Tankless water heater hot water return system

a tankless water heater and hot water return technology, applied in the field of plumbing systems, can solve the problems of non-functional recirculating hot water systems, and achieve the effect of facilitating traditional hot water return and eliminating the use of water storage tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

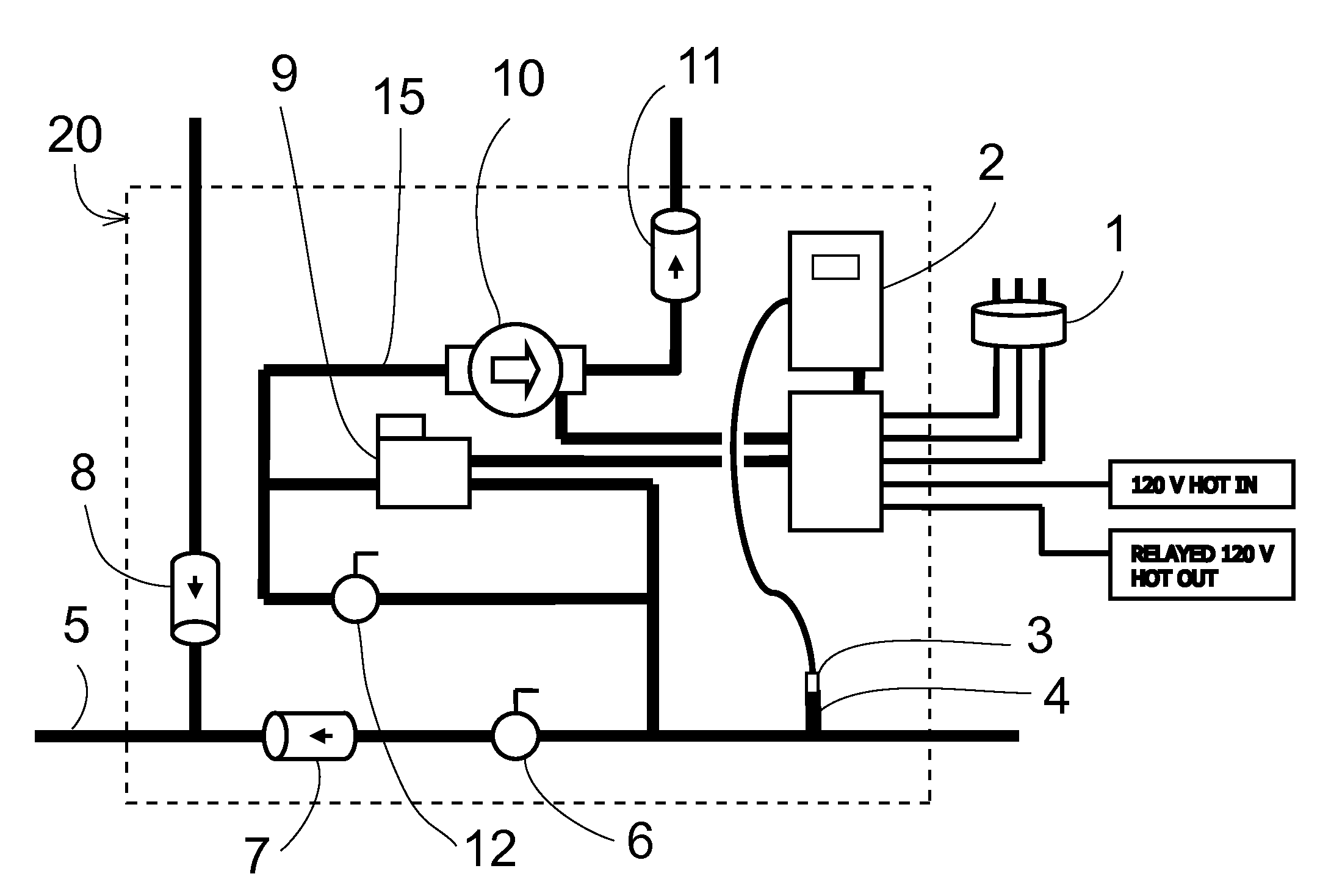

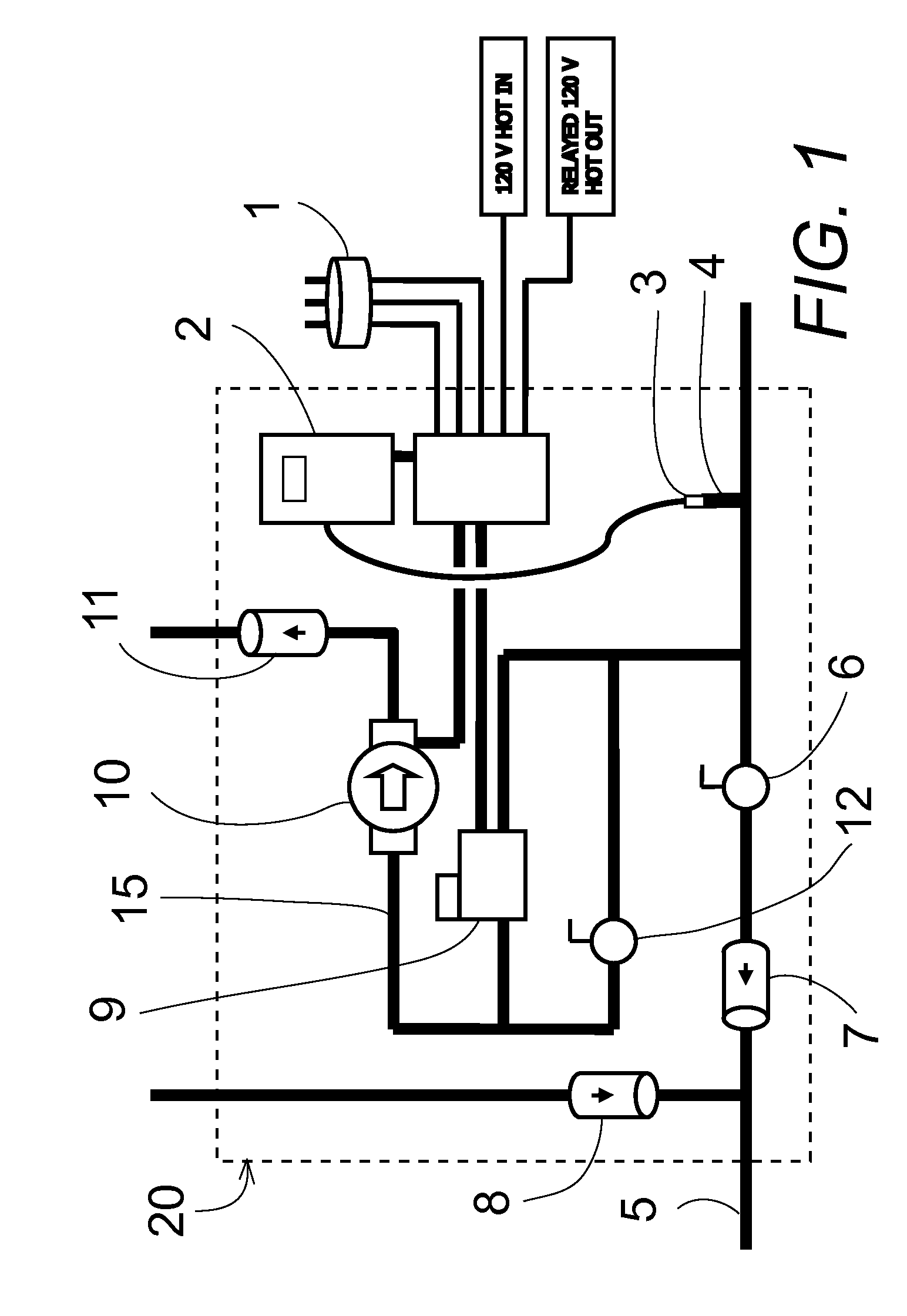

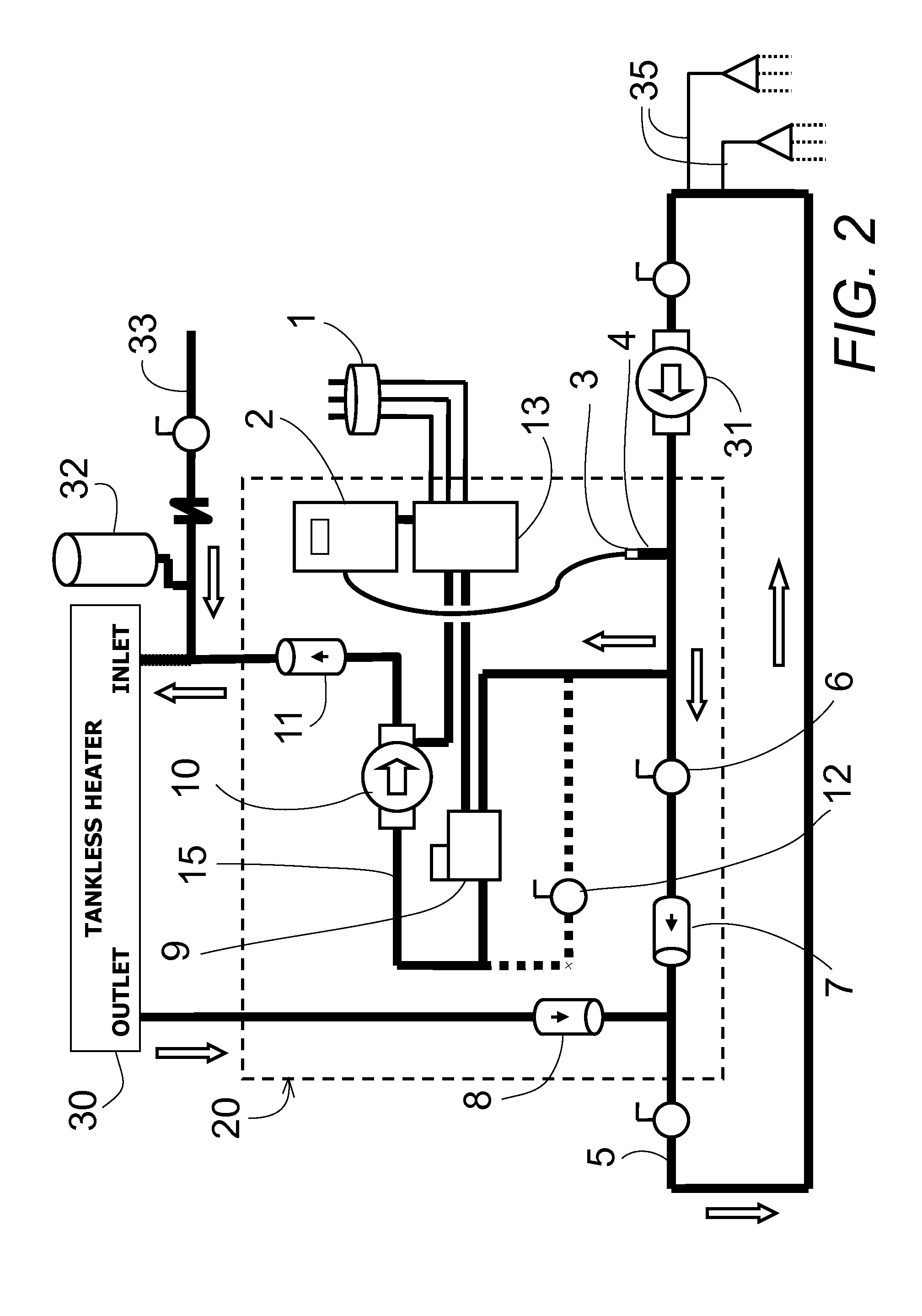

[0091]In FIGS. 1-4, a tankless hot water return recirculation system 20 (indicated by dashed rectangle in FIGS. 1-3) is integrated into a tankless hot water distribution heater 30 and pipe array.

[0092]The hot water return recirculation system 20 is alternately connected to and isolated from the tankless hot water heater 30 having a cold water feed pipe 16 and a hot water distribution pipeline 5. The hot water return recirculation system 20 comprises a recirculation pipeline 15 connecting between the hot water distribution pipeline 5 and the tankless hot water heater 30 for pumping previously heated warm water from the hot water distribution pipeline 5 back through the recirculation pipeline 15 to the tankless hot water heater 30 for reheating the warm water in the hot water heater to send the reheated water back through the hot water distribution pipeline for use. Means for opening and closing a pipeline connection between the hot water distribution pipeline and the water recirculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com