Heat pump system with extended run time boost compressor

a heat pump and compressor technology, applied in the field of heat pump systems with extended run time boost compressors, can solve the problems of increasing the difficulty of drawing heat from the outdoor environment, reducing the energy cost of consumers, and increasing the difficulty of conventional heat pump systems in colder climates. achieve the effect of increasing the heating capacity and easily diverting hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

System Design

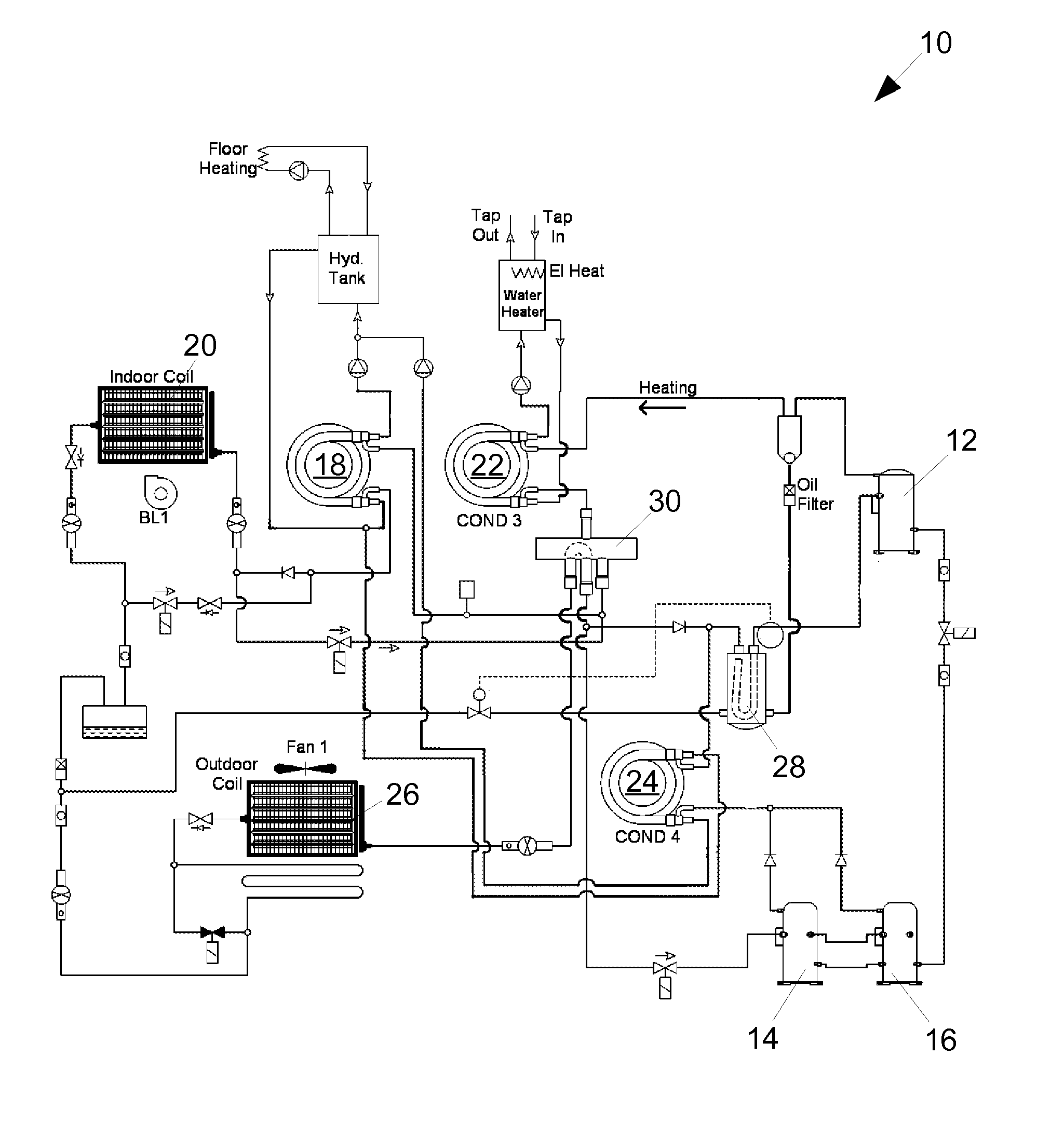

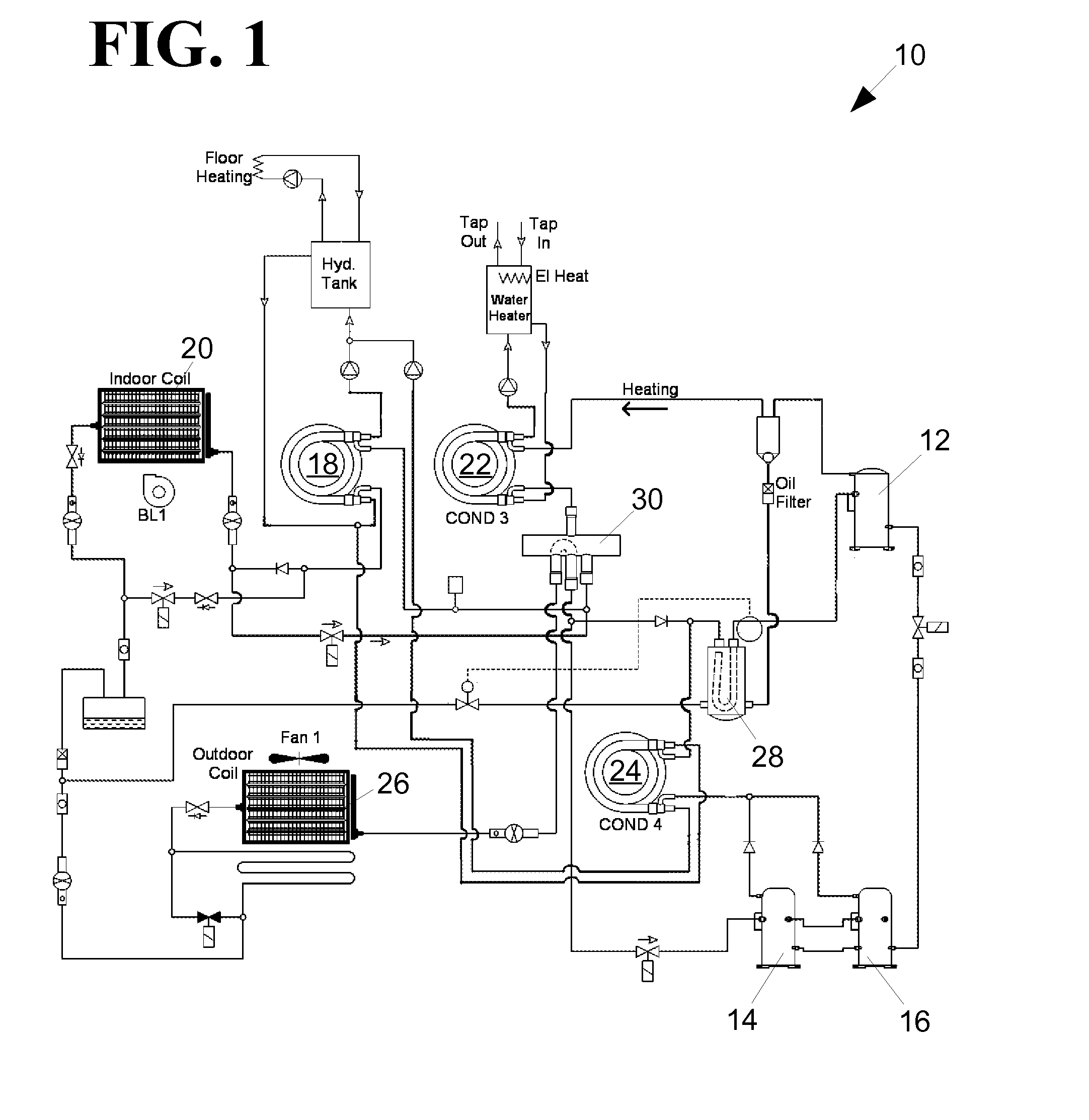

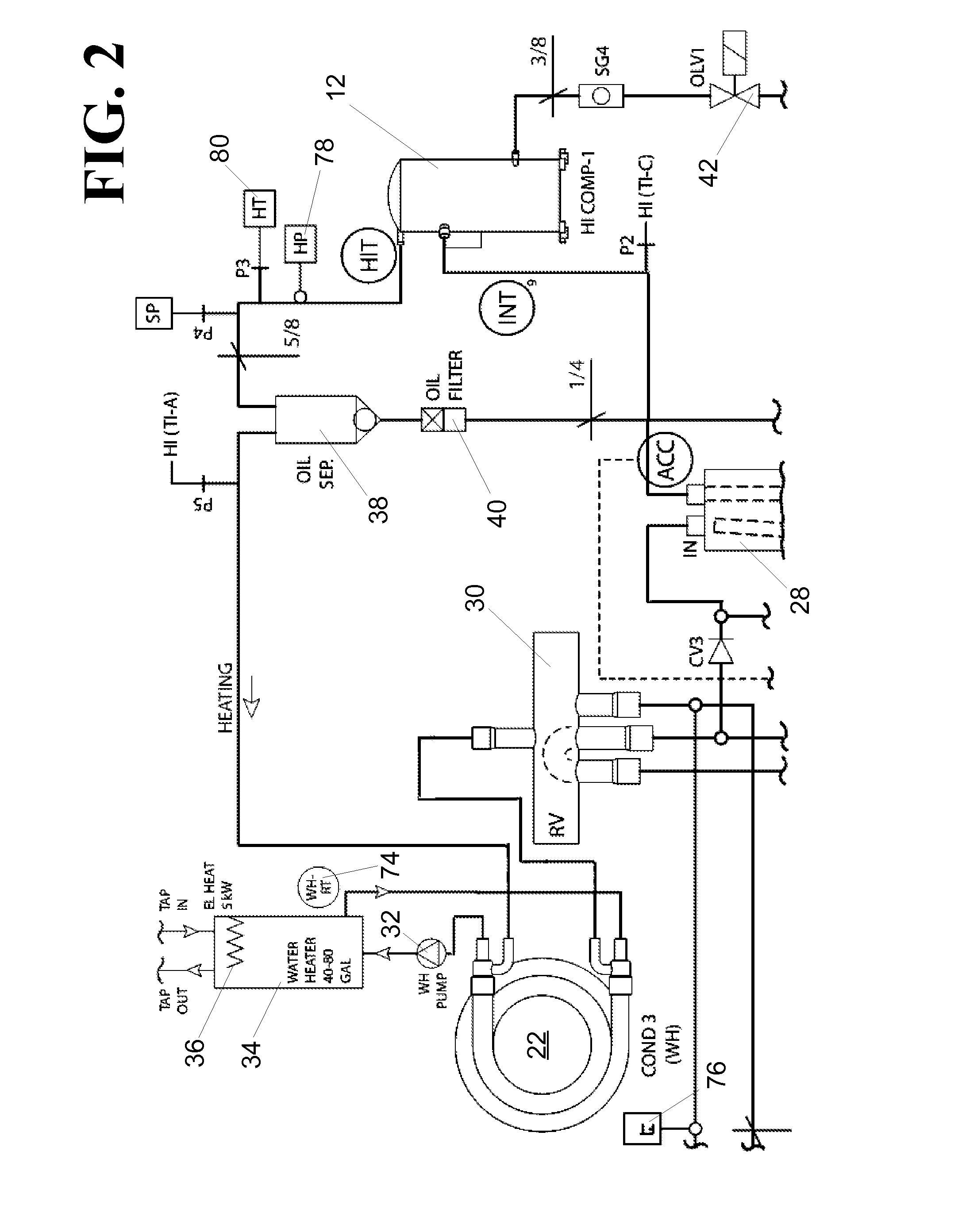

[0065]FIG. 1 is a schematic of the preferred embodiment of the heating and cooling system 10 of the present invention. The primary components of the system include a primary compressor 12, a first booster compressor 14, a second booster compressor 16, a hydronics condenser 18, a indoor air heat exchanger 20, a water tank condenser 22, a boost condenser 24, an evaporator 26, an accumulator 28, and a 4-way valve 30.

[0066]The primary compressor 12 is preferably a scroll-type two-speed compressor that may be operated at two discrete discharge pressure settings. The first and second booster compressors (14 and 16) are preferably single-speed compressors of varied discharge capacities that may be operated at a single discharge pressure setting. The primary compressor may be operated in series with the booster compressors operating in parallel. One or both of the booster compressors (14 and 16) may be bypassed.

[0067]In heating and cooling modes, compressed refrigerant from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com