Bag Cartridge with Anti-Torque Collar

a bag cartridge and anti-torque technology, applied in the field of baginbox (bib) carton packaging, can solve the problems of collapsed jerribox(TM) containers, difficulty in assembly, erection and contents filling of such jerribox(TM) containers, and general incompatibility between adhesive and thin wall bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136]There now follows a description of some particular embodiments of a bag cartridge with anti-toque profile according to the invention, by way of example only, with reference to the accompanying diagrammatic and schematic drawings, in which:

[0137]Bag Cartridge

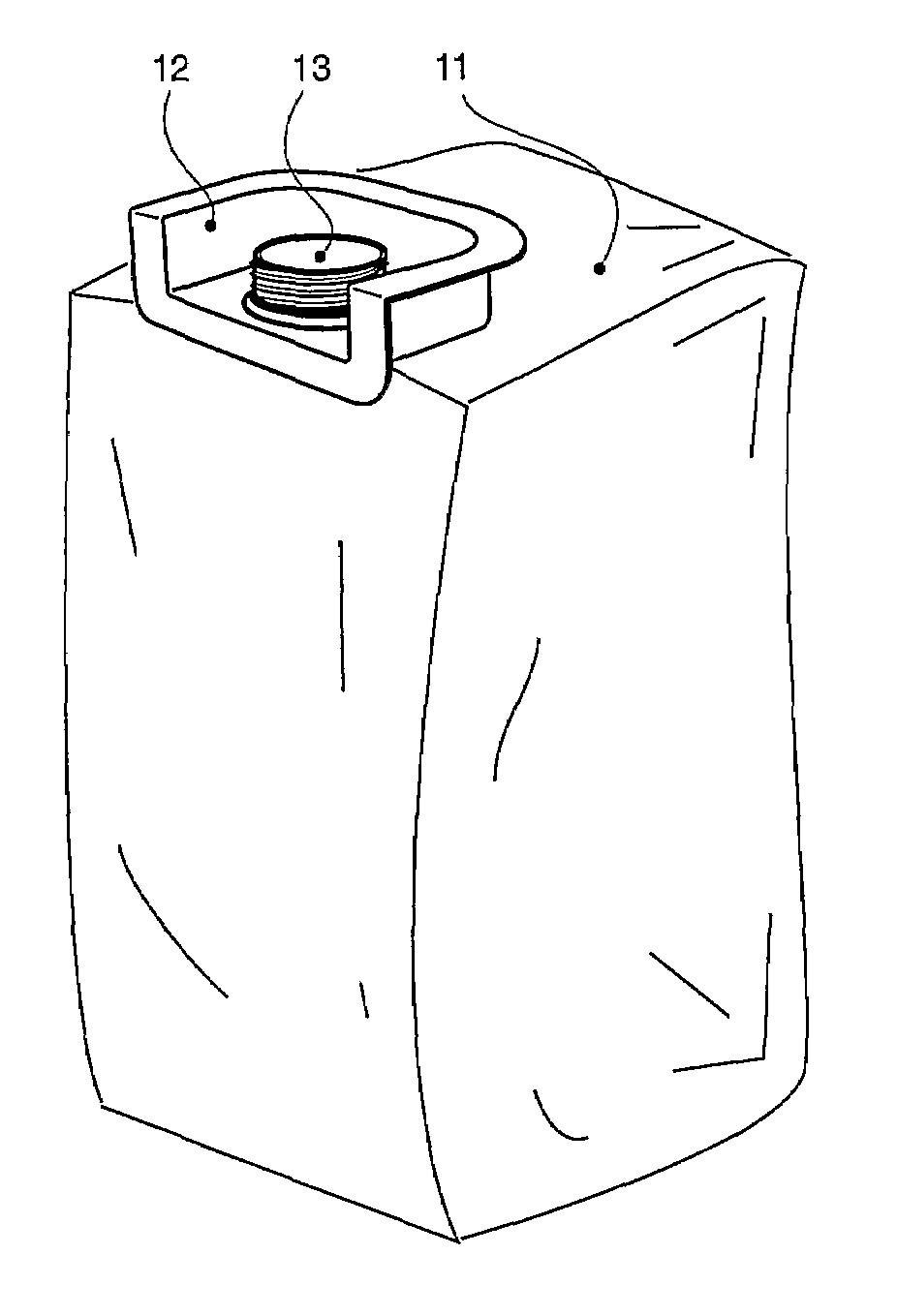

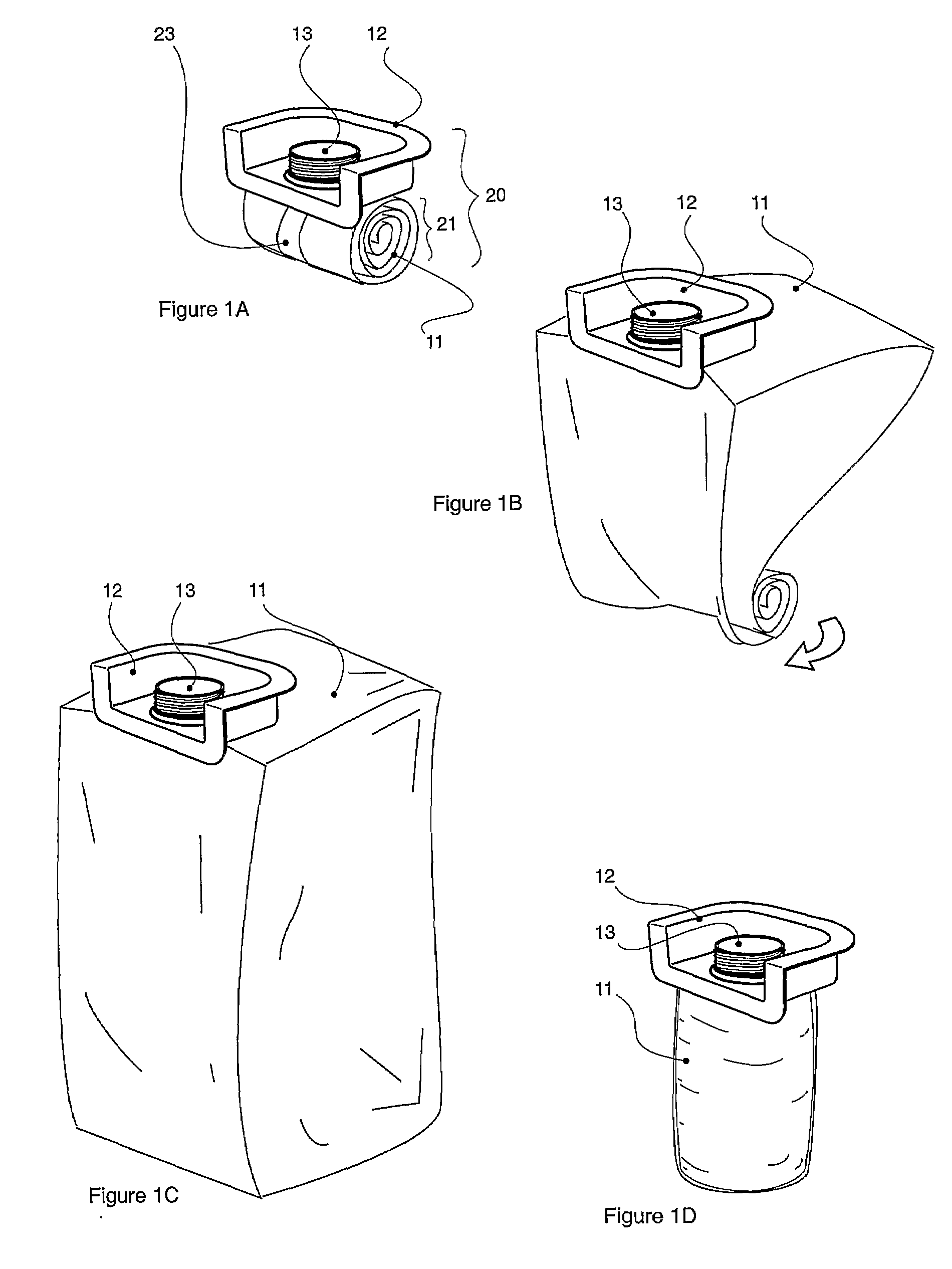

[0138]FIGS. 1A through 1C show progressive deployment stages for a bag cartridge of the invention from initial rolled and taped format to fully deployed or at least unrolled;

[0139]NB . . . full bag erection is upon contents fill, with optional preparatory (air) pulse inflation—after bag insertion in a carton, as reflected in FIG. 3C;

[0140]FIG. 1D shows an alternative collapse rolled bag format about a bag neck axis and temporary containment in an enclosure, wrap, tie collar or sheath;

[0141]NB . . . A particular example would be a paper bag, burstable upon a preparatory air pulse applied through the bag neck for bag deployment.

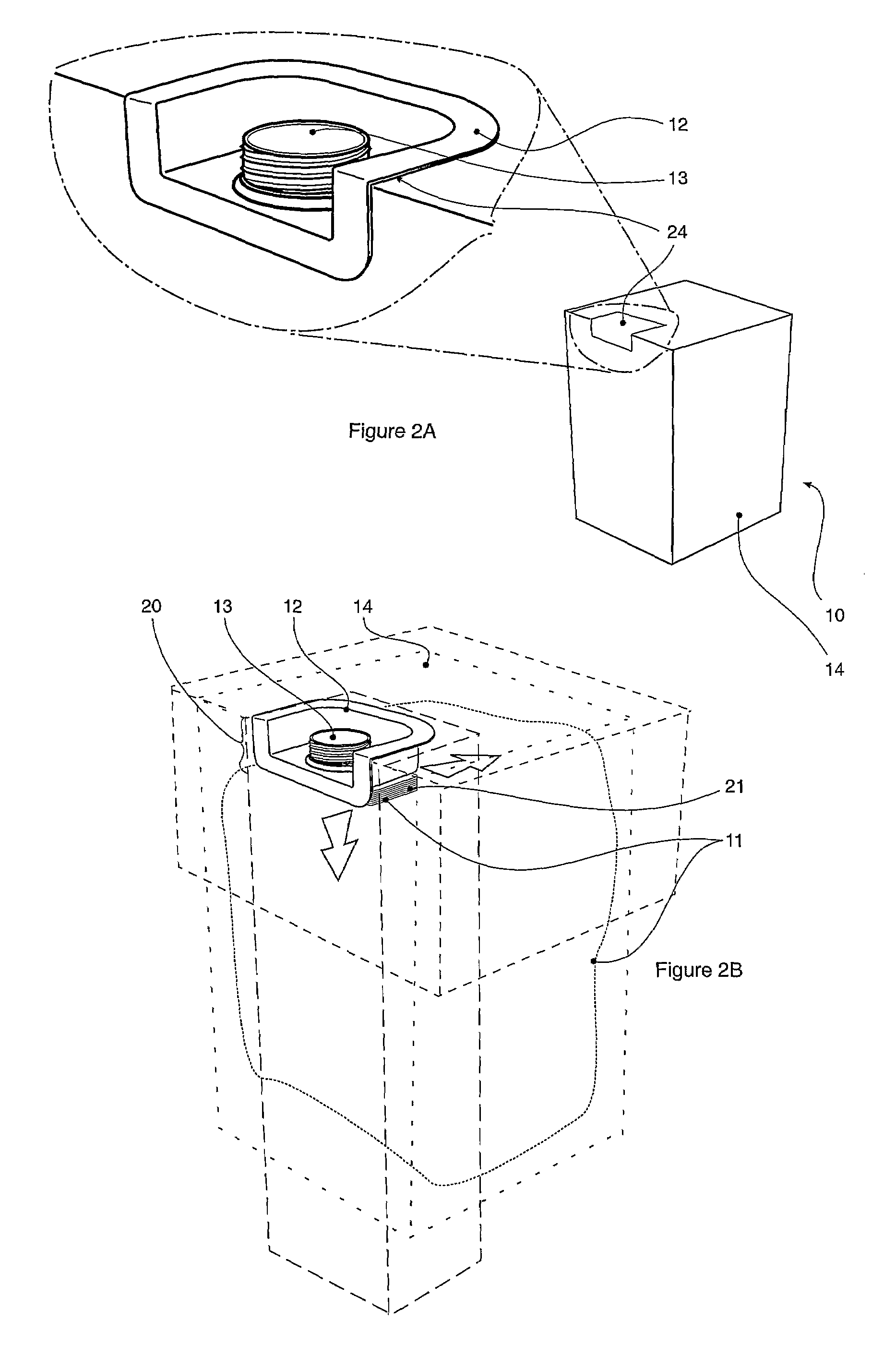

[0142]FIGS. 2A and 2B show collar fitment of a bag cartridge of FIGS. 1A-1C to an erect pre-assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com