Method of cementing an off bottom liner

a cementing method and bottom liner technology, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of time-consuming and labor-intensive steps of drilling plugs out, unproductive cementing out the bottom of the liner, and leaving debris in the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

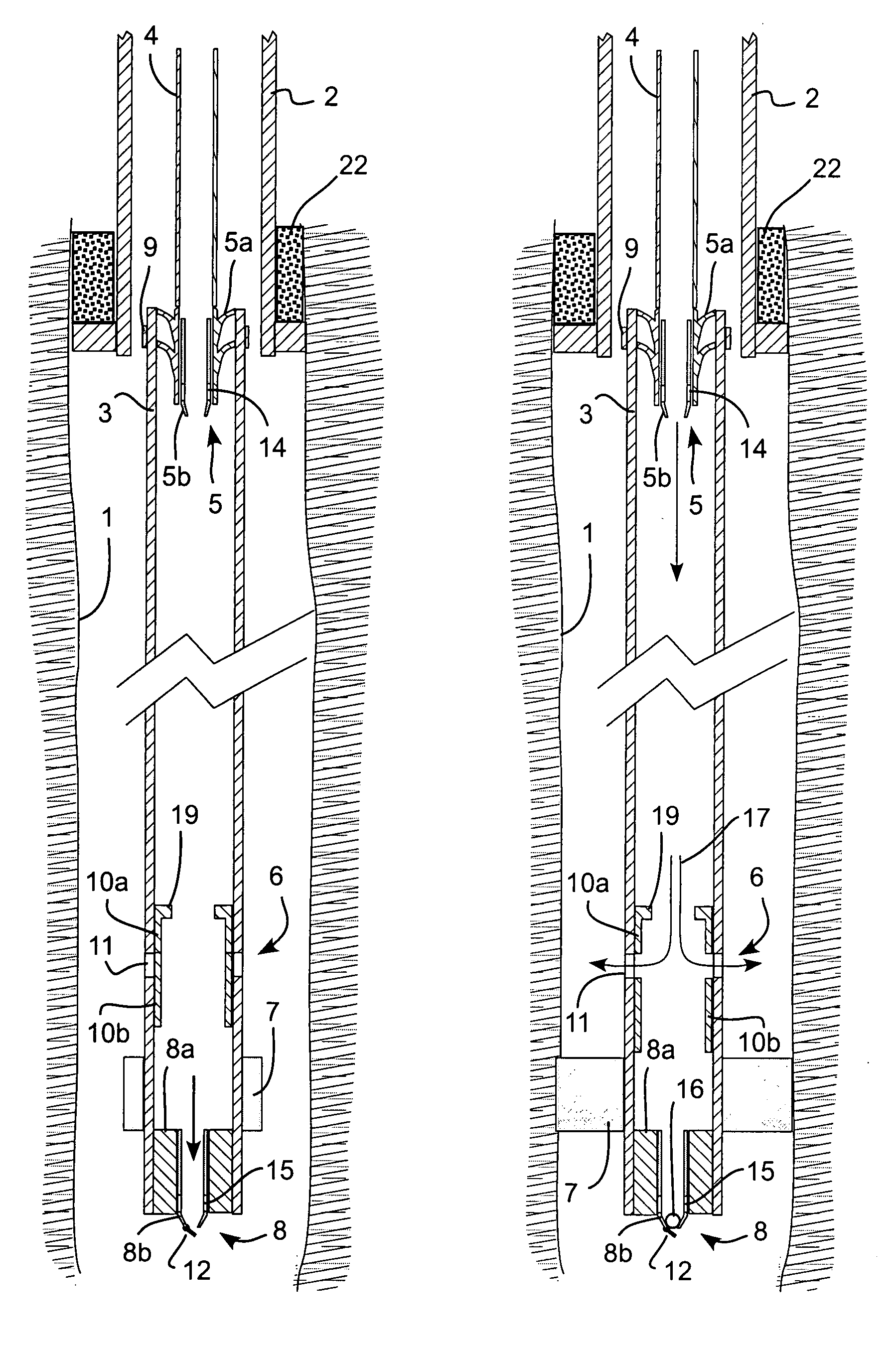

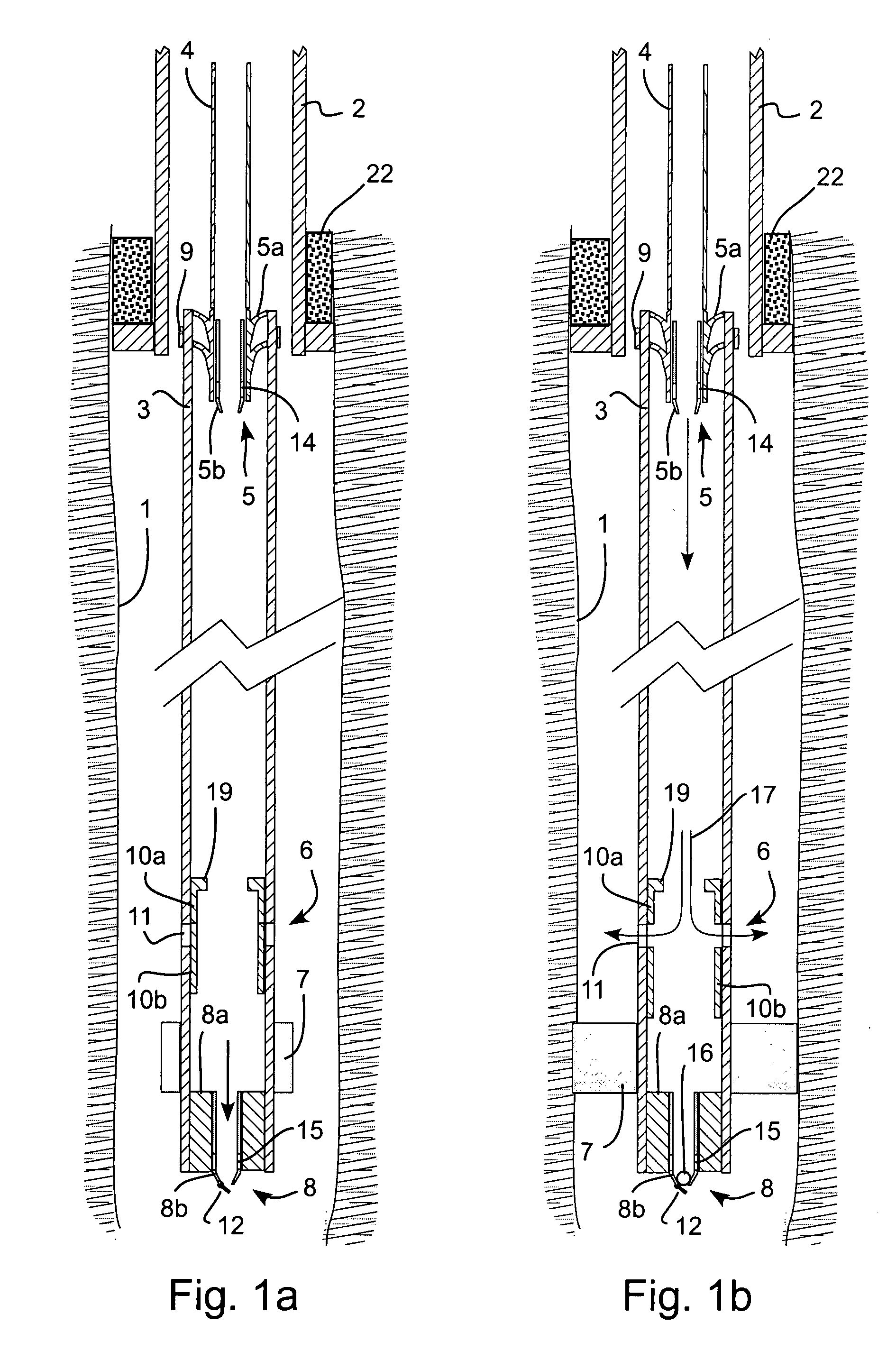

Image

Examples

second embodiment

[0047]In the second embodiment, the bottom plug 30 is of the kind which is commonly called a “disappearing plug”. Plugs of this kind are well known in the industry and can, for example, comprise a plug 31 made of a hard packed material which dissolves when exposed to a high pressure. The plug 31 is arranged in an outer part 32. One example of such a plug is the “Mirage”™ plug manufactured by Halliburton.

[0048]The advantage of using a disappearing plug is that a simpler system is achieved. However, the disadvantage of using a disappearing plug is that during the running in of the liner 3, the bottom of the liner 3 is blocked and it is not possible to flush fluid out of the end of the liner 3. Not being able to flush out the end of the liner 3 is acceptable in cases where the well parameters are well known and there is little risk in the liner 3 installation. Therefore the solution with the disappearing plug is not always suitable.

first embodiment

[0049]The rest of the procedure is the same as the first embodiment, the only difference being that no ball is necessary to block the bottom plug 30. When it is desired to open the bottom plug 30, the pressure inside the liner 3 is raised above the predefined pressure point of the disappearing plug 30 and the plug 30 opens.

[0050]It should be mentioned, that instead of using a disappearing plug 30, a mechanical plug which is similar to the bottom plug 8 of the first embodiment can be used but which is already blocked at the start of the procedure. In this way, it is not necessary to drop a ball 16 into the well. However, as with the disappearing plug, it is not possible to flush fluid out of the end of the liner 3 during the running of the liner 3 when the liner 3 is equipped with this type of bottom plug.

third embodiment

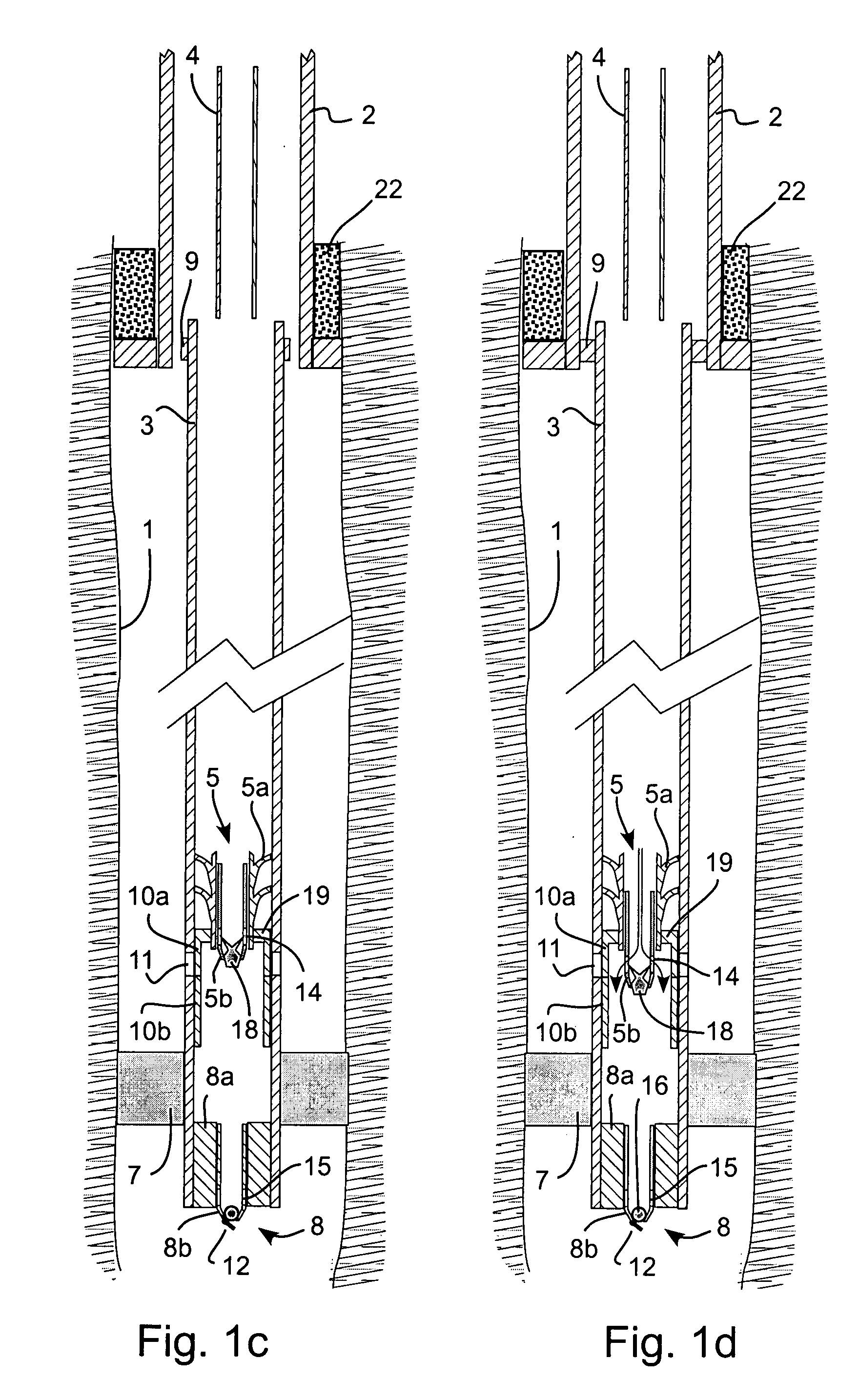

[0051]FIGS. 3a-3f show some steps of a process for cementing an off-bottom liner. Most of the steps are the same as the previous methods, and the same elements have been given the same reference numerals.

[0052]In this embodiment, the difference is that two wiper plugs 5, 40 are suspended from the end of the liner hanger running tool 4. The two plugs are a top wiper plug 5 which is identical to the one used in the first and second embodiments and a bottom wiper plug 40 which is similar to the top wiper plug 5. The bottom wiper plug 40 is attached to the top wiper plug 5 with a release mechanism such as shear pins (not shown). The wiper plugs are of the kind which permit fluid flow through them until they are blocked by a plug 18, 41 which is pumped down the well or dropped into the well. These types of plugs 7, 8 are known in the industry and need not be described in more detail. The plugs which block the wiper plugs are typically in the form of a ball or a wiper dart. In the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com