PROCESS FOR REMOVING FLUORINATED EMULSIFIER FROM FLUOROPOLMER DISPERSIONS USING AN ANION-EXCHANGE RESIN AND A pH-DEPENDENT SURFACTANT AND FLUOROPOLYMER DISPERSIONS CONTAINING A pH-DEPENDENT SURFACTANT

a technology of fluoropolymer and anion exchange resin, which is applied in the direction of water/sewage treatment by ion exchange, chemical/physical processes, separation processes, etc., can solve the problems of poor biodegradability of fluorinated emulsifiers, poor dispersion, and high cost of fluorinated emulsifiers, so as to reduce the amount of fluorinated emulsifiers and stabilize the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

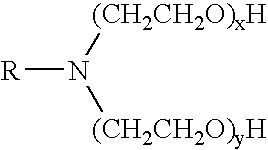

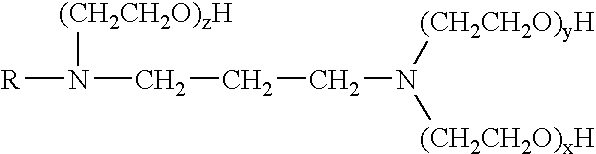

Method used

Image

Examples

example 1

[0096]To 500 g of the same PTFE dispersion of the comparative example above were added 5% wt (based on the solid content of the dispersion) of an aqueous solution containing 25% by wt of TRITON RW 150 (an ethoxylated amine available from Dow Chemical Company, Midland, Mich., USA). The pH of the dispersion was adjusted to pH 10 by adding an aqueous ammonia solution (25% wt of ammonia). The dispersion was then submitted to the same ion-exchange process as described in C1 above. The resulting dispersion had an APFO content of 5 ppm. The pH of the dispersion was then reduced to a pH of 3 by adding a 10% aqueous oxalic acid solution. Then 26 g of zinc sulphide were added to the dispersion under mild stirring. The salt concentration was increased by adding 7 ml of an aqueous ammonium sulphate solution (40% wt of ammonium sulphate) by which coagulation was initiated. Coagulation was completed by applying shear force using a Turrax mixer (8,000 rpm, 15 minutes). The coagulated dispersion sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average diameter | aaaaa | aaaaa |

| number average diameter | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com