Work sheet conveying device

a conveying device and work sheet technology, applied in the direction of metal-working feeding device, transportation and packaging, manufacturing tools, etc., can solve the problems of difficulty in increasing the speed of the traveling member and reducing the time required for acceleration and deceleration, so as to improve the efficiency, improve the speed of the conveying of work sheets, and reduce the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

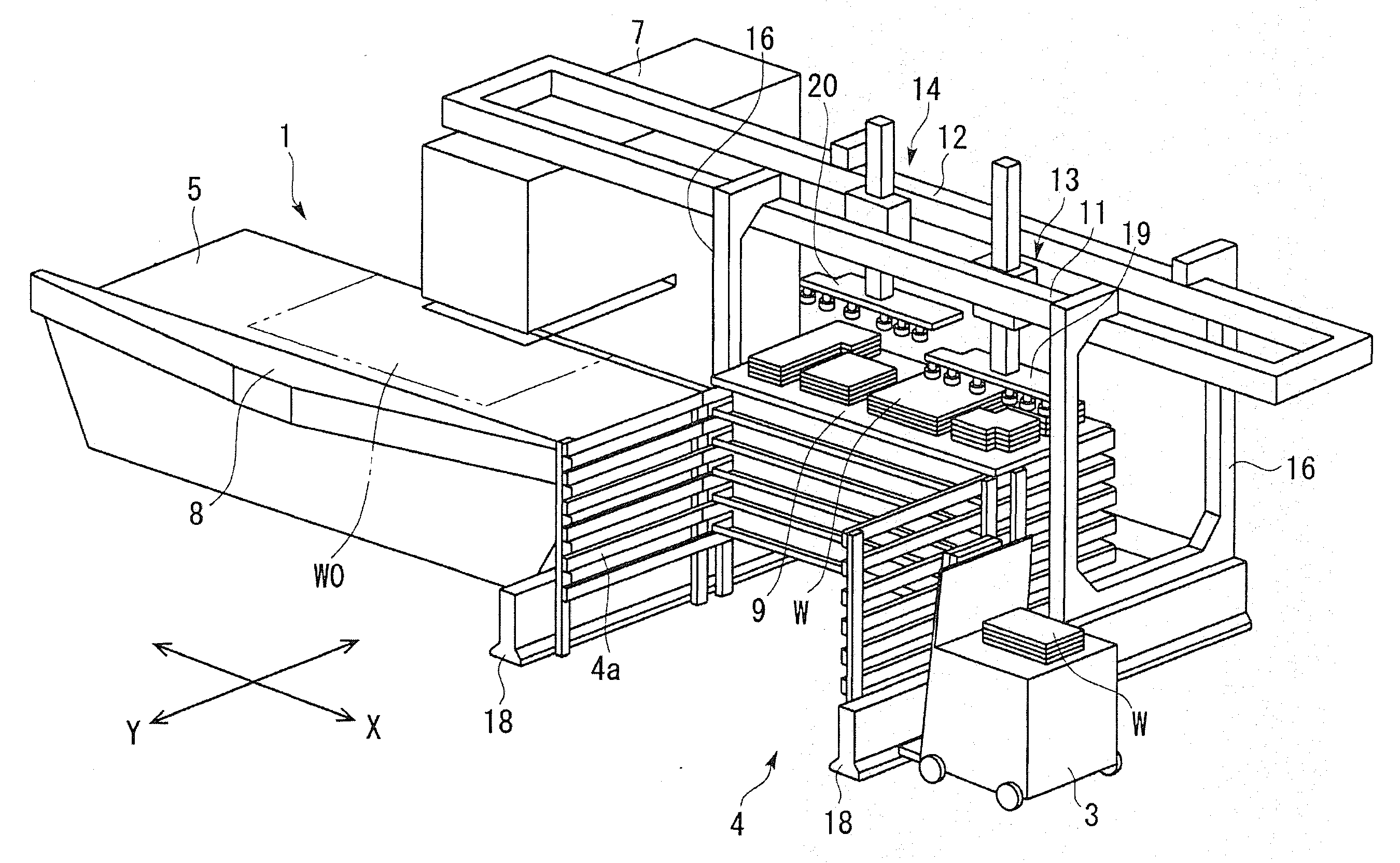

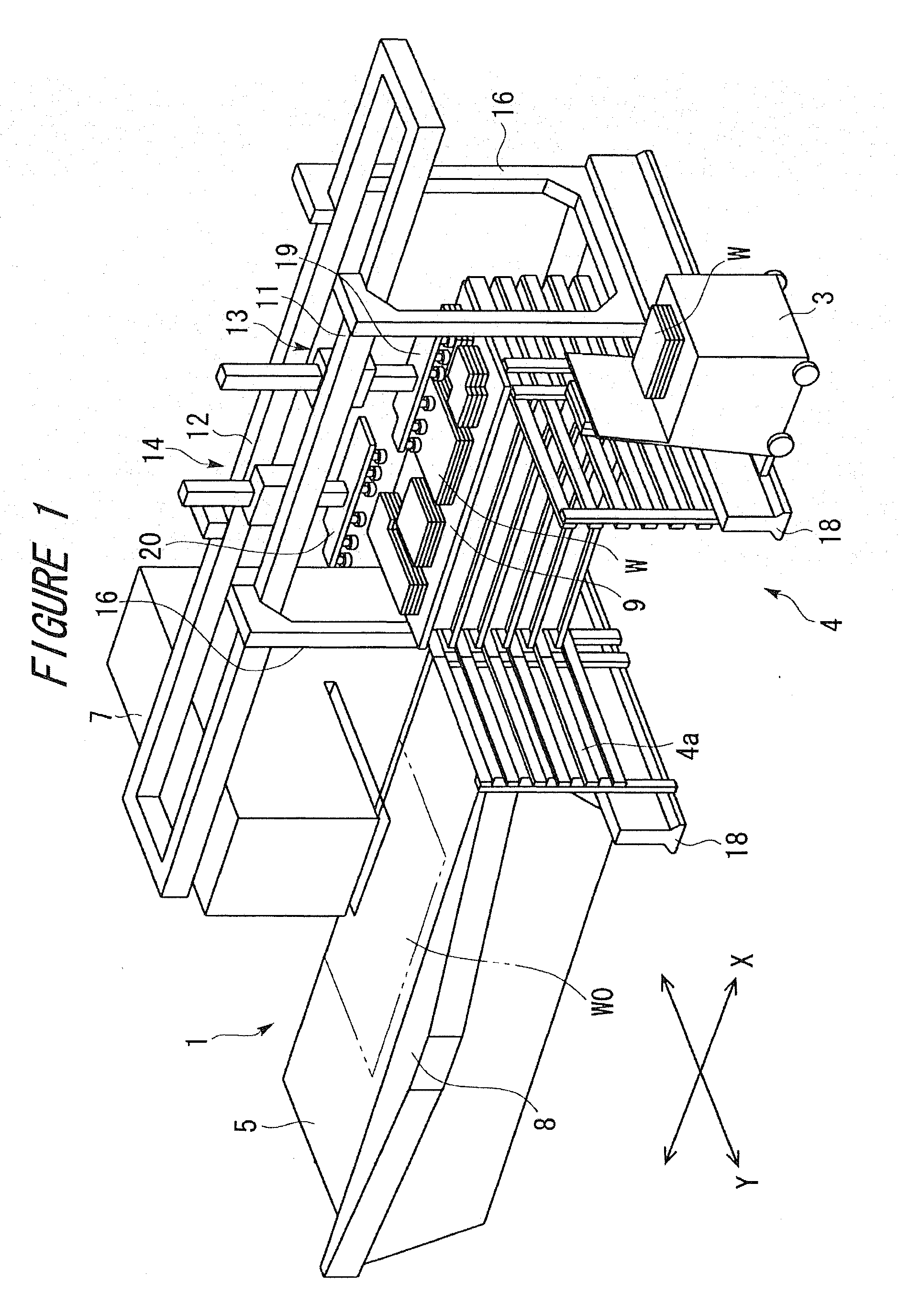

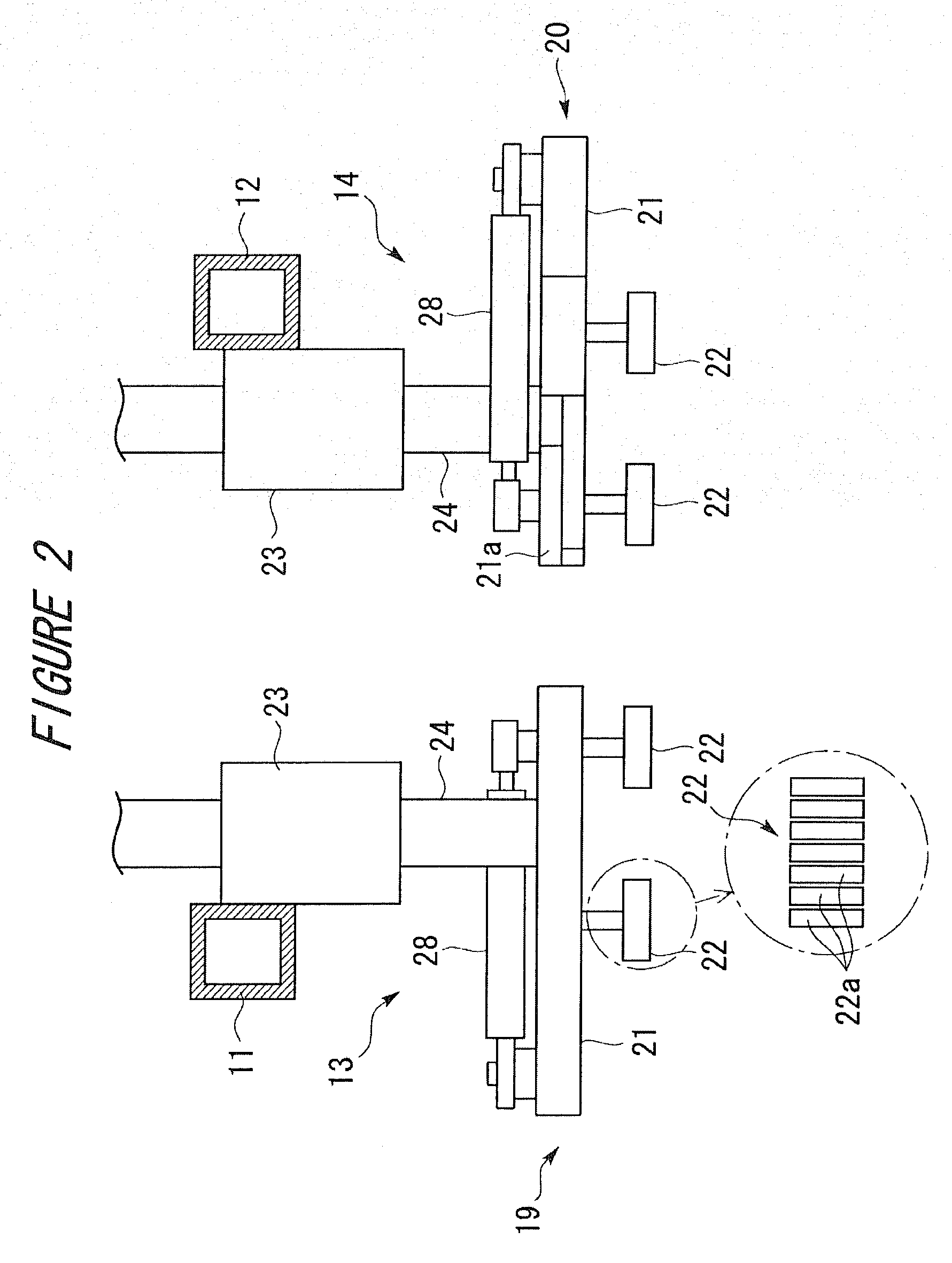

[0020]An embodiment of the present invention will be described with reference to FIGS. 1 to 4. FIG. 1 is a perspective view of an entire work sheet processing system comprising a work sheet processing machine 1, a work sheet conveying device 2, a palette 9 and a work sheet transporting vehicle 3 which serve as a work sheet placement portion, and a work sheet stocker 4. The work sheet processing system further comprises a work sheet carry-in device (not shown in the drawings) that carries a material work sheet WO into the work sheet processing machine 1. However, the description of the work sheet carry-in device is omitted.

[0021]The work sheet processing machine 1 comprises a function of cutting a plurality of product work sheets W from the material work sheet WO on a table 5 by means of punching or the like. The work sheet processing machine 1 is composed of a punch press, a laser processing machine, or the like. In this example, the work sheet processing machine 1 is a punch press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com