Silent Surface Fastener

a surface fastener and silent technology, applied in the direction of snap fasteners, press-button fasteners, buckles, etc., can solve the problems of reducing the peeling strength, generating abnormal noise, and reducing the product value of the surface fastener, so as to suppress the generation of abnormal noise and reduce the vibration of the flat base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

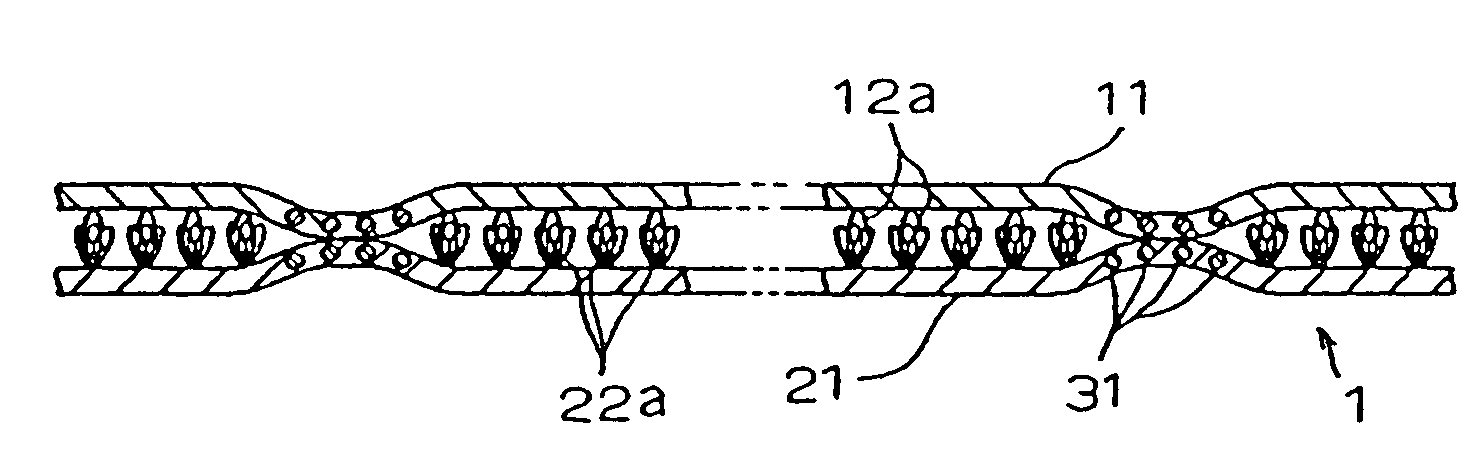

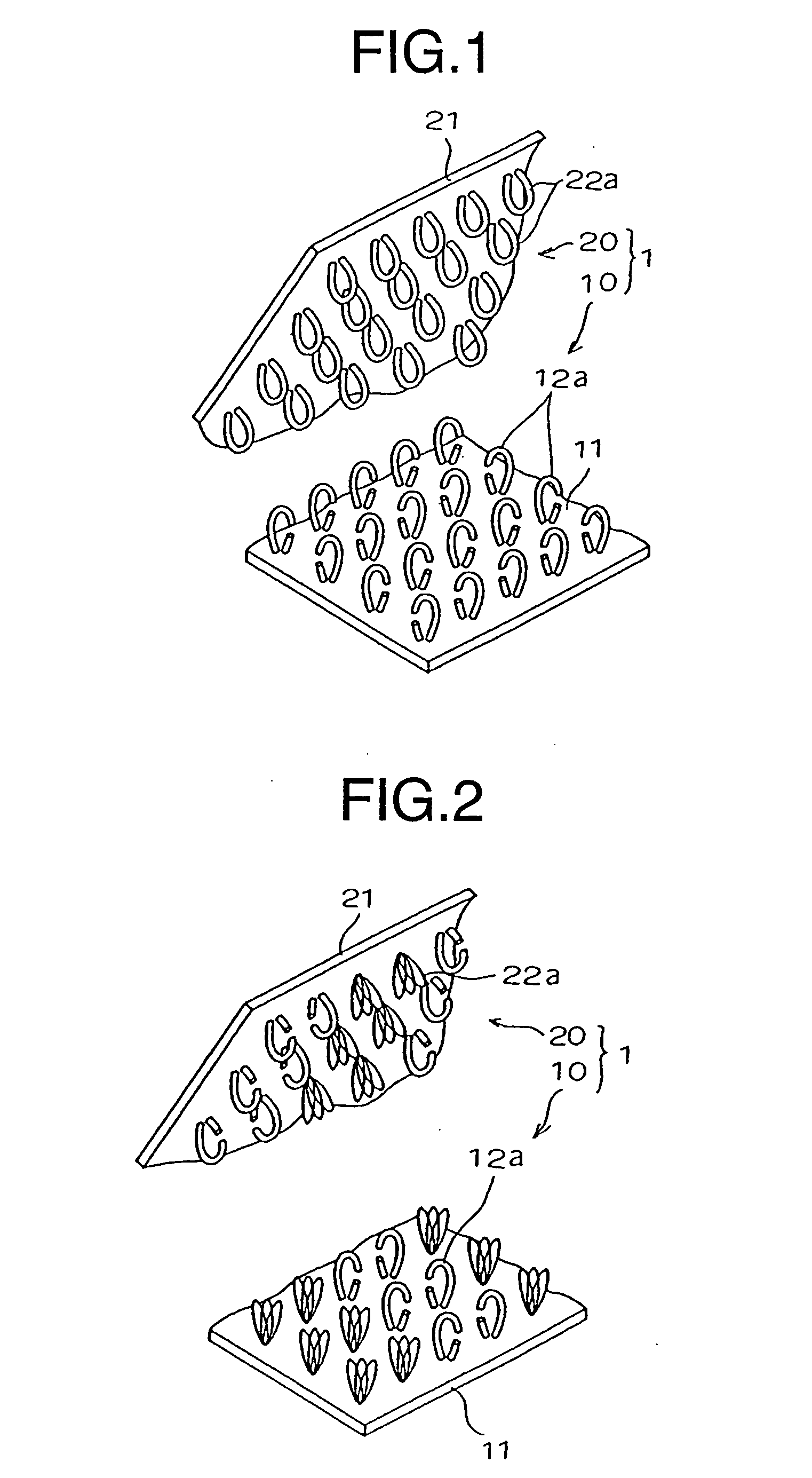

first embodiment

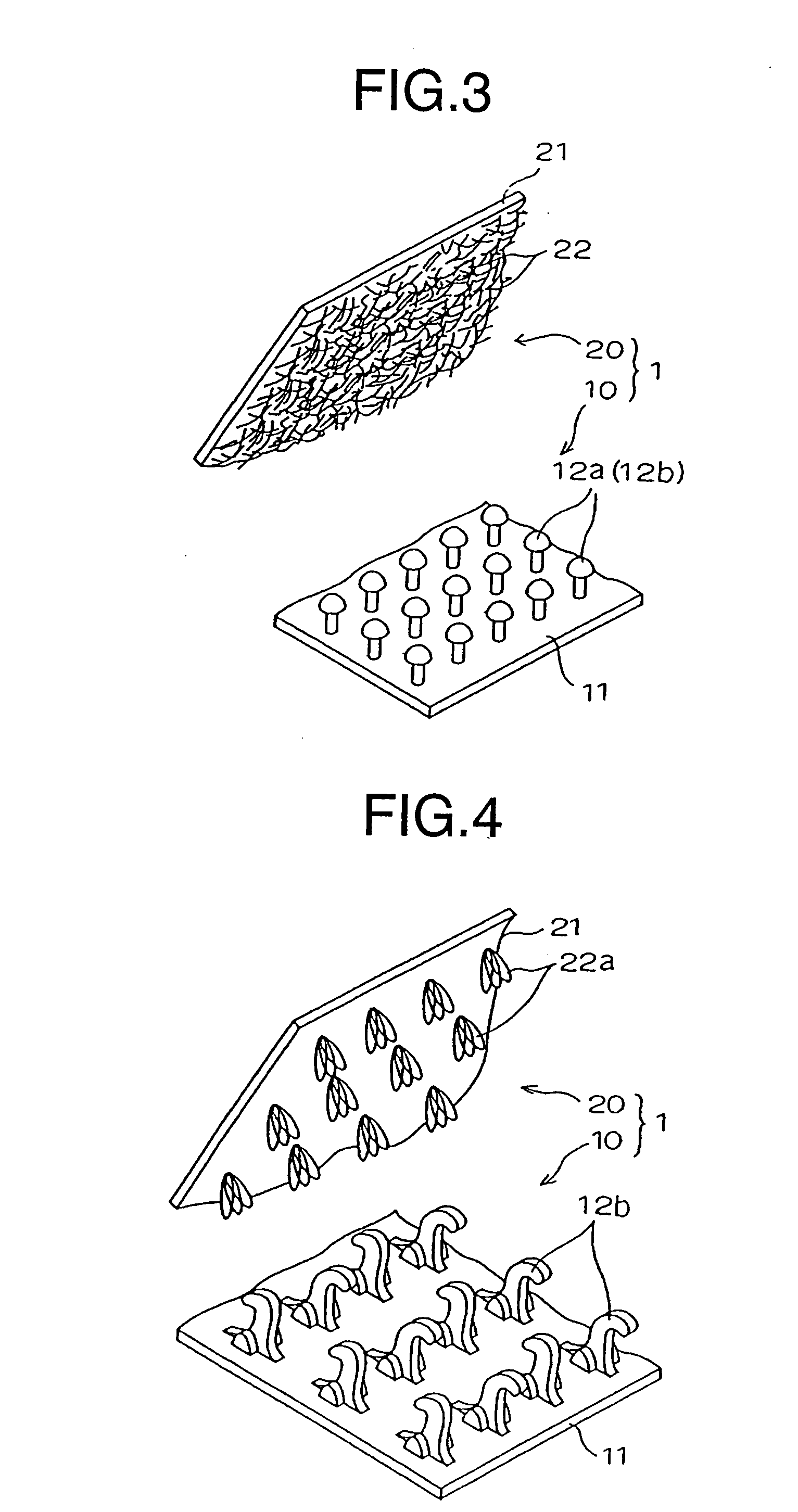

[0171] shown in FIGS. 16 to 18, the magnetic linear material 31 is woven into a non-formation area B in which no engaging elements 12a, 22a are formed, the area B existing in each of the flat base materials 11, 21 of the first and second surface fastener members 10, 20. In this case, no special noise suppressing engaging and disengaging means is adopted for the hook-like male engaging element constituted of monofilament and the loop-like female engaging element 22a constituted of multifilament. Examples of the magnetic linear material 31 include a metal linear material composed of a permanent magnet that is produced by making magnetic metal into a linear material directly and processing it with magnetism, and a resin linear material produced by mixing monofilament of a synthetic resin material with powder having magnetism. The respective magnetic linear materials 31 which magnetically attract each other is permitted to have magnetism or no magnetism. If both of them have magnetism, ...

fourth embodiment

[0184]FIGS. 28 to 31 show the silent surface fastener 1 of the present invention. According to this embodiment, block pieces 33 and projections 34 are provided in a formation area A and / or a non-formation area B for the engaging elements 12, 22 formed on the base materials 11, 21 of the first and second surface fastener members 10, 20. This block piece and projections are formed of synthetic resin. Preferably, they are formed of a soft synthetic resin material such as polyethylene. The first and second surface fastener members 10, 20 are provided with magnetism by mixing magnetic powder directly in the block piece 33 and projection 34, or as shown in FIGS. 32 and 33 by integrating a magnetic piece 35 on the surface of the block piece 33 or projection 34 by bonding, fusion or coating. In the meantime, the height of the block piece 33 or the projection 34 from the flat base material surface is set equal to or slightly lower than the height of peripheral engaging elements 12, 22.

[0185]...

fifth embodiment

[0189]FIG. 34 shows the silent surface fastener 1 of the present invention. According to this embodiment, a first projection 34 made of synthetic resin, as shown in FIG. 32, is provided protrudedly in an area of the fiber-made base material 11 of the first surface fastener member 10, in which no hook-like engaging elements composed of monofilament are formed. A coil 36 made of a metal magnetic linear material is buried in the projection 34. Both ends of the coil 36 are connected to a power supply 37 such as a battery through a switch (not shown).

[0190]On the other hand, a second projection 38 made of synthetic resin is provided protrudedly in an area of a surface of the fiber-made flat base material 21 of the second surface fastener member 20, the area corresponding to the projection 34 of the first surface fastener member 10. A plurality of loop-like engaging elements 22a are formed between these projections 38 so as to form the engaging element formation area A. Magnetic powder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com