Cooling module

a technology of cooling module and cooling module, which is applied in the direction of machines/engines, combustion air/fuel air treatment, transportation and packaging, etc., can solve the problems of increasing difficulty in providing sufficient free space above the front end panel, so as to reduce the weight of the cooling module, reduce the effect of increasing the temperature of the air to be introduced into the engine and effectively us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

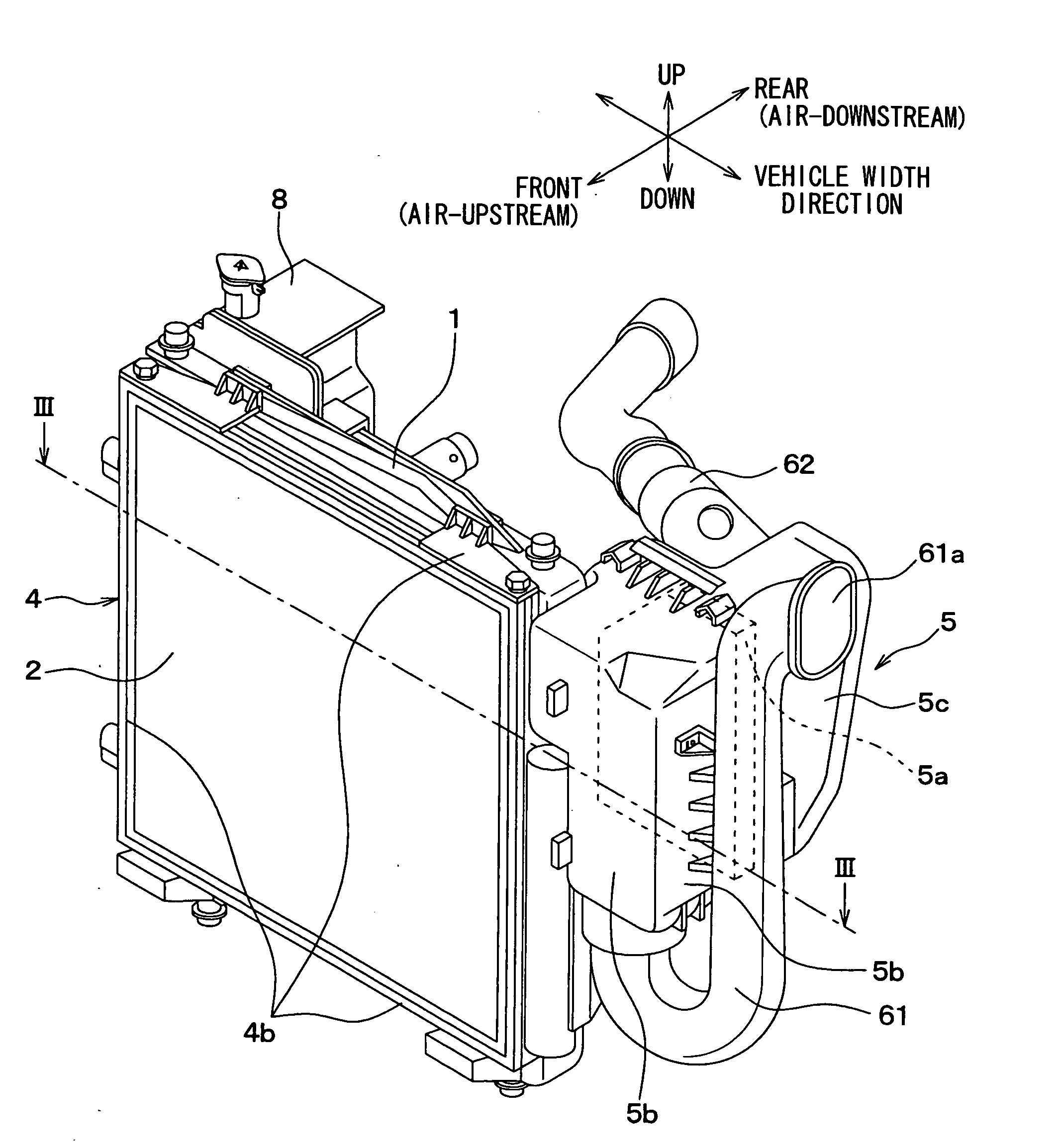

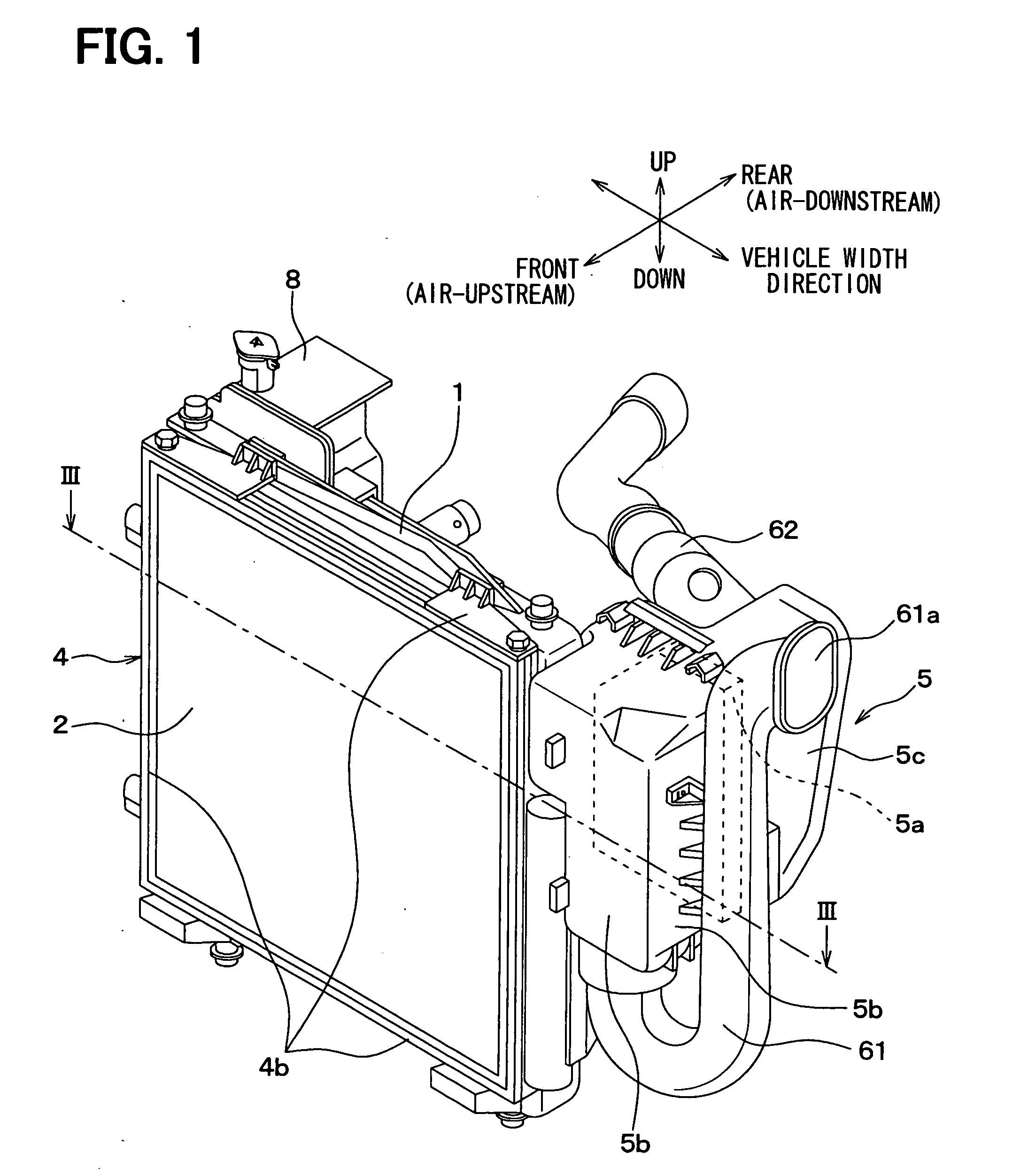

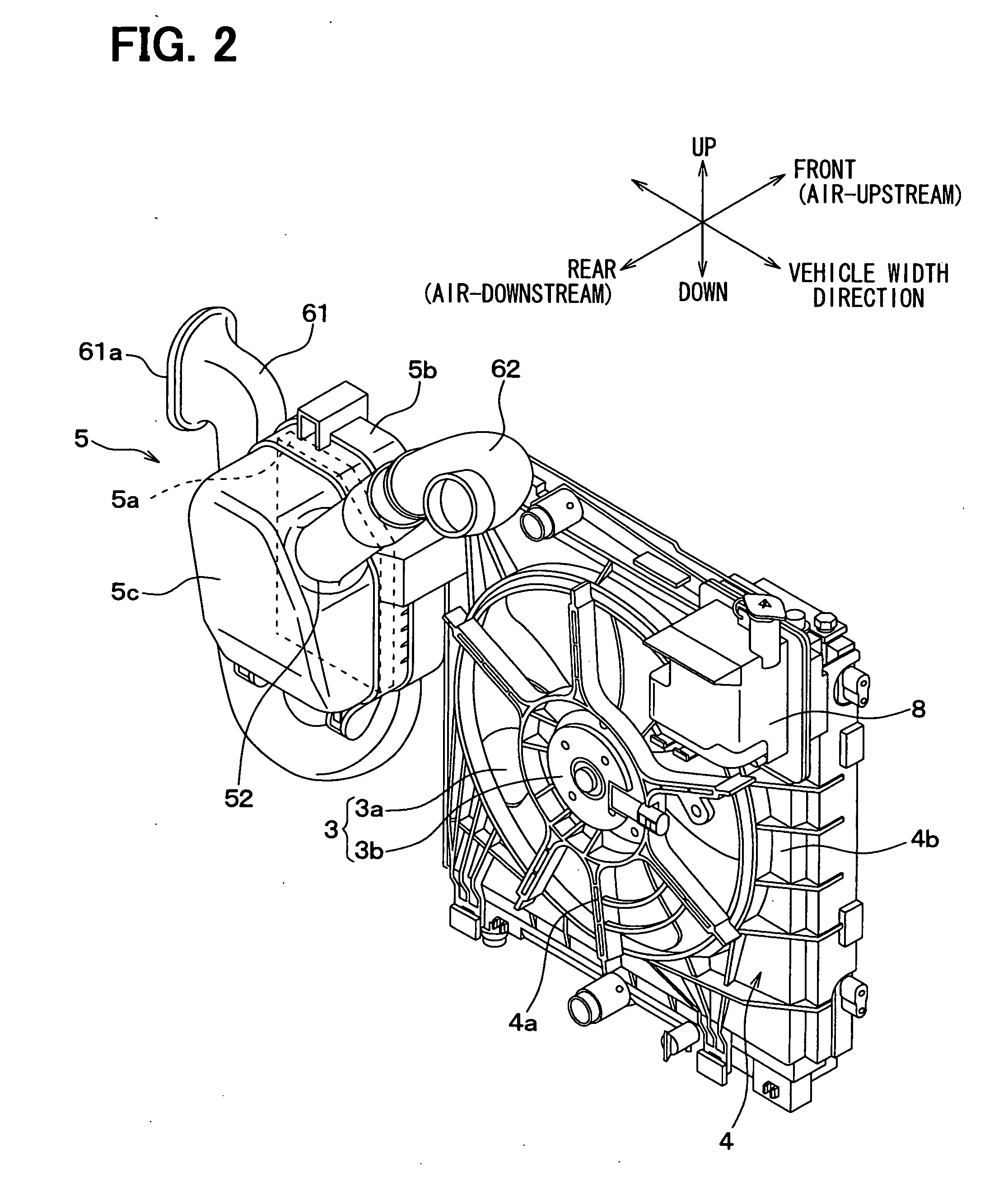

[0021]A first embodiment of the present invention will now be described with reference to FIGS. 1 to 5. In the present embodiment, a cooling module is mounted in an engine compartment provided at a front end of a vehicle.

[0022]Referring to FIGS. 1 to 3, the cooling module generally includes a radiator 1, a condenser 2, an electric fan unit (blower) 3, a fan shroud 4 and an air cleaner unit 5. The radiator 1 is a heat exchanger that performs heat exchange between a cooling fluid of an internal combustion engine (hereinafter, engine) and outside air introduced from an outside of a vehicle, thereby cooling the cooling fluid. The condenser 2 is a heat exchanger that performs heat exchange between a refrigerant of a refrigerant cycle of a vehicular air conditioner (not shown) and the outside air, thereby cooling the refrigerant.

[0023]The blower 3 is disposed to introduce the outside air to the radiator 1 and the condenser 2 for cooling the radiator 1 and the condenser 2. The fan shroud 4...

second embodiment

[0055]A second embodiment of the present invention will now be described with reference to FIG. 6. Hereinafter, like components are denoted by like reference characters and a description thereof is not repeated. In FIG. 6, the illustration of the reserve tank 8 is omitted.

[0056]In the present embodiment, as shown in FIG. 6, the radiator 1 is fixed to the fan shroud 4. The fan shroud 4 to which the radiator 1 is fixed is mounted to the vehicle body 10 through the elastic rubber bushings 9. For example, the fan shroud 4 has pins 4c on its upper and lower ends. The rubber bushings 9 are fixed to the pines 4c beforehand. The pins 4c are engaged with portions of the vehicle body 10. Thus, the fan shroud 4 to which the radiator 1 is fixed, that is, the cooling module is mounted to the vehicle. In this case, the condenser 2 can be fixed to the radiator 1 beforehand. Alternatively, the condenser 2 can be independently and directly fixed to the vehicle body 10. Also in the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com