Waste Water Lifting System

a technology of lifting system and waste water, which is applied in the direction of pump control, sewer system, positive displacement liquid engine, etc., can solve the problems of restricted or jeopardized function of float switches, and achieve the effects of convenient exchange, simple snap-fastening, and simplified manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

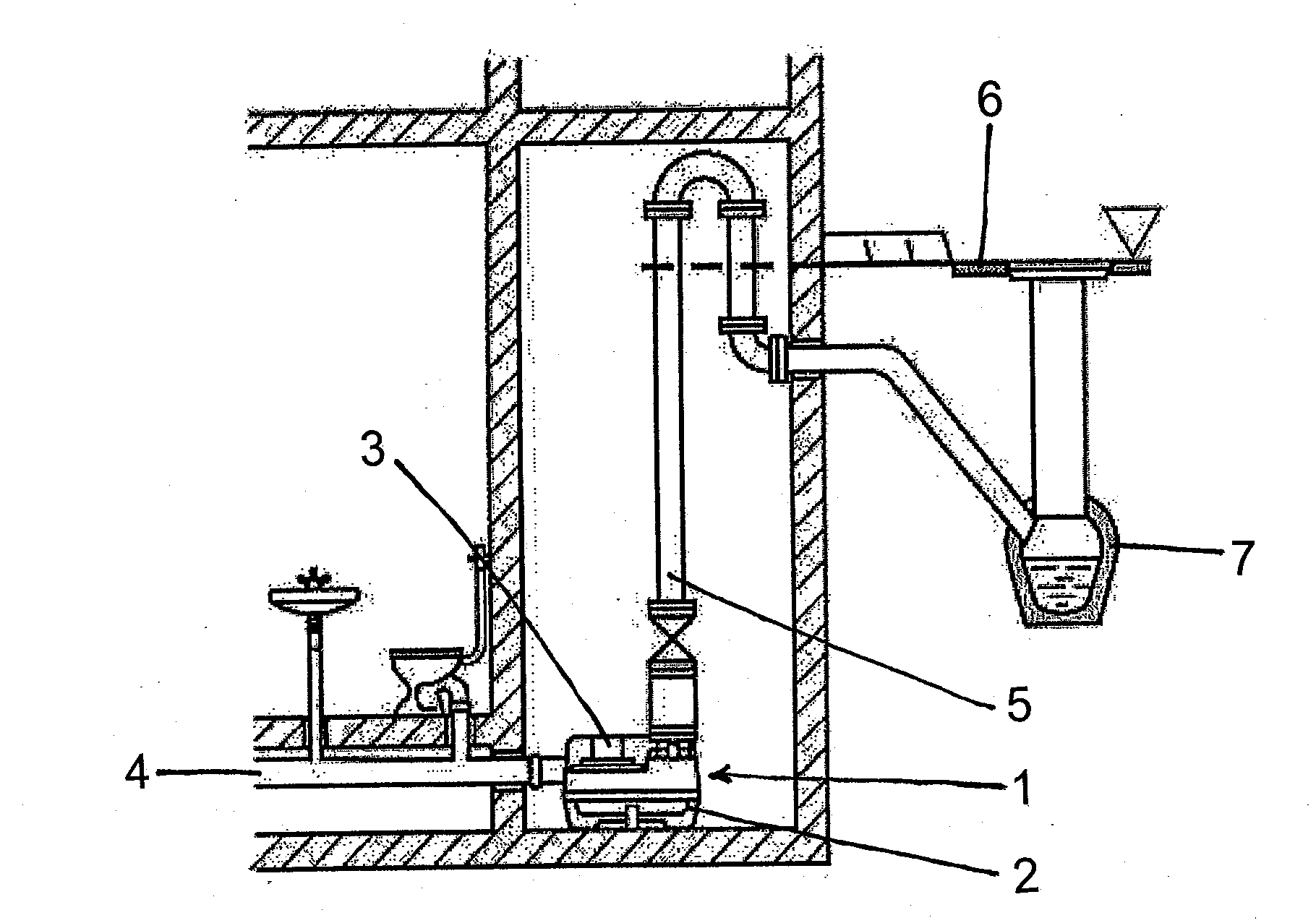

[0020]In FIG. 1, a cross section through a building is shown, in the basement of which a sanitary device is represented. Sewage from the sanitary device and other liquids to be disposed of flow to a waste water lifting system 1 and are collected therein until a sufficiently high fill level for an ad hoc conveyance is reached. The waste water lifting system 1 comprises a liquid-tight and odor-tight tank 2 and a pump 3, disposed sealingly therein, in the form of a motor pump unit, which is designed for the smooth-running conveyance of such liquids. Via an inlet pipe 4, accrued waste water is led into the tank 2, and via an outlet pipe 5 in the form of a pressure line, is conveyed over a backwash level 6 in order to flow from there into a sewage system 7. In general, such a tank 2 is provided with a ventilation (not represented here), whereby a gas evacuation is achieved and the creation of an overpressure in the tank 2 is prevented. Such a ventilation port is generally run over the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com