Reinforcing Assemblies and Reinforced Concrete Structures

a technology of reinforced concrete and assemblies, applied in the direction of building reinforcements, construction, building material handling, etc., can solve the problems of structural failure, undesirable cracking and/or breaking of structural concrete members, structural failure, etc., to achieve better anchorage, reduce structural concrete failure, and eliminate or minimize structural concrete failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

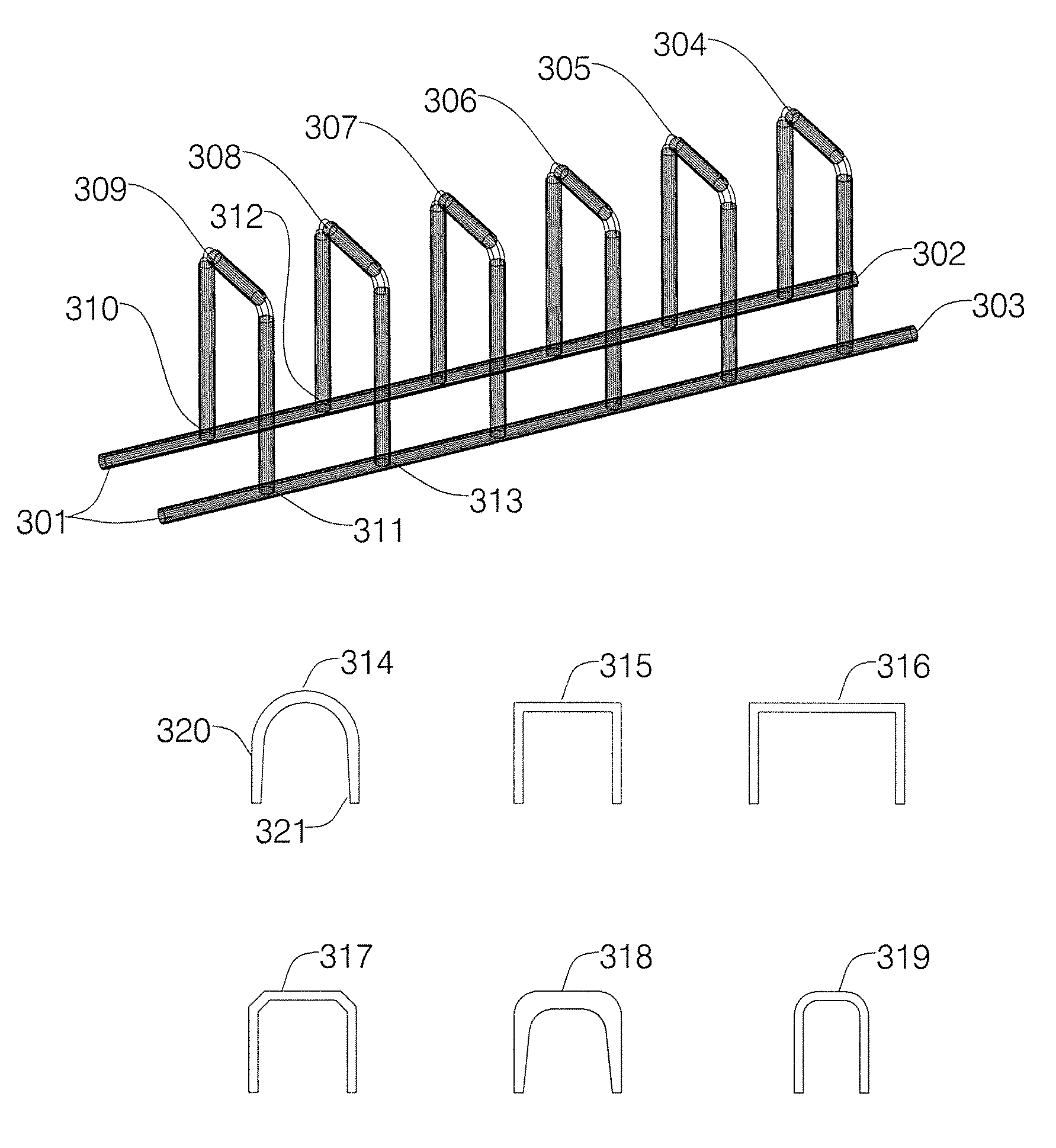

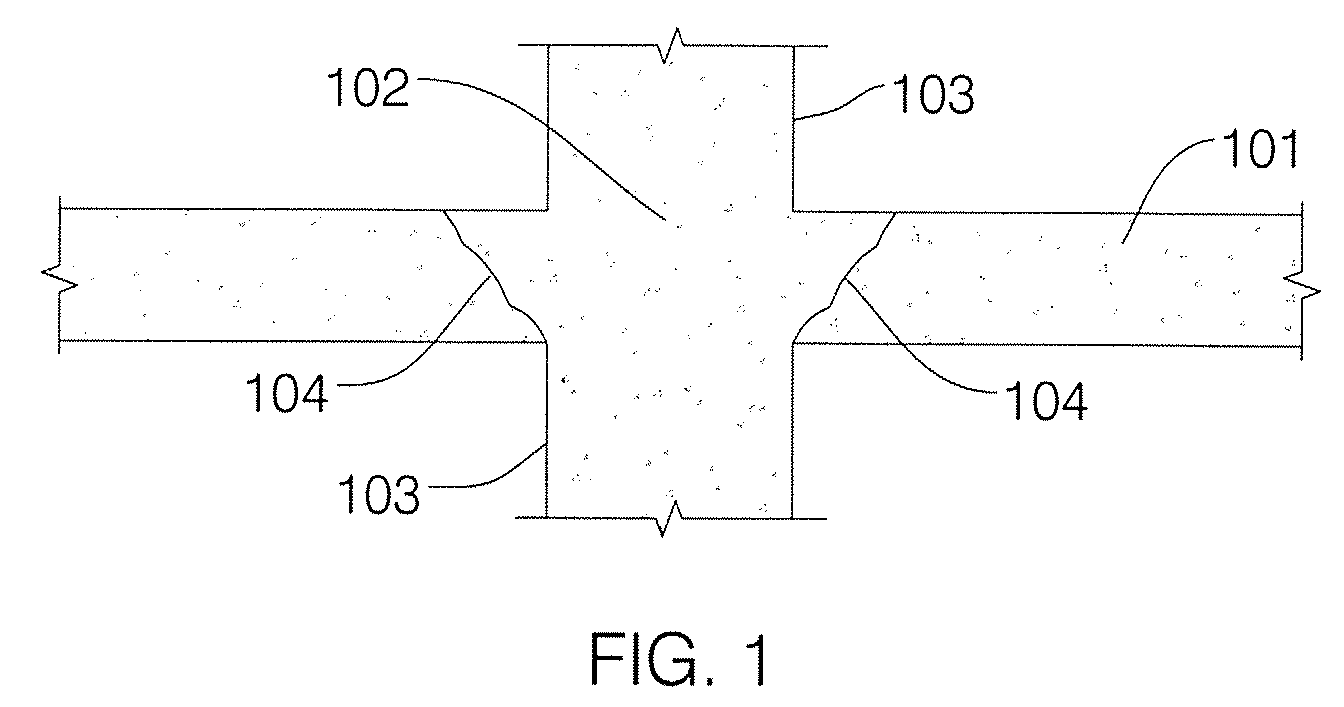

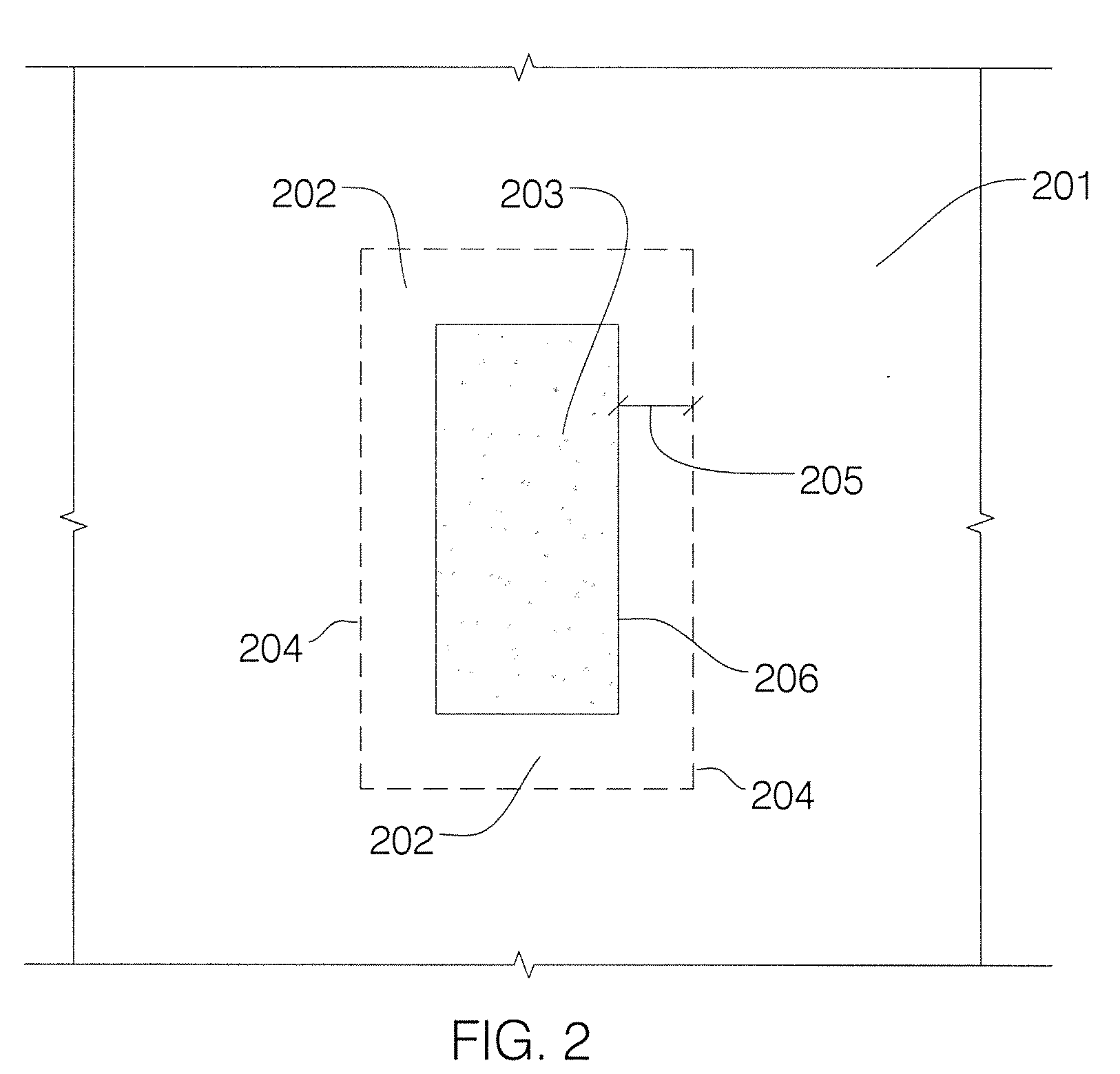

[0016]The invention will now be described with reference to its application to a post-tensioned slab structure that is supported by a column, which may be a steel supporting column or a concrete supporting column. FIG. 1 represents a cross-sectional view of a concrete slab structure 101 at the “loaded” area 102 (also referred to as the “reaction” area) surrounding the intersection of the slab structure with concrete supporting column 103, and showing undesirable cracking 104 caused by punching shear forces. This is a typical two-way shear situation. FIG. 2 is a top view of the concrete slab structure depicted in FIG. 1 and shows post-tensioned concrete slab 201 (slab 101 in FIG. 1) intersected by concrete supporting column 203 (column 103 in FIG. 1) and creating loaded, or reaction, area 202 delineated by shear critical section perimeter 204. The maximum distance 205 at which the American Concrete Institute (“ACI”) requires any reinforcing assembly to be located inside a concrete sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com