S-shaped roof vent, ventilated roof employing the same and method of installing the same

a technology of ventilated roof and s-shaped roof, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of numerous different skeletons, difficult to achieve, and difficult to achieve, and achieve the effect of optimizing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

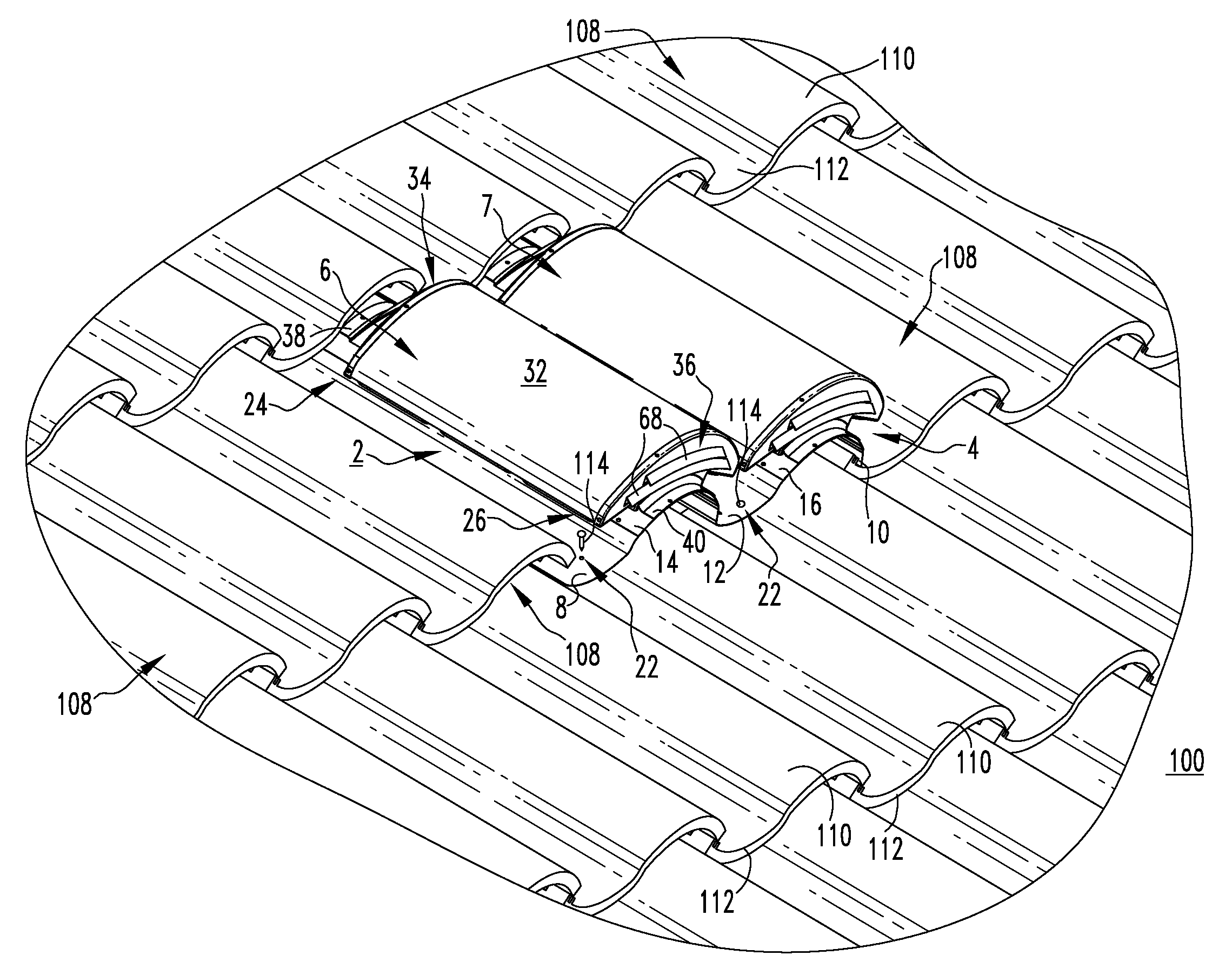

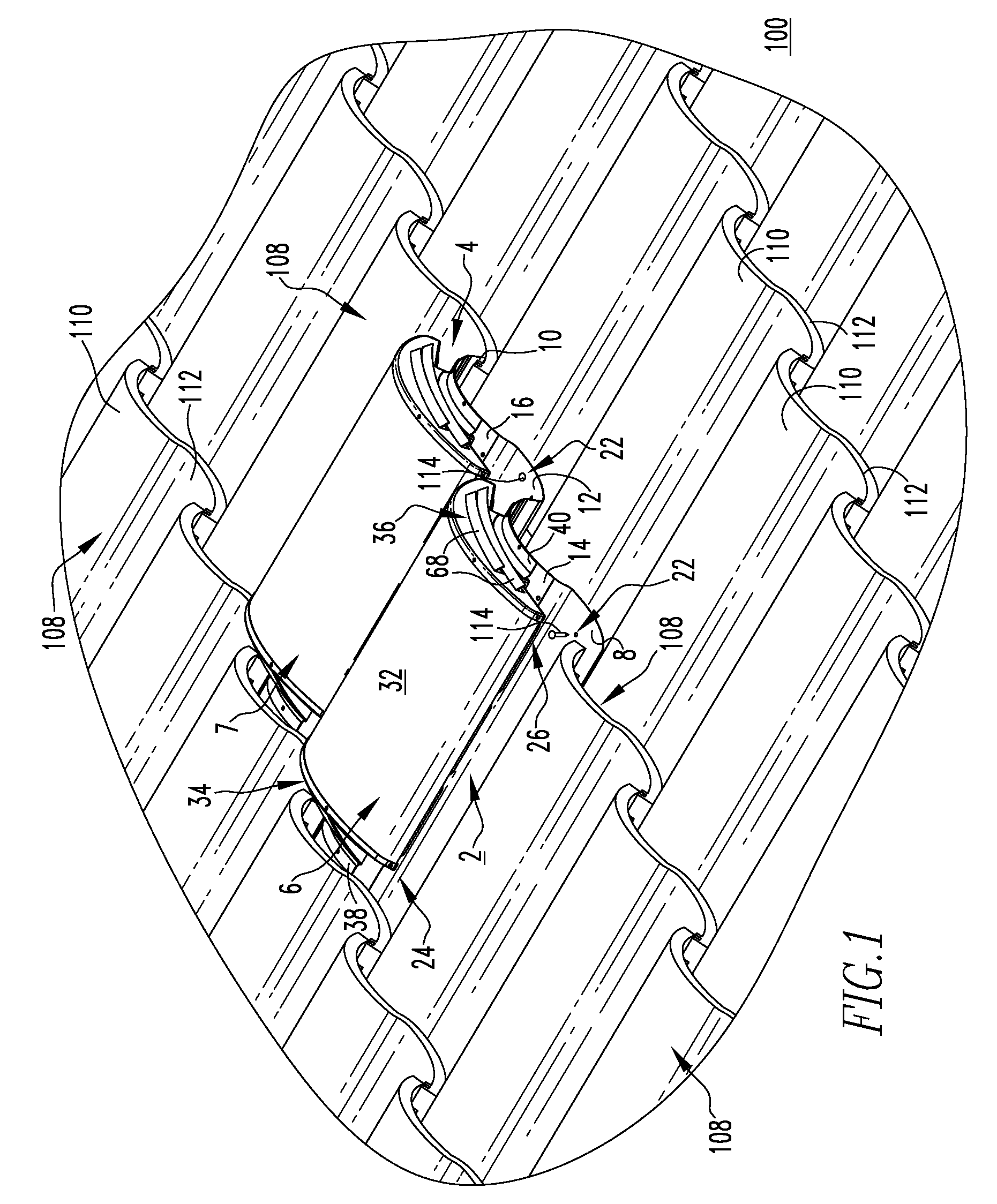

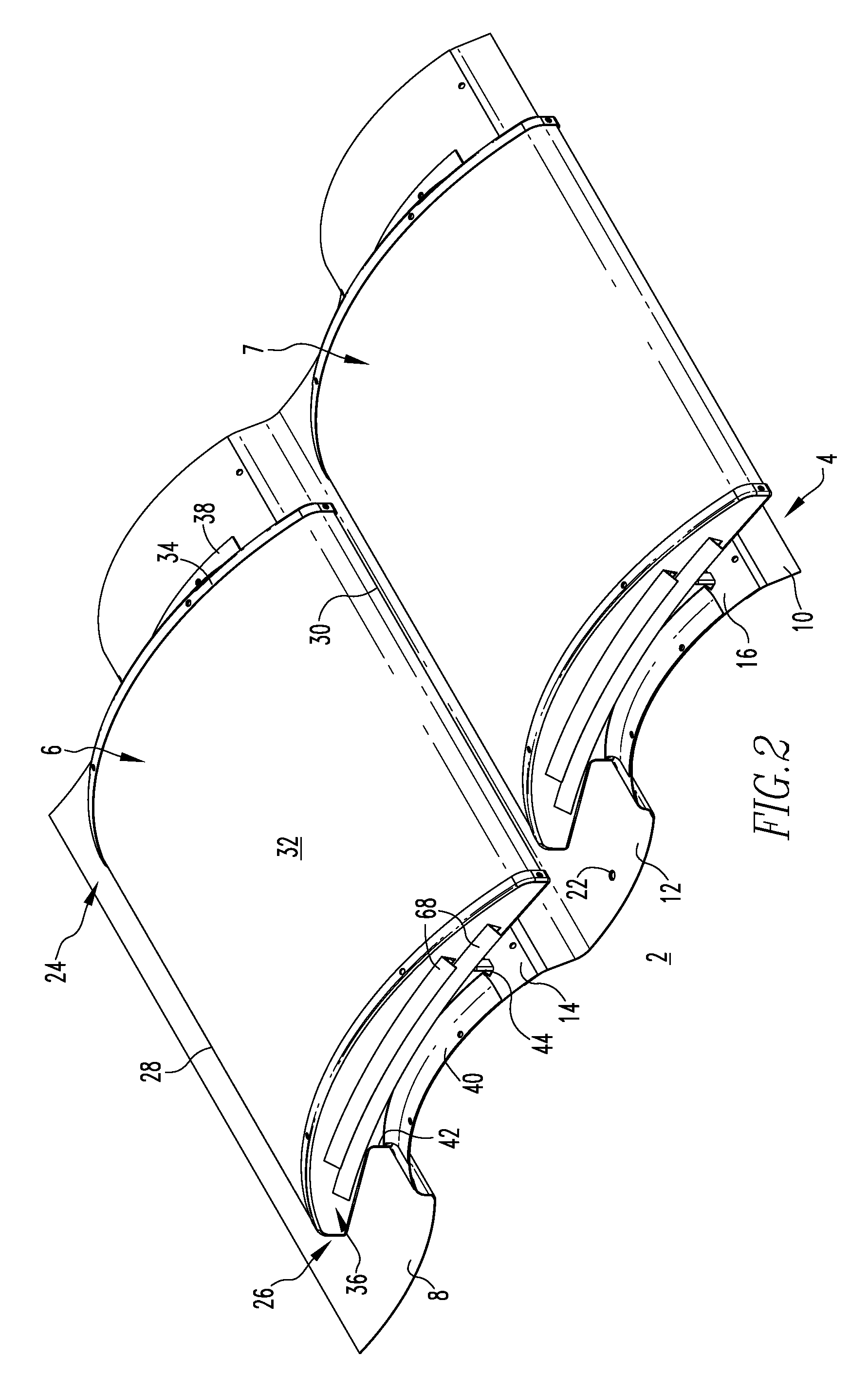

[0035]For purposes of illustration, embodiments of the invention will be described as applied to roof vents in which a segment of the vent comprising one concave section and one convex section of the base assembly and a single cap member coupled to the convex section, has a generally S-shaped cross-sectional profile when viewed from an end elevation perspective. It will, however, become apparent that they could also be applied to roof vents having a cross-sectional profile which is not S-shaped such as, for example and without limitation, an arcuate shape which does not resemble the letter S.

[0036]Directional phrases used herein, such as, for example, left, right, front, back, top, bottom and derivatives thereof, relate to the orientation of the elements shown in the drawings and are not limiting upon the claims unless expressly recited therein.

[0037]As employed herein, the terms “fastener” and “fastening mechanism” refer to any known or suitable connecting, tightening or securing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com