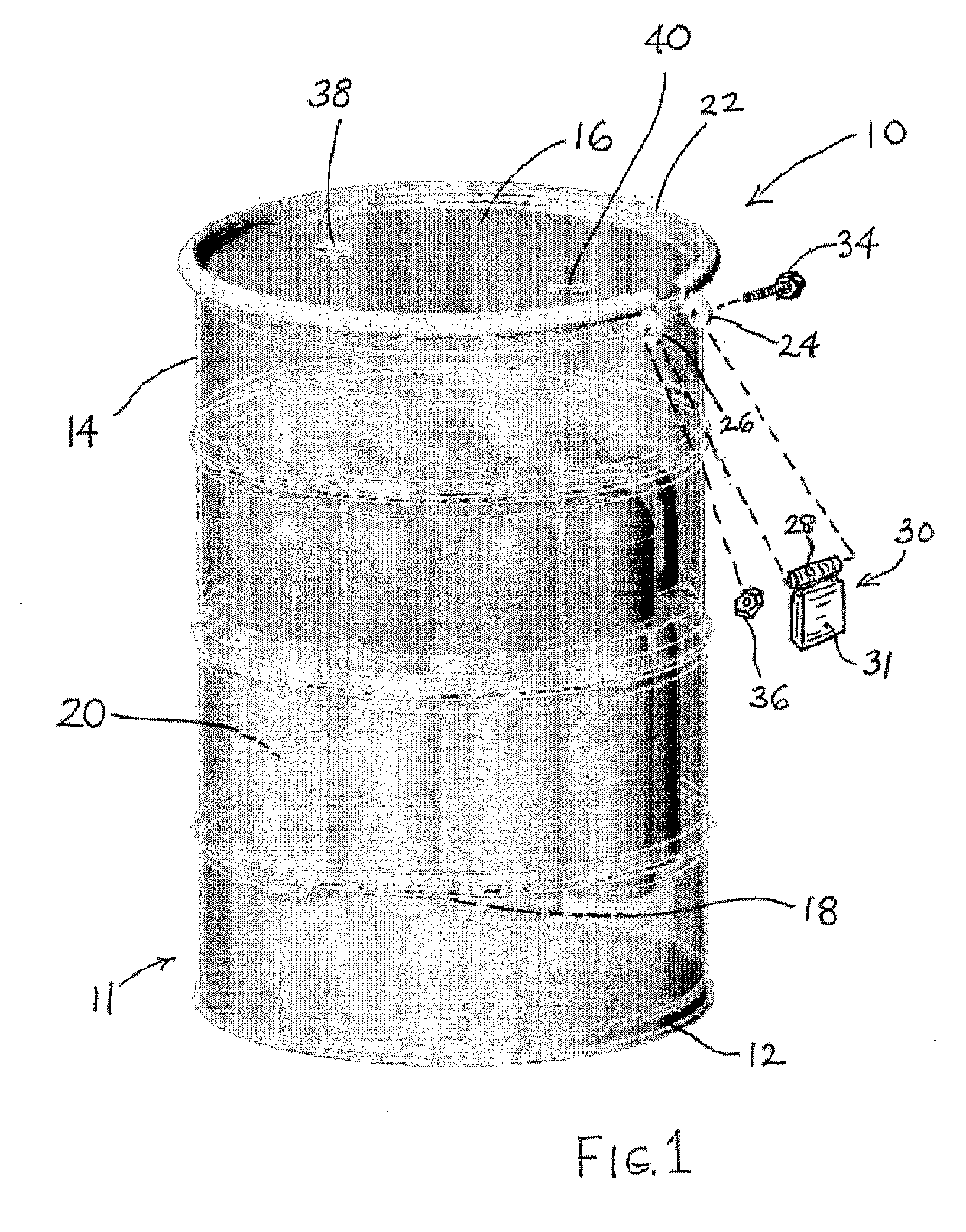

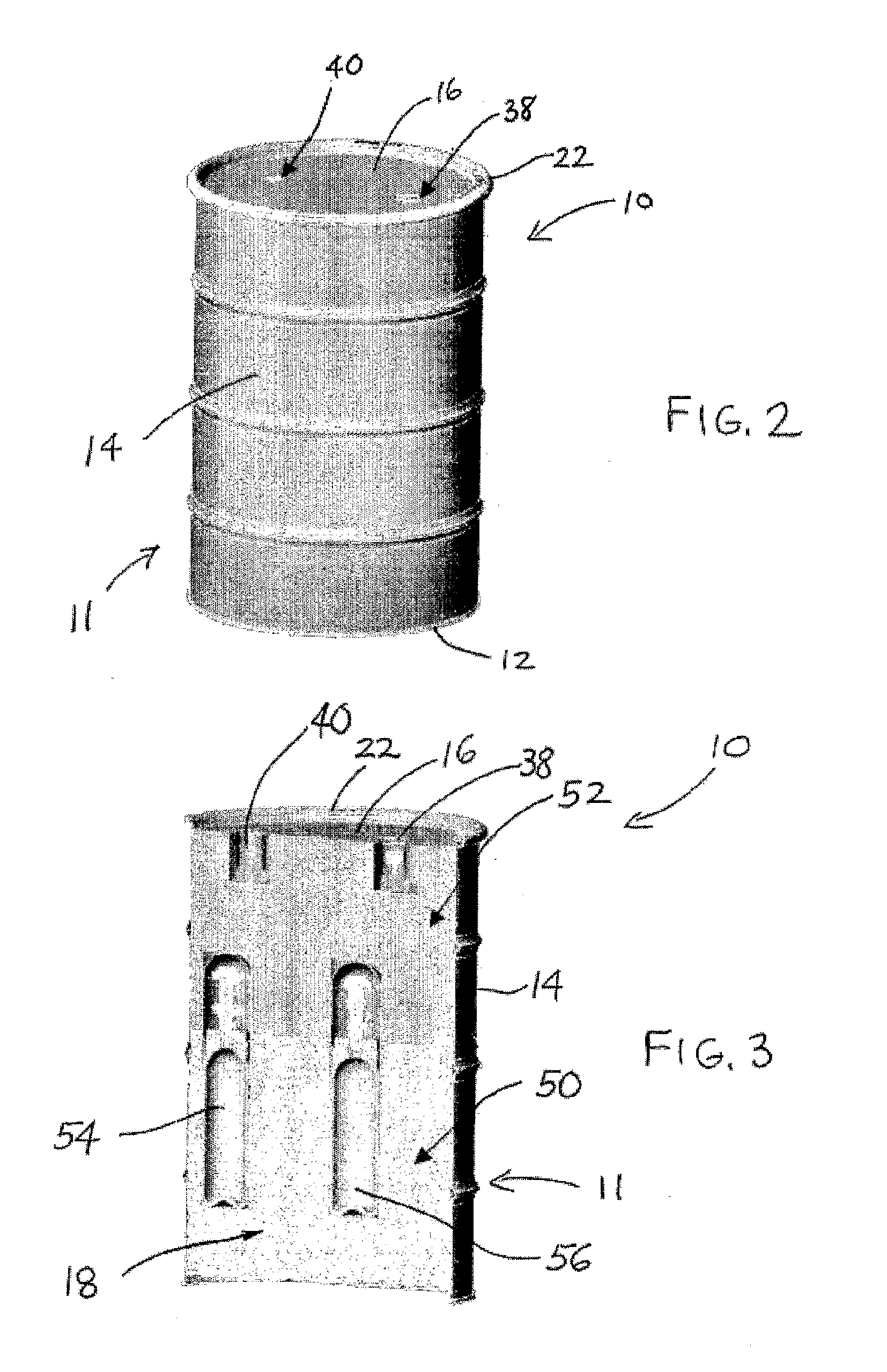

[0038]The present invention relates to containment packages having utility for the storage and / or transport of materials, preferably hazardous materials, more preferably liquids and / or gases, most preferably gases, and to security systems for controlling access to packages, e.g., hazardous gas containment packages.

[0039]As used herein the term “hazardous materials” is defined as including any material identified in 49 CFR-172.101 Hazardous Materials Table and sanctioned by Hazardous Materials Regulations.

[0040]In one specific aspect, the invention relates to a containment package, including an overpack for improving the safety and security of gas-containment vessels during transportation, e.g., air shipment, and a global positioning system (GPS) coordinated programmable lock and key system suitable for use with a package such as container packages for hazardous gases.

[0041]The vessels described herein can be any container for materials. Preferably, the vessel comprise a subatmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| transportation time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com