Patents

Literature

50results about How to "Suppresses the generation of abnormal noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

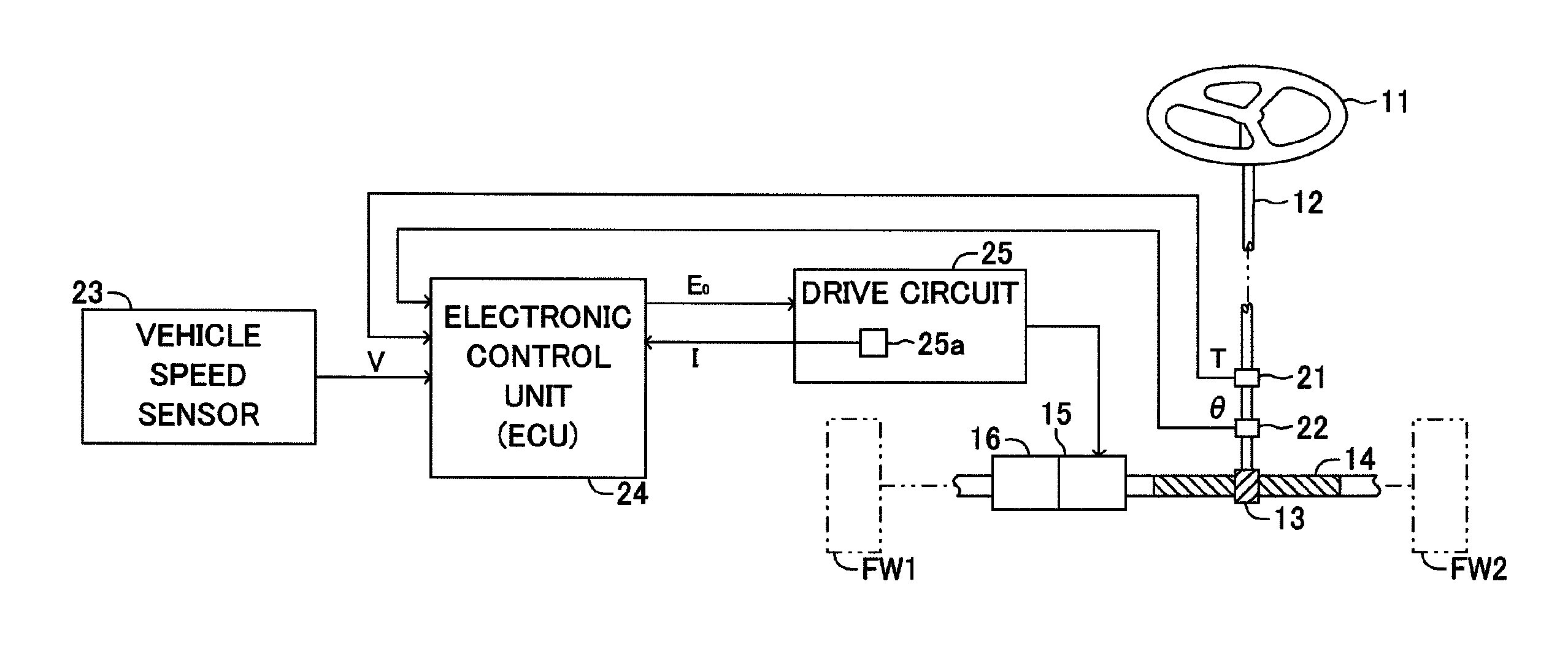

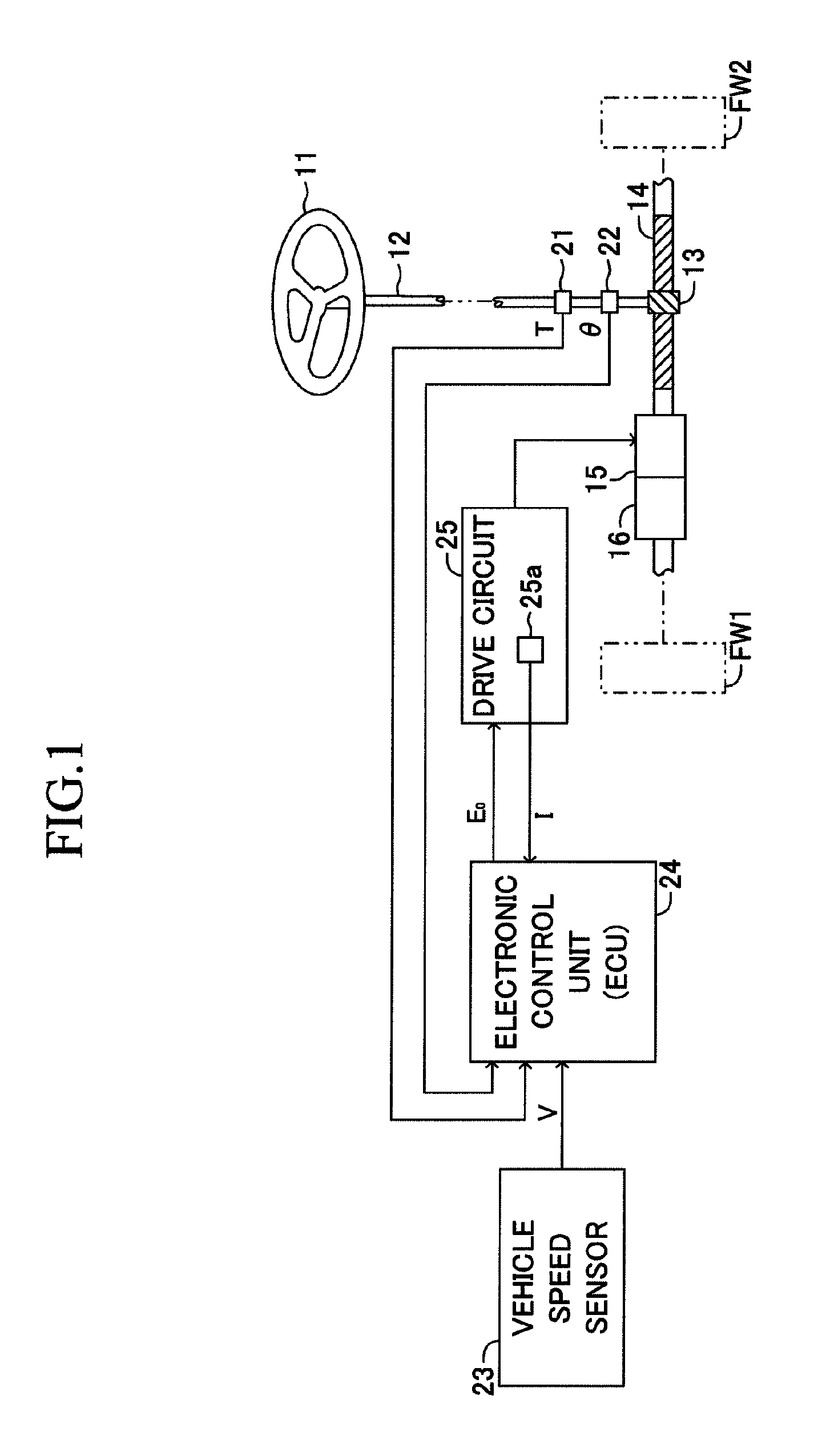

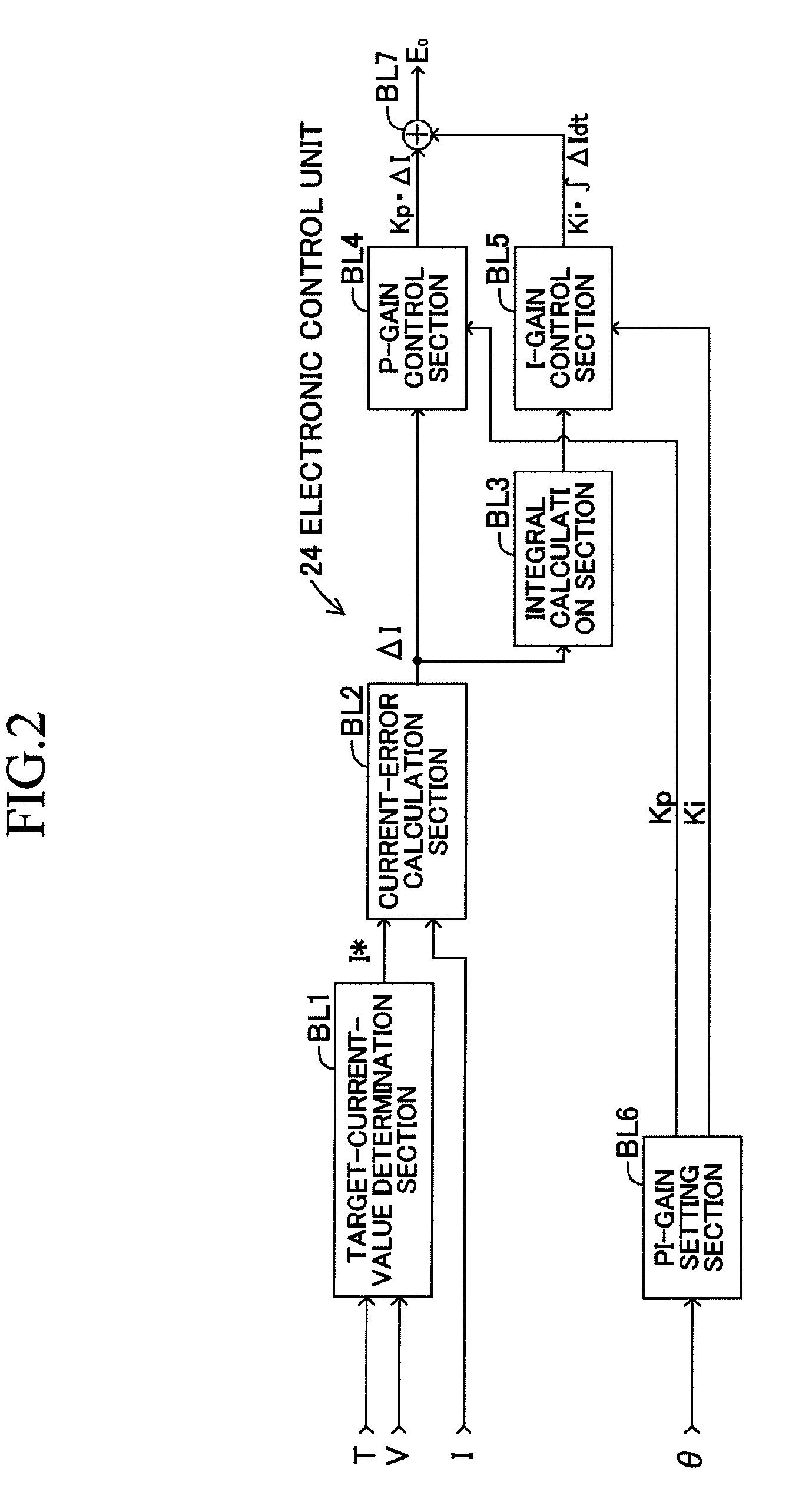

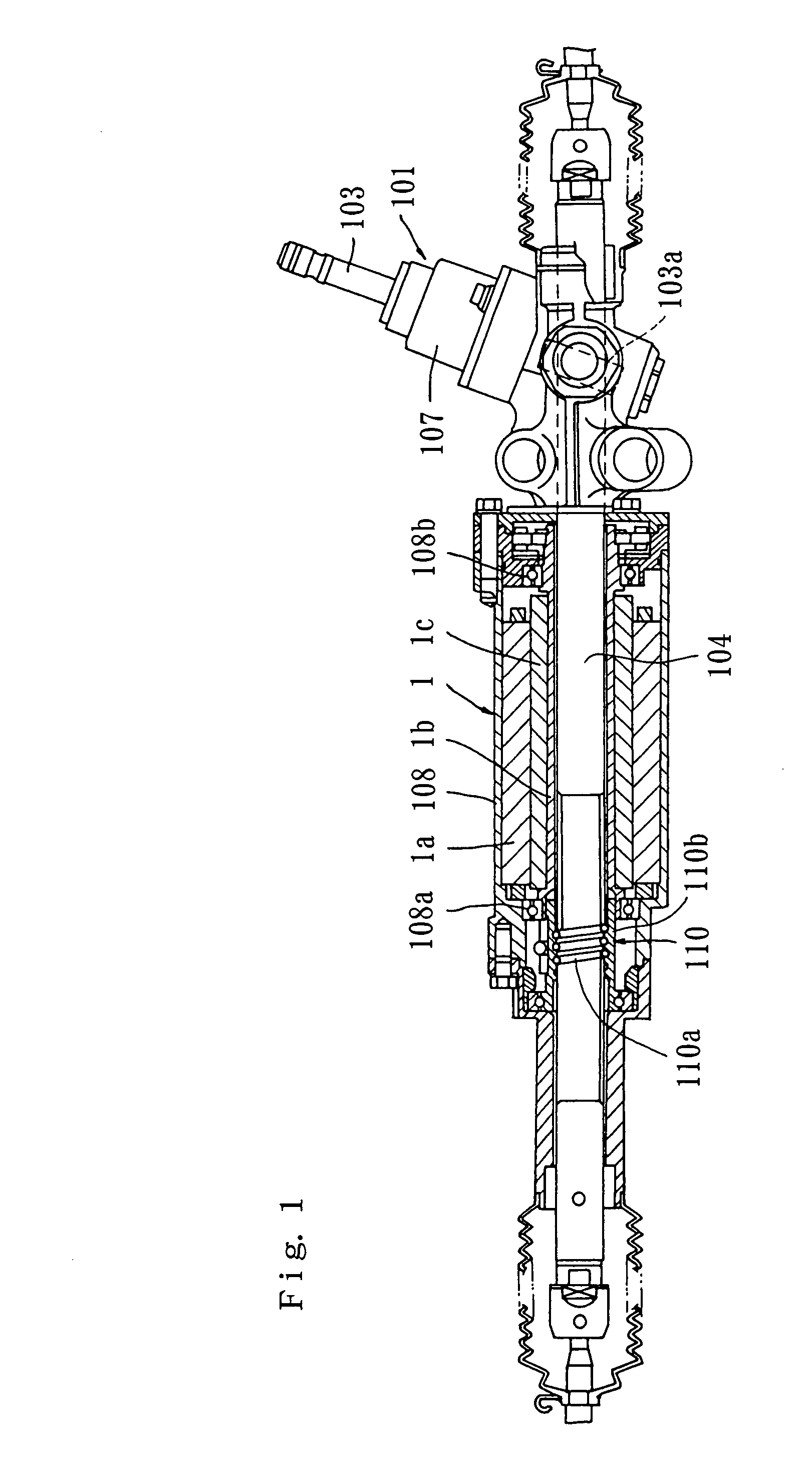

Steering assistance device for vehicle

ActiveUS20090069979A1Reduce the chance of changeReduce switching frequencyDigital data processing detailsSteering initiationsSteering angleCurrent sensor

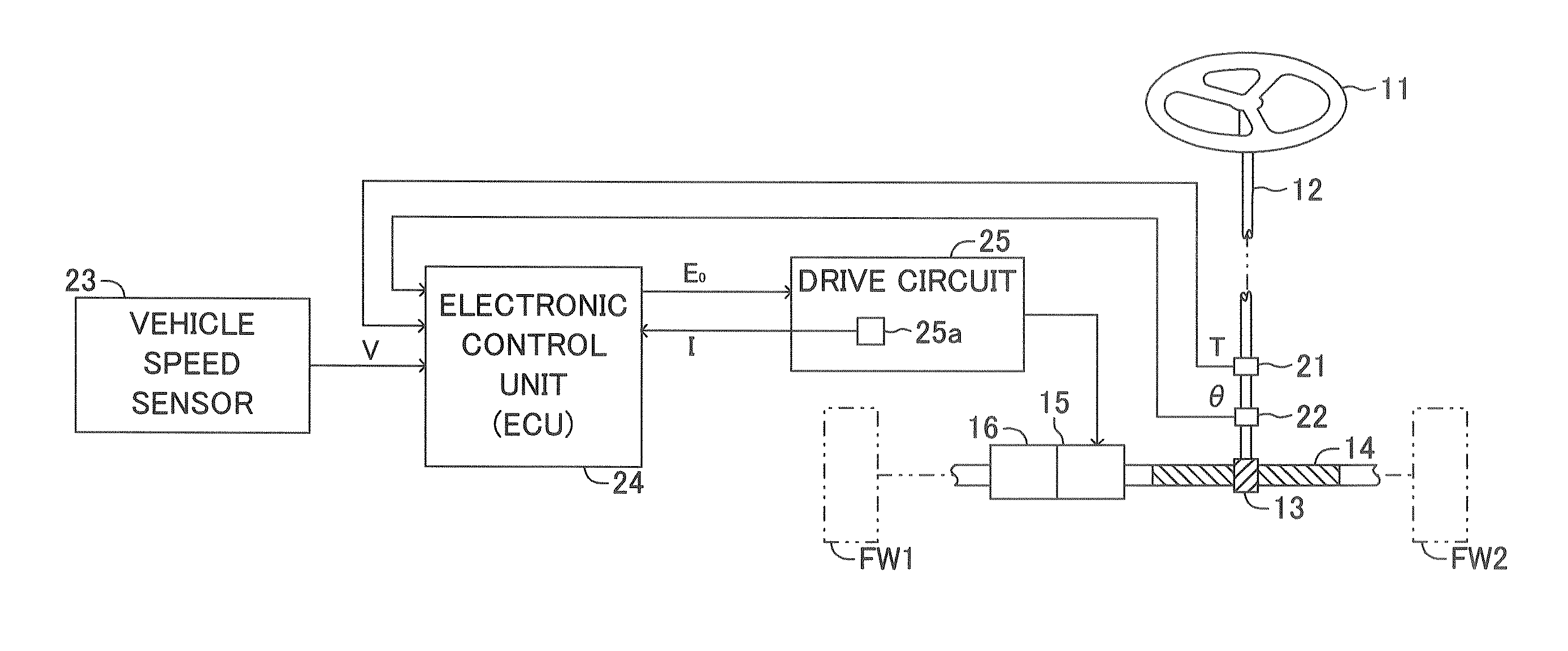

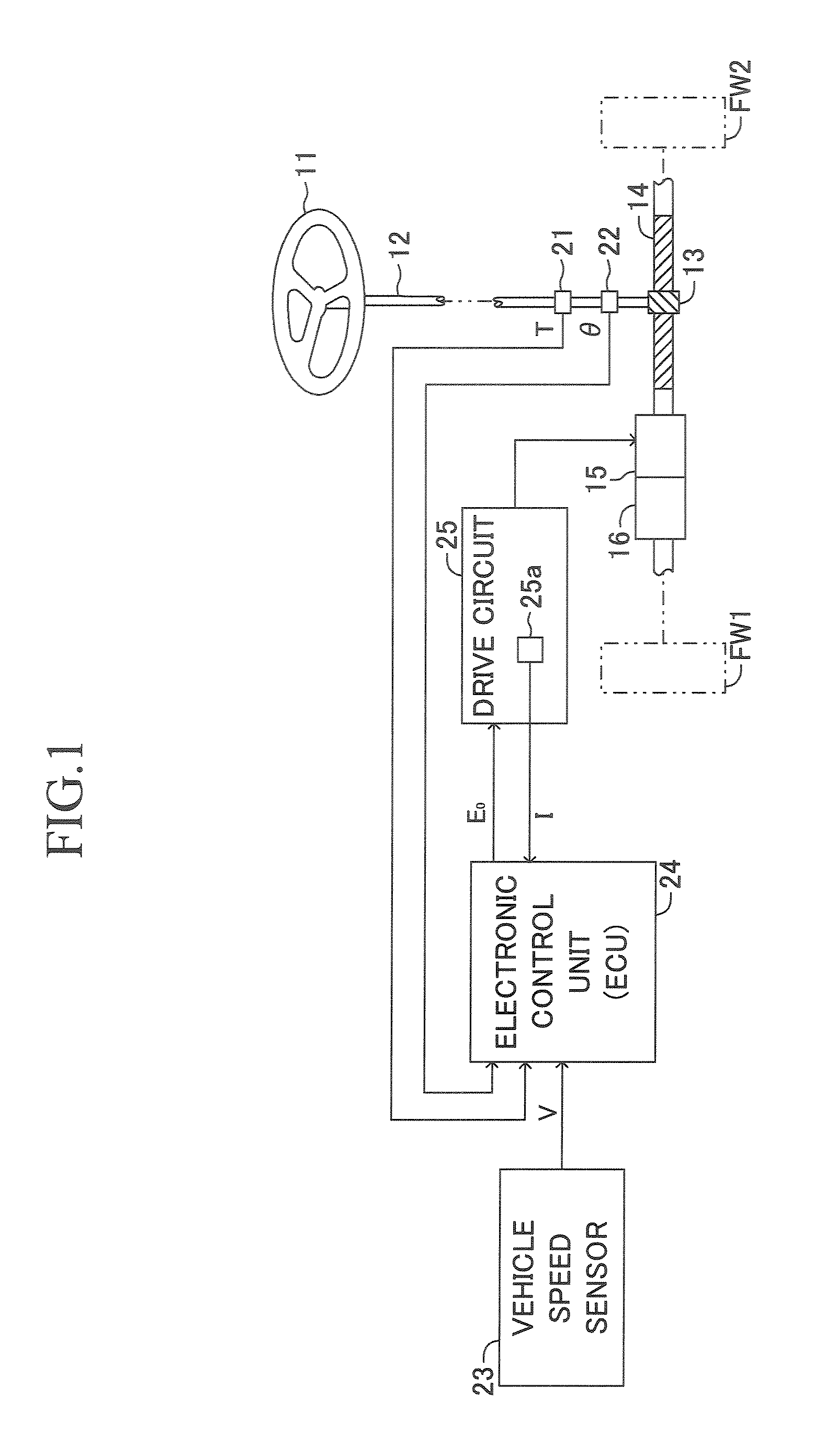

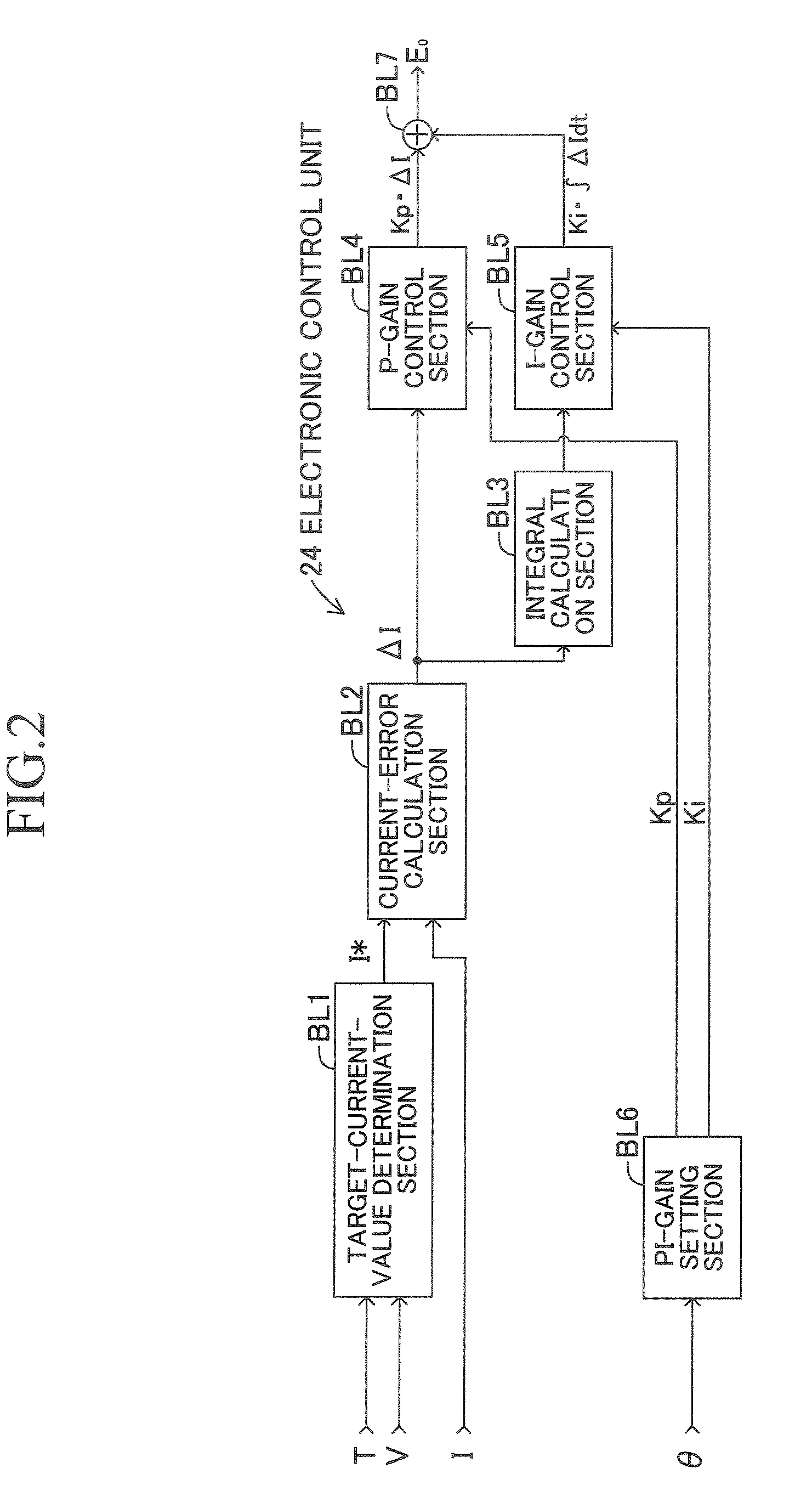

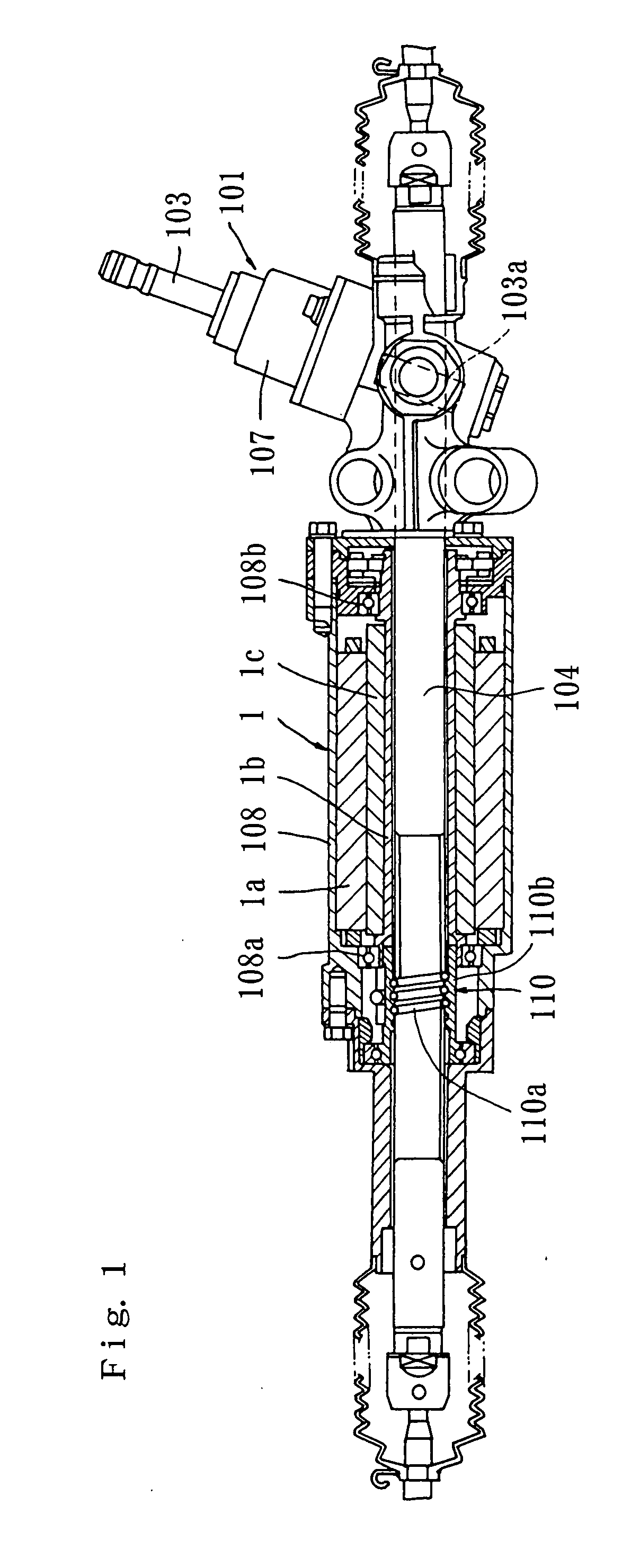

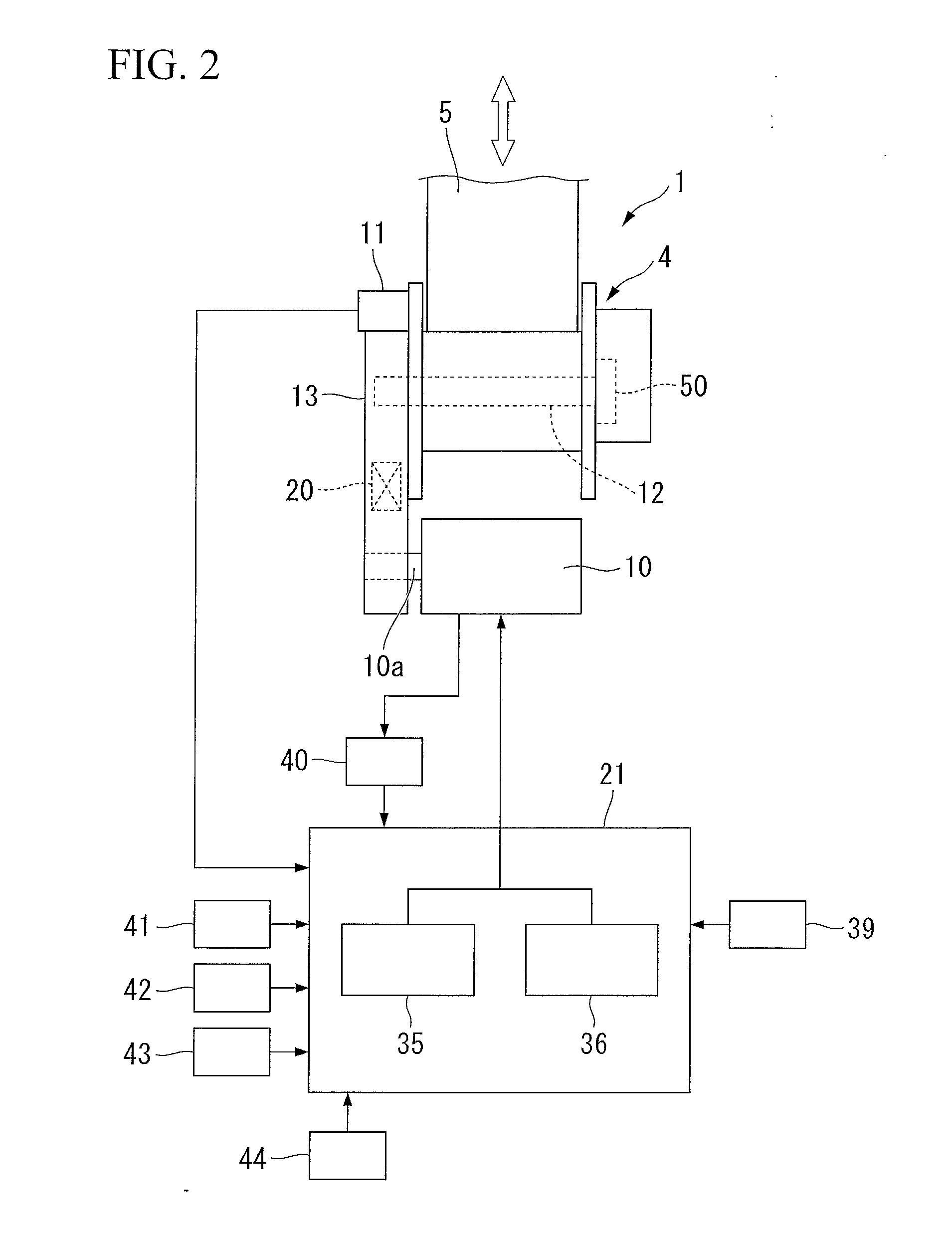

A steering assist apparatus for a vehicle includes an electric motor for steering assist. Rotation output of the electric motor is reduced in speed by a ball-screw mechanism and converted to rectilinear motion, which is transmitted to a rack bar. An electronic control unit determines a target current value in accordance with a steering torque detected by a steering torque sensor and a vehicle speed detected by a vehicle speed sensor. While using an actual current value of the electric motor detected by a current sensor as a feedback, the electronic control unit controls the current flowing through the electric motor to be equal to the target current value. The electronic control unit changes the feedback gain of the feedback control in accordance with a steering angle detected by a steering angle sensor, to thereby suppress abnormal noise generated at a steering mechanism, without deteriorating steering feel.

Owner:TOYOTA JIDOSHA KK

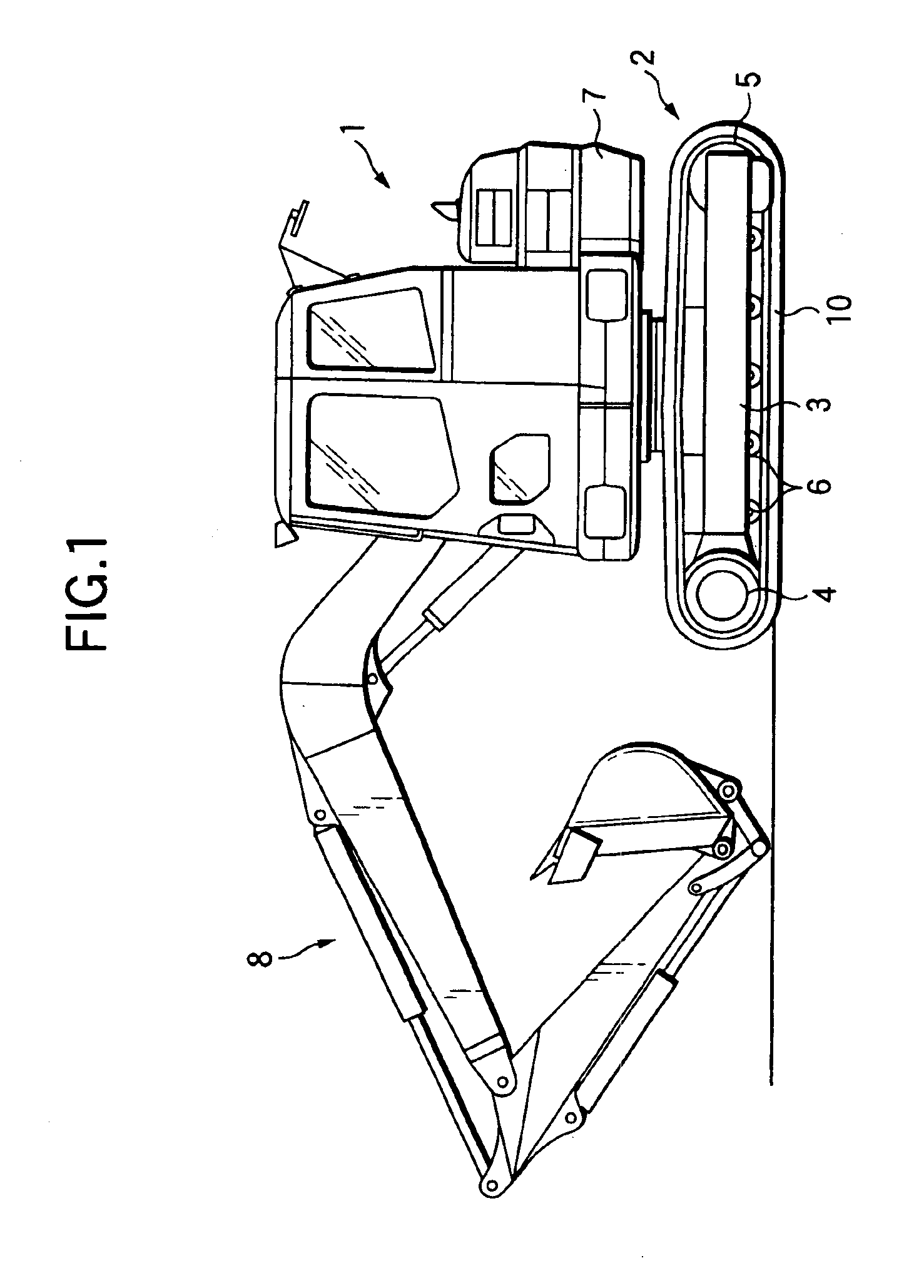

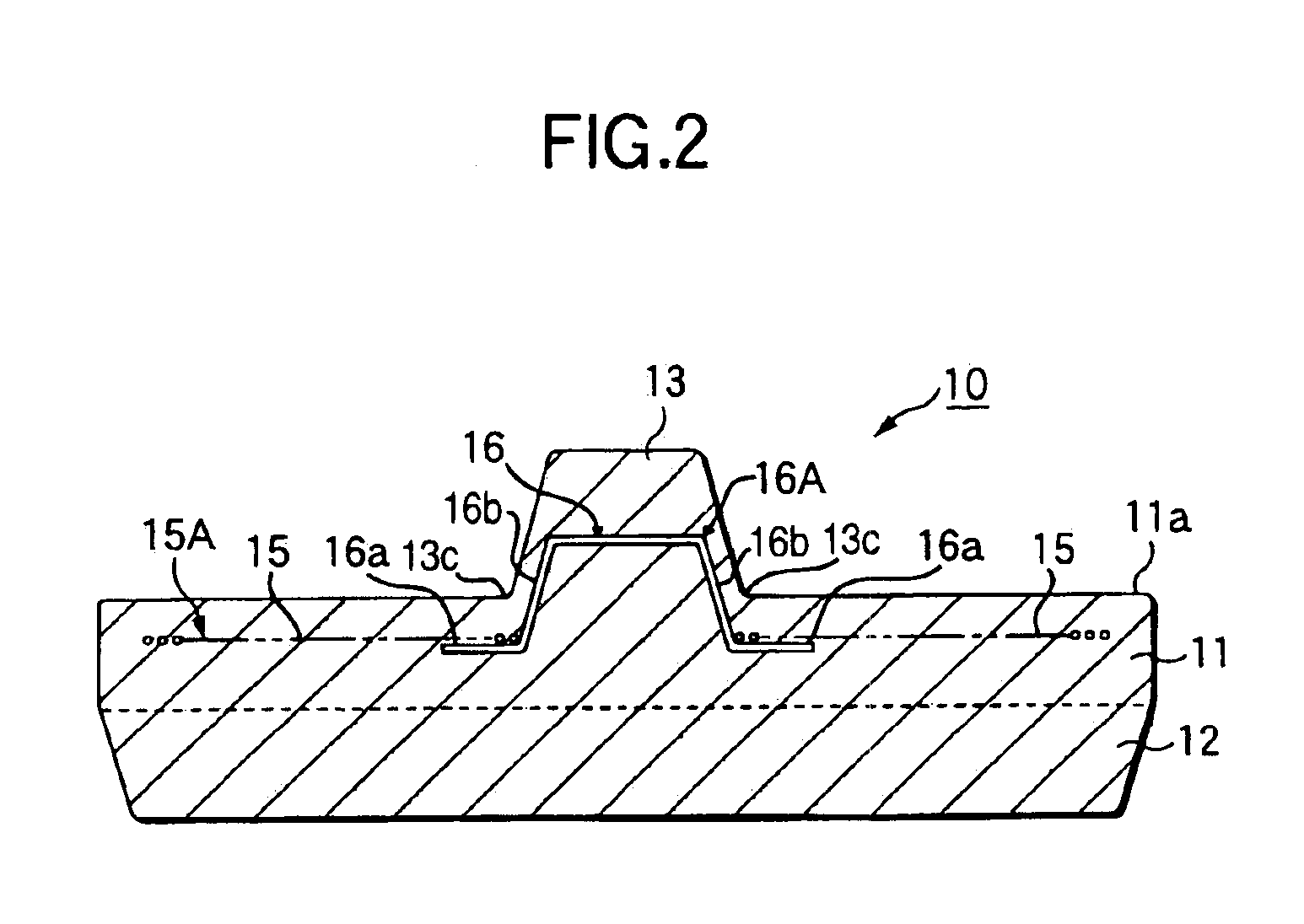

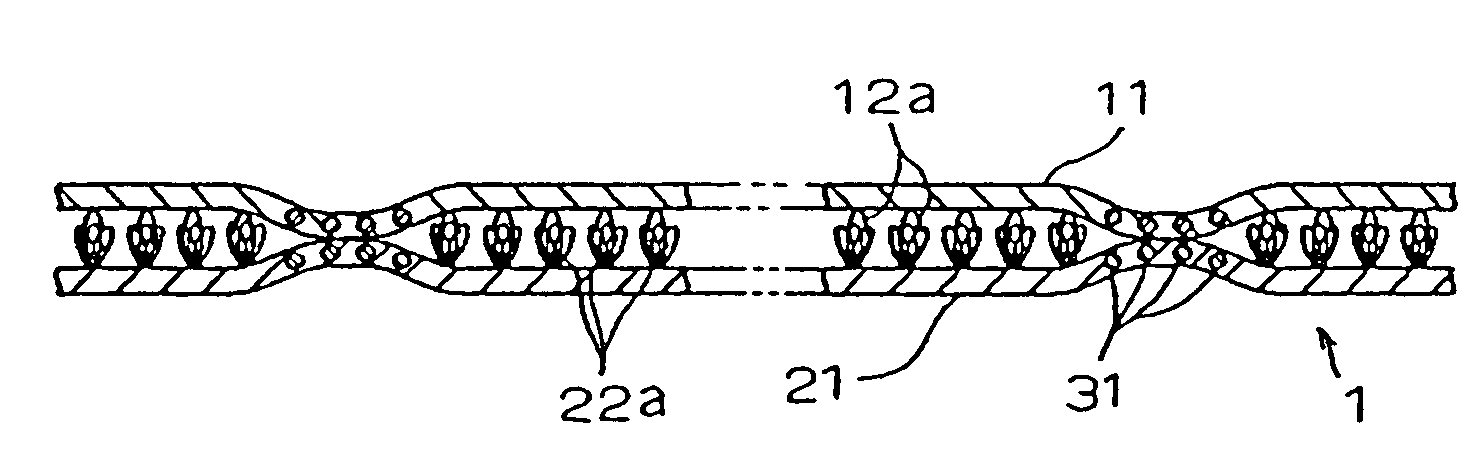

Elastic-bodied crawler

InactiveUS6932442B2Increased durabilityDriven projectionDriving beltsEndless track vehiclesElastomerEngineering

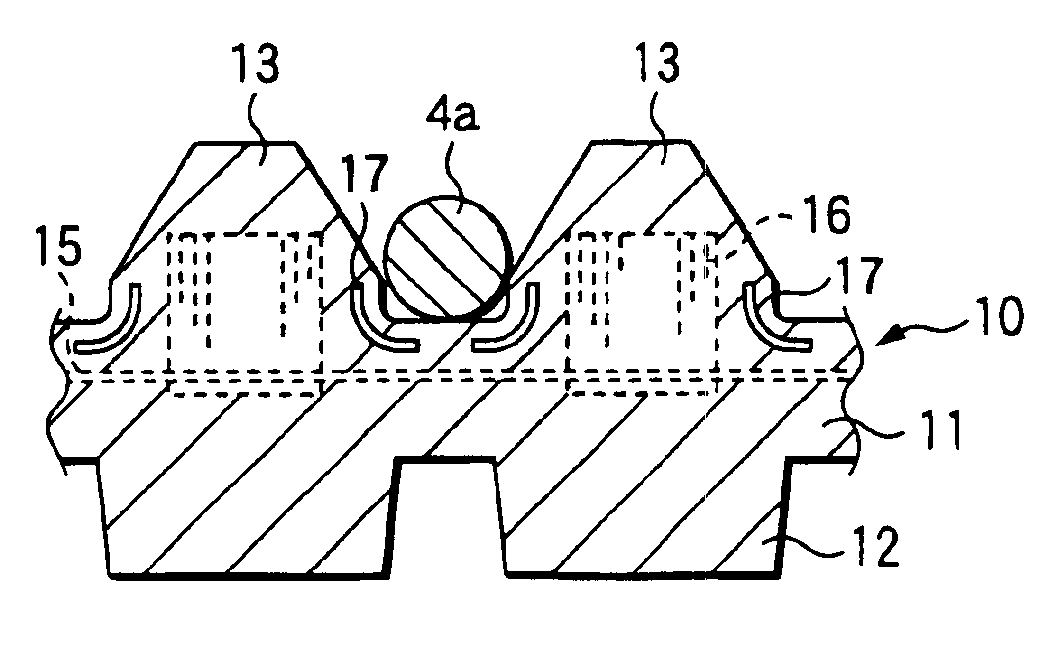

An elastic-bodied crawler, in which damages, such as local wear, coming-off of driven projections and the like in use, are prevented from being brought about, and frictional resistance is decreased at engaging portions to provide for durability, comprises a body with a reinforcement layer of reinforcement cables embedded therein circumferentially, driven projections provided in a predetermined pitch on an inner peripheral surface of the body, lug portions formed on an outer surface of the body, and reinforcement members (driven projection reinforcement cables) embedded to bridge the driven projections and the body.

Owner:KOMATSU LTD

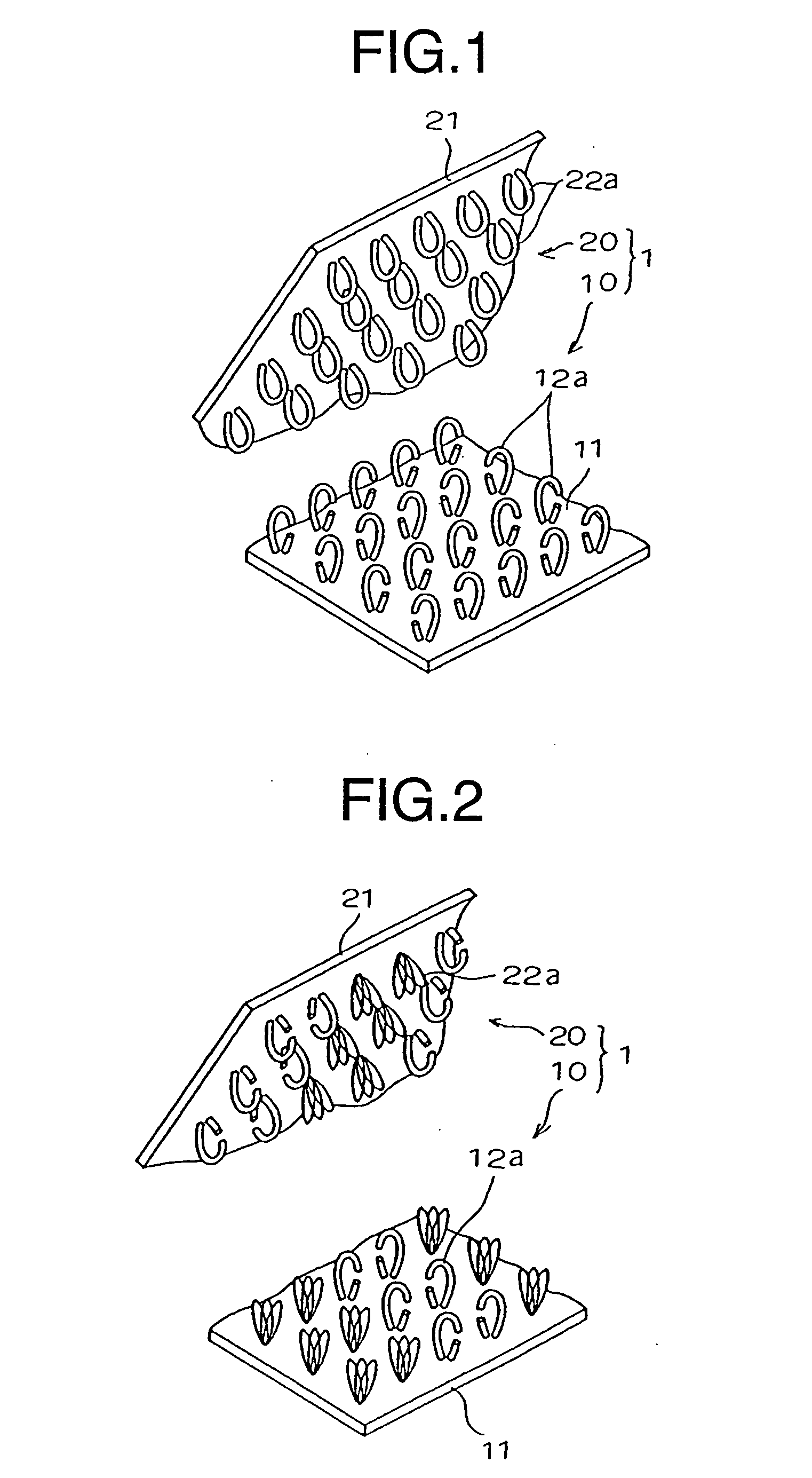

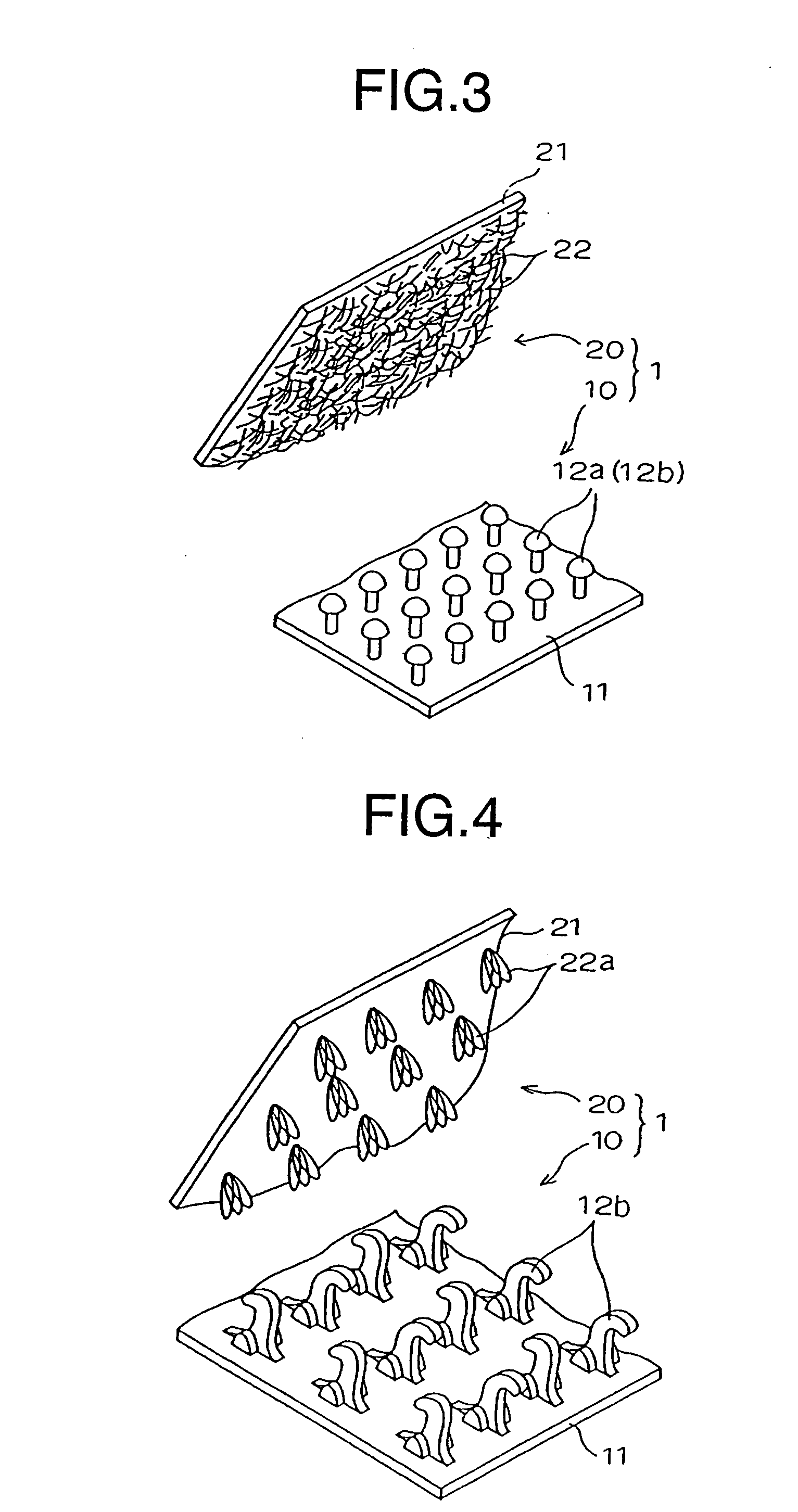

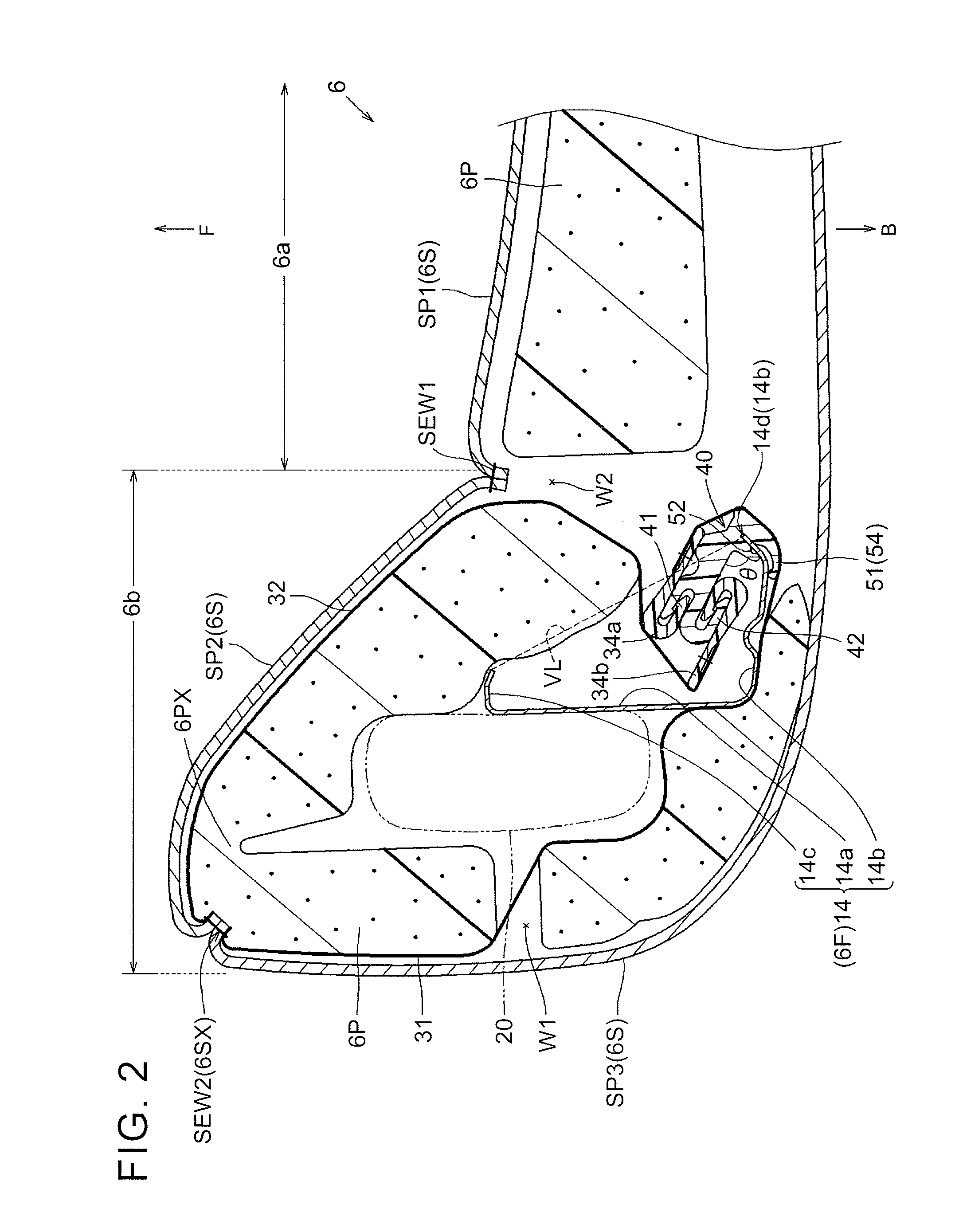

Silent Surface Fastener

InactiveUS20090013506A1Reduce vibrationSuppresses the generation of abnormal noiseSnap fastenersClothes buttonsEngineeringUltimate tensile strength

The present invention relates to a silent surface fastener, wherein the surface fastener is provided with noise suppressing means and auxiliary engaging and disengaging means, so that even if joining strength necessary for a surface fastener (1) cannot be obtained due to adoption of the noise suppressing means, not only the joining strength necessary for the surface fastener (1) is compensated by the auxiliary engaging and disengaging means, but also only a peeling noise suppressed by the noise suppressing means is generated at the time of peeling of the surface fastener because the auxiliary engaging and disengaging means generates no noise when the engagement of the surface fastener is released, and consequently, only a quiet sound of 80 dB at a maximum is generated.

Owner:YKK CORP

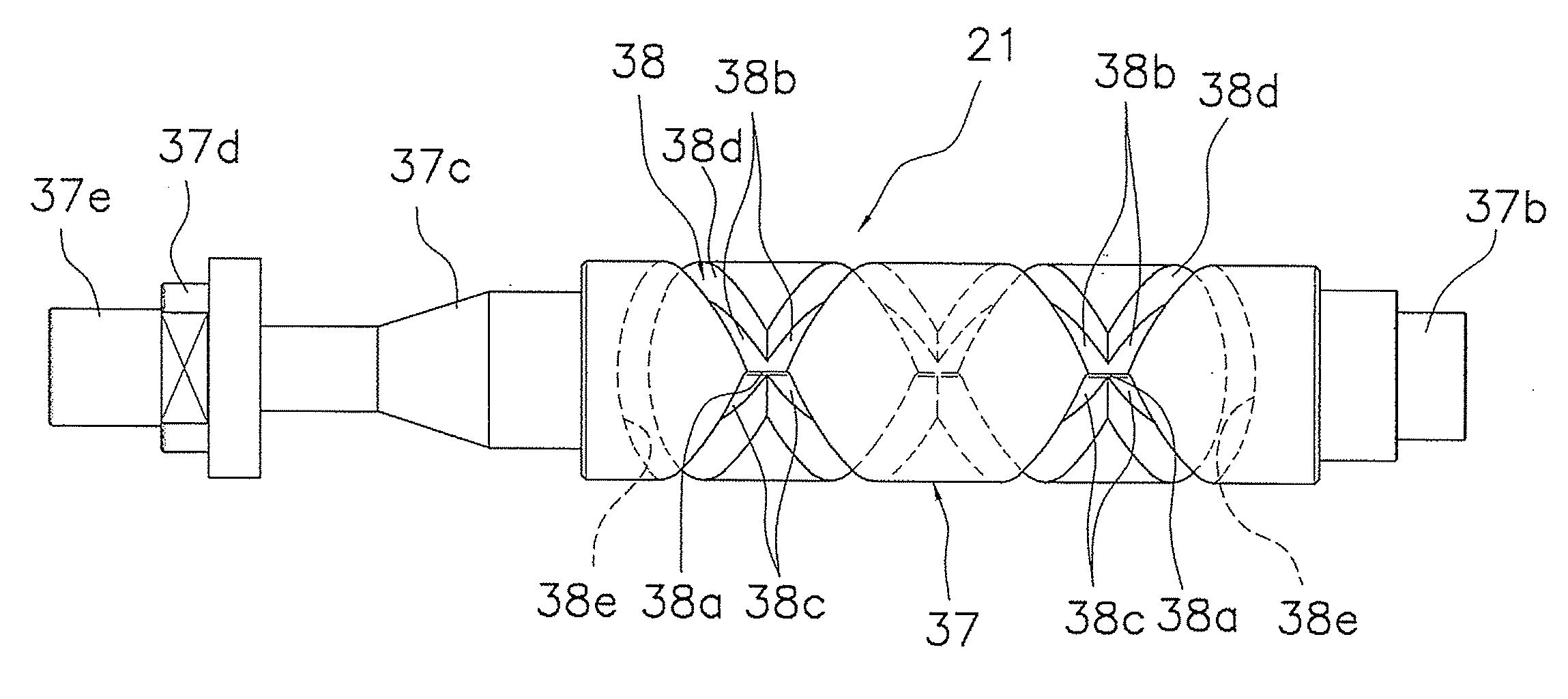

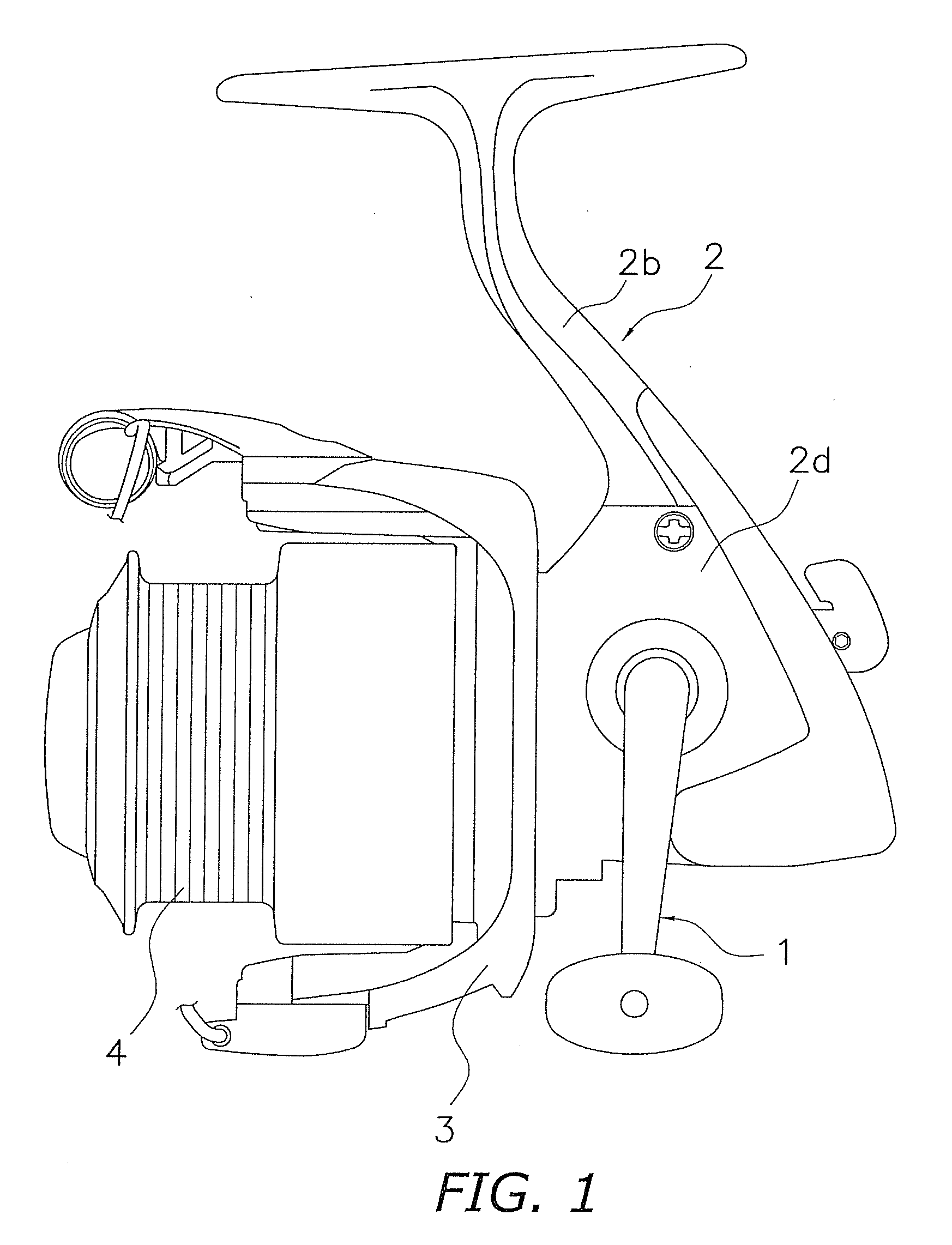

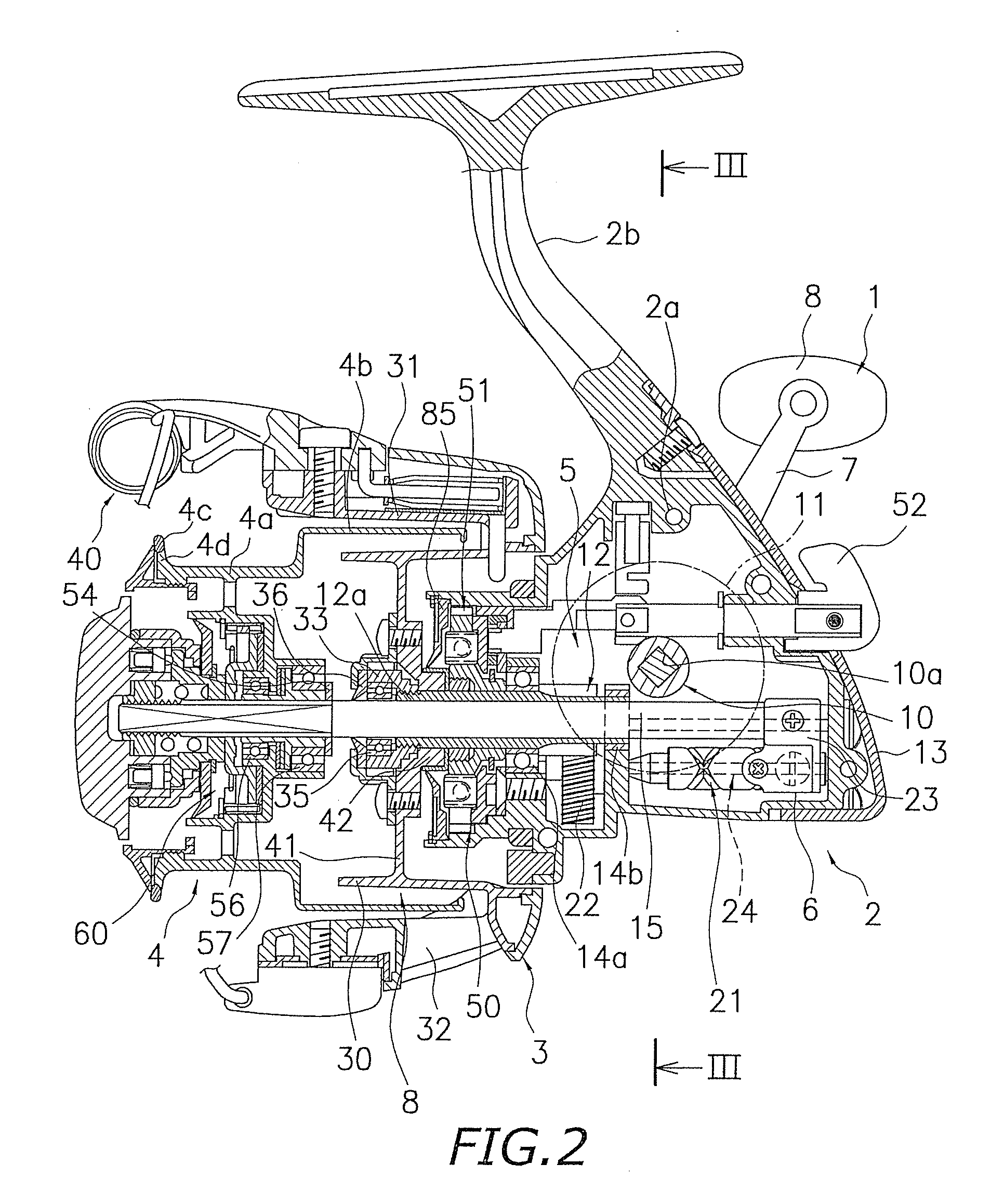

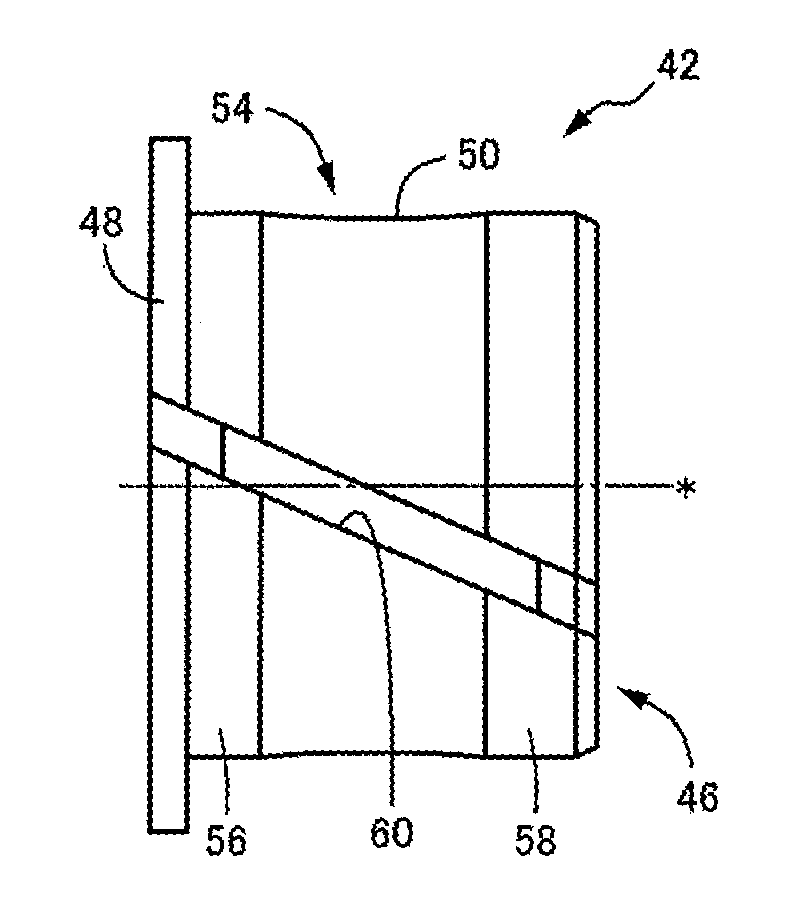

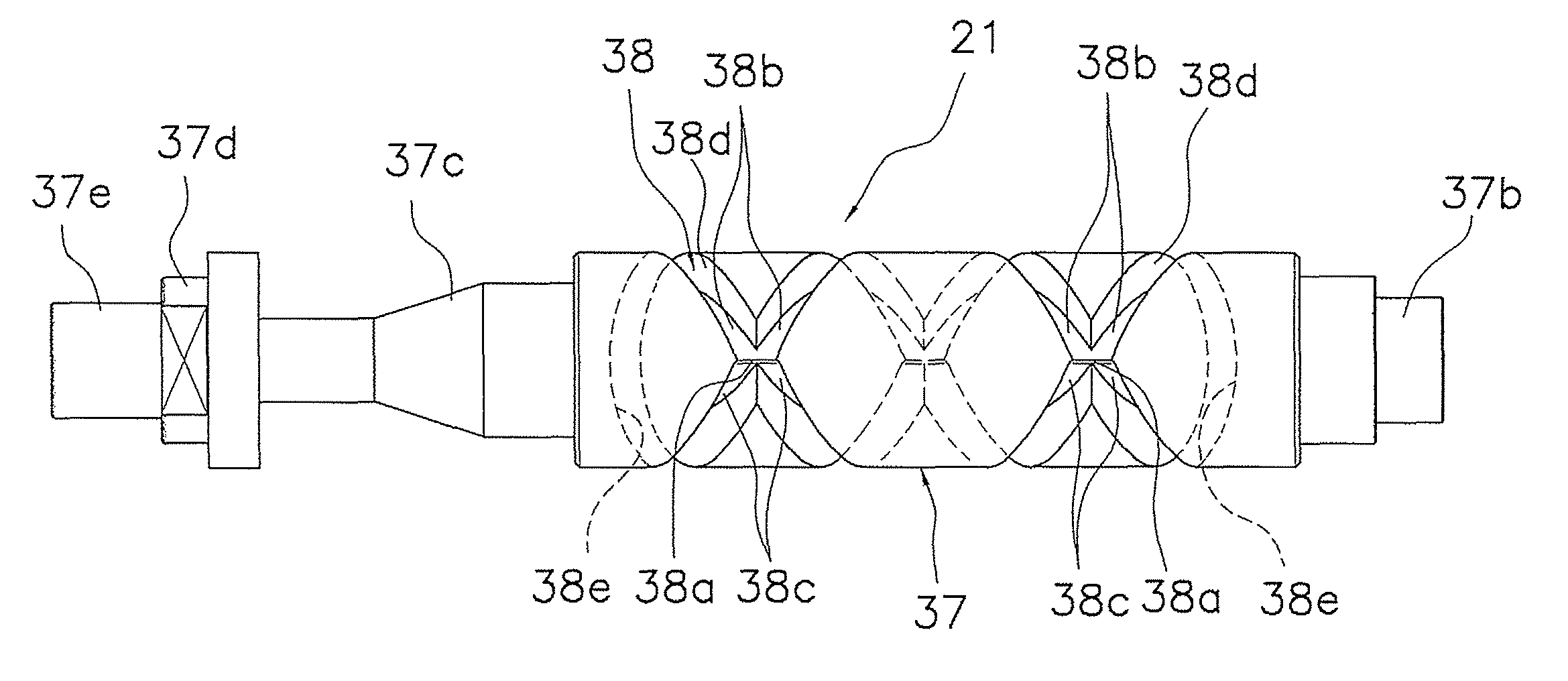

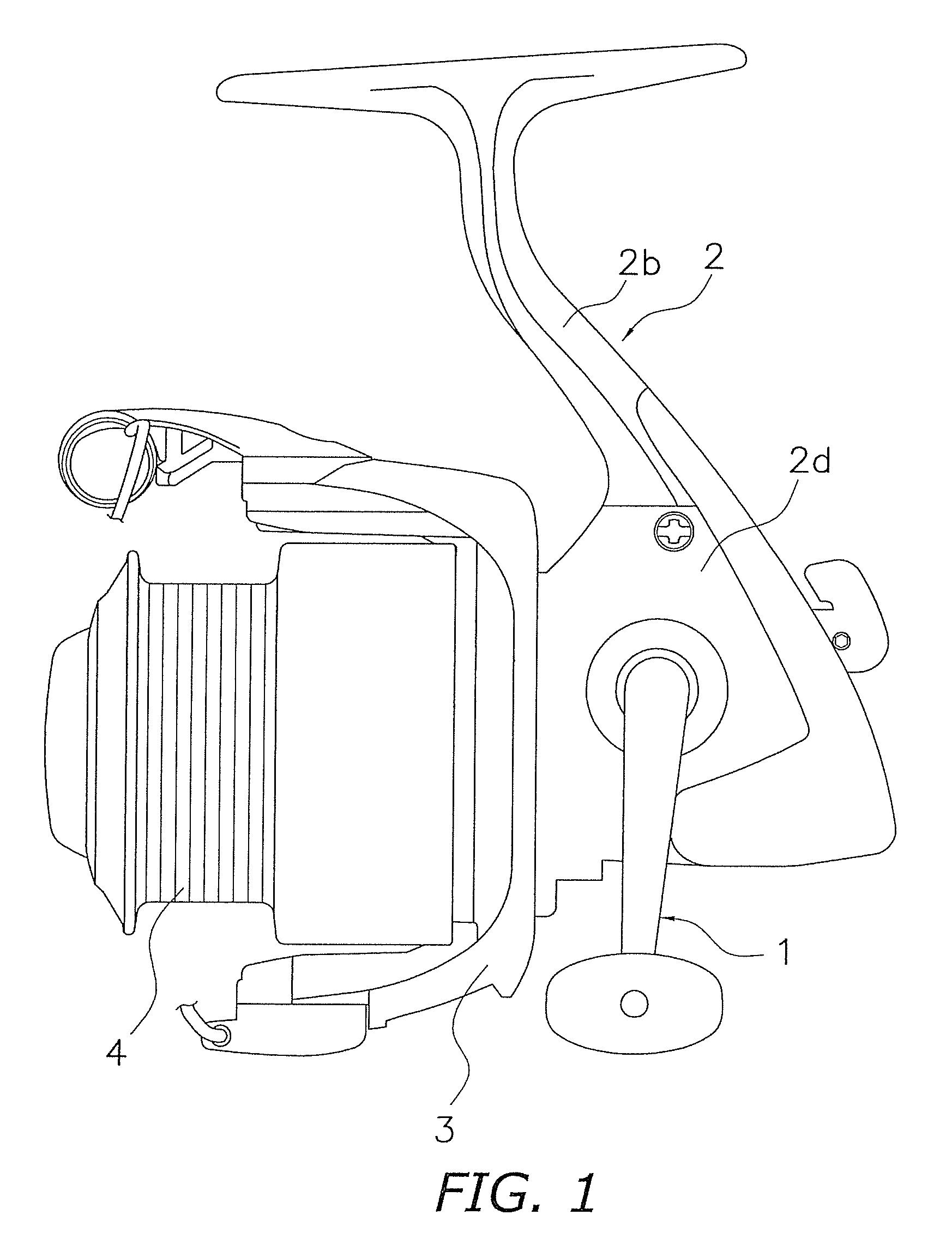

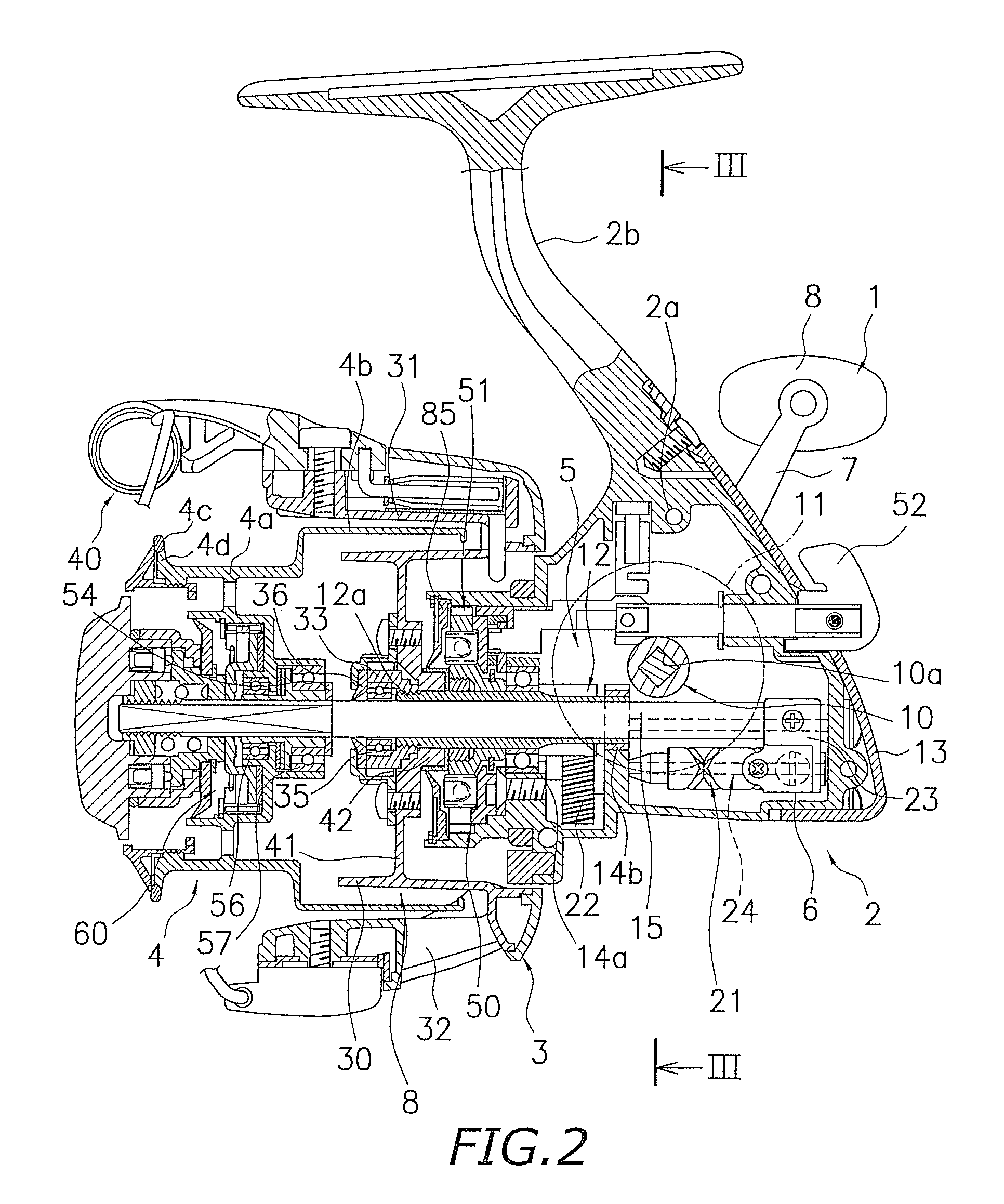

Traverse camshaft for fishing reel and reciprocal movement mechanism for fishing reel employing the traverse camshaft

ActiveUS20100187346A1Suppress unnecessary turningSuppresses the generation of abnormal noiseGearingReelsEngineeringCam

In a spinning reel, a traverse camshaft 21 is arranged to engage with an engaging member used to cause a bail arm and a spool to undergo a relative reciprocal movement. The traverse camshaft 21 has a shaft body 37 and a cam groove 38. The shaft body 37 is arranged to rotate in coordination with rotation of a handle assembly in at least a line reel-in direction. The cam groove 38 is formed in an external circumferential surface of the shaft body 37 and configured to engage with the engaging member. The cam groove 38 is also configured to intersect itself. The cam groove 38 has a first groove section 38b and a second groove section 38c on opposite sides of an intersecting portion 38a. The first groove section 38b and the second groove section 38c have different widths at the intersecting portion 38a.

Owner:SHIMANO INC

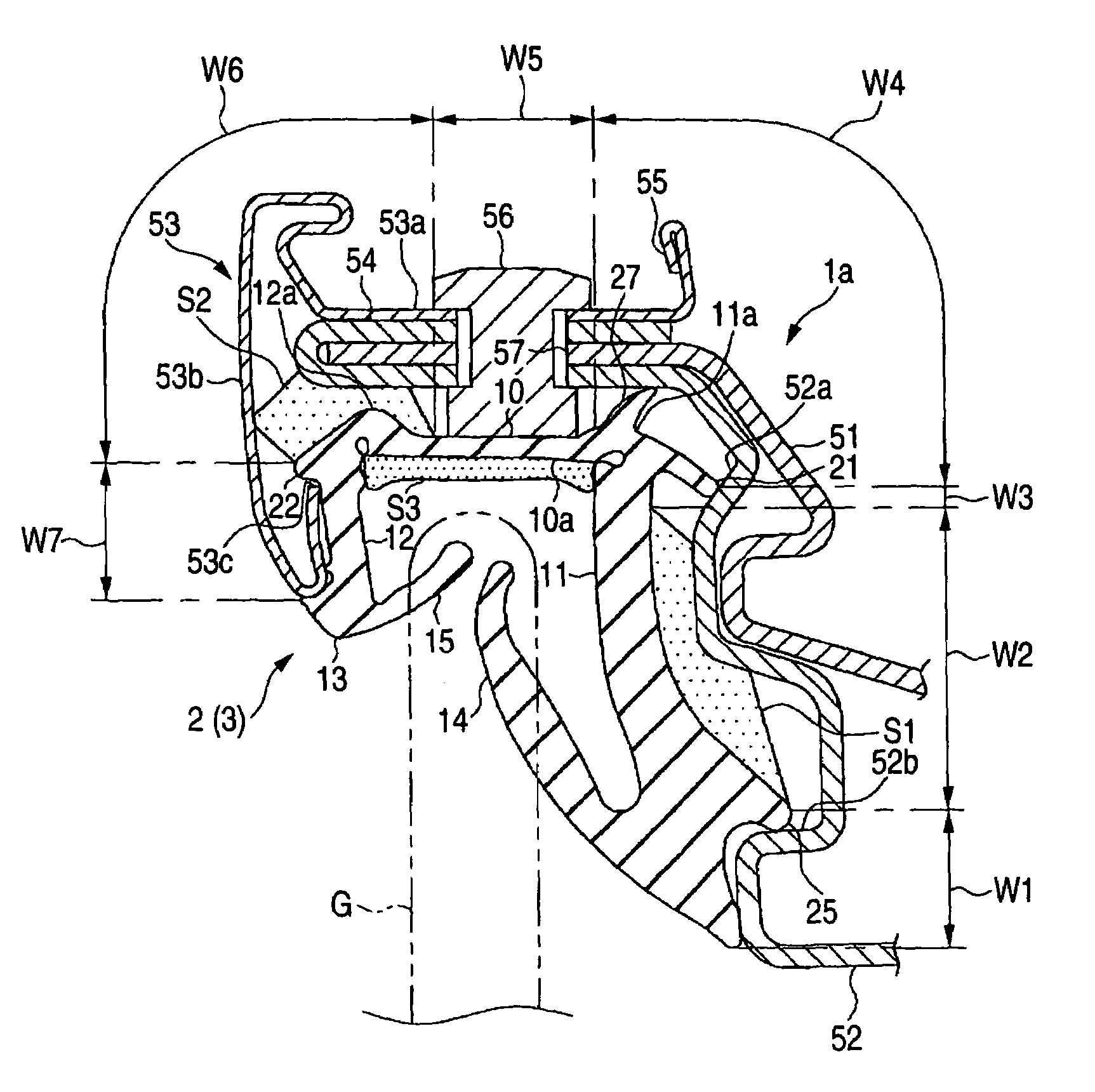

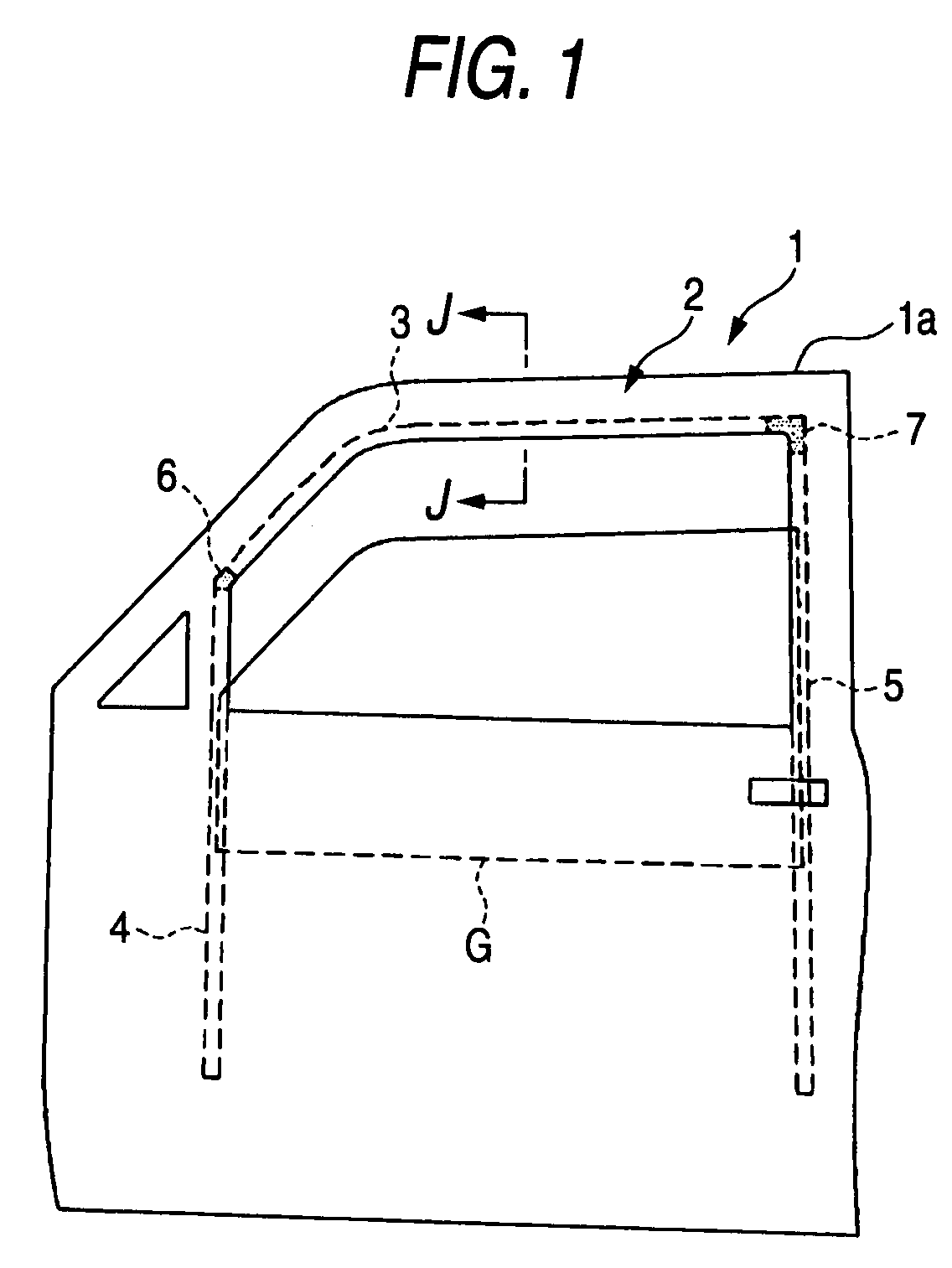

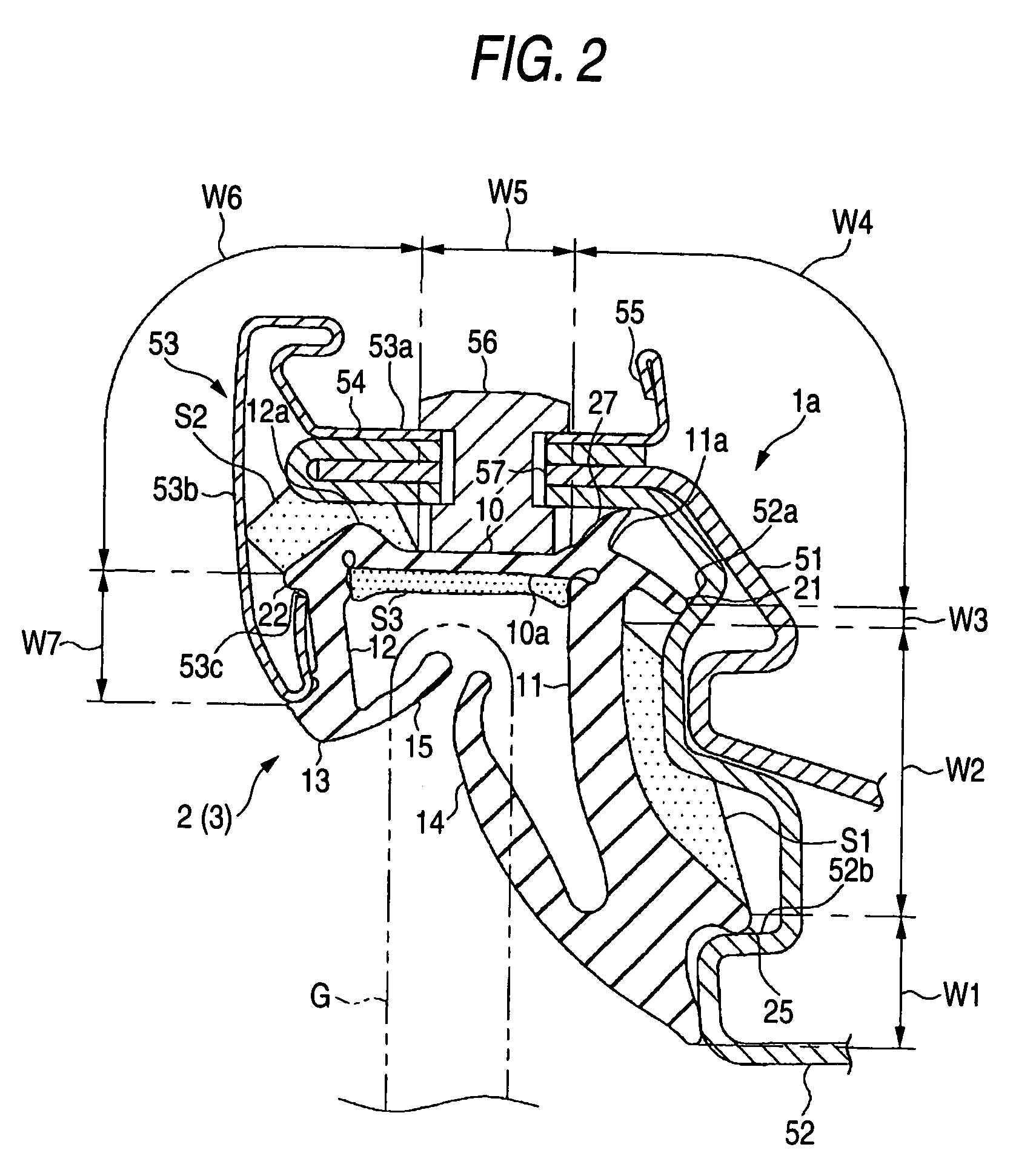

Glass run

InactiveUS7410203B2Suppresses the generation of abnormal noiseImprove AssemblabilityVehicle seatsWindowsEngineeringMechanical engineering

An automobile door has a glass run corresponding to a glass door. The glass run includes a body portion, which has a bottom wall portion, and a vehicle interior side wall portion and a vehicle exterior side wall portion respectively extending from opposite ends of the bottom wall portion, and also includes a pair of seal lips which performs sealing between the door glass and the glass run. Furthermore, in a cross-sectionally substantially-U-shaped outer peripheral portion of the body portion, sponge rubber layers are provided in a predetermined range in a longitudinal direction of a cross-section of the vehicle interior side surface wall portion and a predetermined zone including a continuously connecting portion between the bottom wall portion and the inner outer side surface wall portion, respectively. An auxiliary lip is provided at a continuously connecting portion between the bottom wall portion and the vehicle interior side wall portion. Additionally, a sponge rubber layer is formed on a door glass facing surface of the bottom wall portion.

Owner:TOYODA GOSEI CO LTD

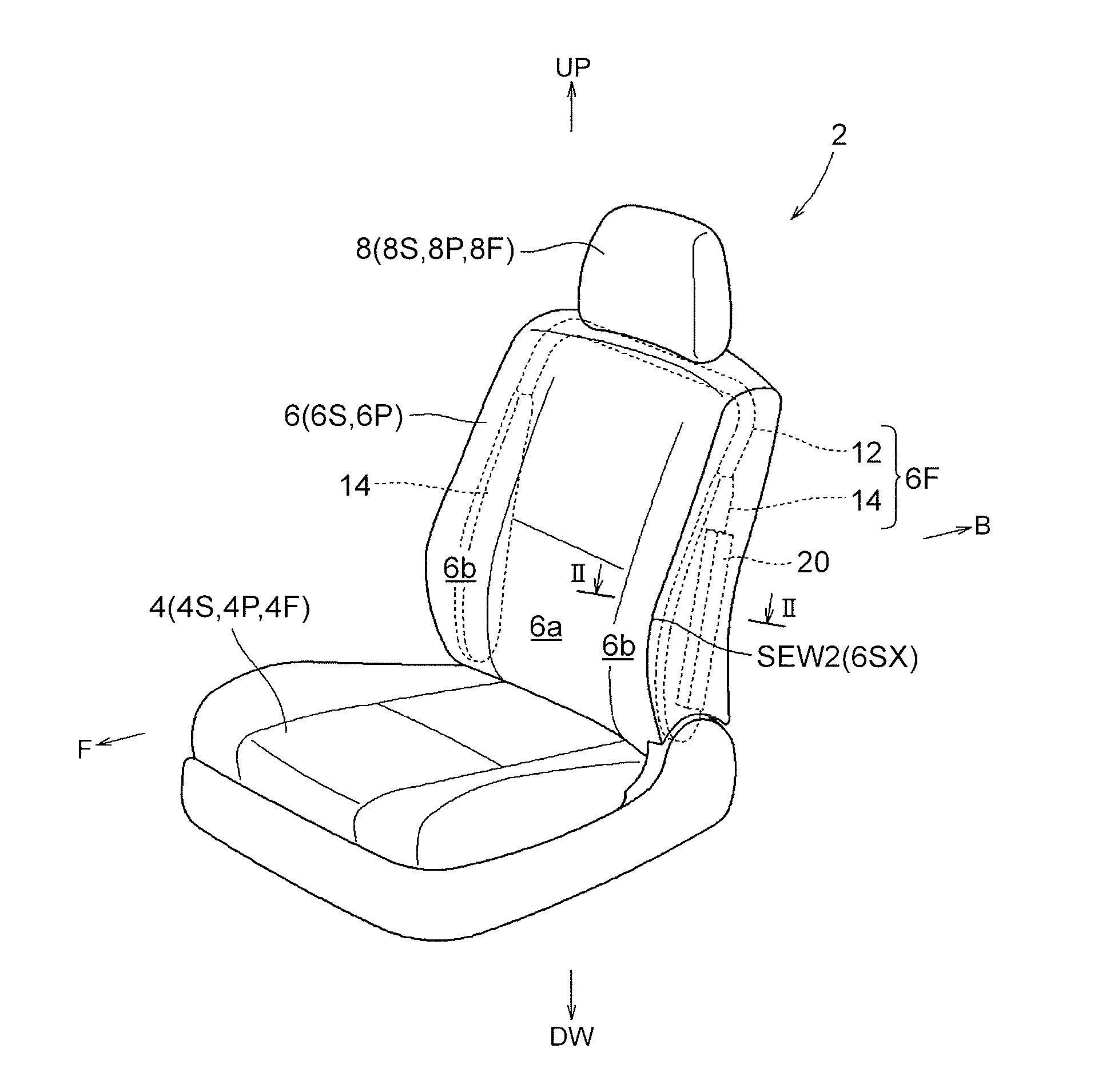

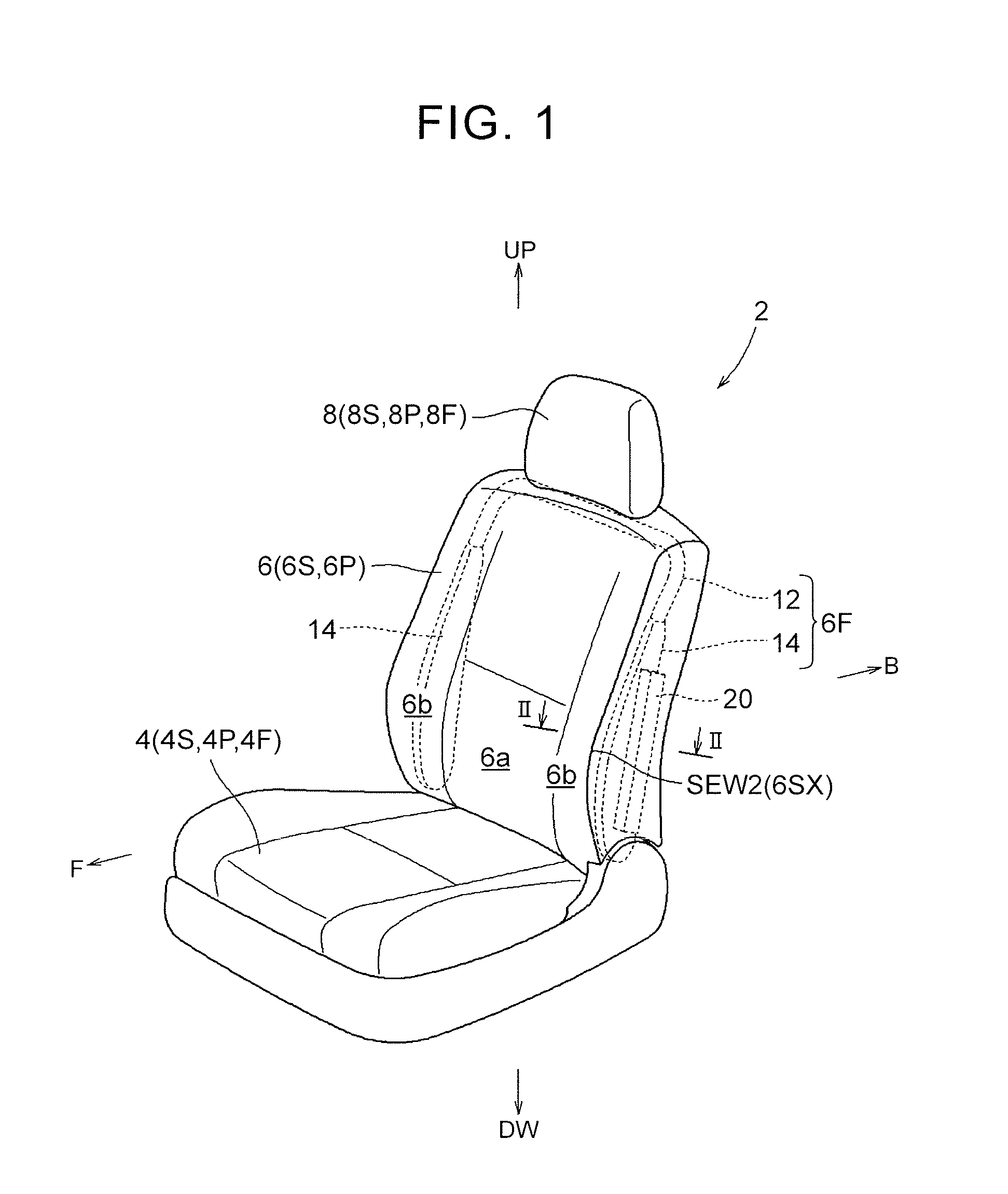

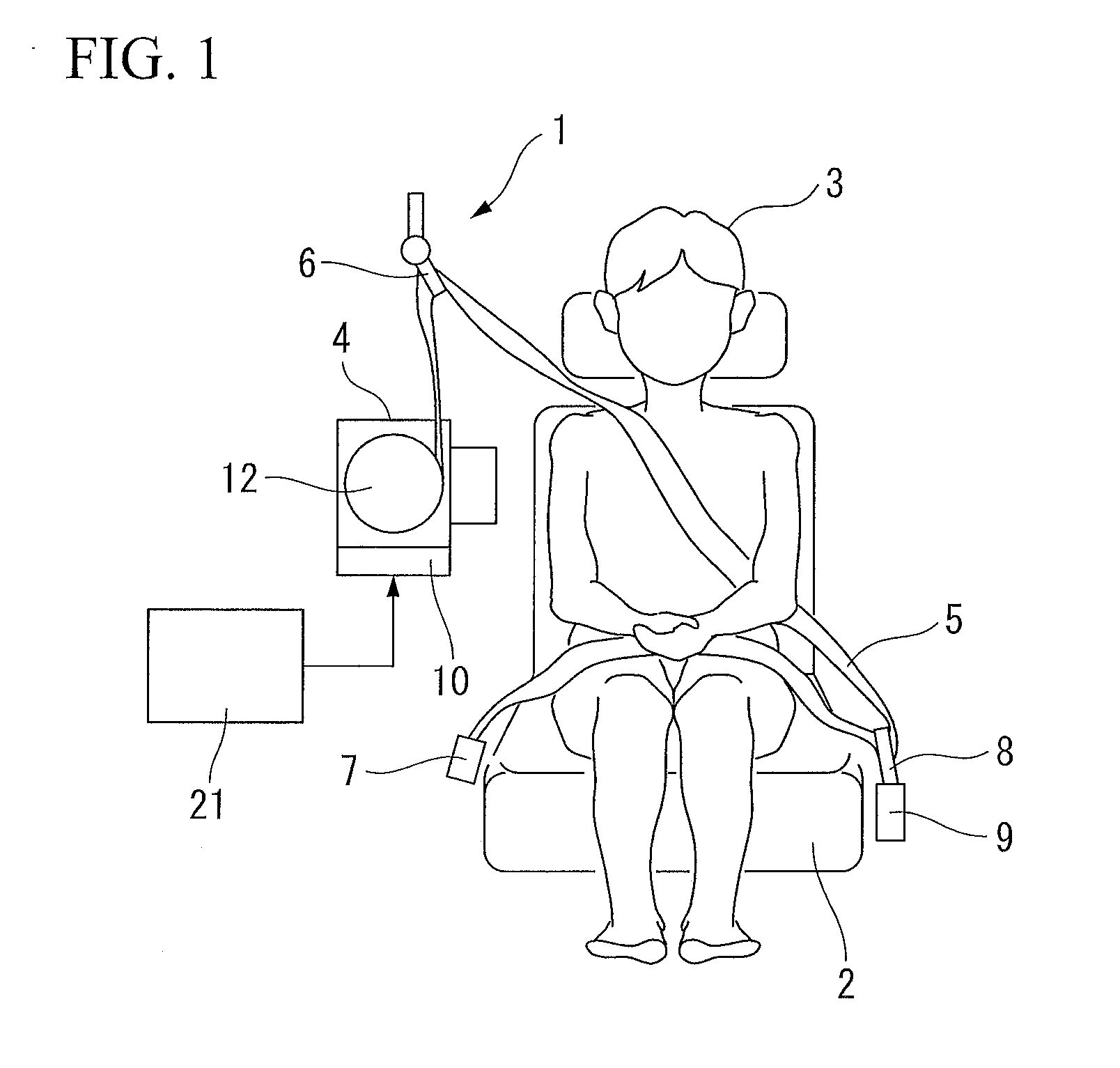

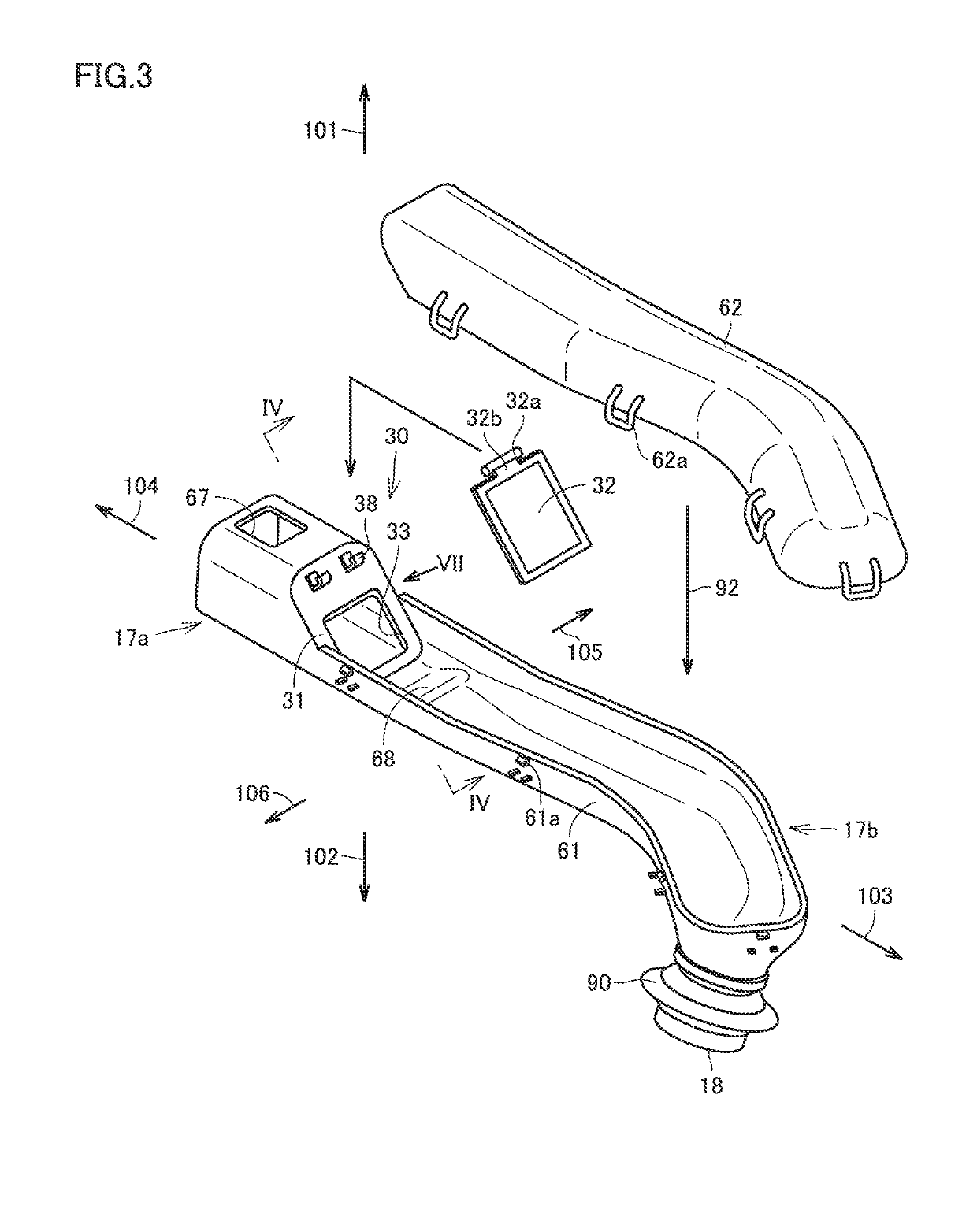

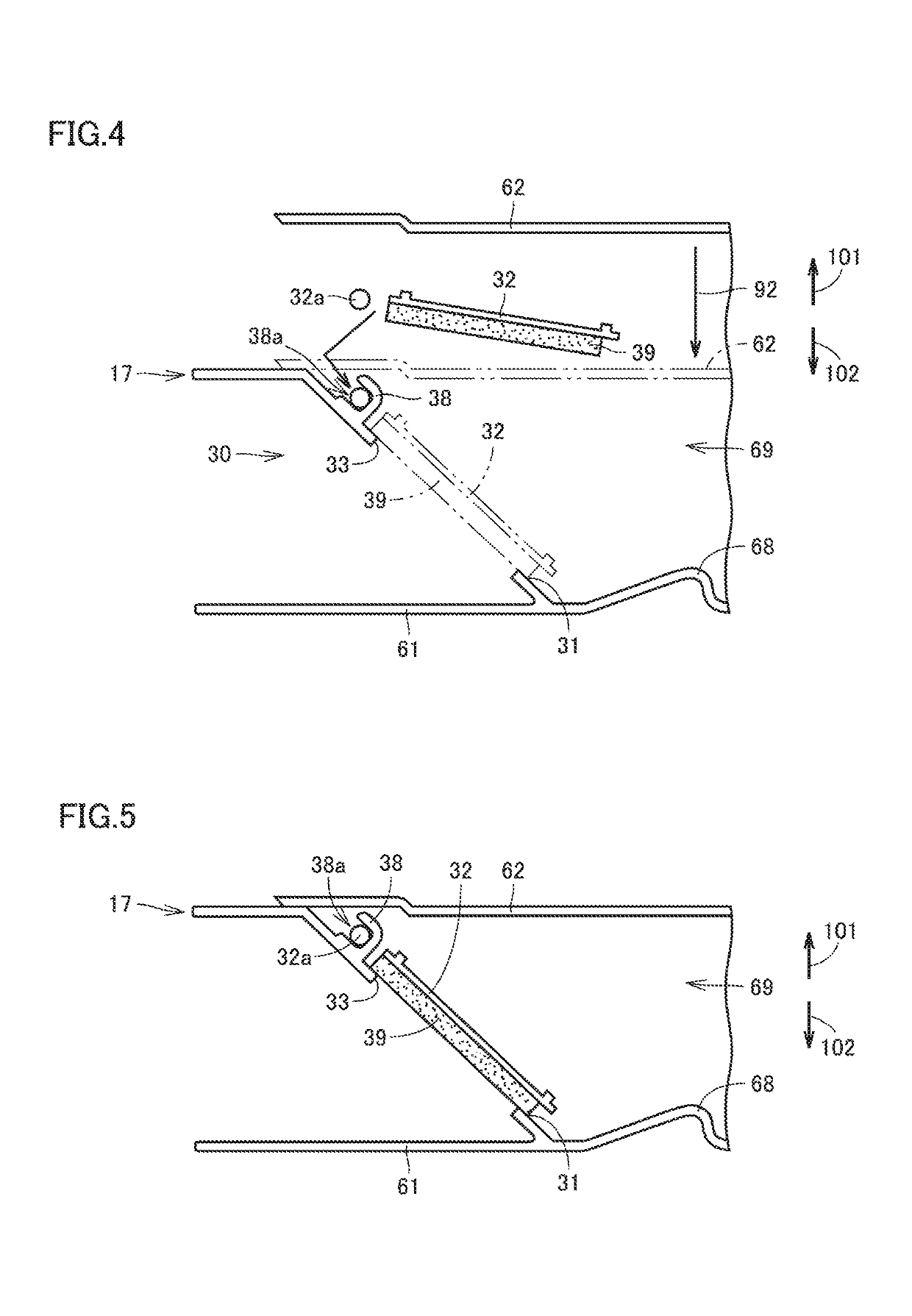

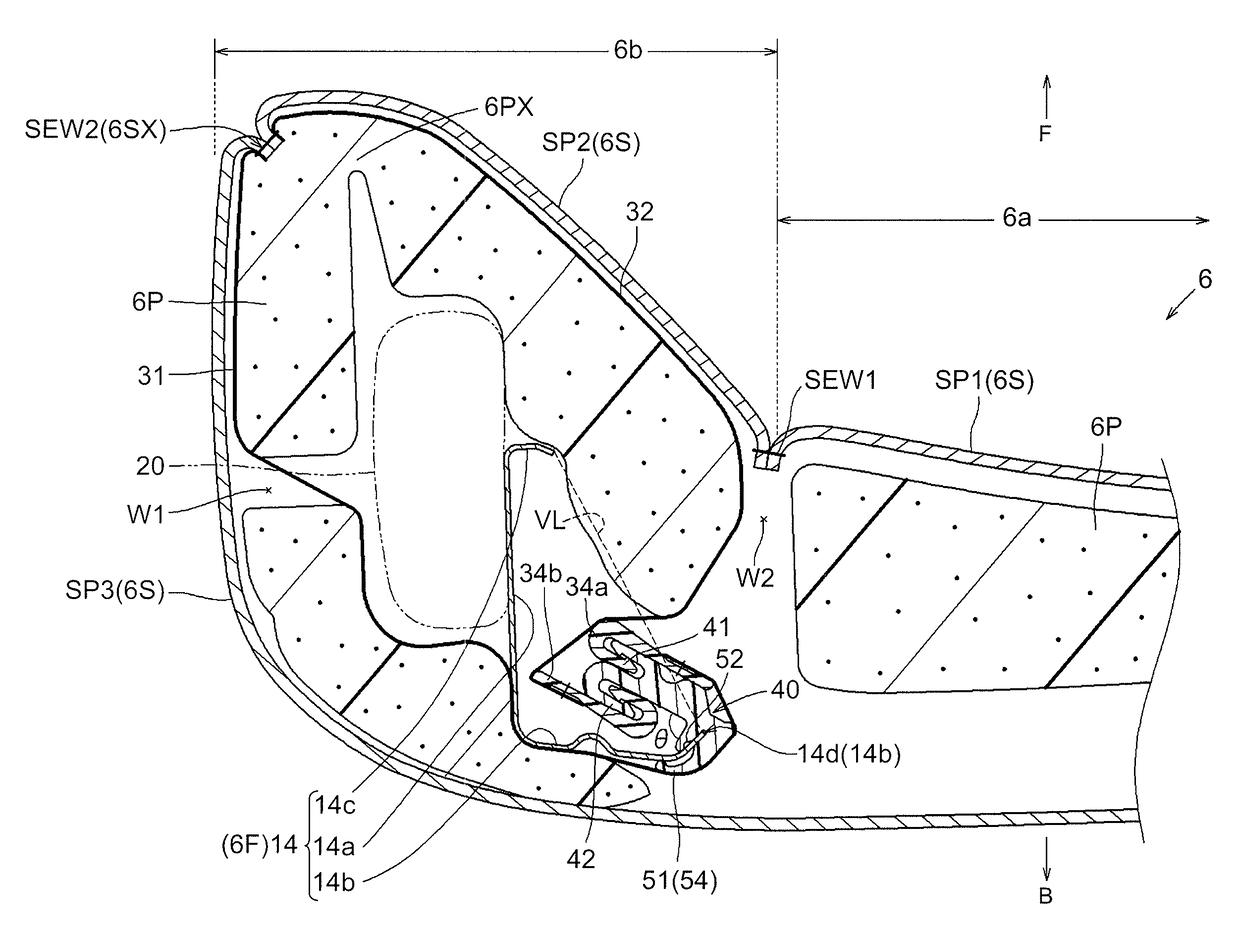

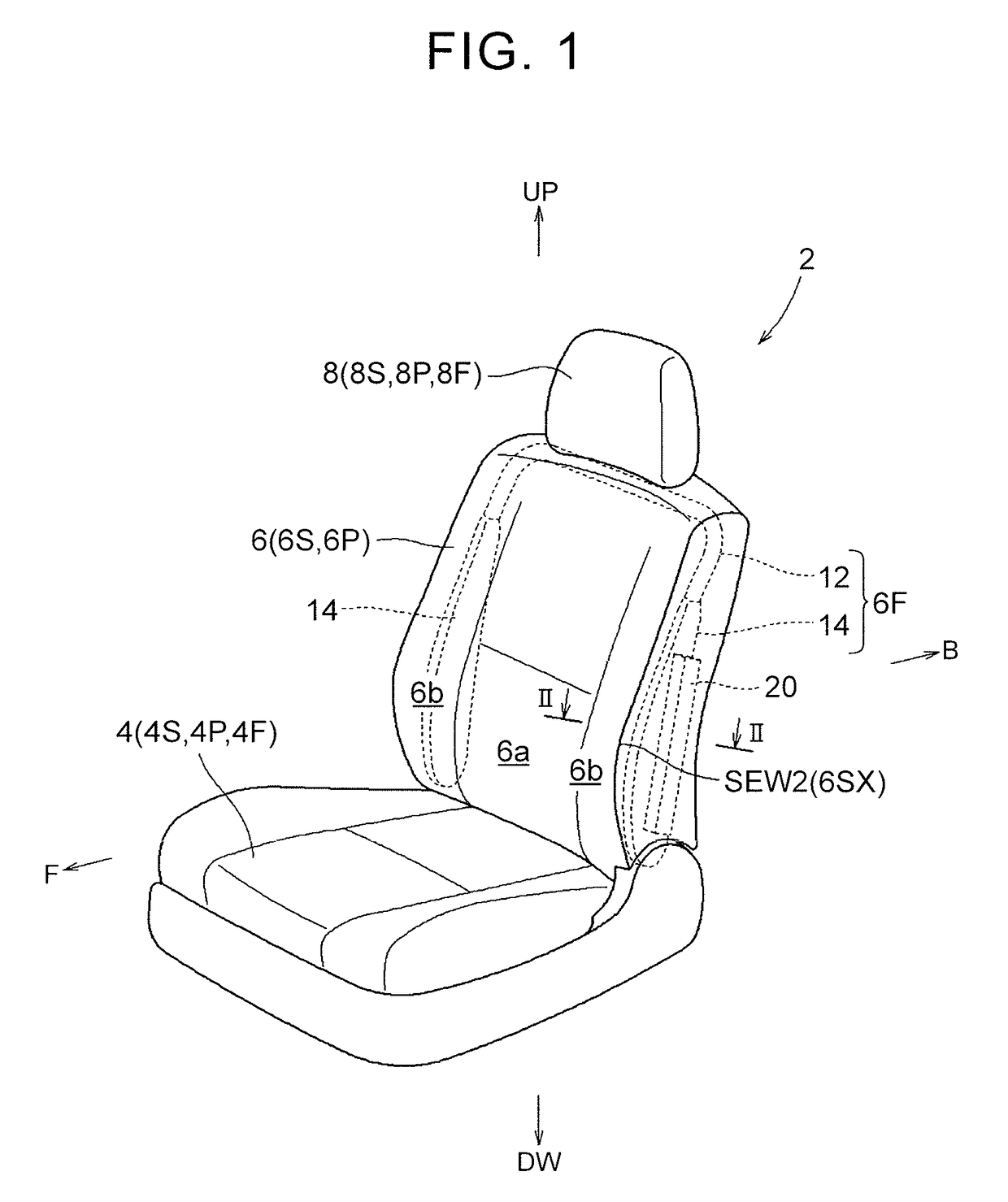

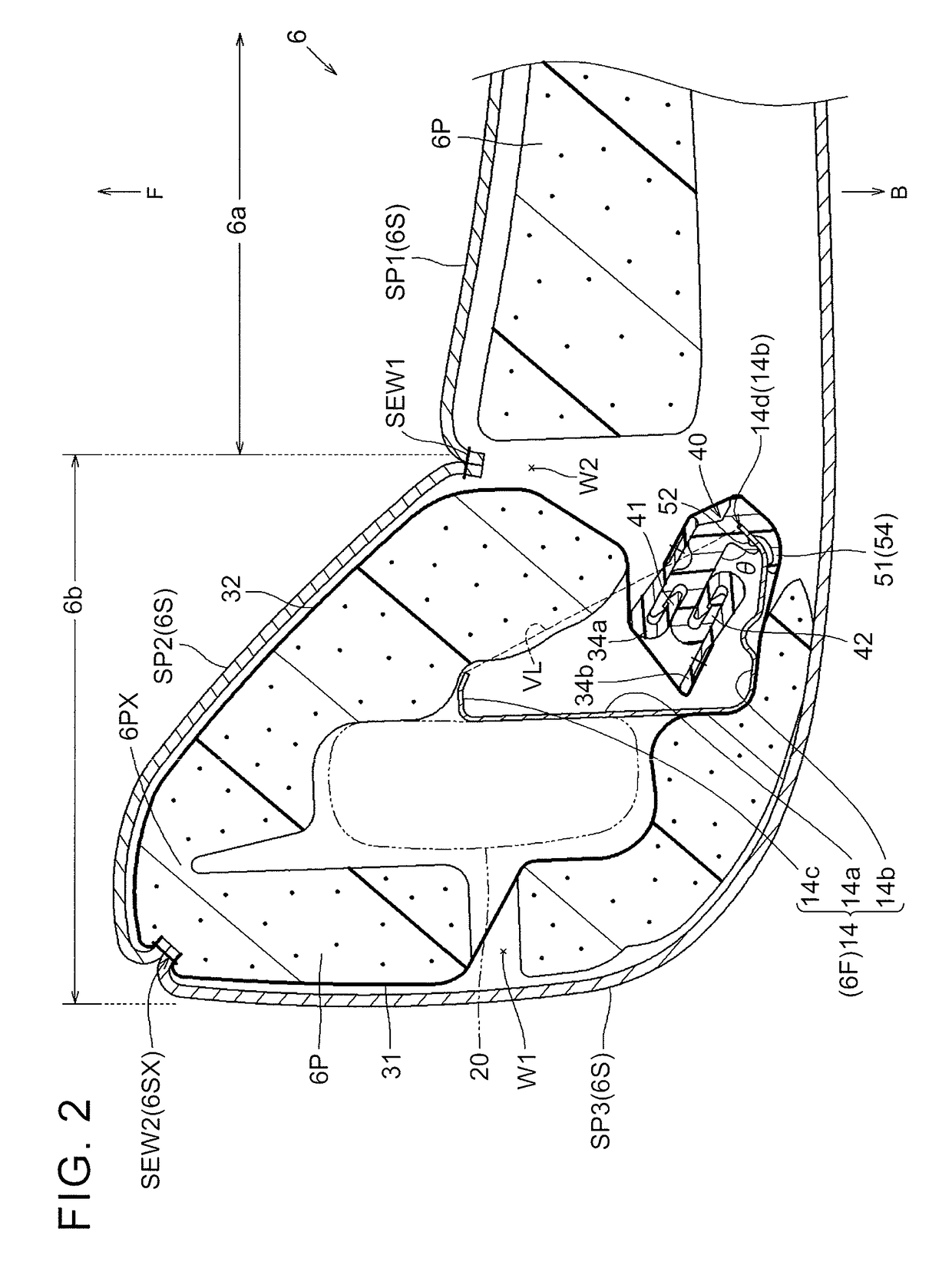

Vehicle seat

ActiveUS20160114751A1Suppresses the generation of abnormal noiseSuppress damage to the respective webbingsSeat coveringsPedestrian/occupant safety arrangementEngineeringAirbag

A vehicle seat includes: a seat frame; a seat cover provided with a rupture portion; an airbag disposed in the seat; a pair of webbings provided so as to surround the airbag on a back surface side of the seat cover, one end sides of the webbings being mounted to the rupture portion; and a mounting section mounting the other end sides of the webbings to the seat frame. In a vehicle collision, the airbag is protruded out of the seat by rupturing and opening the rupture portion. The mounting section is provided at a place where a body of the seat frame is disposed. When the airbag is uninflated, the mounting section holds the other ends of the webbings apart from the body of the seat frame, and an inhibition portion in the mounting section inhibits contact between an edge-shaped portion formed in the body and the webbings.

Owner:TOYOTA BOSHOKU KK +1

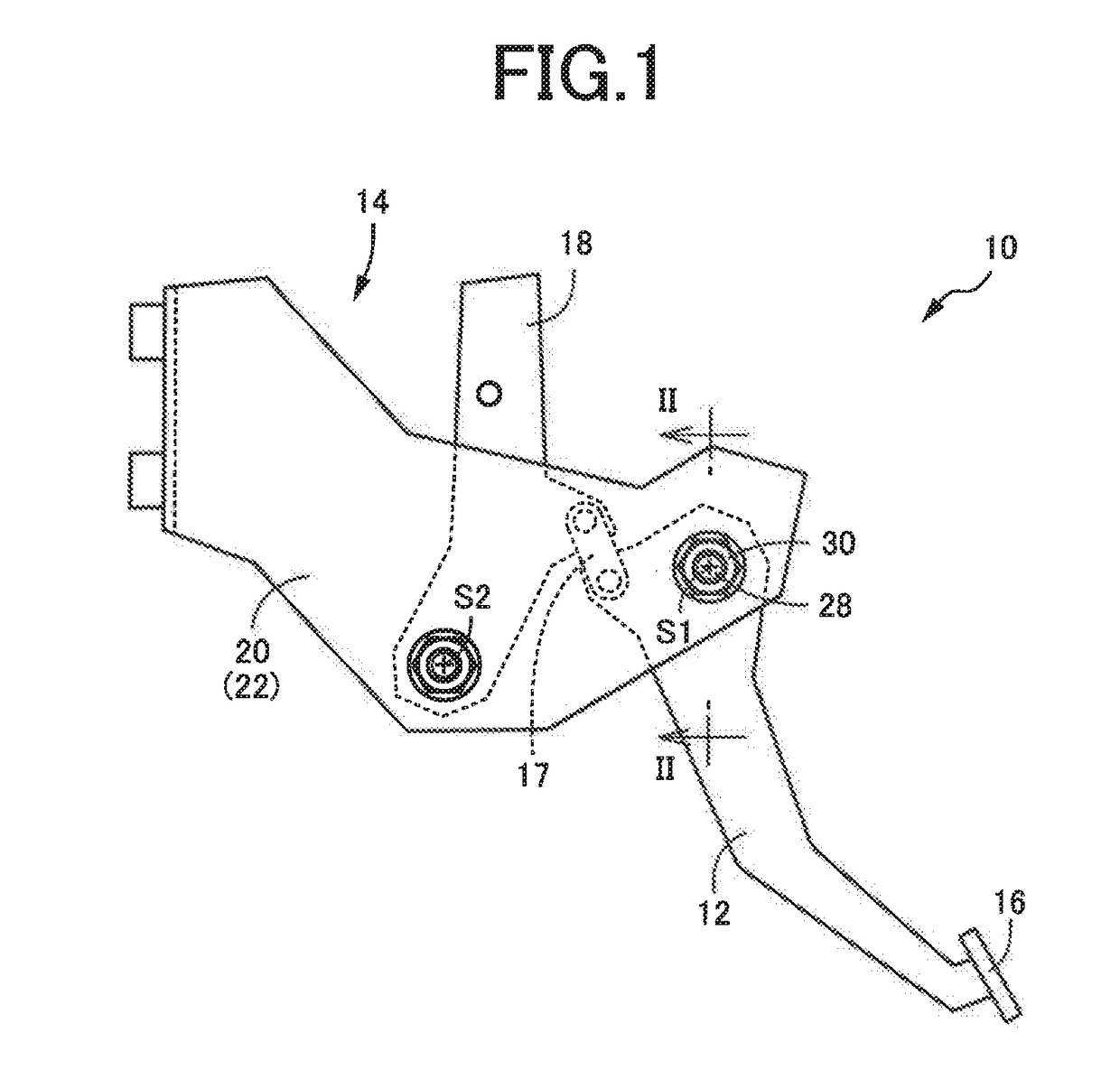

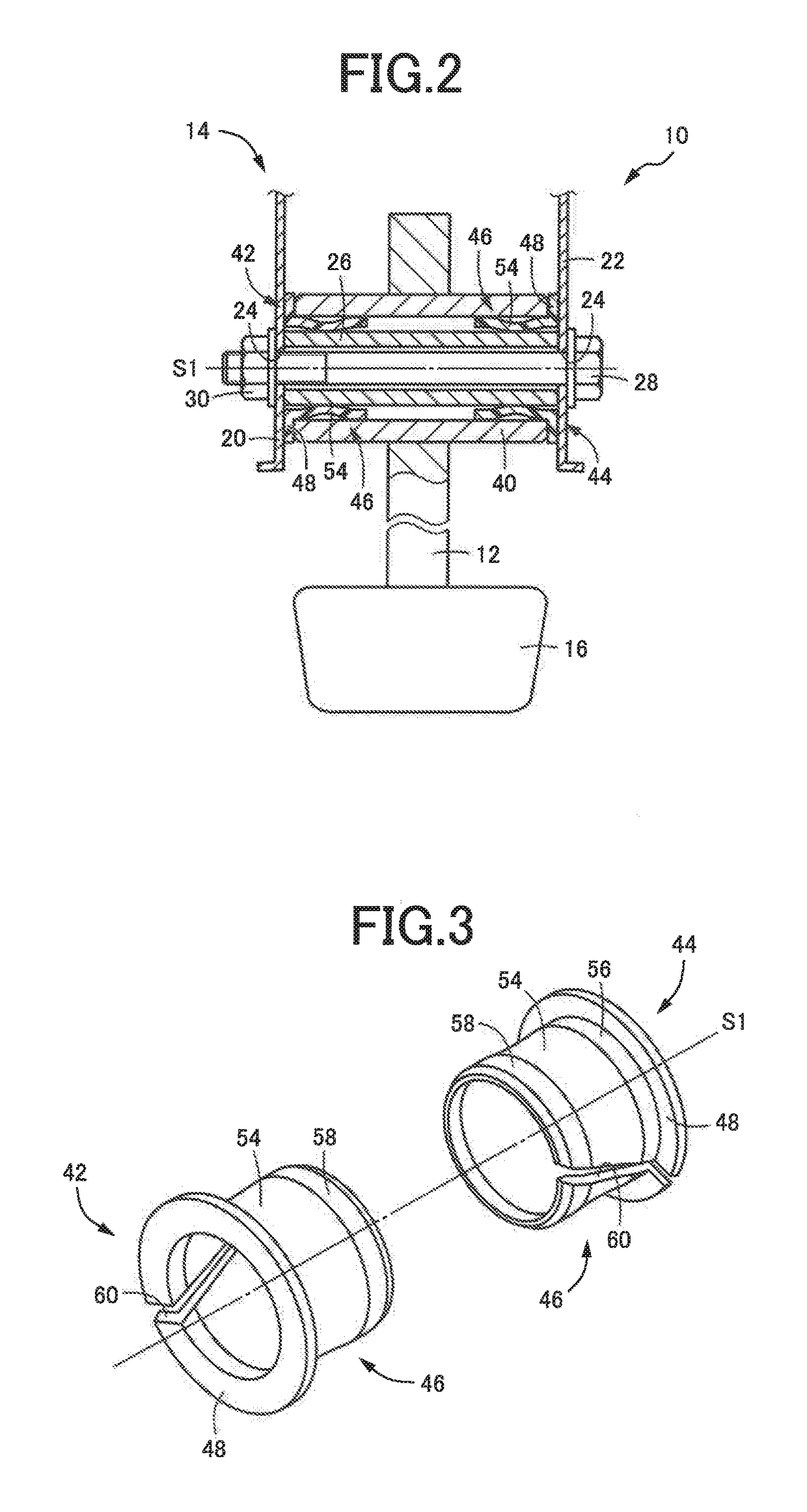

Bearing structure for vehicle pedal device and flanged bushing

InactiveUS20170227047A1Abnormal noise be generateEasily insertControlling membersShaftsEngineeringMechanical engineering

Bearing structure of a pedal device, wherein a support member having a cylindrical outer peripheral surface is fixedly attached to a pedal bracket to be substantially horizontal, a boss of a pivot member radially outside the support member via a pair of flanged bushings each made of resin and having a flange portion at one end of a cylindrical portion so the boss turns about an axis, both axial ends of the flanged bushing cylindrical portion closely contact the boss inner peripheral surface; the flanged bushing cylindrical portion have, in intermediate portion, in an axial direction, a narrow portion having both inner and outer peripheral surfaces reduced in diameter so the narrow portion is curved inward in radial direction; the narrow portion smallest inside diameter being smaller than the support member outside diameter having interference; at least the narrow portion smallest diameter portion of elastically closely contact the support member outer peripheral surface.

Owner:TOYODA IRON WORKS CO LTD

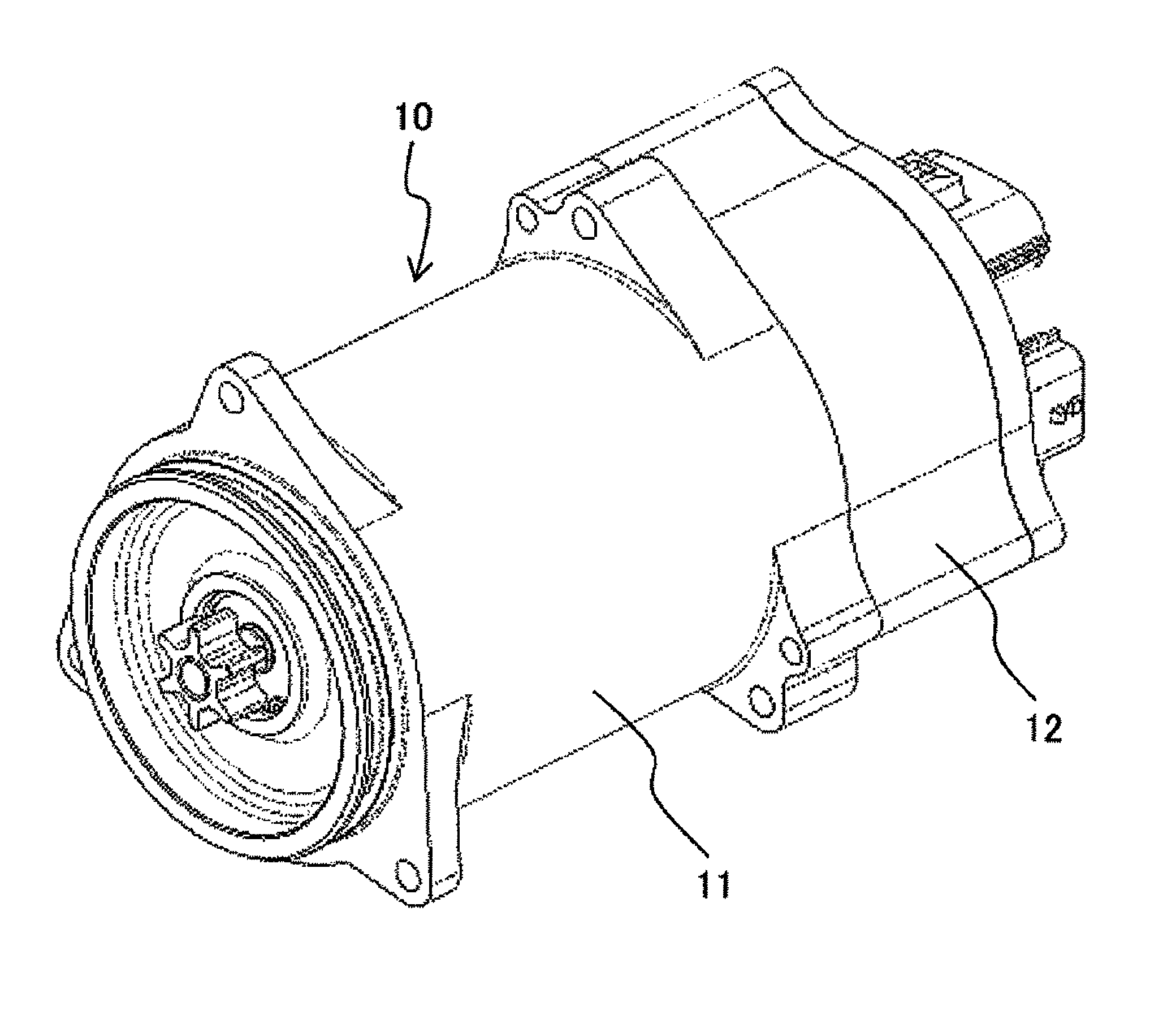

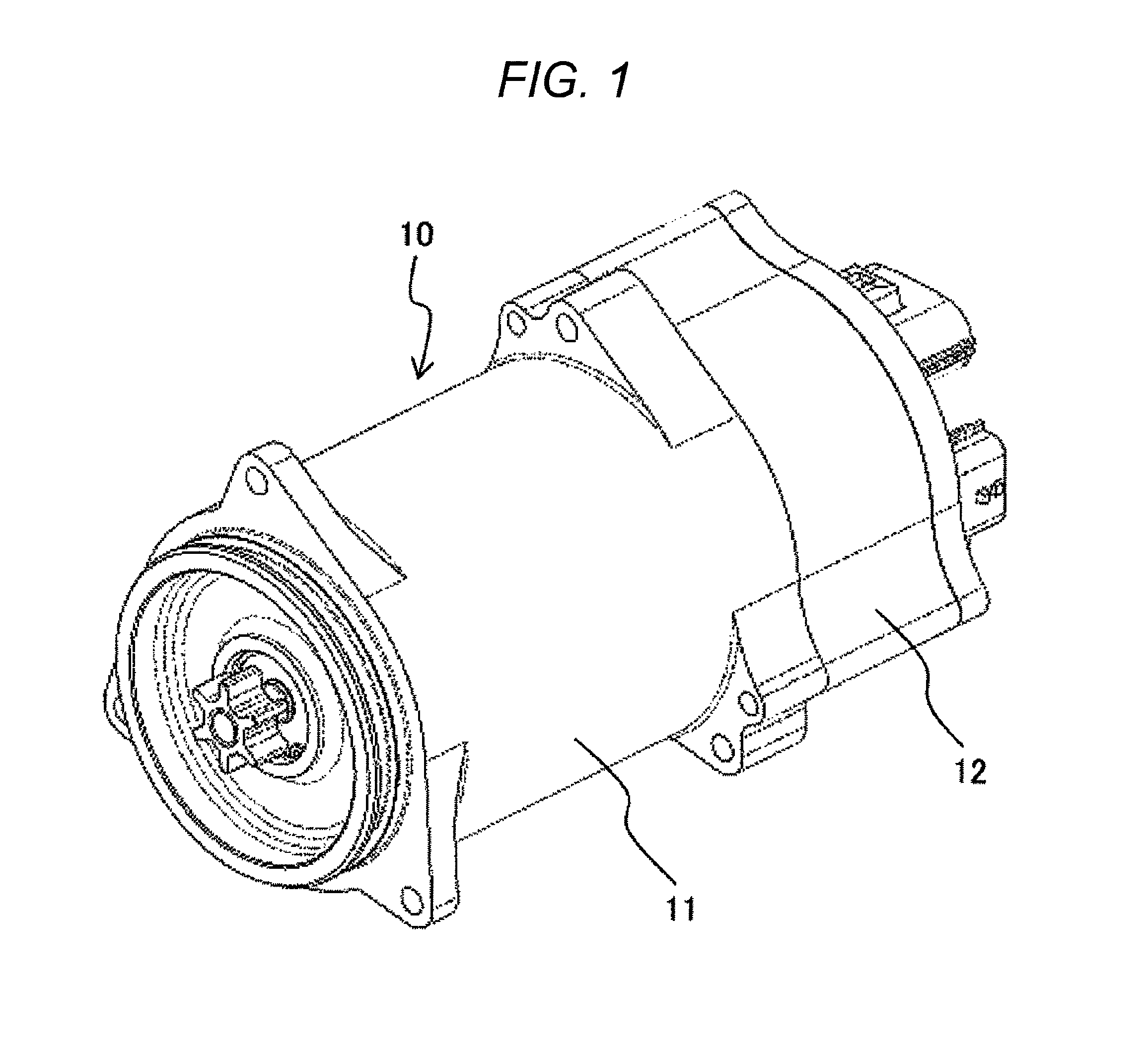

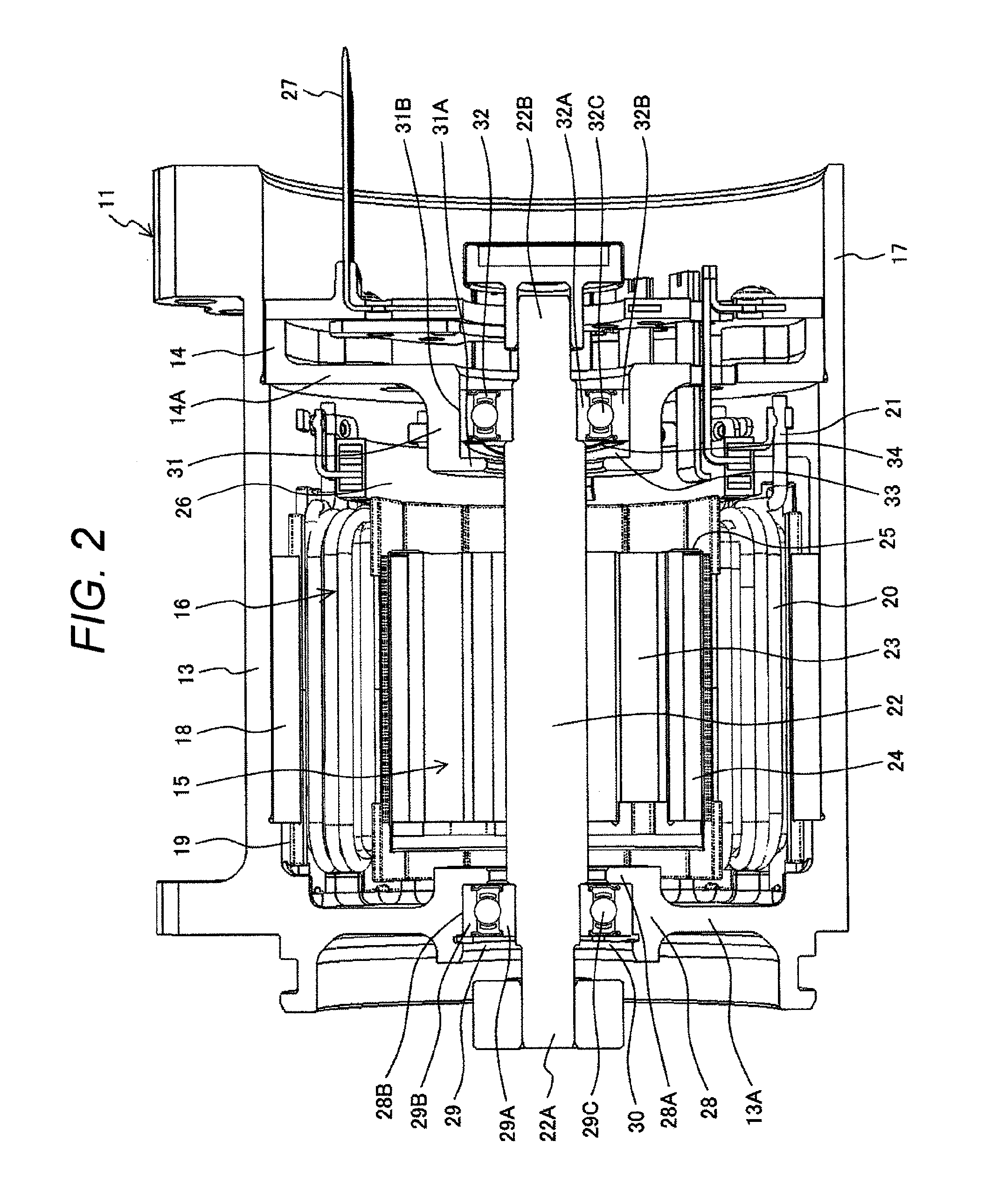

Rotating electrical machine

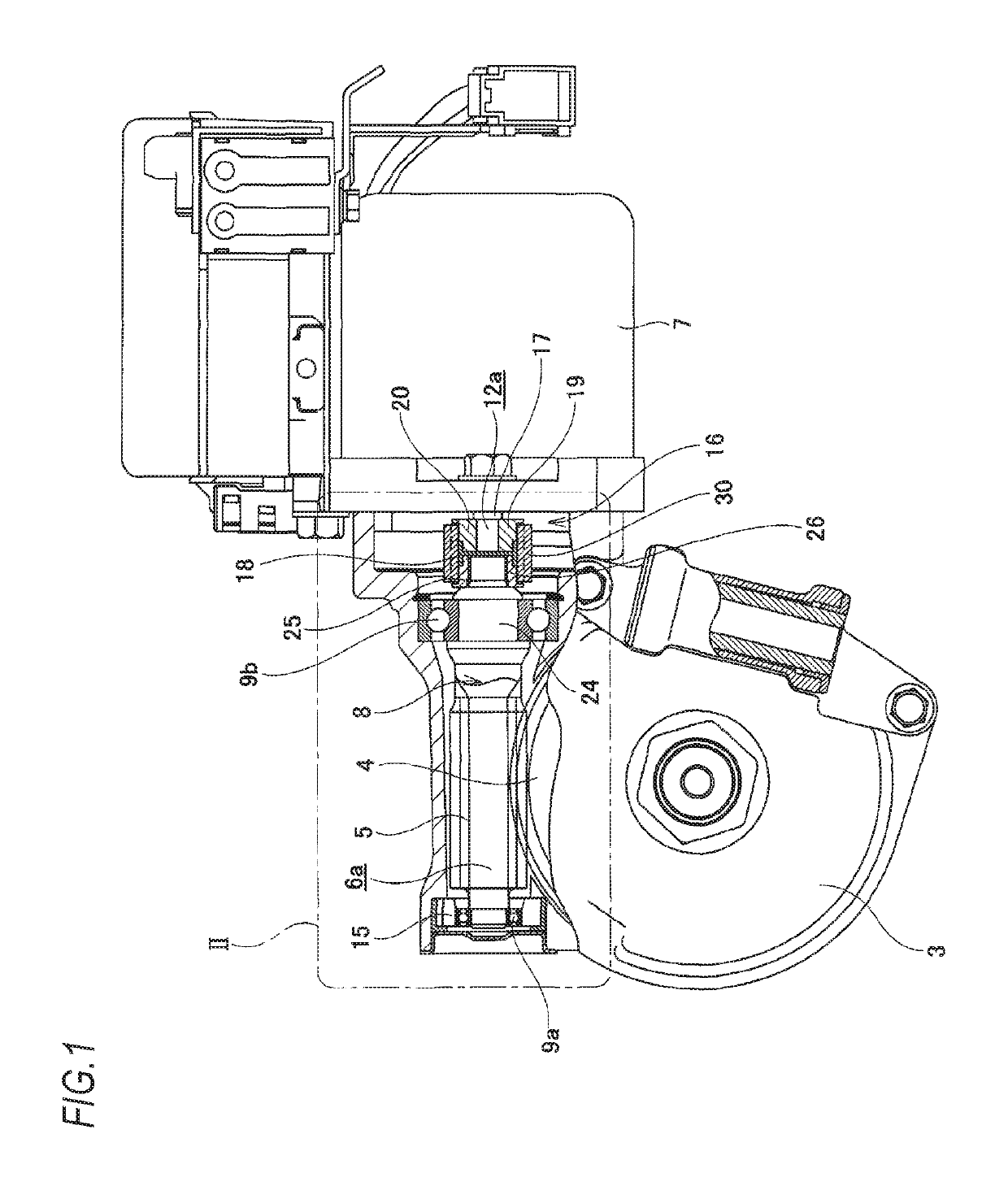

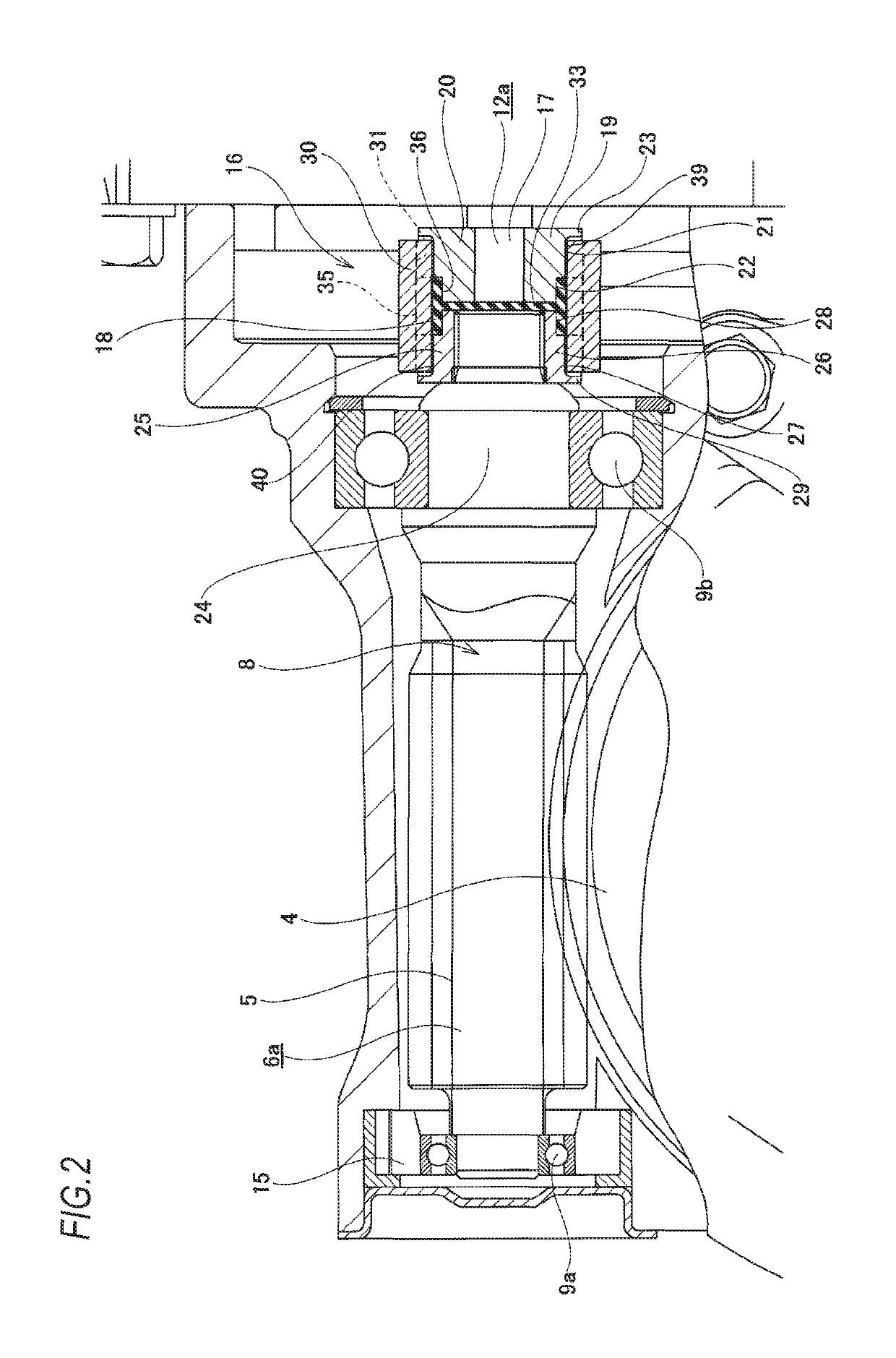

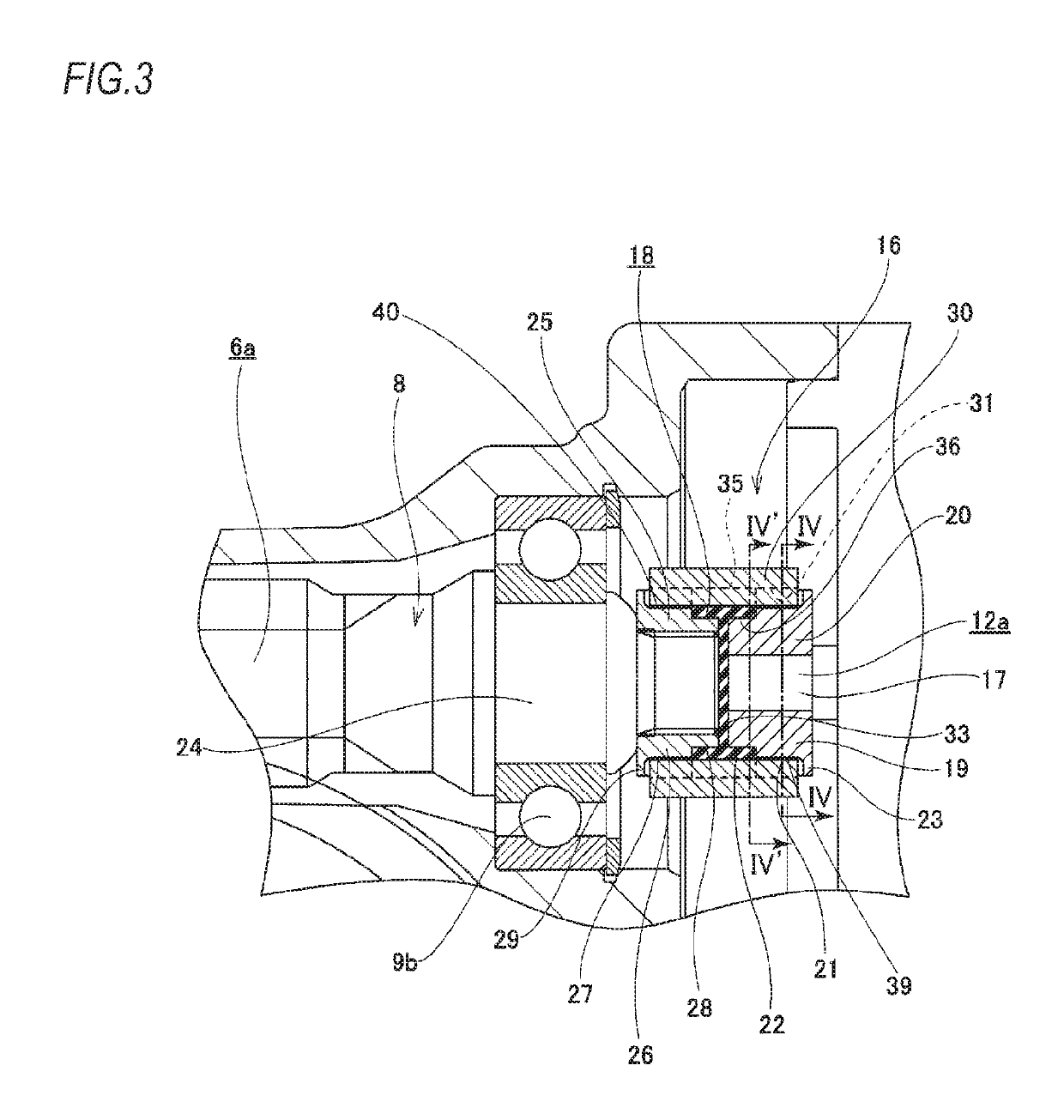

InactiveUS20140009041A1Suppression of abnormal noiseGood effectShaftsBall bearingsElectric machineEngineering

Inner rings of bearings arranged at both ends of a rotor shaft are fixed to the rotor shaft, and outer rings of both of the bearings are arranged at bearing holding parts movably in an axial direction of the rotor. A preload imparting member is attached to one of the bearings, the preload imparting member being configured to bias the rotor shaft in one direction and to apply a biasing force to make a housing and a flange, which constitute a chassis, come close to each other.

Owner:HITACHI AUTOMOTIVE SYST LTD

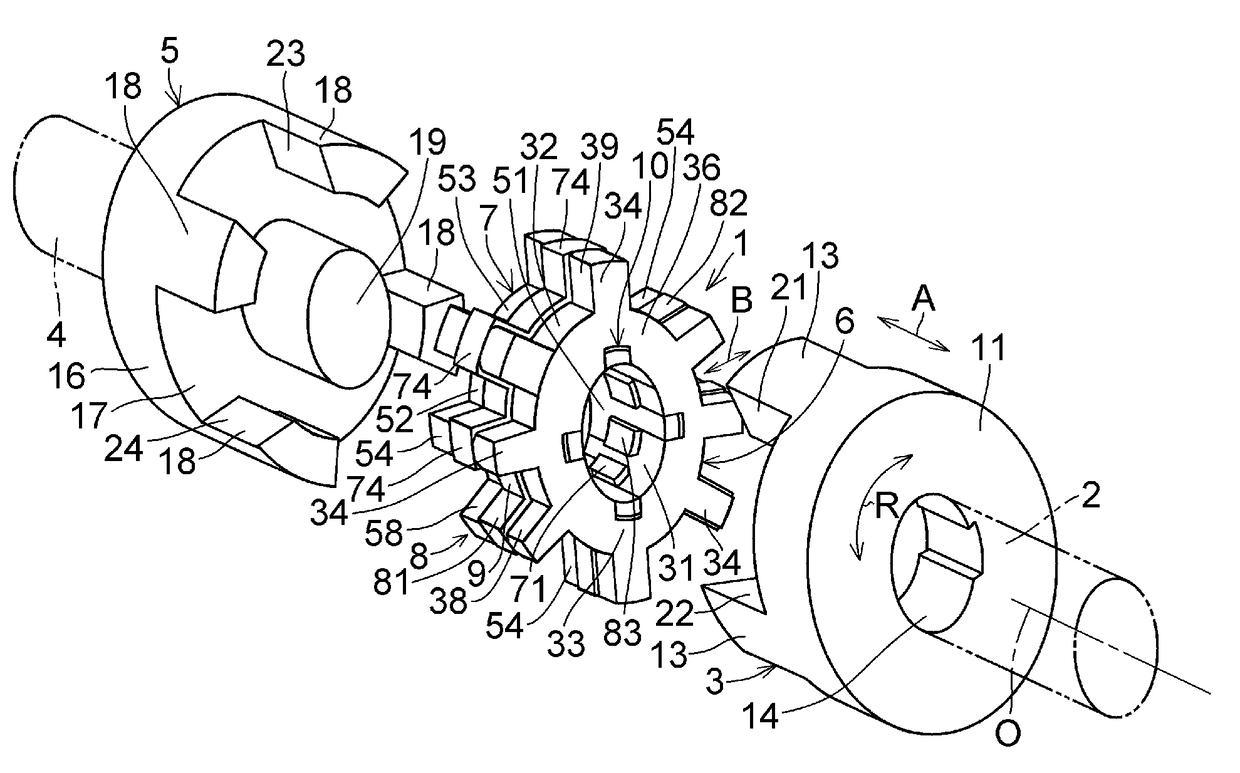

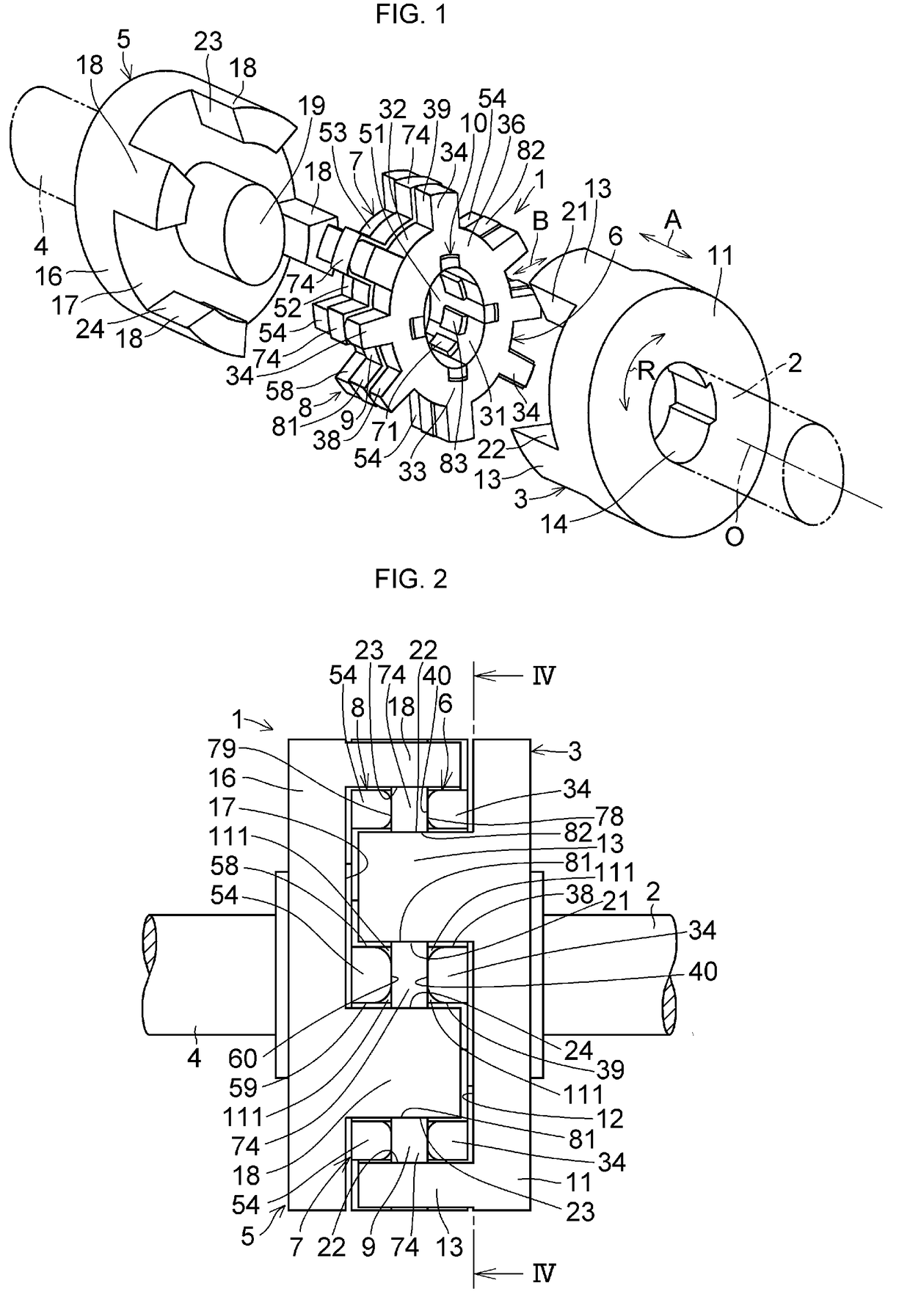

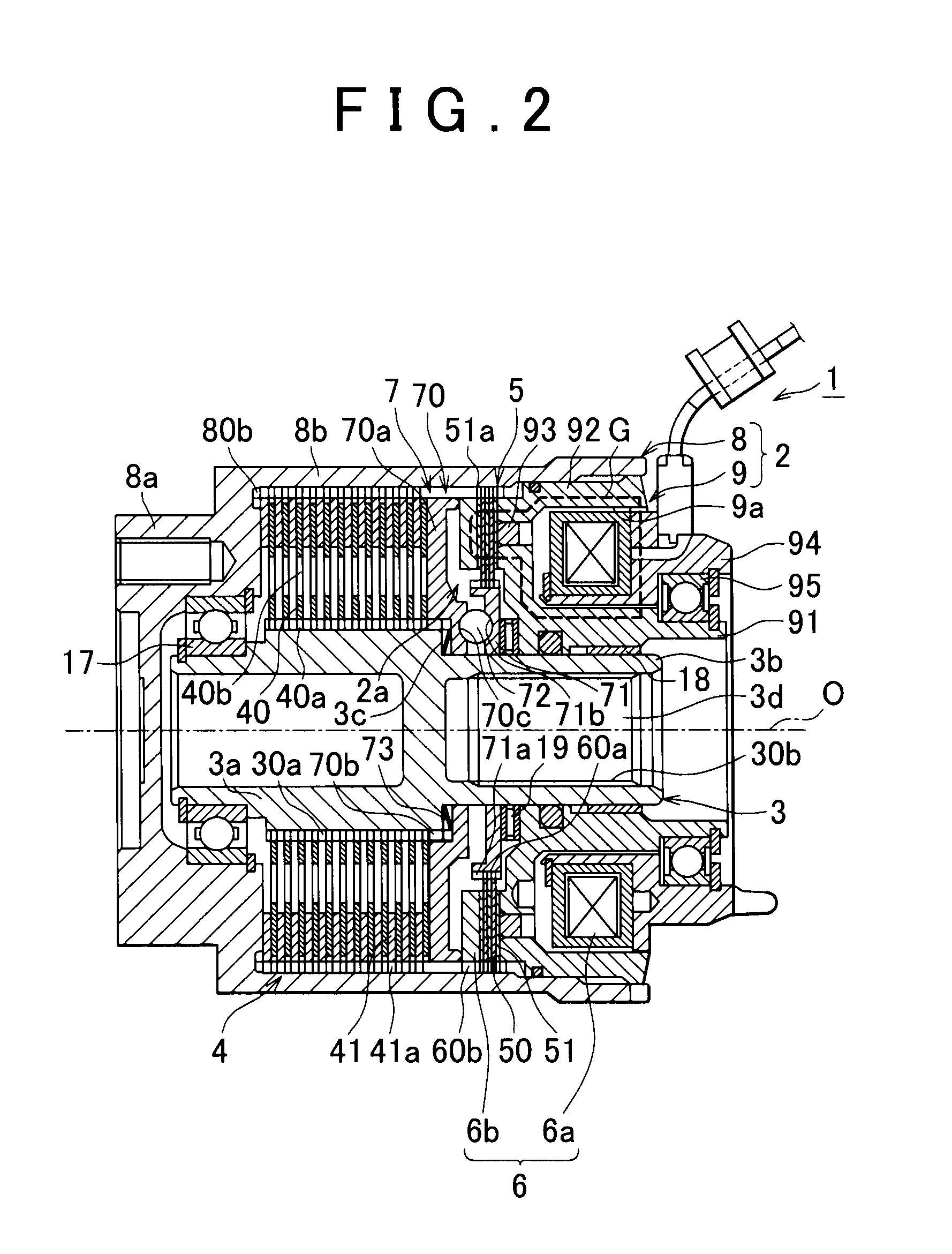

Torque transmission joint and electric power steering device

ActiveUS10288126B2Suppresses the generation of abnormal noiseSuppress generationYielding couplingElectrical steeringElectric power steeringCoupling

A driving-side transmission portion of an output shaft of an electric motor and a driven-side transmission portion of a worm shaft are coupled to each other via a torque transmission joint including an elastic member and a coupling such that the torque can be transmitted. One axial end portion of a coupling-side concave-convex portion of the coupling is engaged with a first driving-side concave-convex portion of the driving-side transmission portion with a gap in the circumferential direction, and the other axial end portion thereof is engaged with a first driven-side concave-convex portion of the driven-side transmission portion with a gap in the circumferential direction. The elastic member is provided between an axial center portion of the coupling-side concave-convex portion, and a second driving-side concave-convex portion of the driving-side transmission portion and a second driven-side concave-convex portion of the driven-side transmission portion such that the torque can be transmitted respectively.

Owner:NSK LTD

Shaft coupling mechanism for electric power steering apparatus

InactiveUS20170114837A1Suppresses the generation of abnormal noiseAvoid collisionYielding couplingElectrical steeringElectric power steeringRotational axis

A shaft coupling mechanism 1 for an electric power steering apparatus includes a coupling base body 3 coupled to a rotating shaft 2; a coupling base body 5 coupled to a rotating shaft 4; a rotation transmitting member 8 constituted by a pair of rigid rotation transmitting members 6 and 7 disposed between the rotating shaft 2 and the rotating shaft 4 through both coupling base bodies 3 and 5 and adapted to transmit the rotation of the rotating shaft 2 in an R direction about an axis O to the rotating shaft 4; an elastic member 9 interposed between the rotation transmitting members 6 and 7 and coupled to the rotation transmitting members 6 and 7 in such a manner as to be axially superposed on the rotation transmitting members 6 and 7; and a coupling means 10 for coupling the pair of rotation transmitting members 6 and 7 to each other.

Owner:OILES CORP

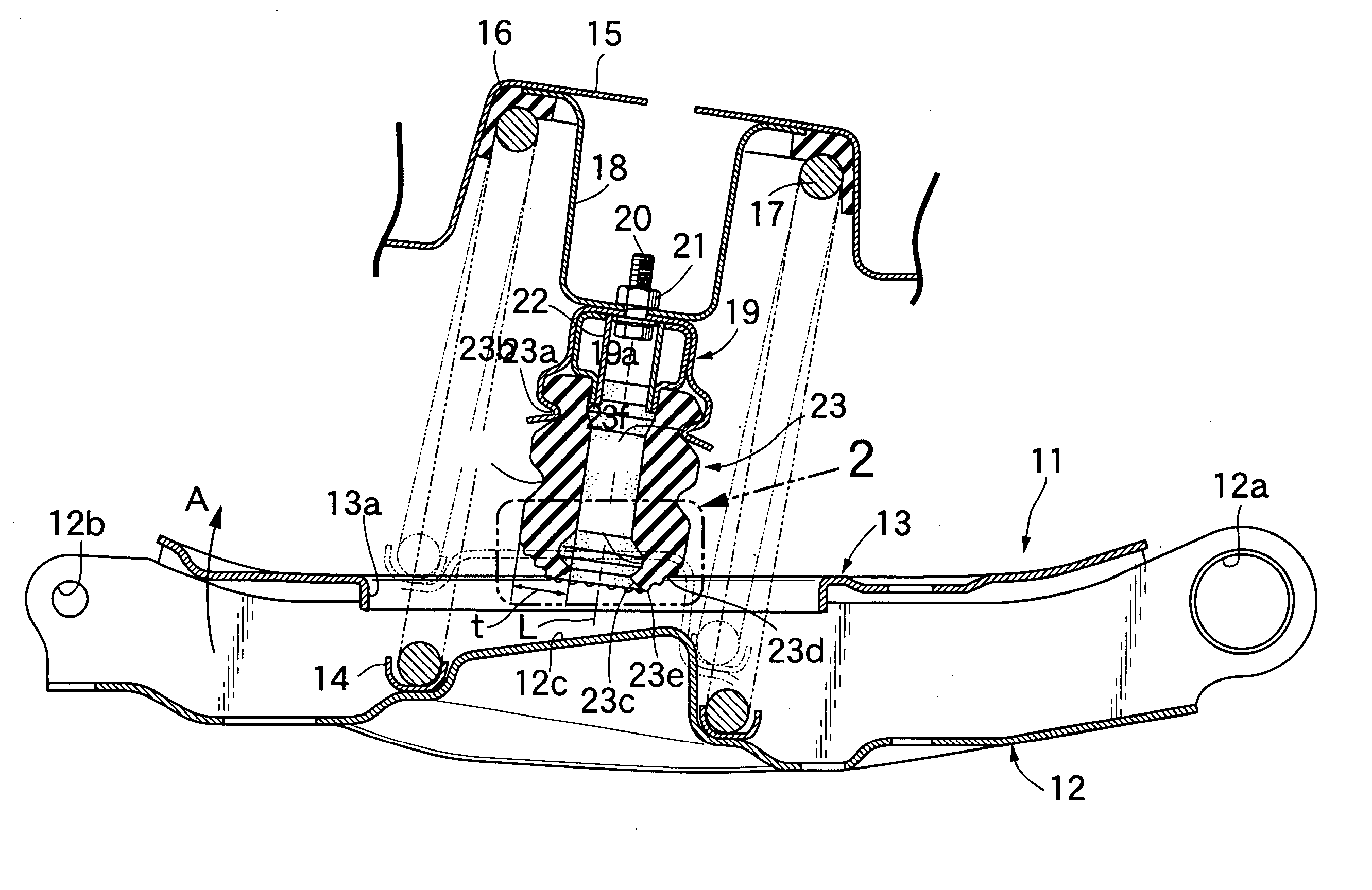

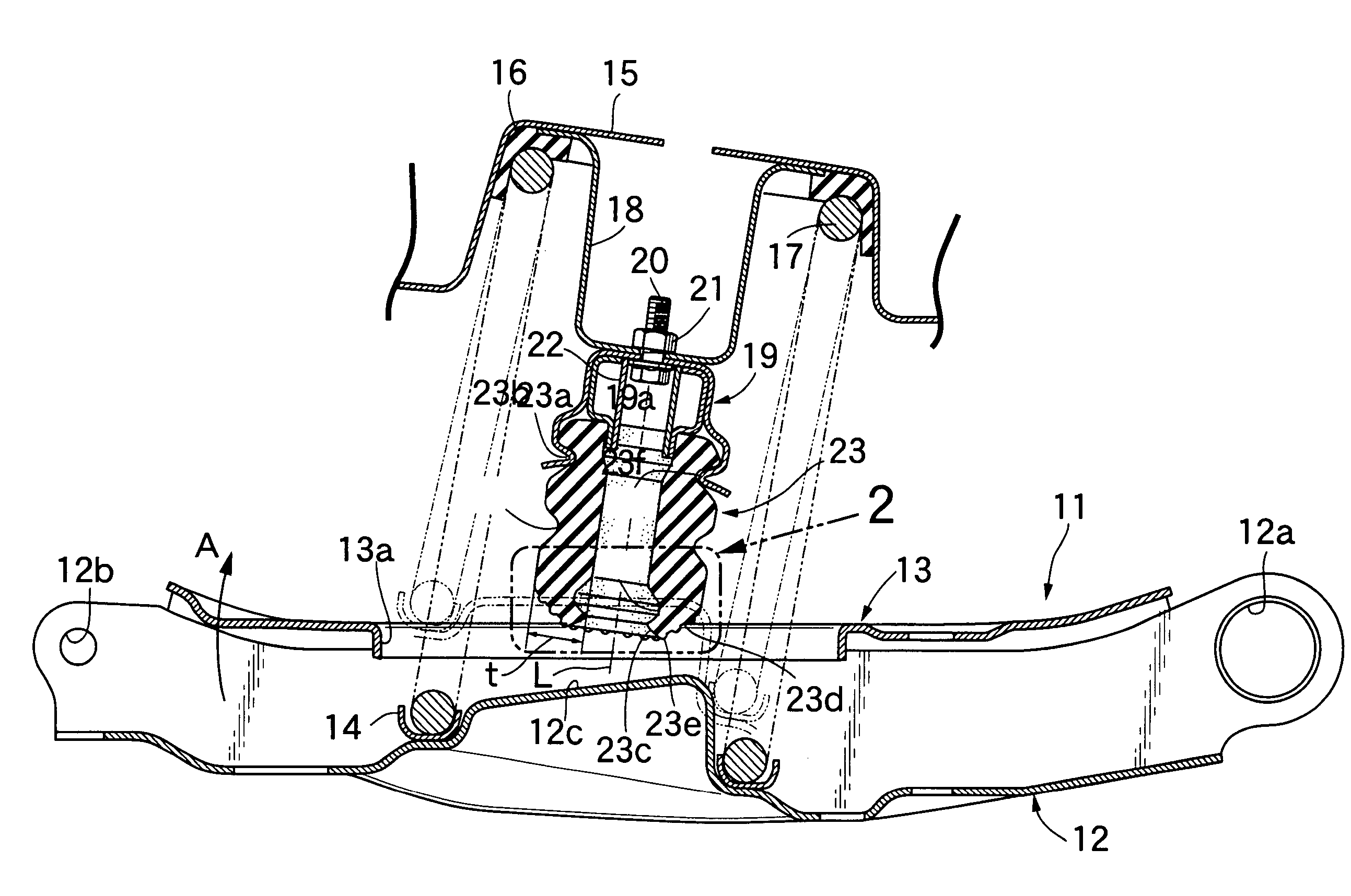

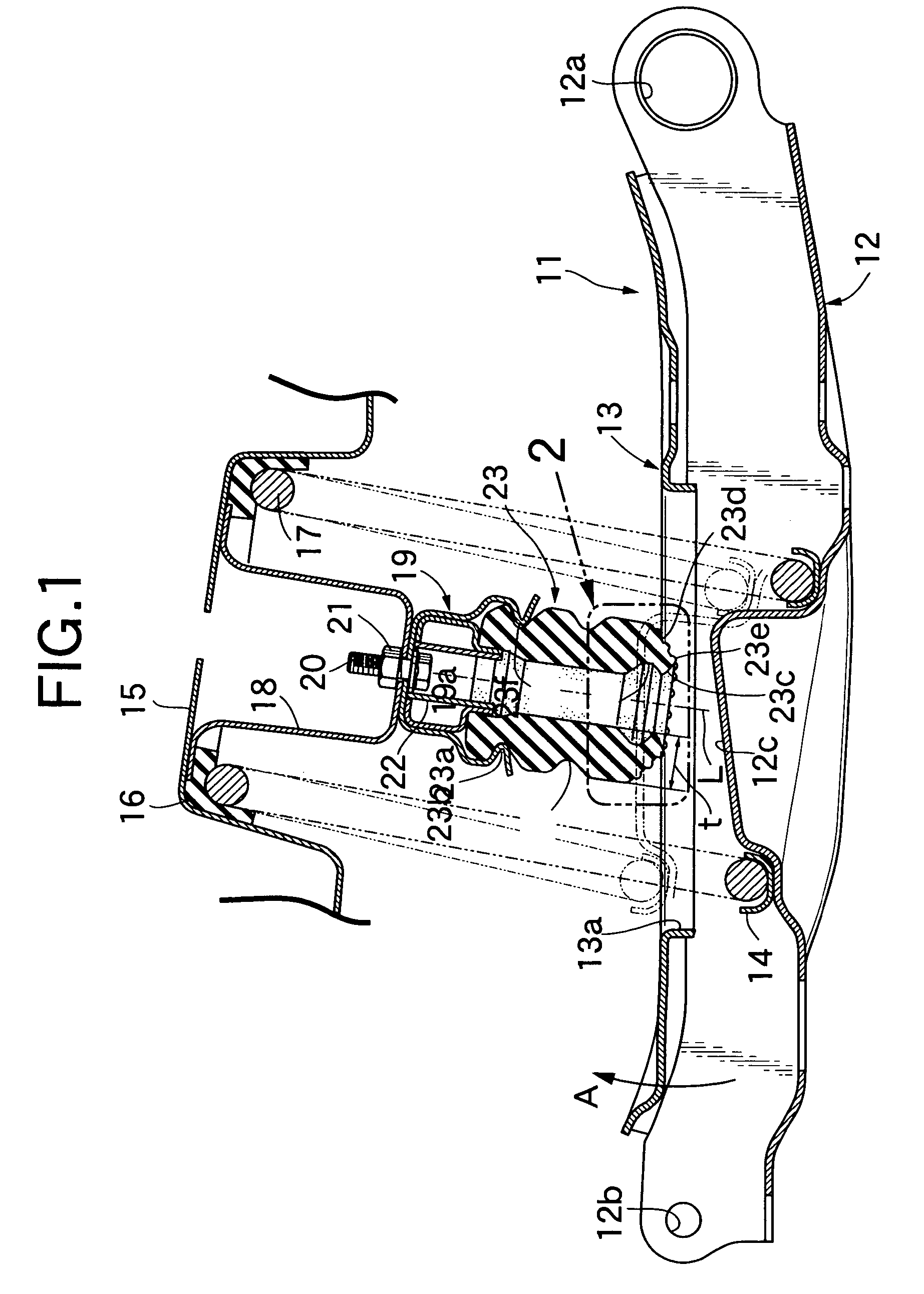

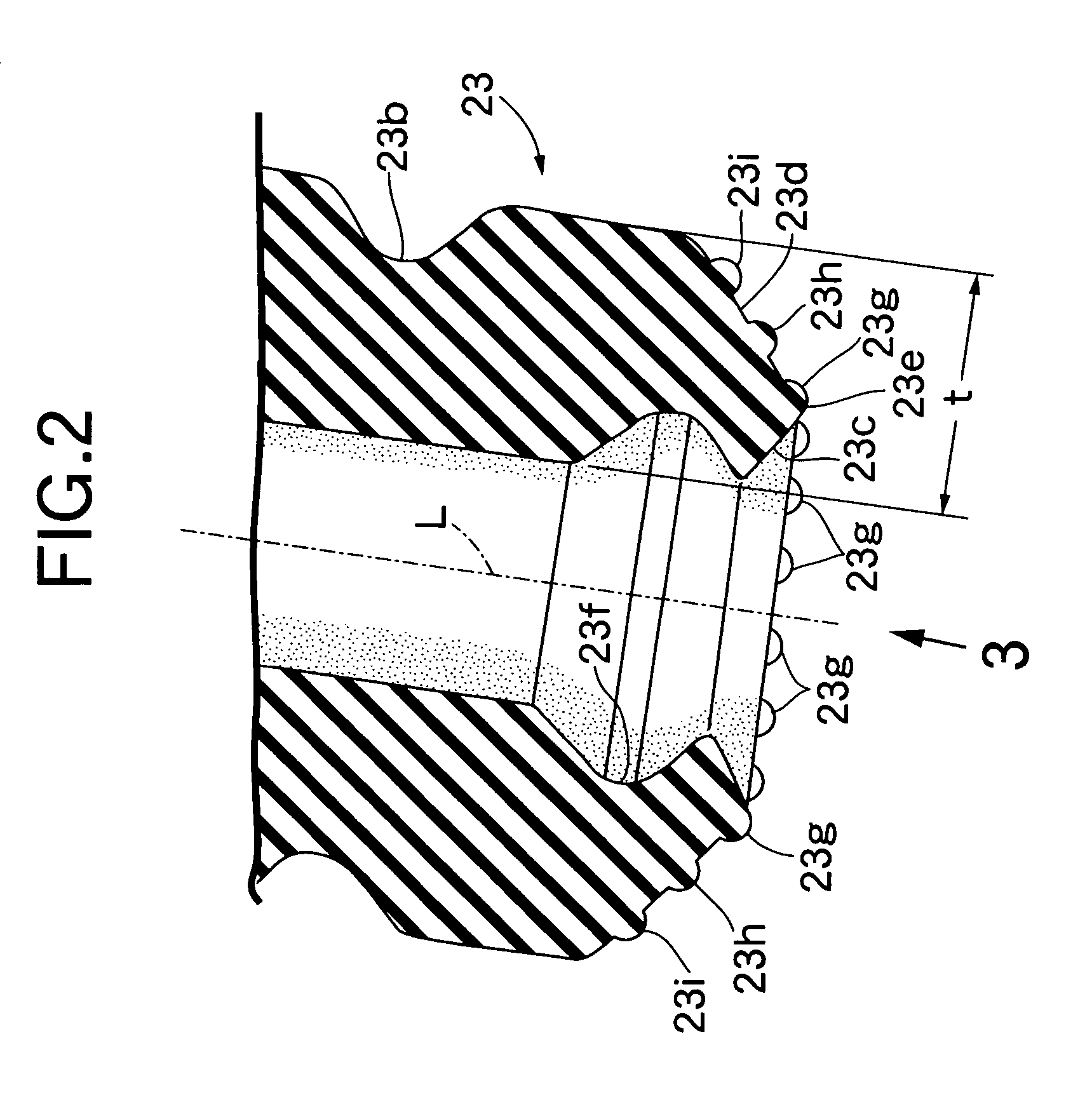

Vehicle suspension system

InactiveUS20060049604A1Reduce the numberReduce frequencySpringsSprings/dampers design characteristicsEngineeringAbutment

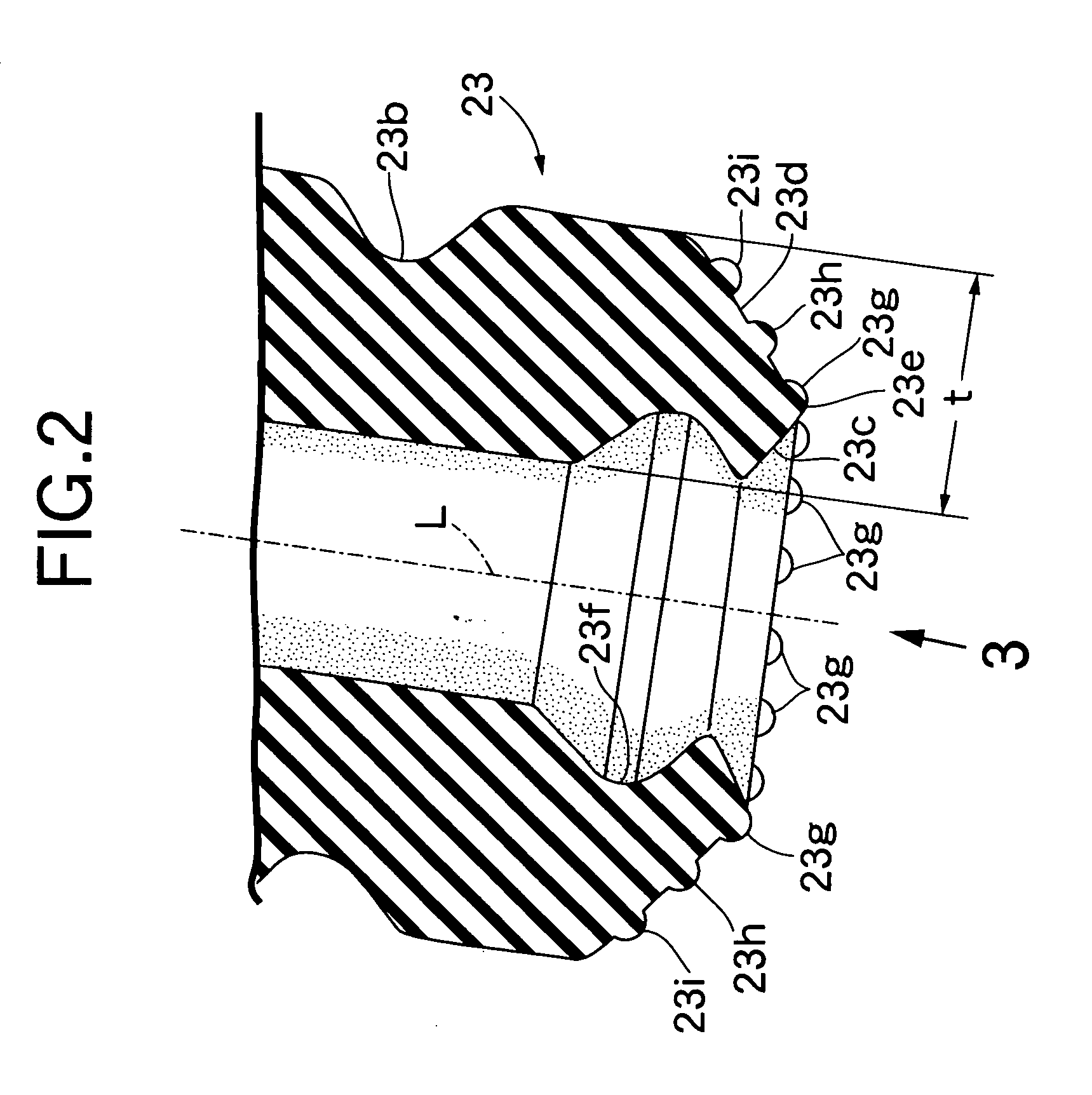

A vehicle suspension system connects a swing member to a vehicle body. The vehicle suspension system includes a bump stopper, which is provided on one of the swing member and the vehicle body and includes an axis, a substantially cylindrical tip end which abuts an abutment surface provided on the other one of the swing member and the vehicle body, and an apex formed at the tip end. Abutment is initiated, in a circumferential direction of the tip end, in a state wherein the abutment surface inclines relative to the axis of the bump stopper. The apex at the tip end of the bump stopper first abuts the abutment surface and is located at an intermediate portion of the bump stopper in a direction of a wall thickness (t) of the bump stopper. A plurality of projections may also be formed on the tip end of the bump stopper.

Owner:HONDA MOTOR CO LTD

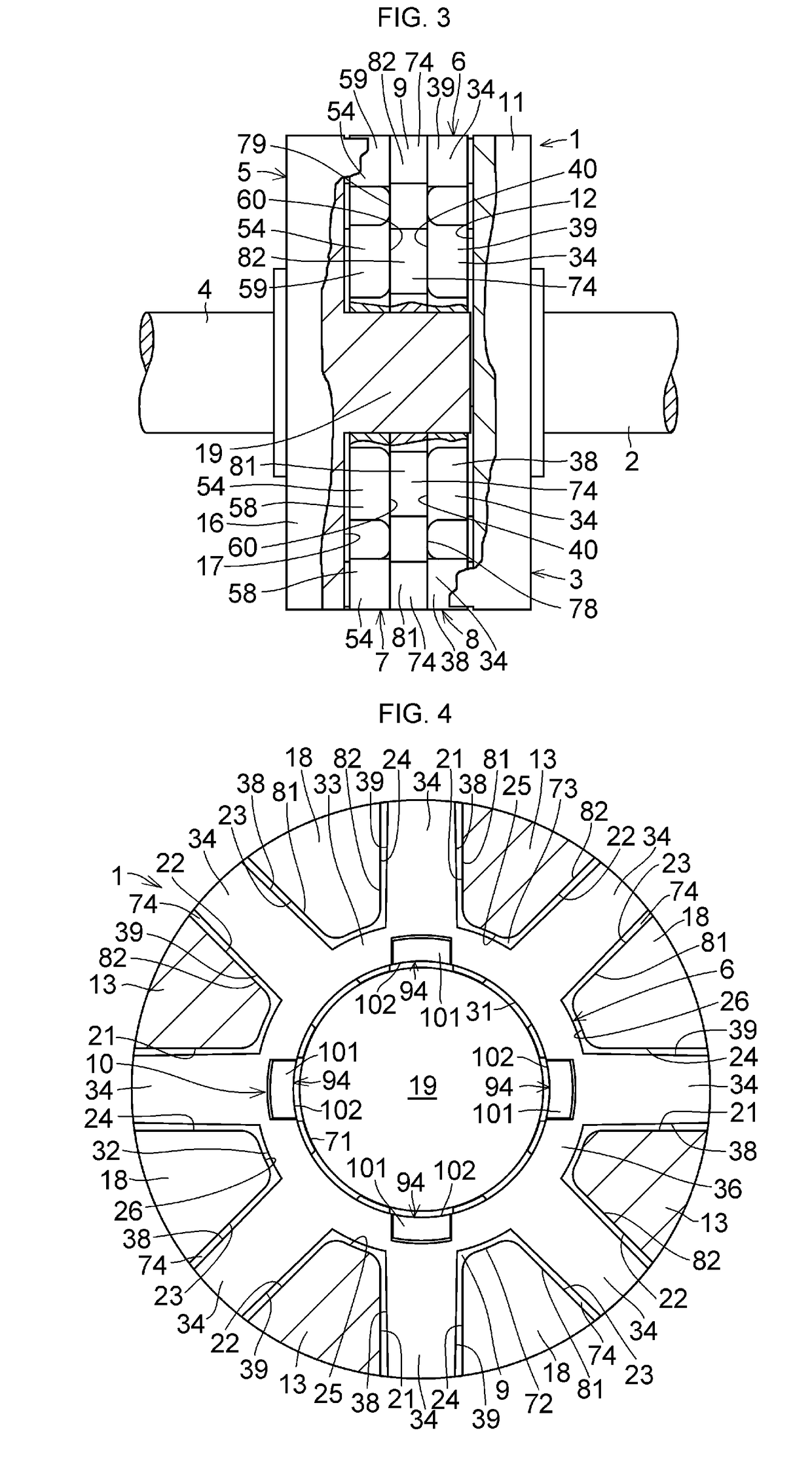

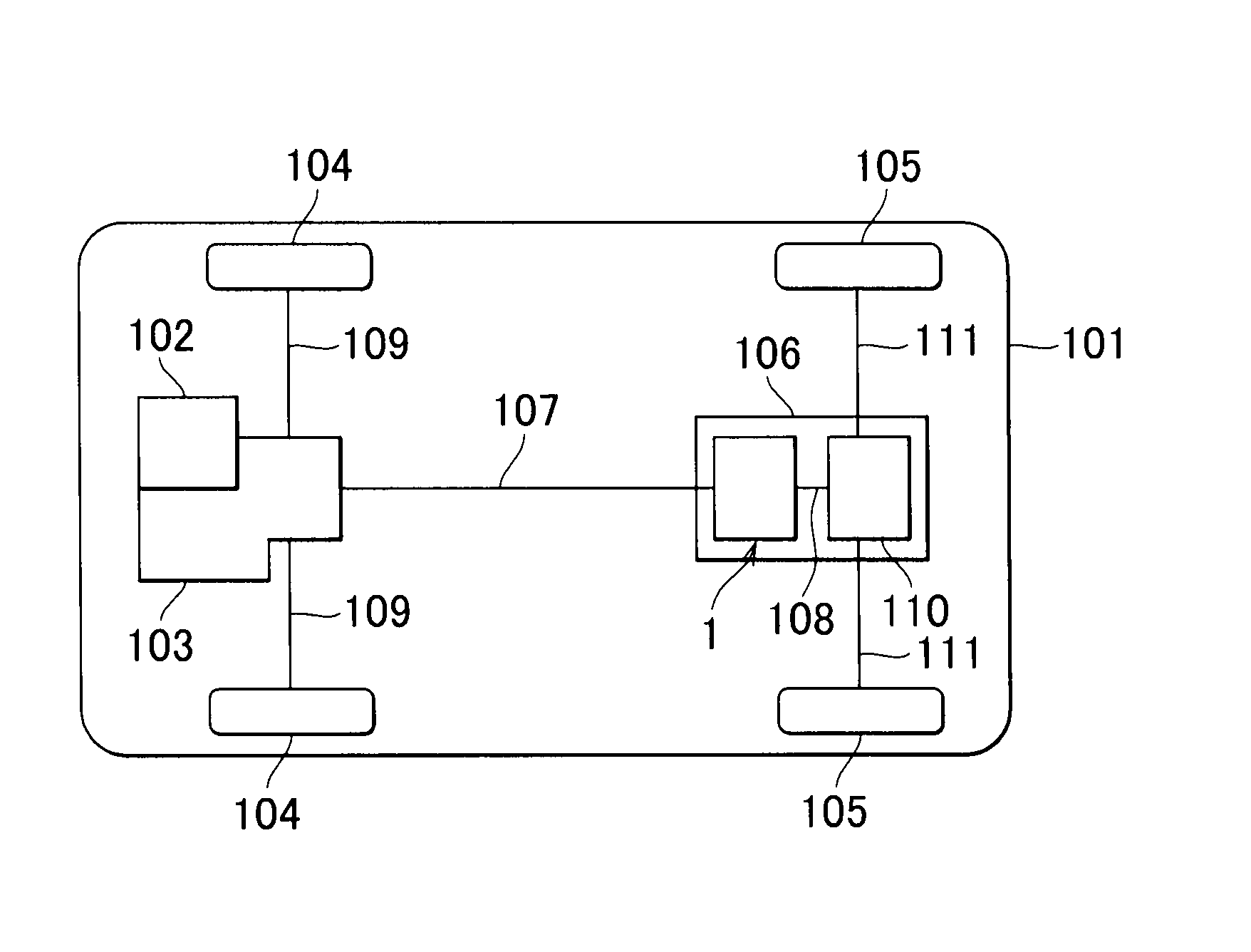

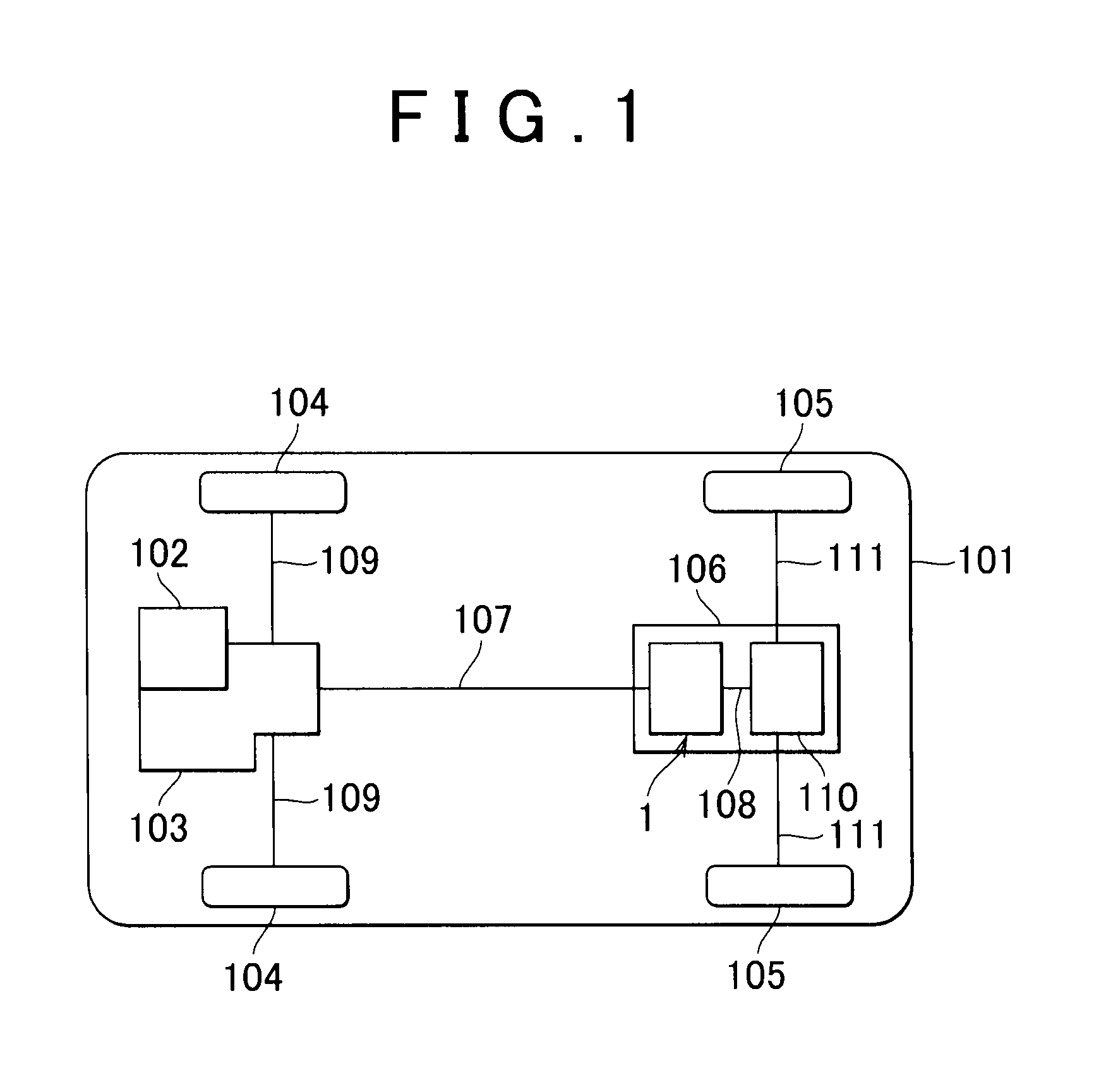

Driving force transmission apparatus and vehicle

ActiveUS8641575B2Suppresses the generation of abnormal noiseSuppress generationMagnetically actuated clutchesFriction clutchesEngineeringCam

A driving force transmission apparatus includes: a front housing and an inner shaft coaxially with each other and rotatable relative to each other; a main clutch transmitting torque between the front housing and the inner shaft; and a cam mechanism having a main cam and a pilot cam and using the main cam to press the main clutch. Where a circumferential gap angle between each spline tooth of the front housing and a corresponding first protrusion of outer clutch plates is θ1, a circumferential gap angle between each spline tooth of the inner shaft and a corresponding protrusion of inner clutch plates is θ2 and a circumferential gap angle between each spline tooth of the inner shaft and a corresponding protrusion of the main cam is θ3, the inequality θ1+θ2−θ3≧1.0° is satisfied.

Owner:JTEKT CORP

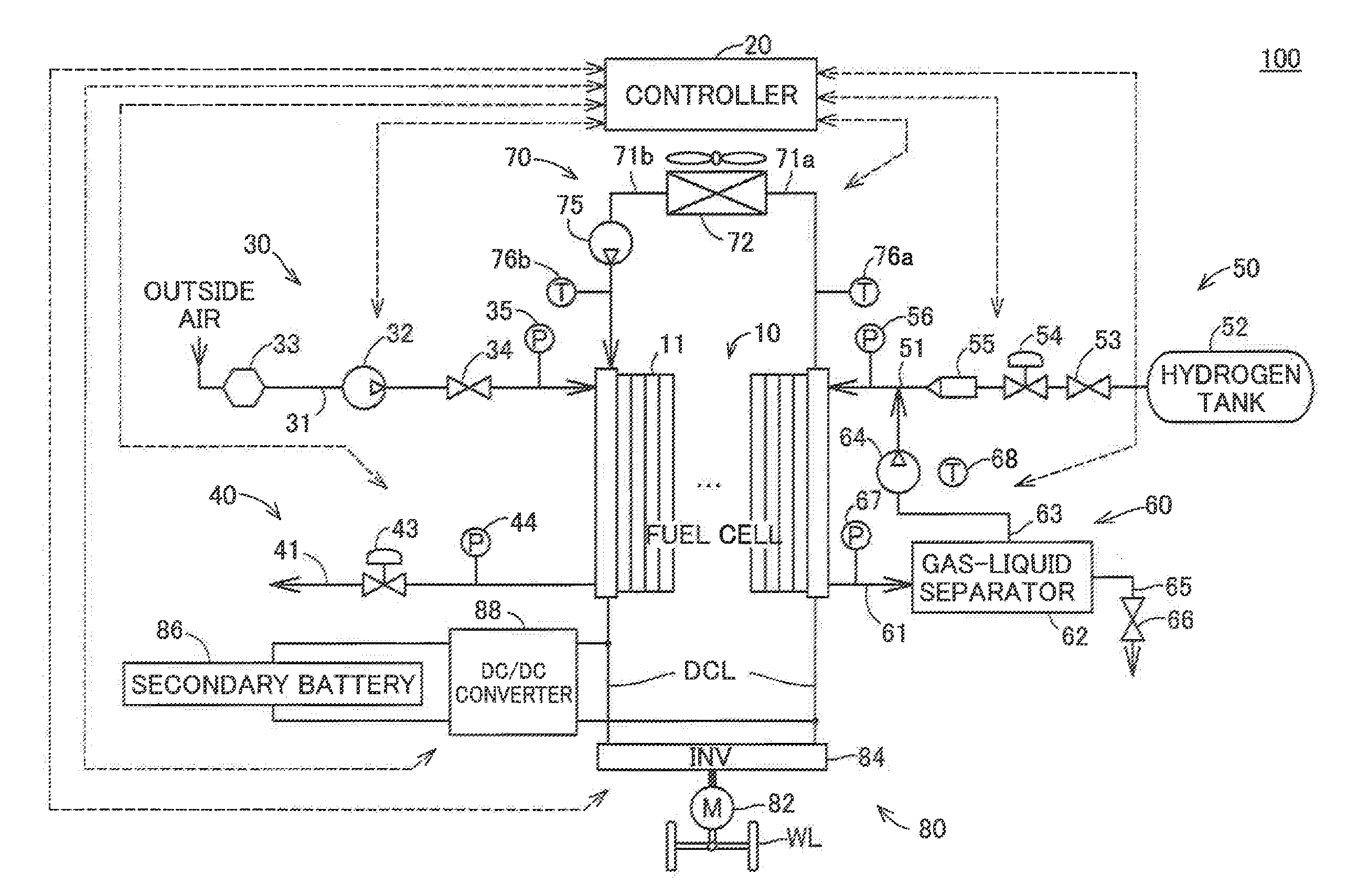

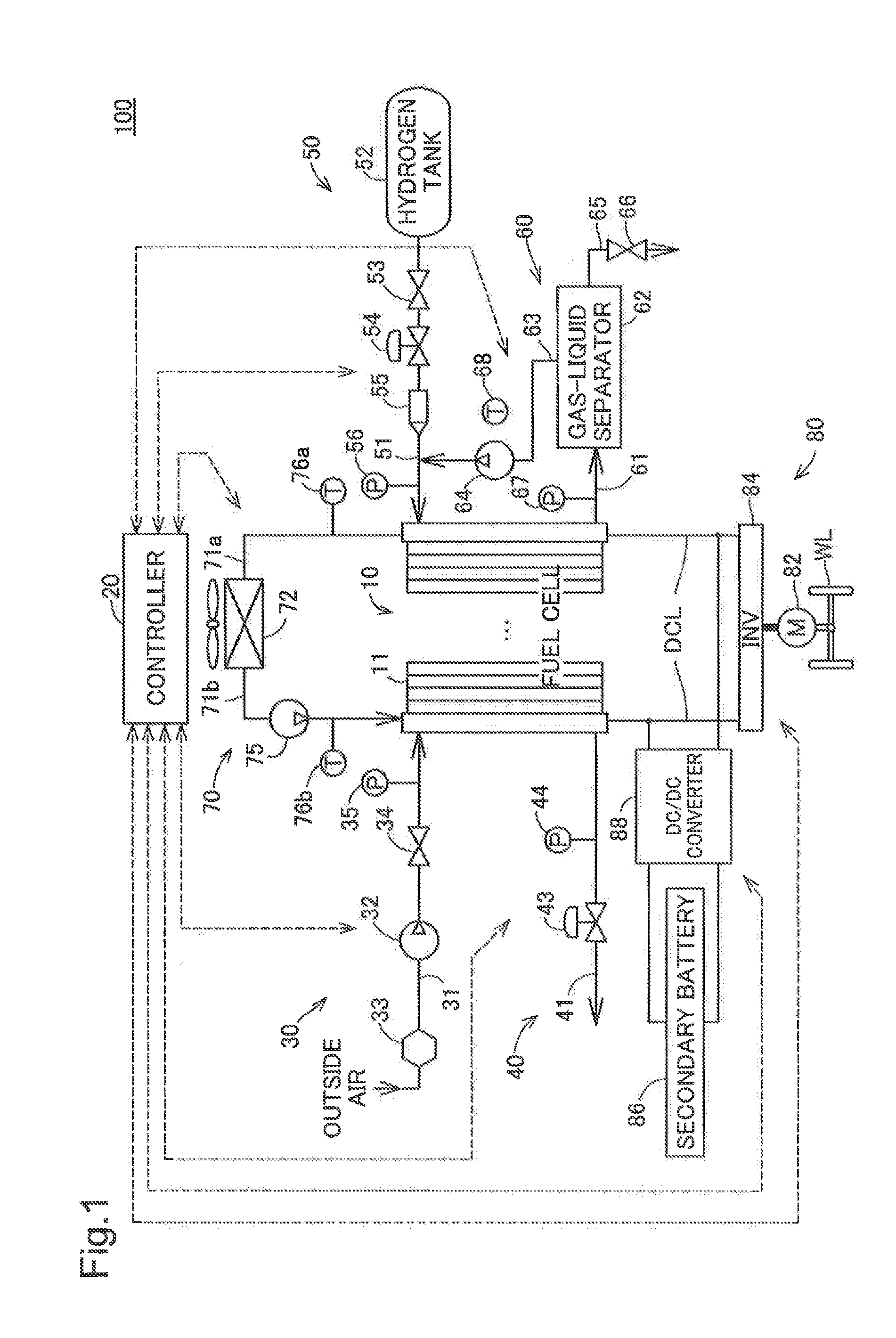

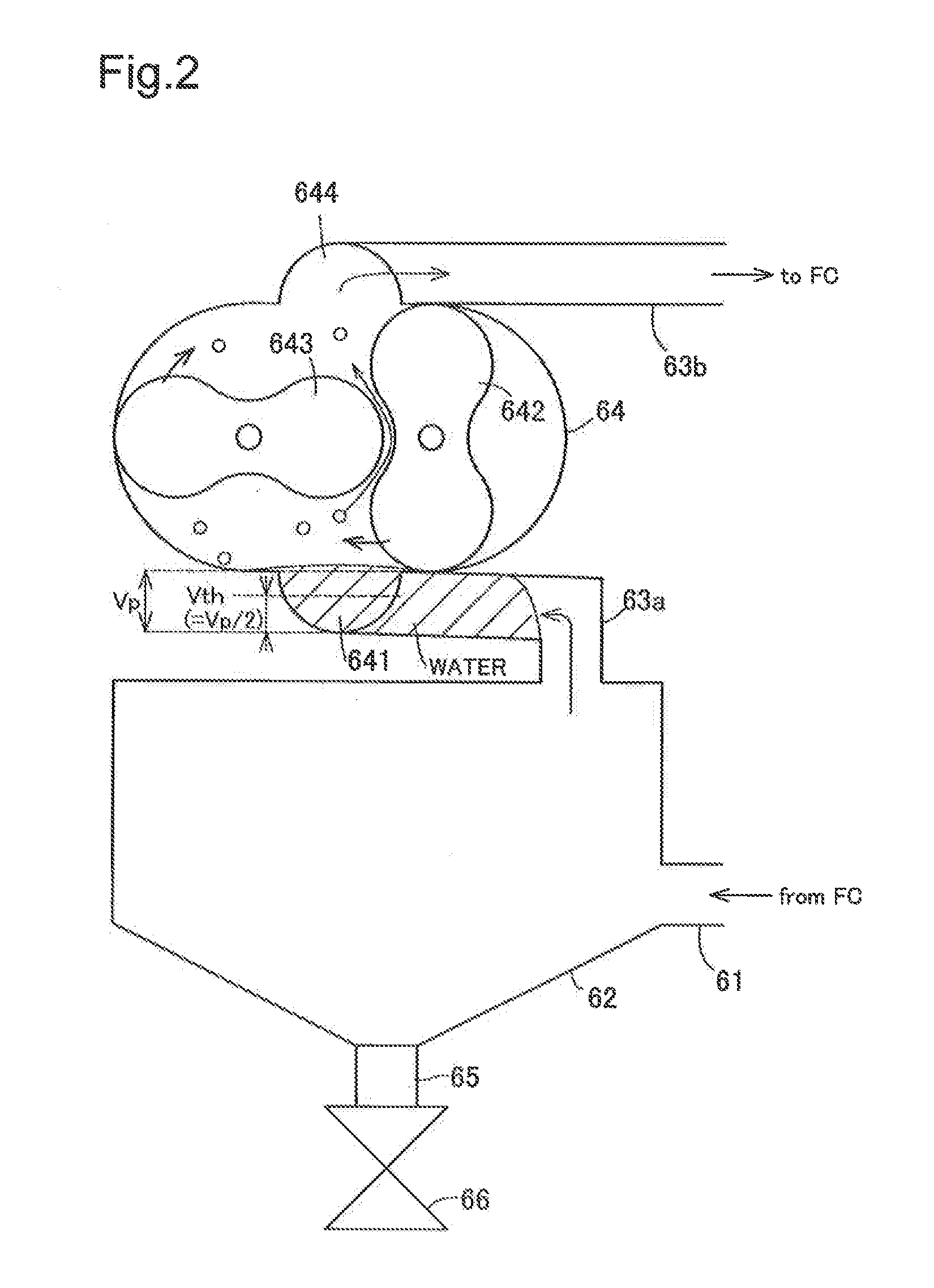

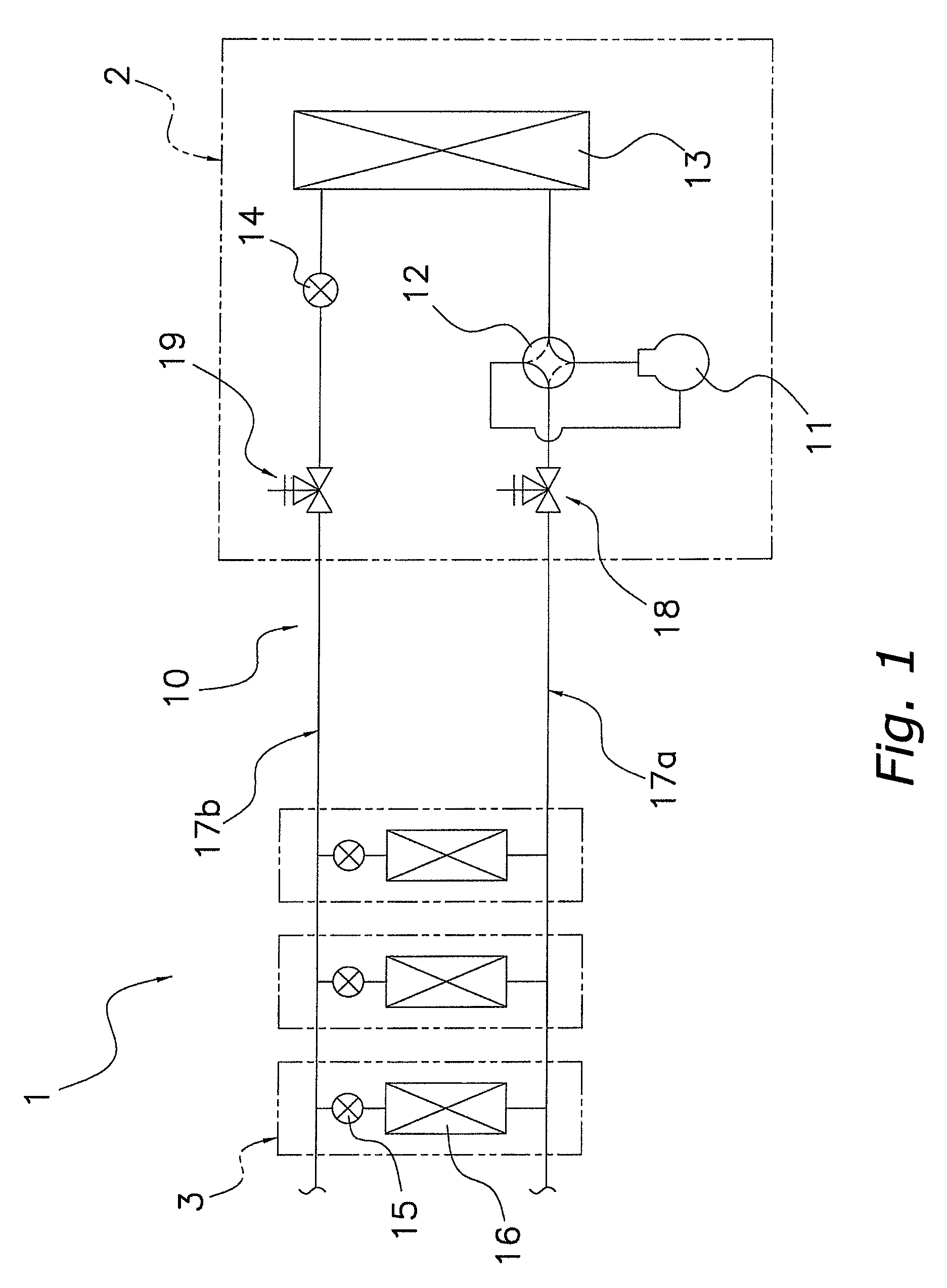

Fuel cell system and control method therefor

A fuel cell system includes: a fuel cell; an anode gas supply flow path for supplying an anode gas to the fuel cell; an anode gas discharge flow path for discharging an anode off gas from the fuel cell; an anode gas circulation flow path for connecting the anode gas supply flow path and the anode gas discharge flow path to each other; a circulation device provided on the anode gas circulation flow path and serving for supplying the anode off gas to the anode gas supply flow path; and a controller. When liquid water is residing in the circulation device, the controller controls a circulation flow rate of the circulation device to discharge the liquid water residing in the circulation device. The controller restricts an increasing rate of the circulation flow rate of the circulation device if it is decided that a quantity of the liquid water residing in the circulation device is equal to or more than a specified value.

Owner:TOYOTA JIDOSHA KK

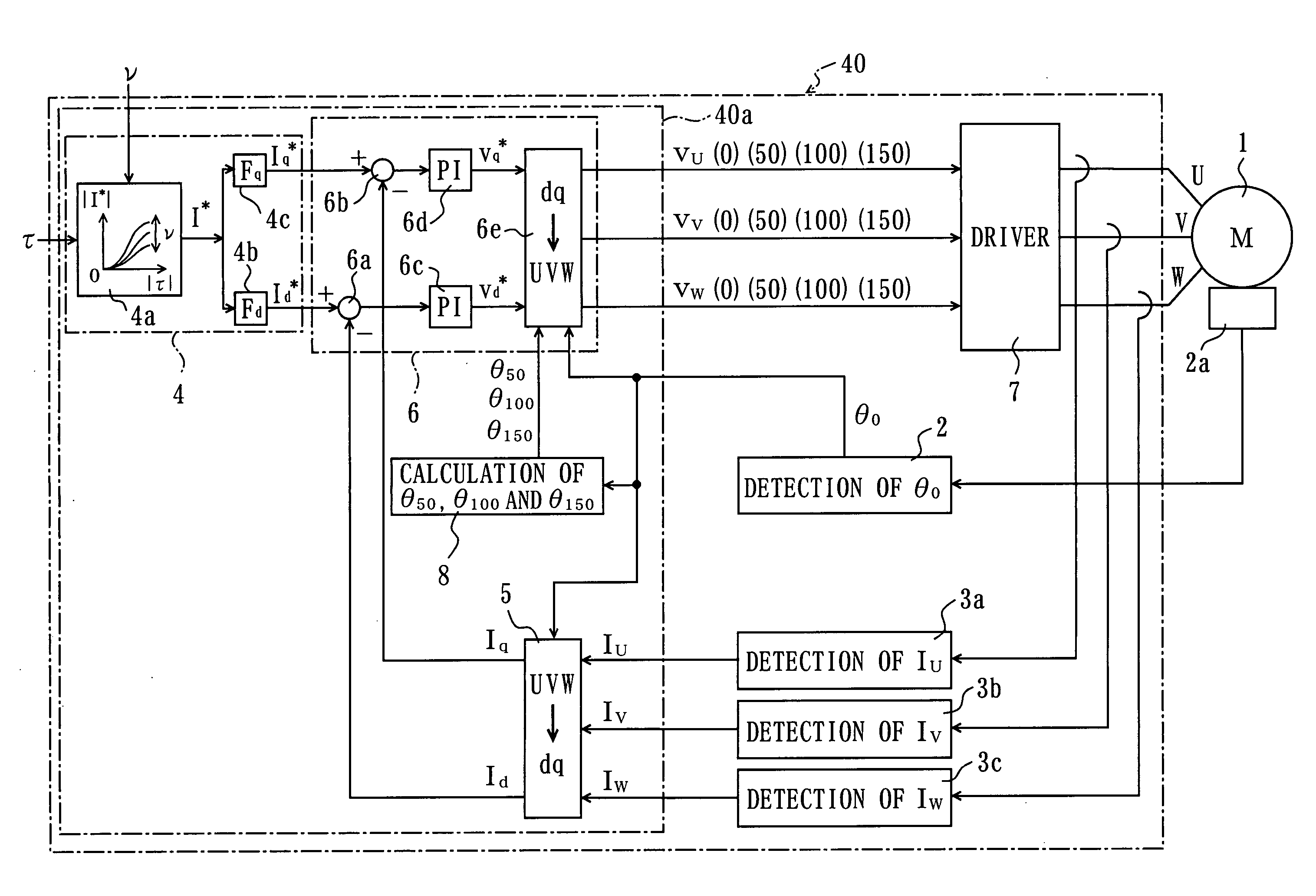

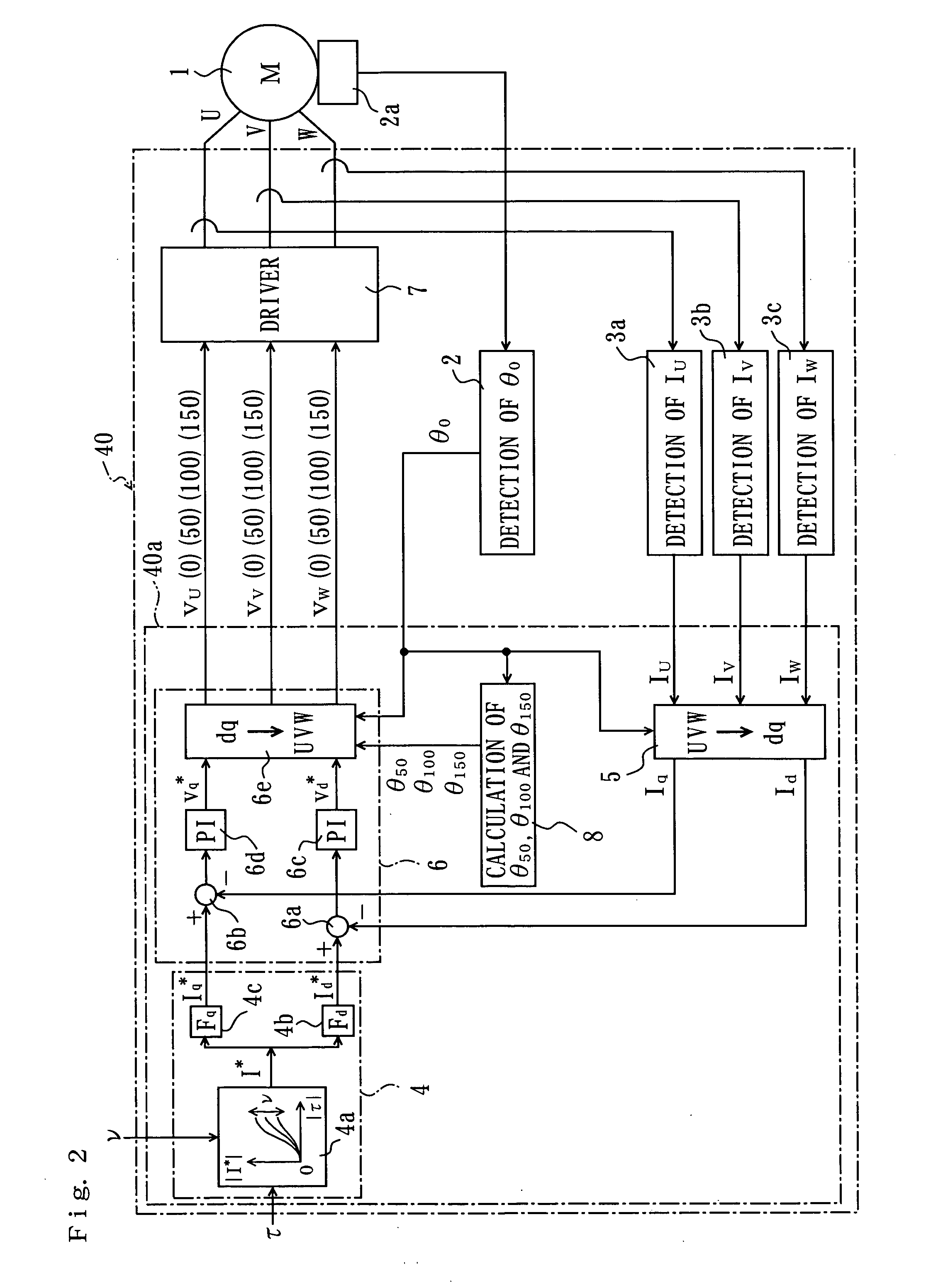

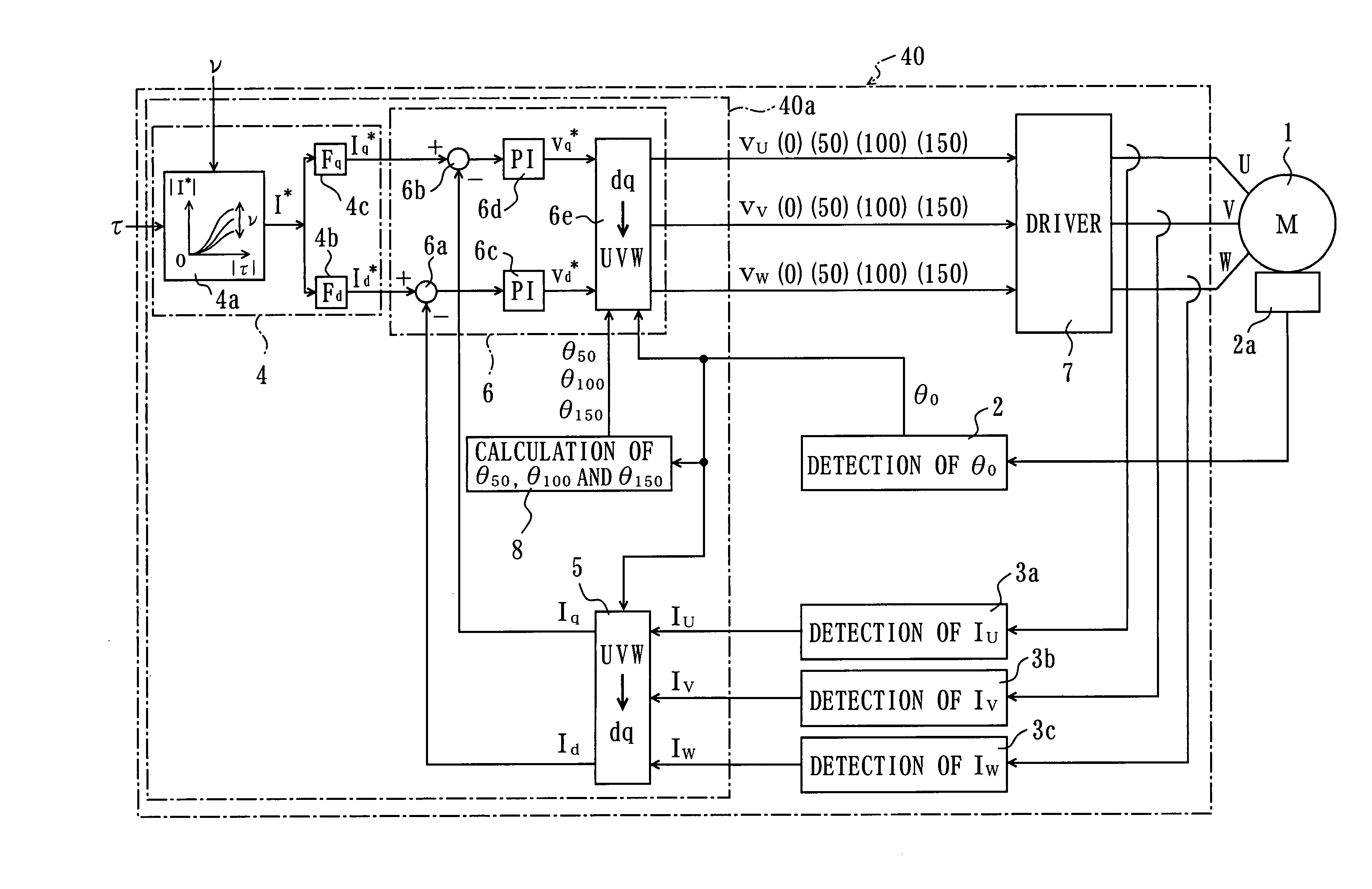

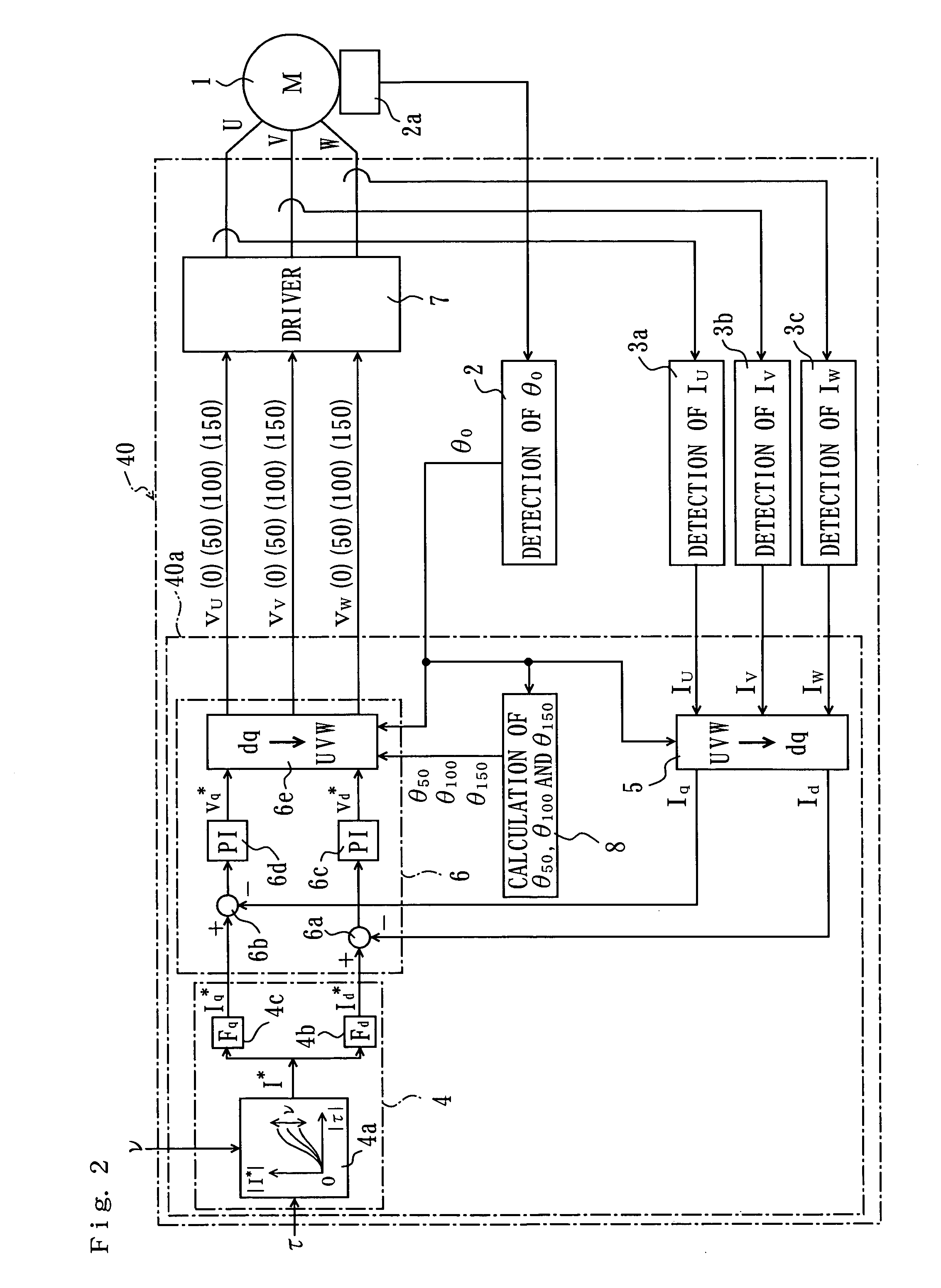

Controller for brushless motor

ActiveUS20060208690A1Reduce update frequencyReduce noiseSingle-phase induction motor startersSynchronous motors startersBrushless motorsEngineering

In a controller for brushless motor which suppresses the generation of abnormal noise when the motor current is controlled by updating voltages applied to the coils, the present values of the applied voltages to the coils are calculated from the d axis target current, the q axis target current, the d axis actual current, the q axis actual current, and the present value of the detected rotational position of the rotor. The updating period of the applied voltages is set as a period that is shorter than this calculation period. The predicted value of the rotational position at a point in time at which the applied voltages are updated until the next calculation of the present values of the applied voltages is determined in accordance with the present value, a past value of the detected rotational position, and the applied voltage updating period. The predicted values of the applied voltages are calculated from the predicted value of the rotational position, the d axis target current, the q axis target current, the d axis actual current, and the q axis actual current. The applied voltages are updated in accordance with the present values and predicted values of the applied voltages.

Owner:JTEKT CORP

Steering assistance device for vehicle

InactiveUS7974752B2Suppresses the generation of abnormal noiseDigital data processing detailsSteering initiationsSteering anglePower flow

A steering assist apparatus for a vehicle includes an electric motor for steering assist. Rotation output of the electric motor is reduced in speed by a ball-screw mechanism and converted to rectilinear motion, which is transmitted to a rack bar. An electronic control unit determines a target current value in accordance with a steering torque detected by a steering torque sensor and a vehicle speed detected by a vehicle speed sensor. While using an actual current value of the electric motor detected by a current sensor as a feedback, the electronic control unit controls the current flowing through the electric motor to be equal to the target current value. The electronic control unit changes the feedback gain of the feedback control in accordance with a steering angle detected by a steering angle sensor, to thereby suppress abnormal noise generated at a steering mechanism, without deteriorating steering feel.

Owner:TOYOTA JIDOSHA KK

Traverse camshaft for fishing reel and reciprocal movement mechanism for fishing reel employing the traverse camshaft

ActiveUS8480020B2Suppress unnecessary turningSuppresses the generation of abnormal noiseGearingReelsReciprocating motionEngineering

In a spinning reel, a traverse camshaft 21 is arranged to engage with an engaging member used to cause a bail arm and a spool to undergo a relative reciprocal movement. The traverse camshaft 21 has a shaft body 37 and a cam groove 38. The shaft body 37 is arranged to rotate in coordination with rotation of a handle assembly in at least a line reel-in direction. The cam groove 38 is formed in an external circumferential surface of the shaft body 37 and configured to engage with the engaging member. The cam groove 38 is also configured to intersect itself. The cam groove 38 has a first groove section 38b and a second groove section 38c on opposite sides of an intersecting portion 38a. The first groove section 38b and the second groove section 38c have different widths at the intersecting portion 38a.

Owner:SHIMANO INC

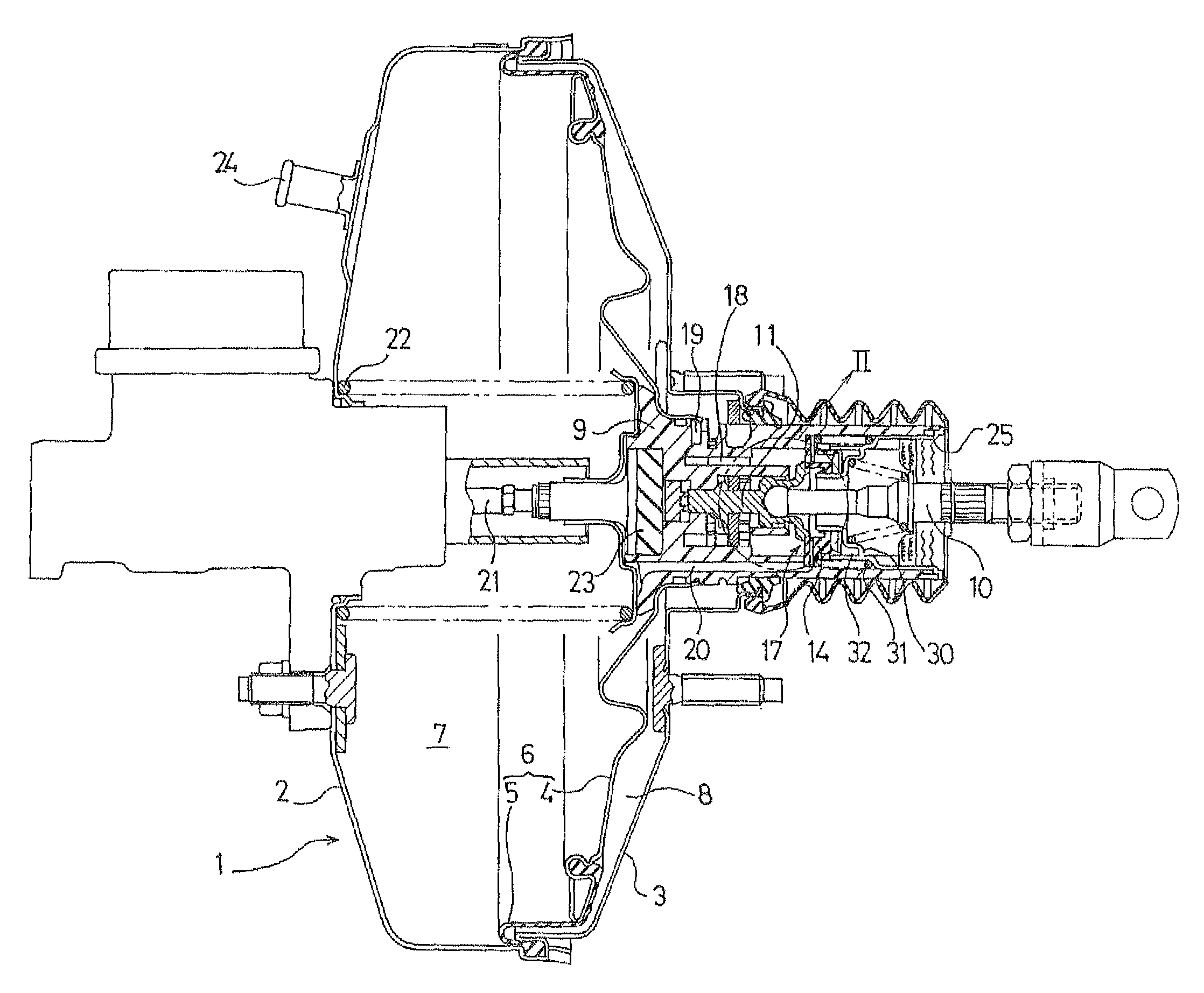

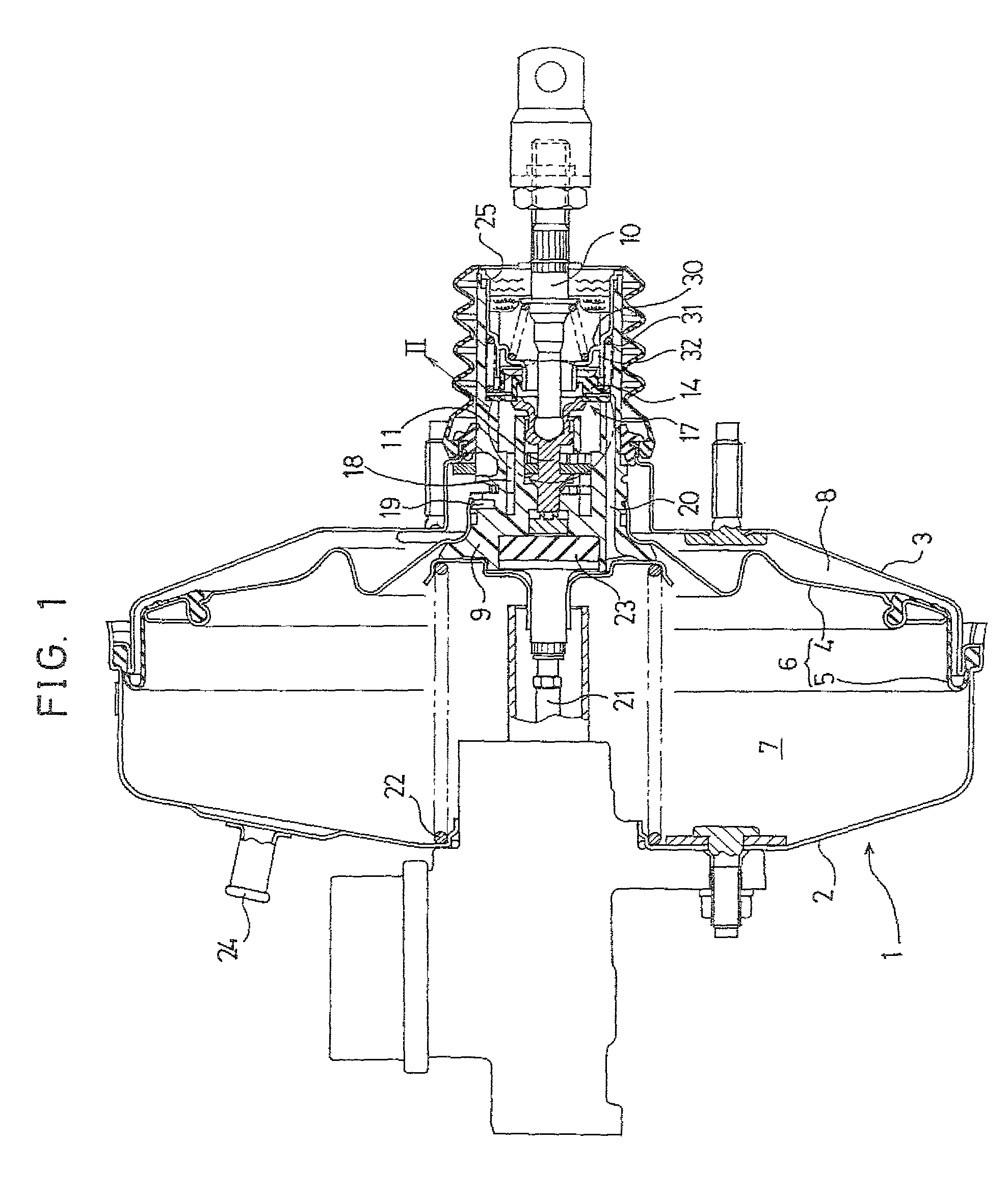

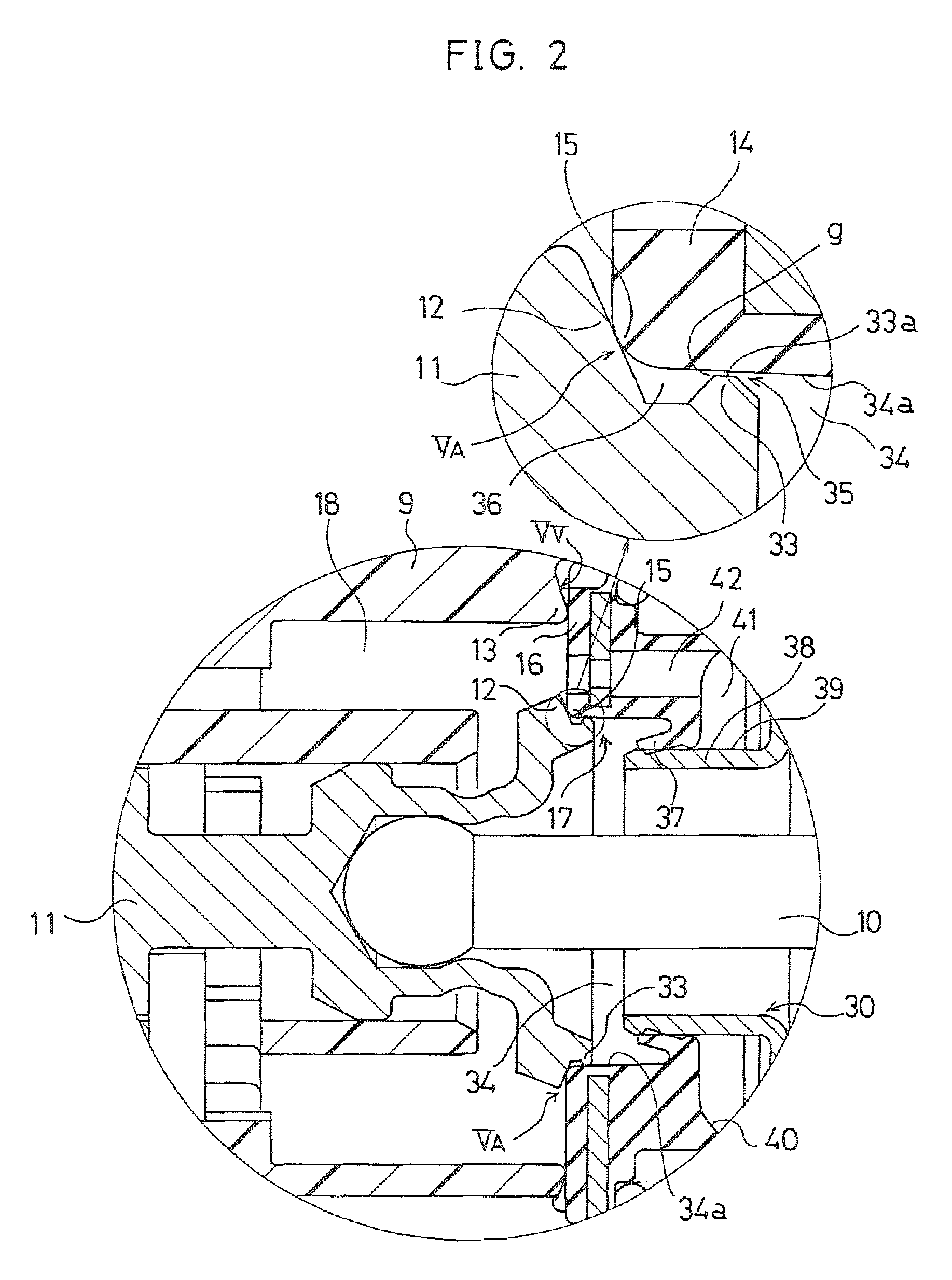

Fluid pressure booster

ActiveUS7954909B2Suppresses the generation of abnormal noiseHinder improvementServomotorsApplication and release valvesEngineeringControl valves

In a fluid pressure booster, when an input shaft and a valve plunger advance, an atmosphere valve opens to introduce air into a variable pressure chamber. At this time, the input shaft has not moved by a predetermined stroke, and thus a projection of the valve plunger is positioned within an inner peripheral surface of a control valve body, thus forming an orifice, which causes air to be sucked at a restricted flow rate. As a result, generation of noise is suppressed. When the input shaft moves the predetermined stroke, the projection of the valve plunger is positioned away from the inner peripheral surface of the control valve body and the orifice is no longer formed. Accordingly, the flow rate of the air is not restricted by the orifice, and thus a relatively large amount of air is sucked into and introduced into the pressure variation chamber.

Owner:BOSCH CORP

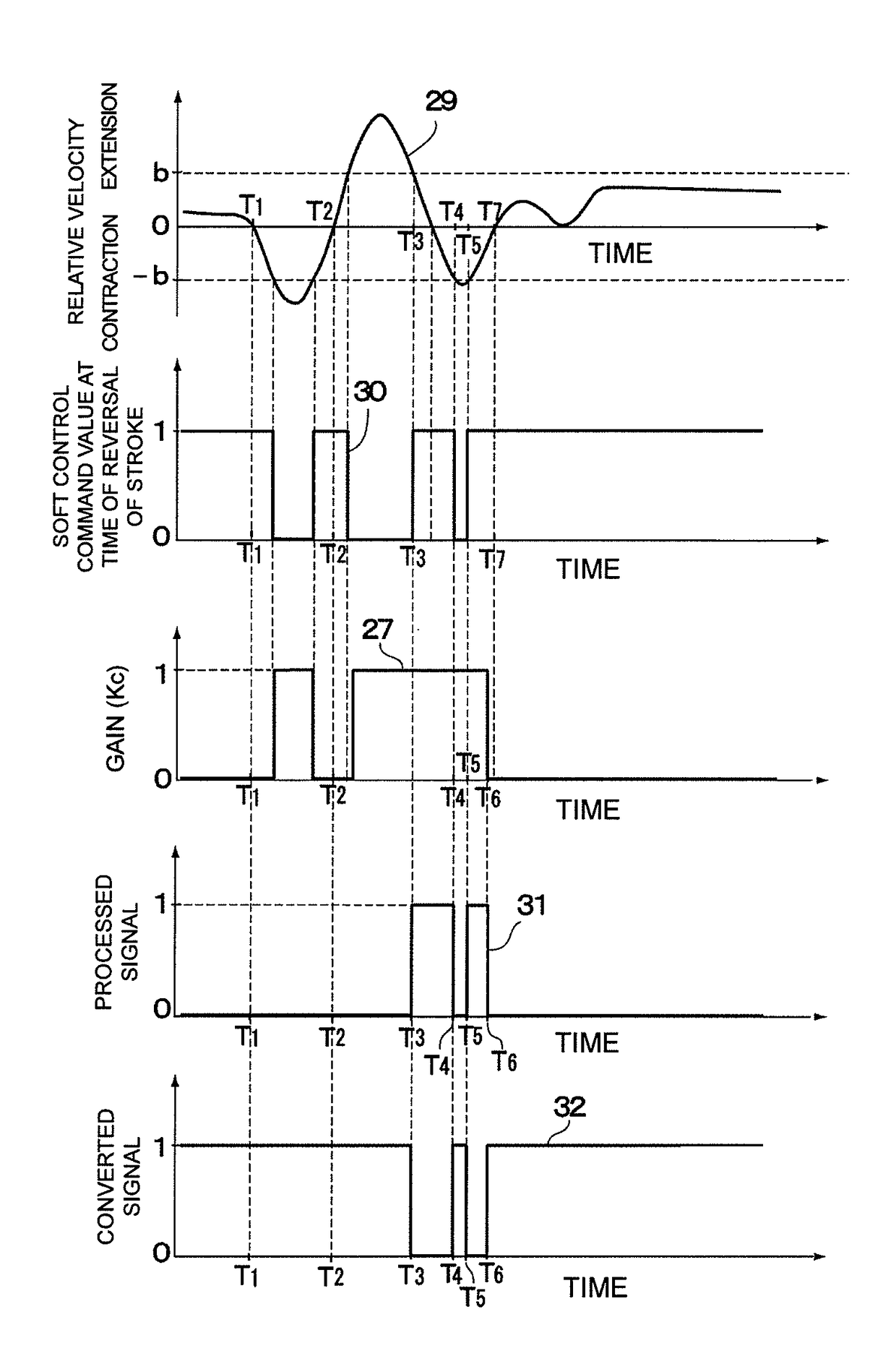

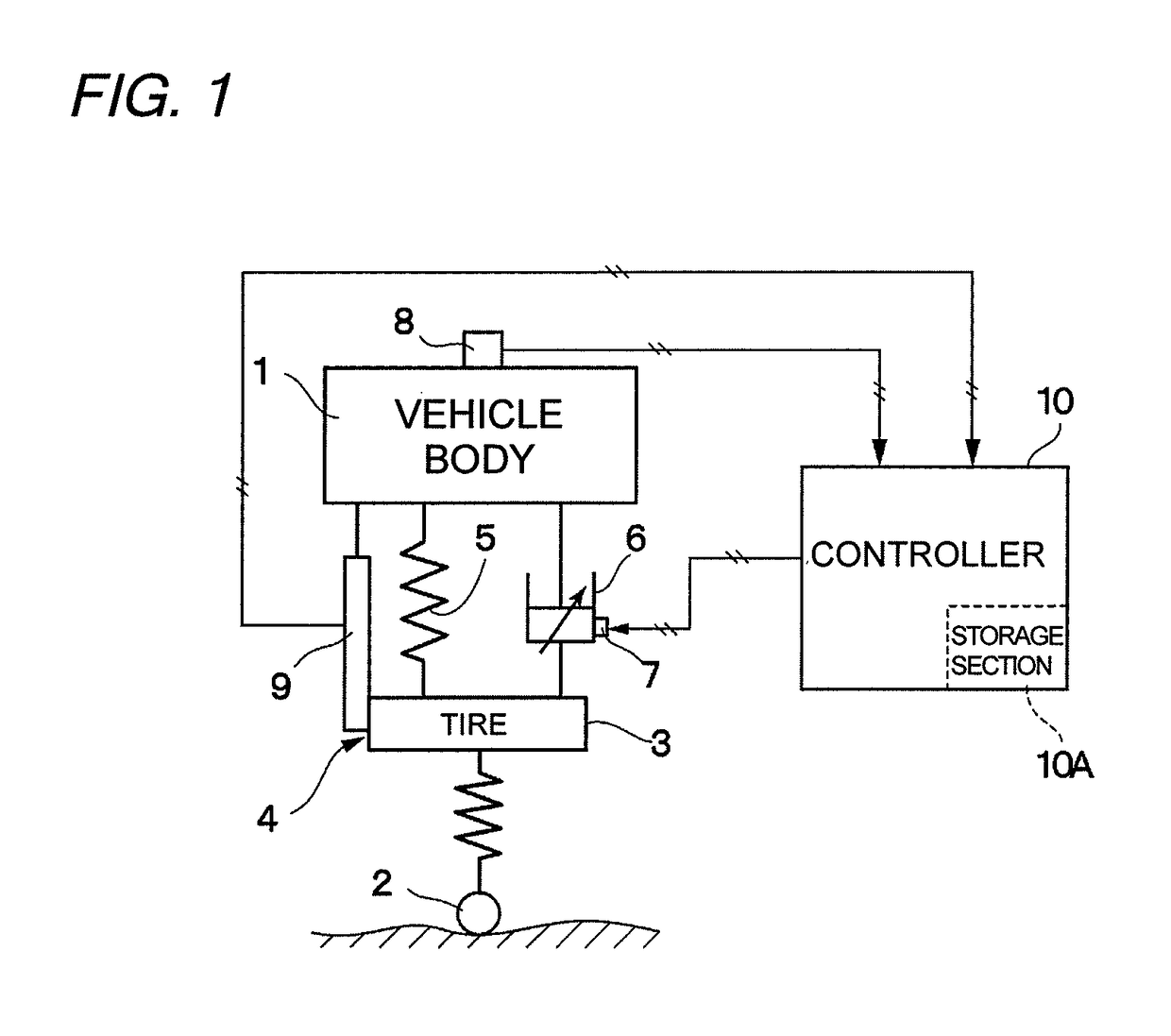

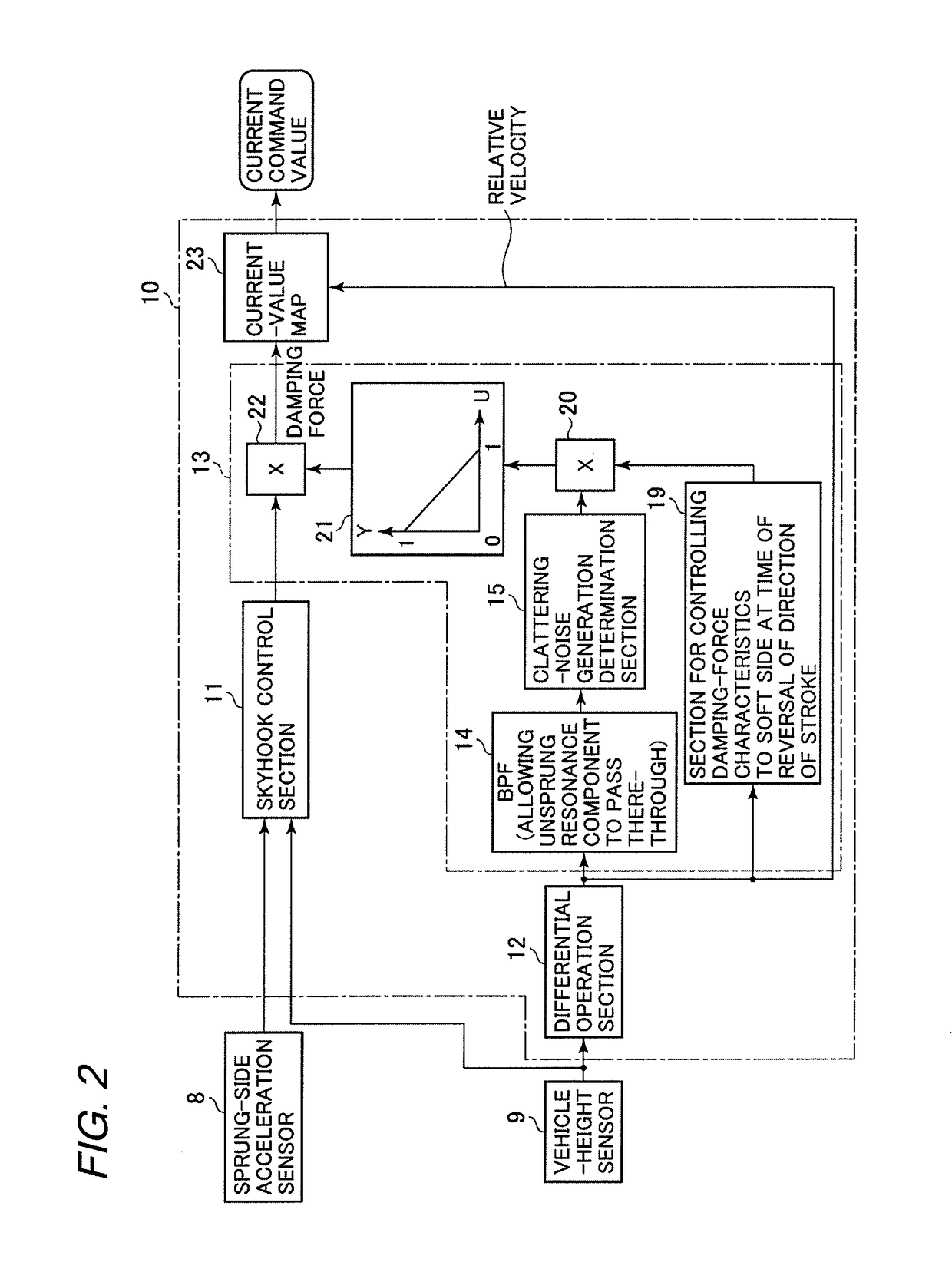

Suspension control apparatus for vehicle and control apparatus for damping-force adjustable shock absorber

ActiveUS10106009B2Suppresses the generation of abnormal noiseSpringsDigital data processing detailsControl theoryShock absorber

A suspension control apparatus for a vehicle including a damping-force adjustable shock absorber interposed between a vehicle body and a wheel of a vehicle, and a controller for variably controlling damping-force characteristics of the damping-force adjustable shock absorber between hard and soft. The controller is configured to switch the damping-force characteristics to a soft side when a direction of a stroke of the damping-force adjustable shock absorber is reversed between an extension stroke and a contraction stroke.

Owner:HITACHI ASTEMO LTD

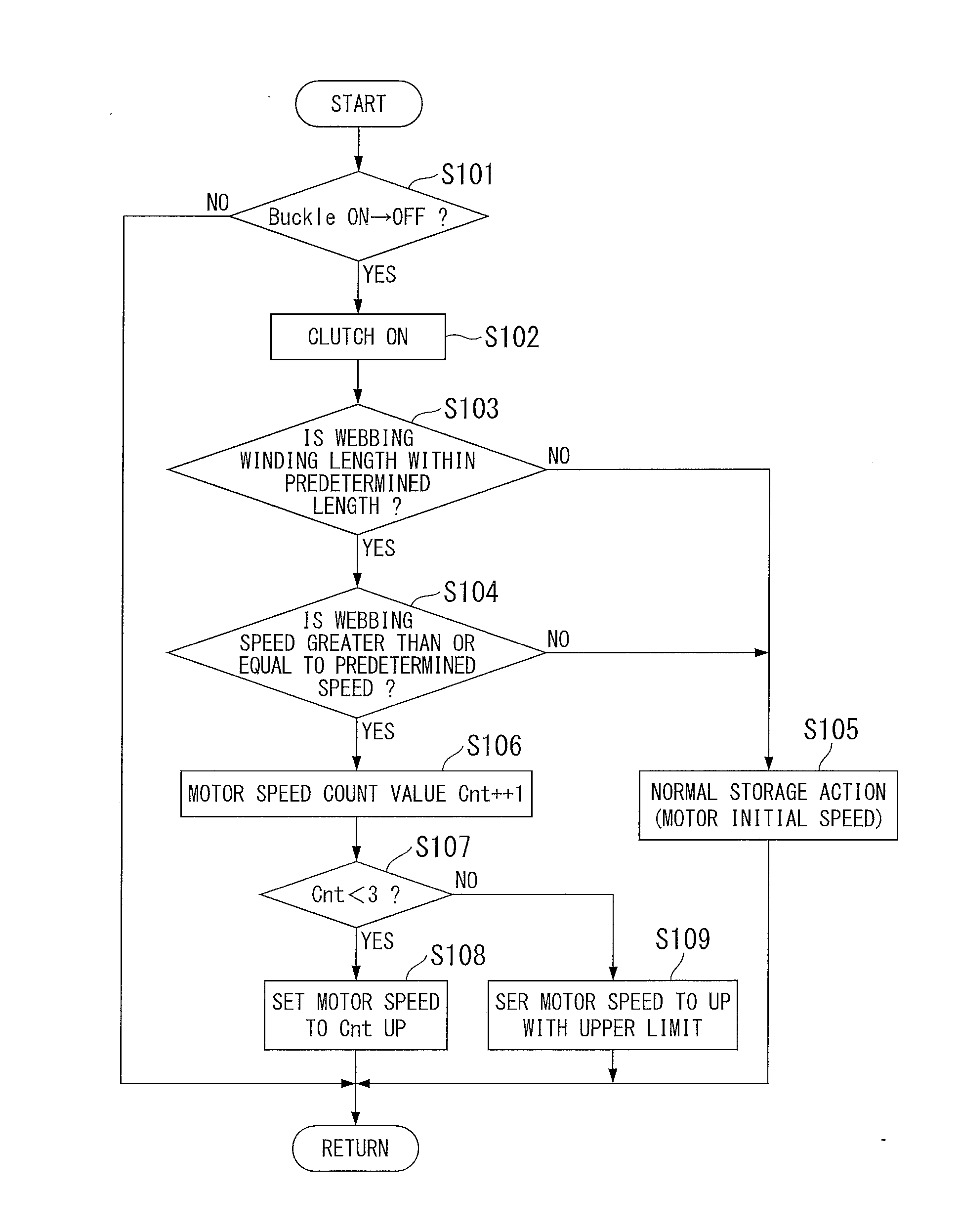

Seat belt device

ActiveUS20140117139A1Abnormal noise be generateSuppresses the generation of abnormal noiseBelt retractorsBelt control systemsClutchSeat belt

A seat belt device includes a belt reel around which webbing is wound, a winding spring that rotationally biases the belt reel in a winding direction, a motor that is configured to transmit a driving force to the belt reel, a clutch that is interposed between the motor and the belt reel, and which performs connection / disconnection of the motor and the belt reel, a webbing speed detection unit that detects the winding speed of the webbing, a fastened / released state detection unit that detects a fastened state and a released state of the webbing, a basic winding control unit that drives the motor in the winding direction in a rotating manner and puts the clutch into a connected state, and a speed increase correction unit that increases the speed of the motor with respect to the speed of the motor obtained by the control of the basic winding control unit.

Owner:HONDA MOTOR CO LTD

Vehicle suspension system

InactiveUS7530587B2Reduce the numberReduce frequencySpringsSprings/dampers design characteristicsEngineeringAbutment

Owner:HONDA MOTOR CO LTD

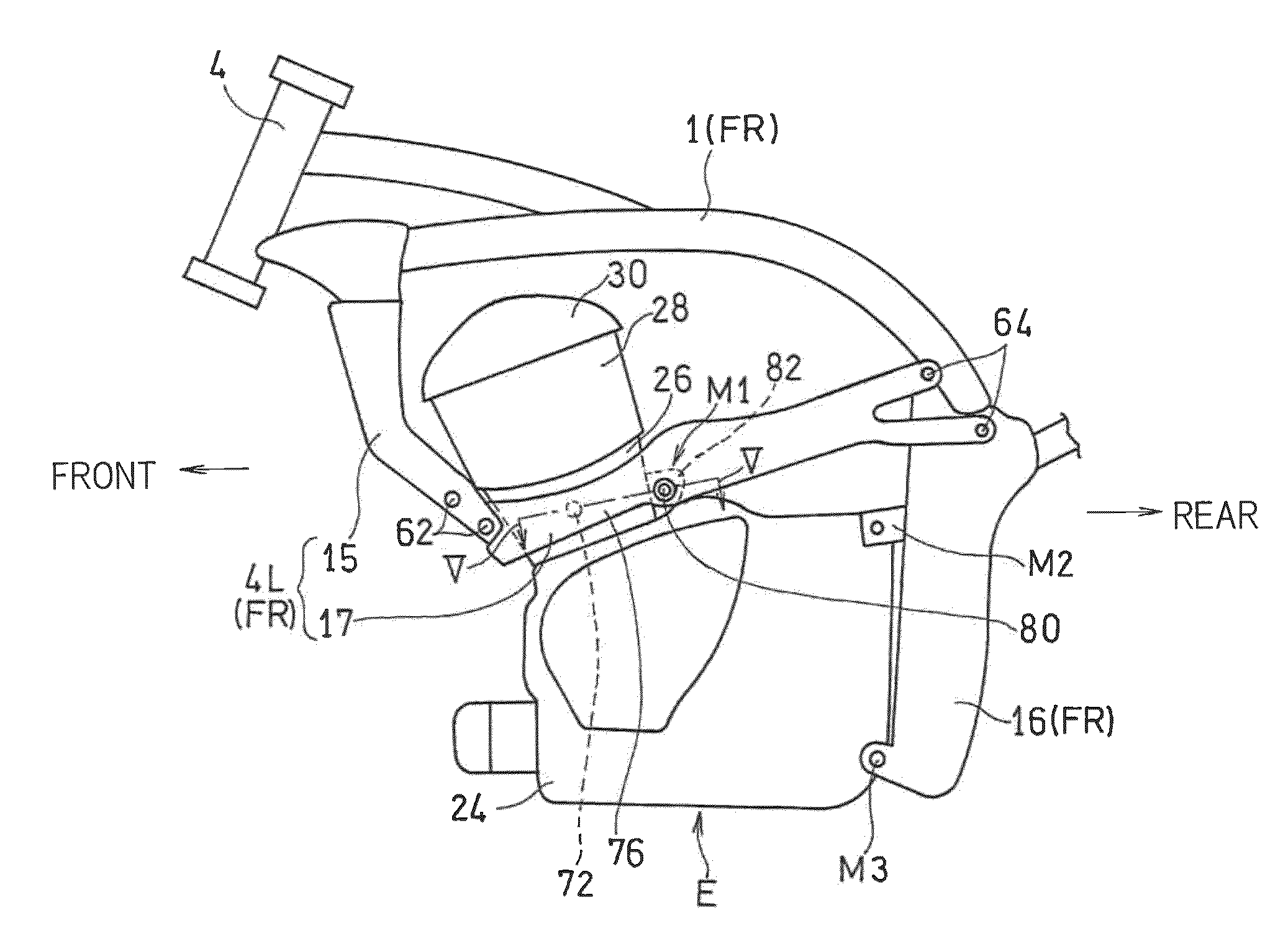

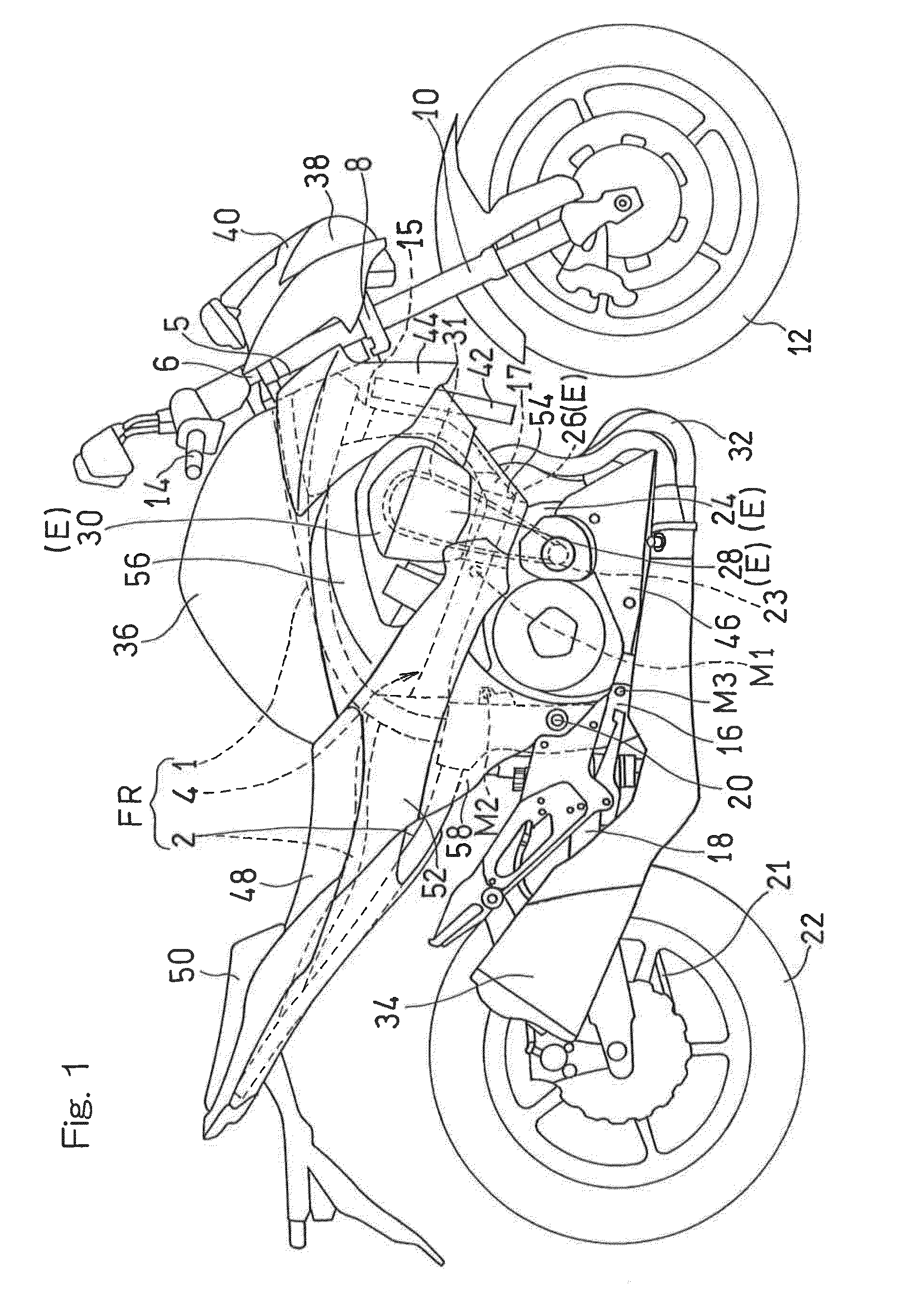

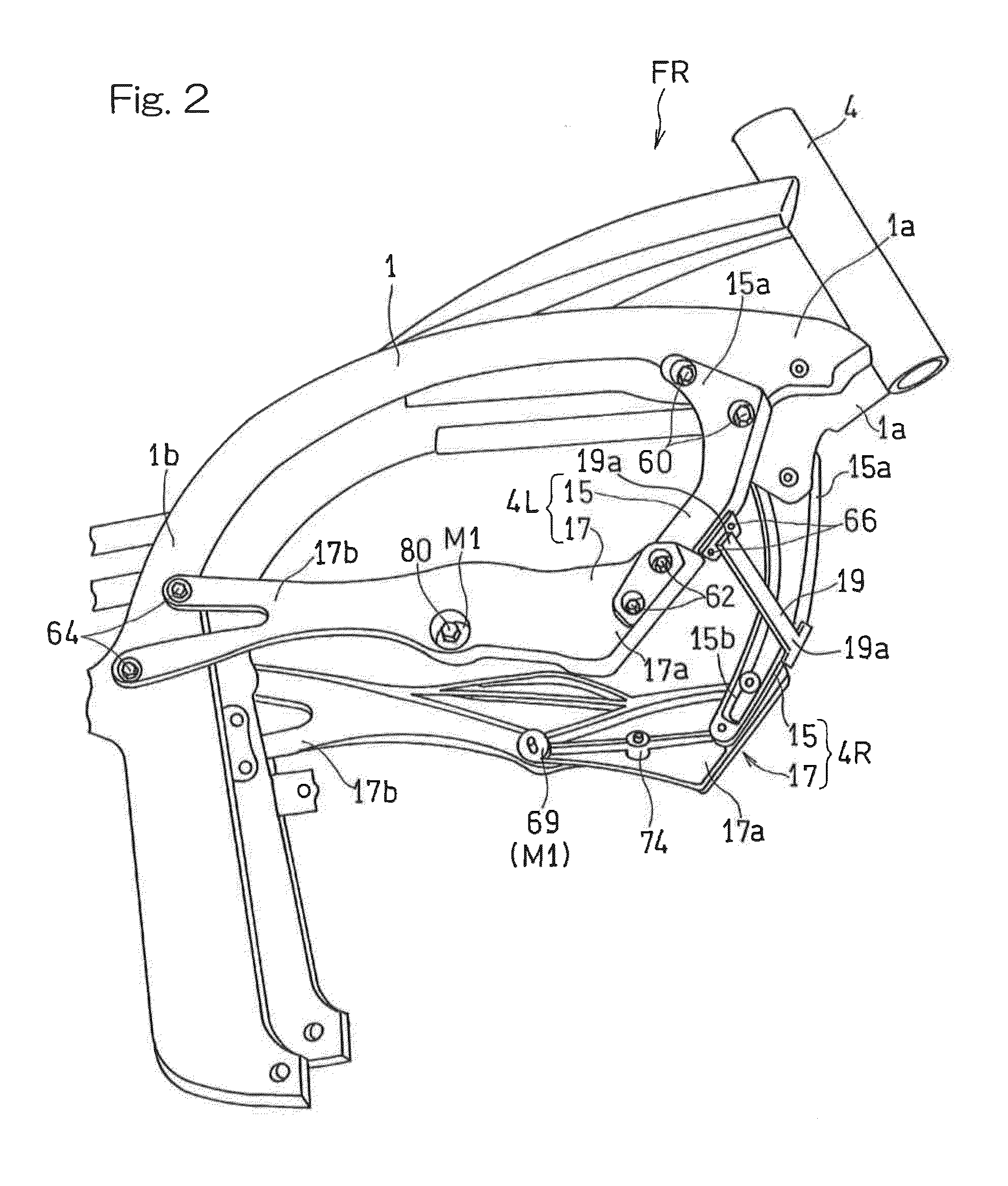

Saddle-riding type automotive vehicle

ActiveUS8955635B2Suppresses the generation of abnormal noiseAvoid assemblyVehicle seatsElectric propulsion mountingVehicle frameCombustion

A motorcycle frame assembly (FR) for a motorcycle includes a main frame (1), which extends from above a combustion engine (E) in a direction rearwardly, and a subframe (4) having front and rear end portions connected with the main frame (1) and also having an intermediate portion positioned laterally outside of a cylinder block (26) of the combustion engine (E). The combustion engine (E) is fixed to a motorcycle frame assembly (FR) by means of first, second and third engine mounting areas (M1, M2, M3). The first engine mounting area (M1) is provided in the intermediate portion of the subframe (4) and, also, a damping unit (72) for suppressing vibrations of a to-be-damped region (76) is provided in the to-be-damped region (76) provided at a location remote from the first engine mounting area (M1) in the subframe (4).

Owner:KAWASAKI MOTORS LTD

Vehicle-mounted battery apparatus

ActiveUS20190198835A1Unusual noise be generateAlleviate impactElectric propulsion mountingVent arrangementsEngineeringCheck valve

A vehicle-mounted battery apparatus to be mounted in a vehicle includes: a battery pack, the battery pack including a battery cell, the battery cell including a gas exhaust portion configured to discharge internal gas; a smoke exhaust duct connected to the battery pack and configured to discharge gas to an outside of the vehicle; and a check valve disposed in the smoke exhaust duct and configured to block flow of gas from the outside of the vehicle toward the battery pack. The check valve includes: a valve seat disposed in the smoke exhaust duct and having a hole; a valve body configured to be seated on the valve seat to cover the hole; and a shock absorbing member disposed between the valve body and the valve seat to alleviate impact of the valve body against the valve seat.

Owner:TOYOTA JIDOSHA KK

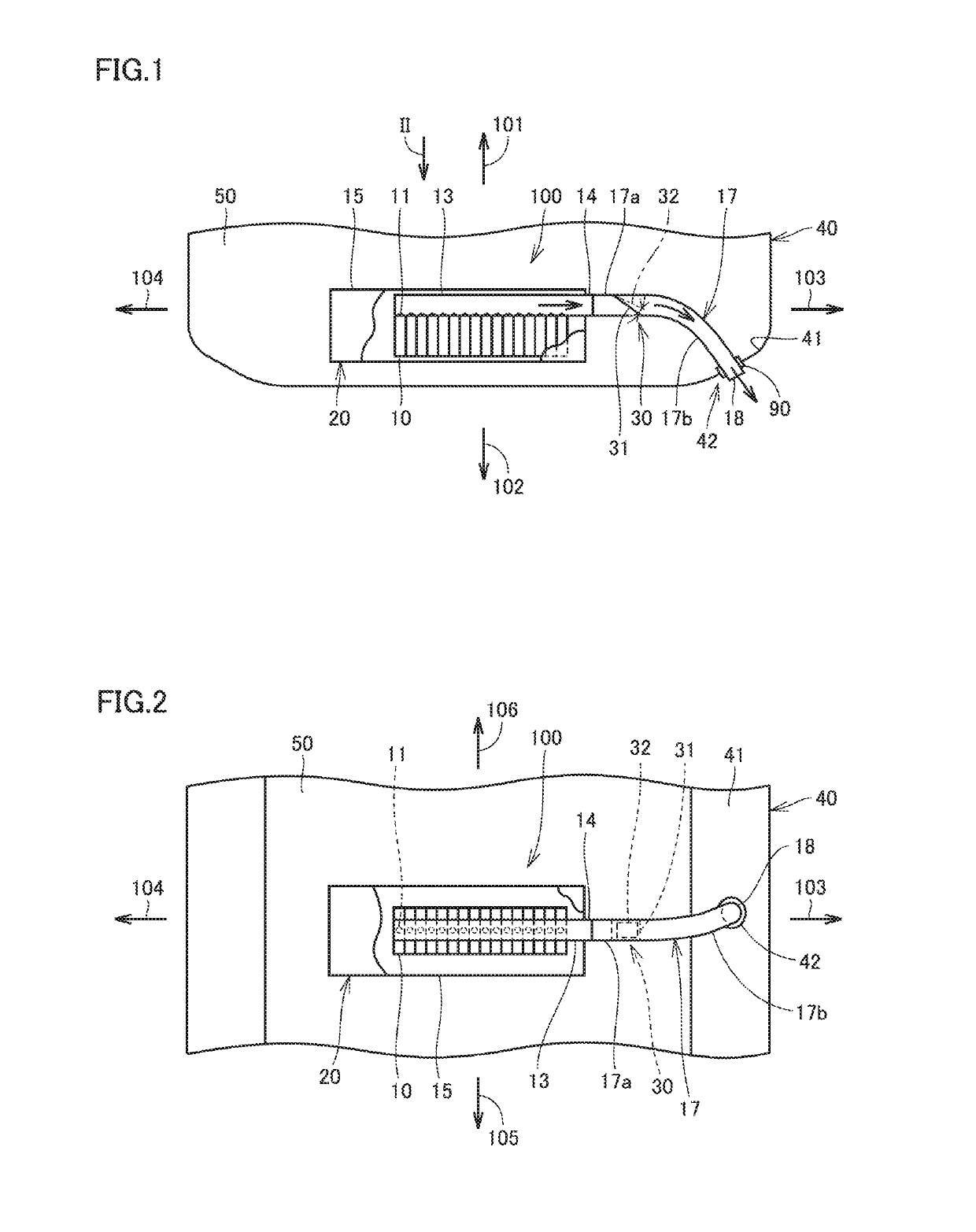

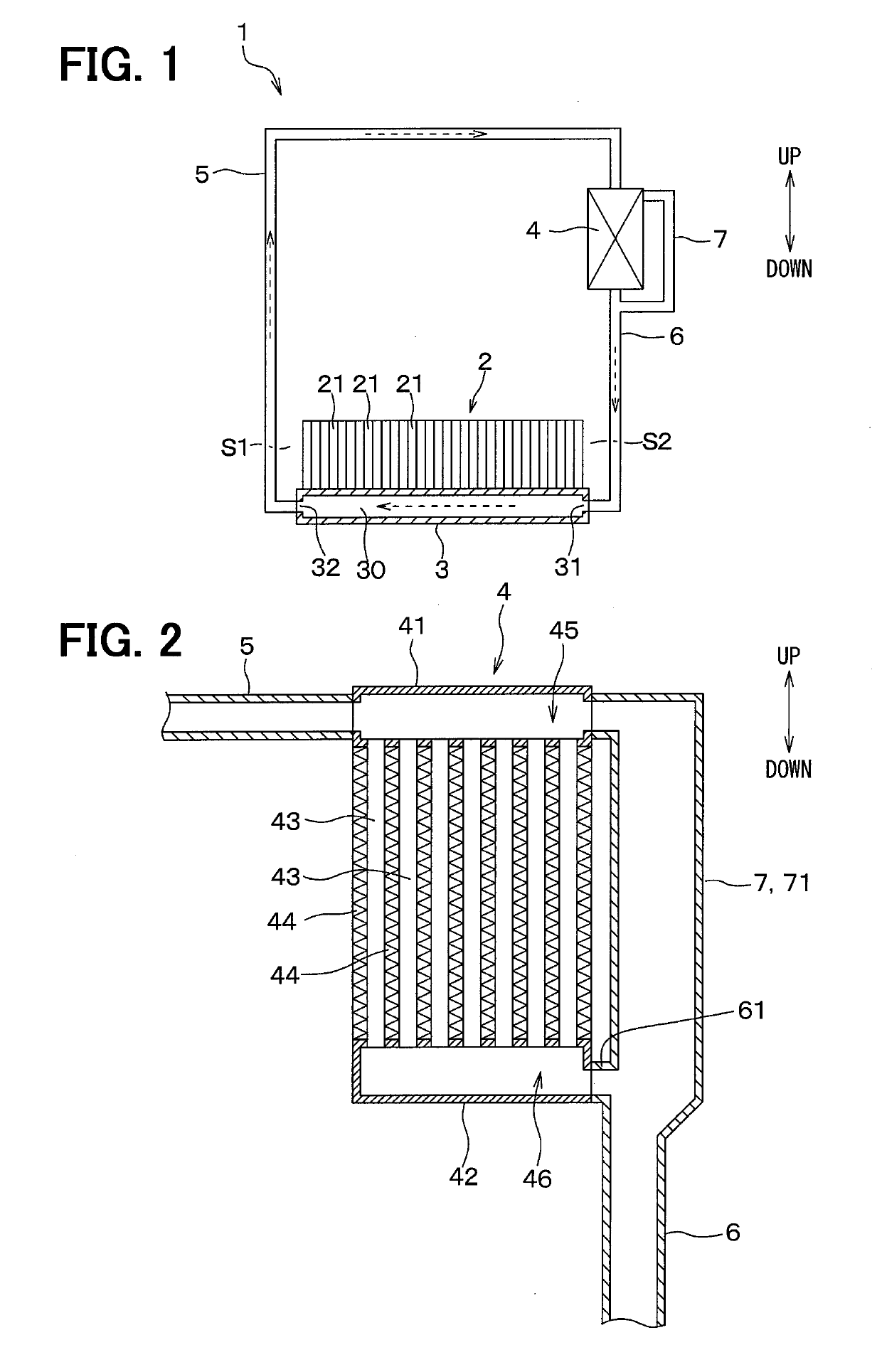

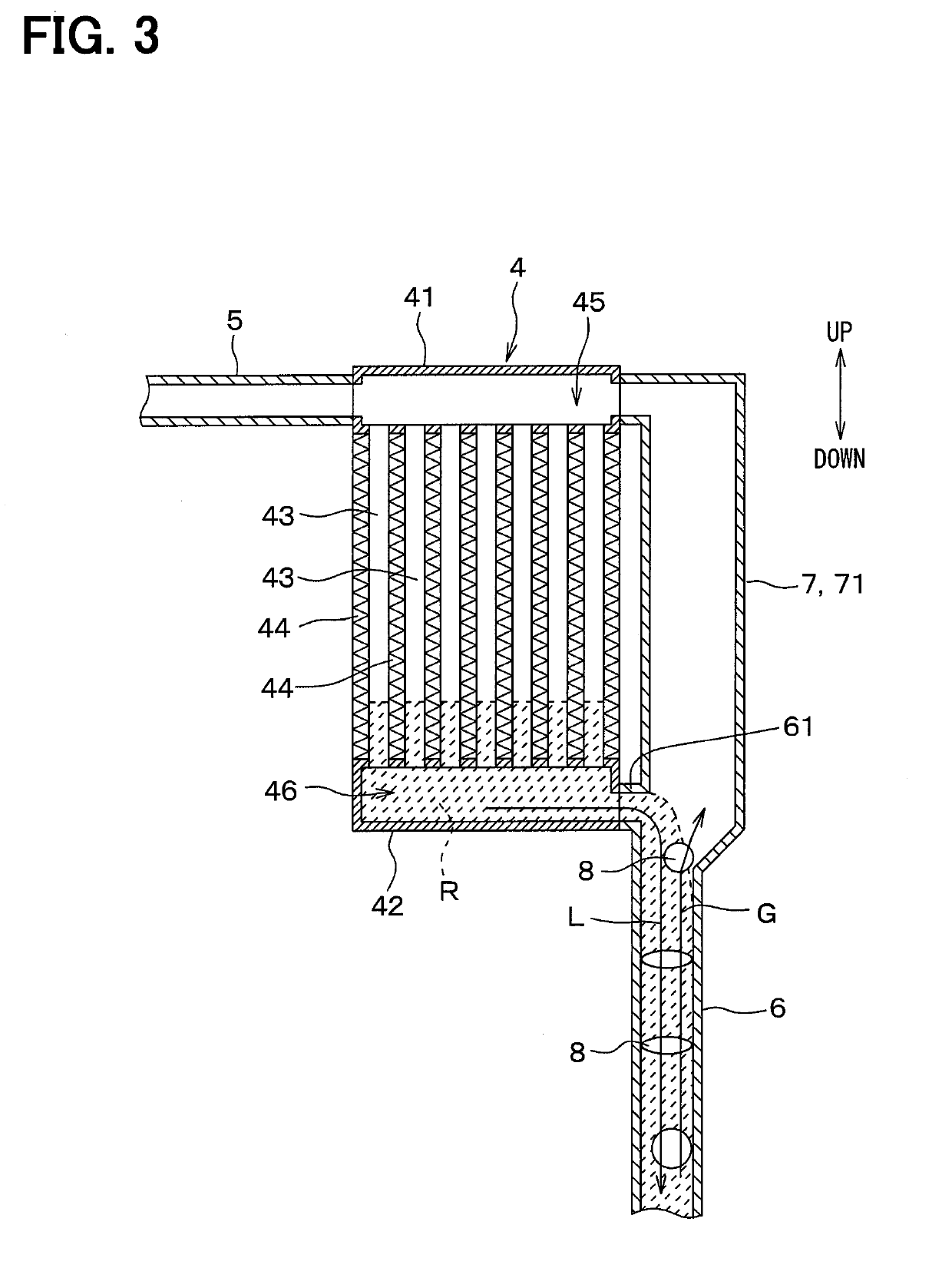

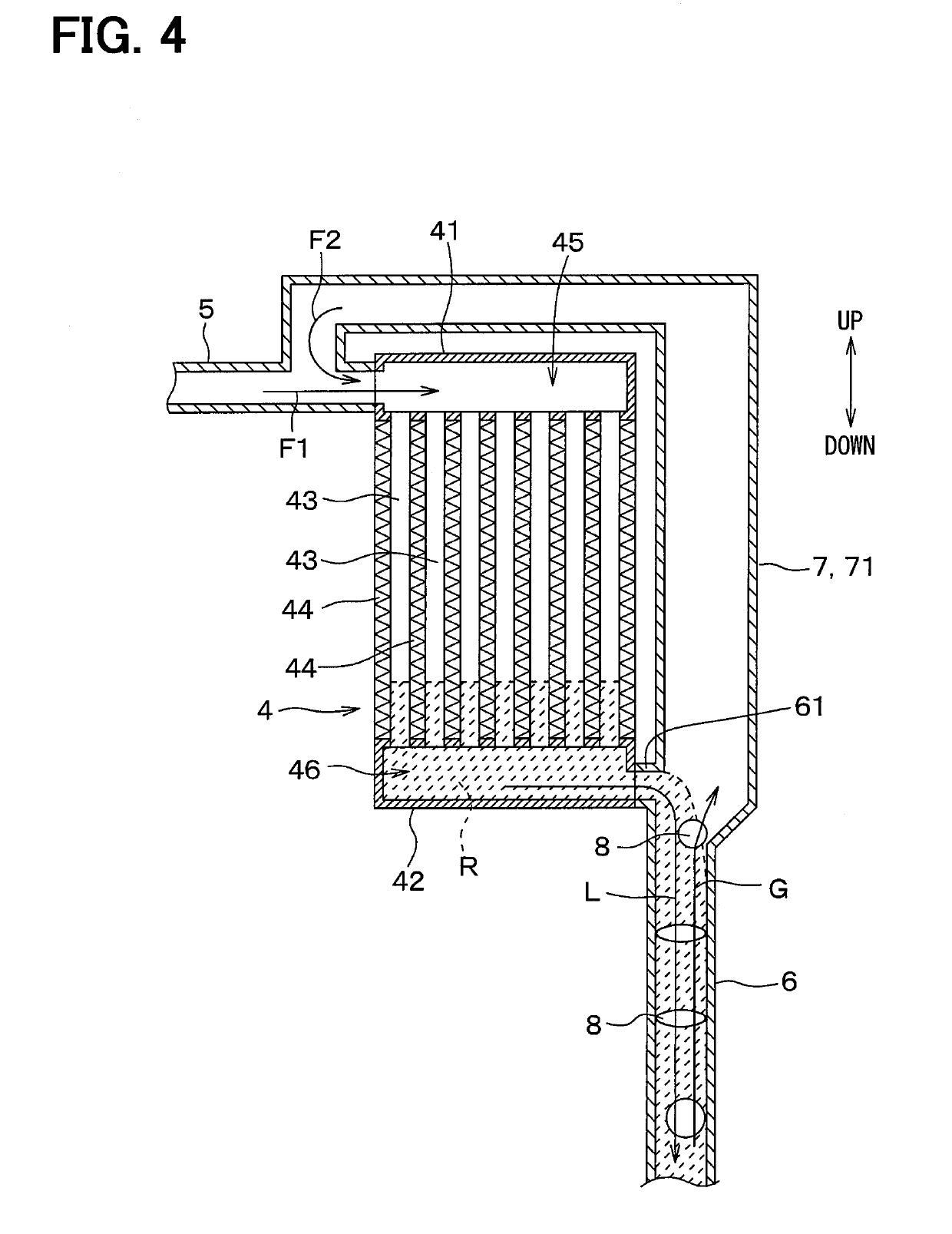

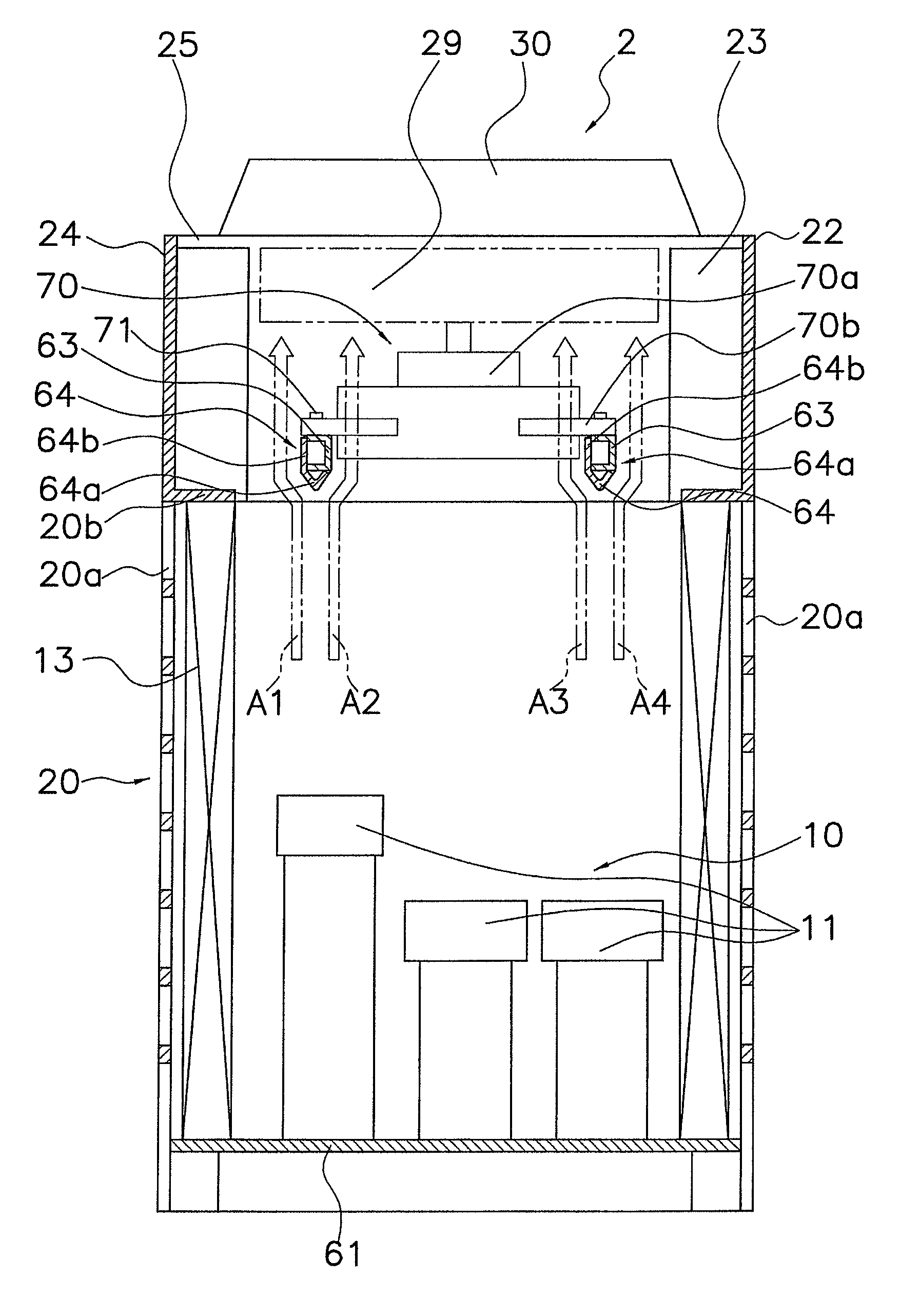

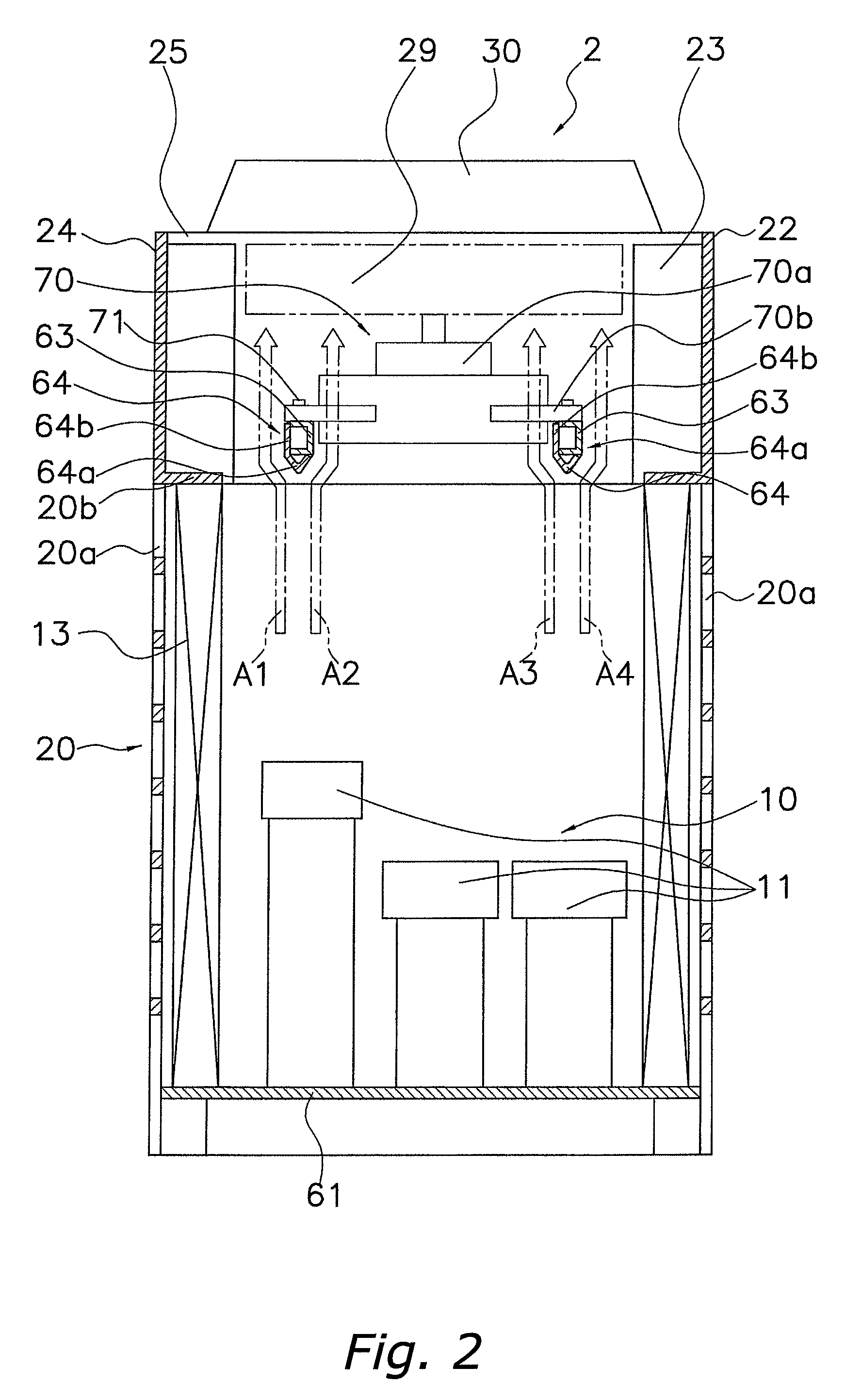

Device temperature regulator

InactiveUS20190204014A1Suppresses the generation of abnormal noiseImprove cooling effectSecondary cellsIndirect heat exchangersWorking fluidGas phase

An evaporator includes a fluid chamber in which a working fluid flows. A condenser includes a gas-phase portion in which the working fluid evaporated in the evaporator flows and a liquid-phase portion in which the working fluid from the gas-phase portion, condensed by heat exchange with an external medium, flows. A gas-phase passage causes the working fluid evaporated in the evaporator to flow to the condenser. A liquid-phase passage causes the working fluid condensed in the condenser to flow to the evaporator. A bypass passage has one end connected to the liquid-phase portion of the condenser or the liquid-phase passage and another end connected to the gas-phase portion of the condenser or the gas-phase passage. A flow rate of a liquid-phase working fluid per unit volume in the bypass passage is smaller than a flow rate of a liquid-phase working fluid per unit volume in the liquid-phase portion of the condenser or the liquid-phase passage.

Owner:DENSO CORP

Vehicle seat

ActiveUS9688231B2Suppresses the generation of abnormal noiseSuppress damage to the respective webbingsSeat coveringsPedestrian/occupant safety arrangementEngineeringAirbag

A vehicle seat includes: a seat frame; a seat cover provided with a rupture portion; an airbag disposed in the seat; a pair of webbings provided so as to surround the airbag on a back surface side of the seat cover, one end sides of the webbings being mounted to the rupture portion; and a mounting section mounting the other end sides of the webbings to the seat frame. In a vehicle collision, the airbag is protruded out of the seat by rupturing and opening the rupture portion. The mounting section is provided at a place where a body of the seat frame is disposed. When the airbag is uninflated, the mounting section holds the other ends of the webbings apart from the body of the seat frame, and an inhibition portion in the mounting section inhibits contact between an edge-shaped portion formed in the body and the webbings.

Owner:TOYOTA BOSHOKU KK +1

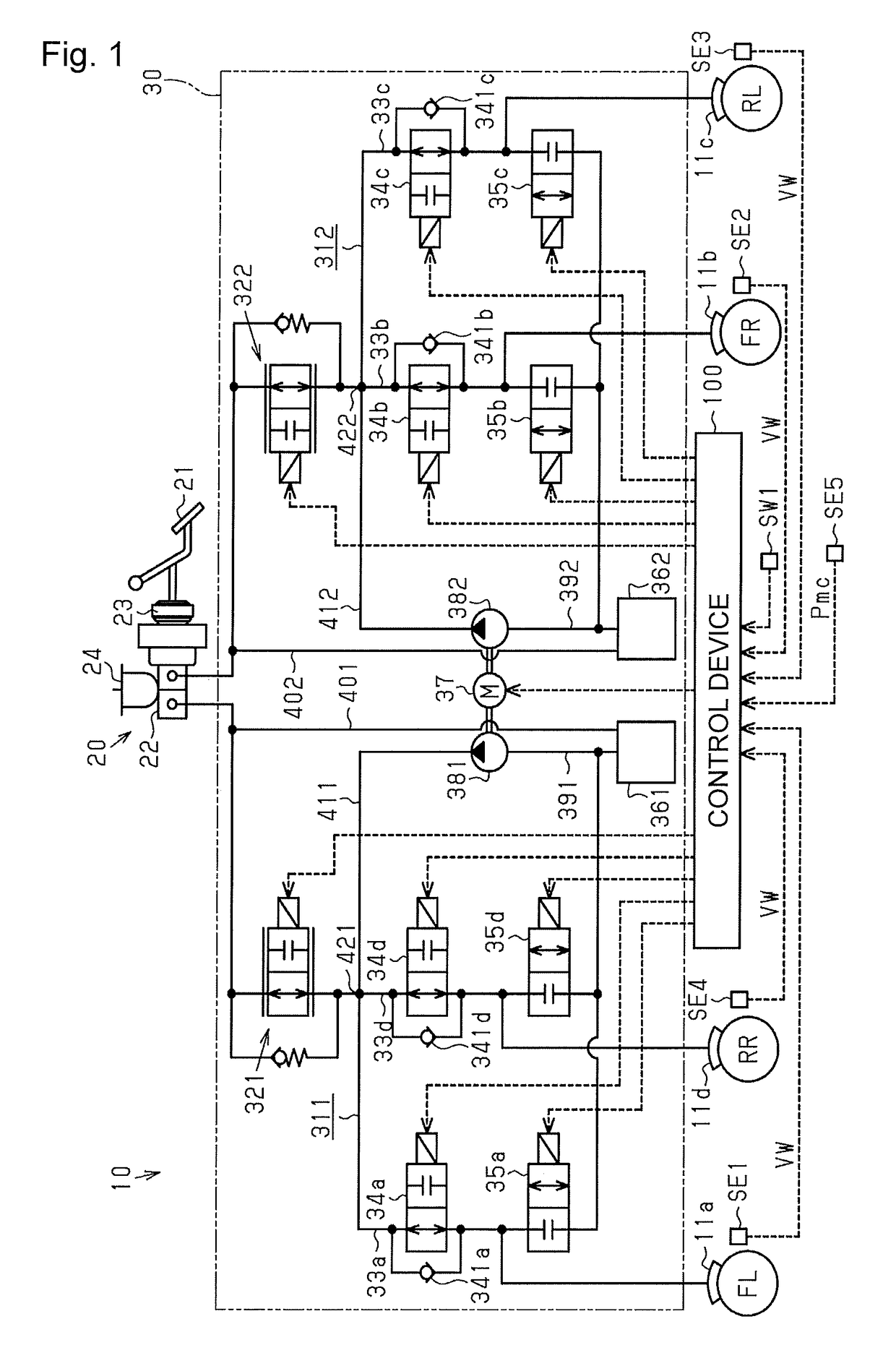

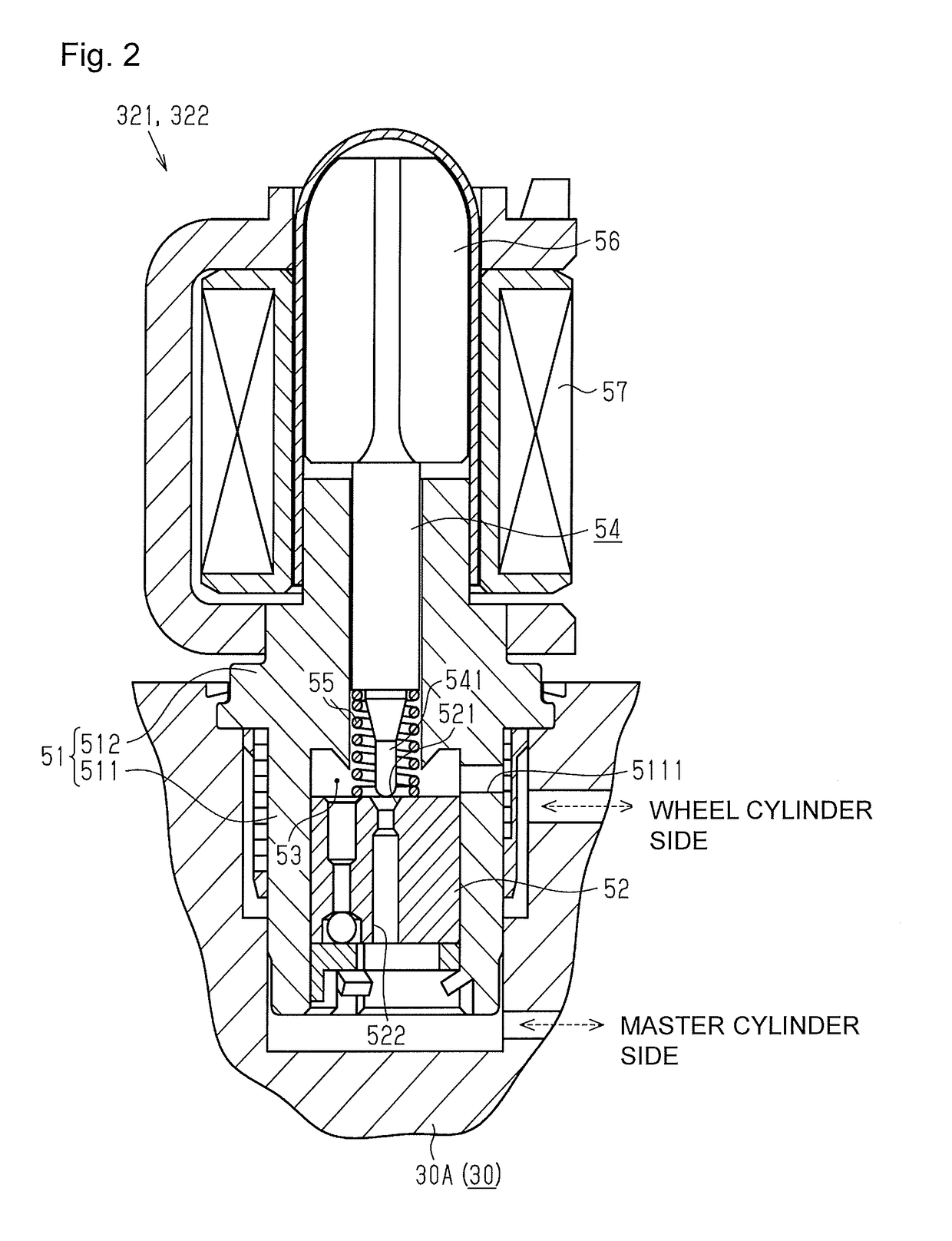

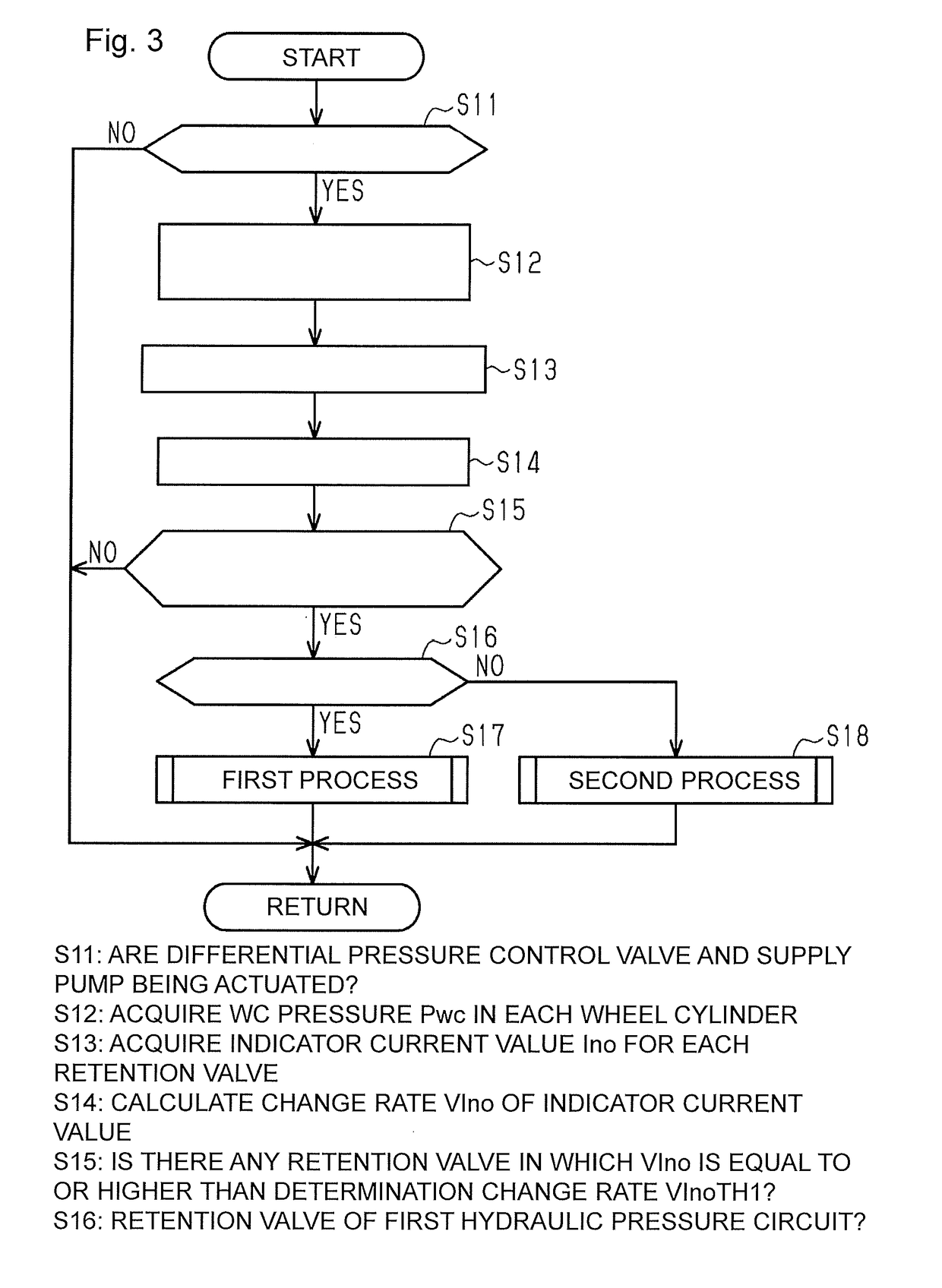

Hydraulic control device for vehicles

ActiveUS20180339684A1Increase rate of changeHigh strengthOperating means/releasing devices for valvesBraking action transmissionSelf excitedDifferential pressure

In the present invention, a brake device is equipped with: differential pressure control valves; pressure adjusting units which are connected to the differential pressure control valves through liquid passages; and a control device which controls the WC pressure Pwc in wheel cylinders by operating the differential pressure control valves and the pressure adjusting units. When predetermined suppression control permission conditions are satisfied while both the supply pumps of the pressure adjusting units and the differential pressure control valves are in operation, the control device performs self-excited vibration suppression control over the differential pressure control valves, the self-excited vibration suppression control being carried out in such a manner that a valve element separated from a valve seat is caused to abut on the valve seat, and, upon abutting on the valve seat, the valve element is separated from the valve seat.

Owner:ADVICS CO LTD

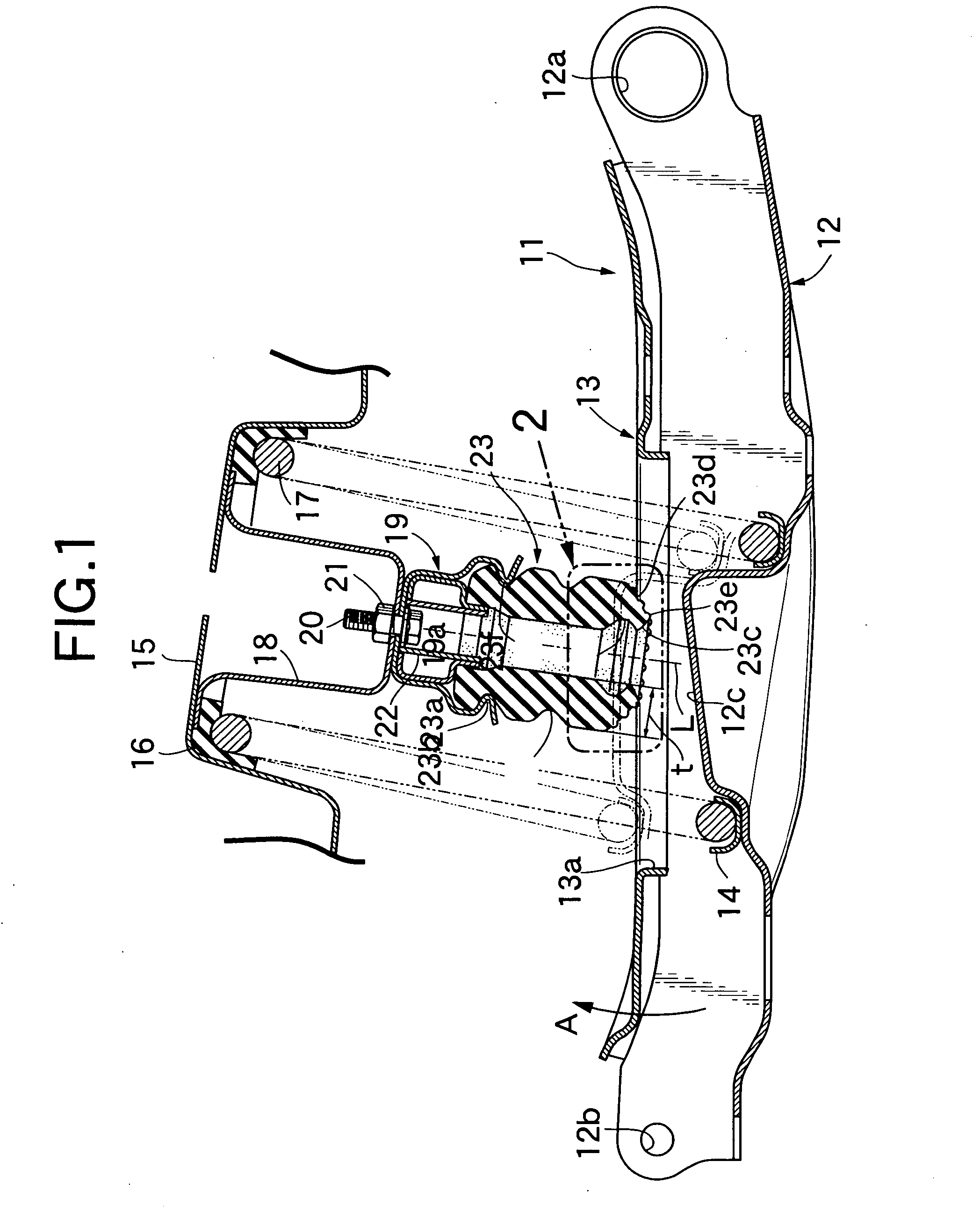

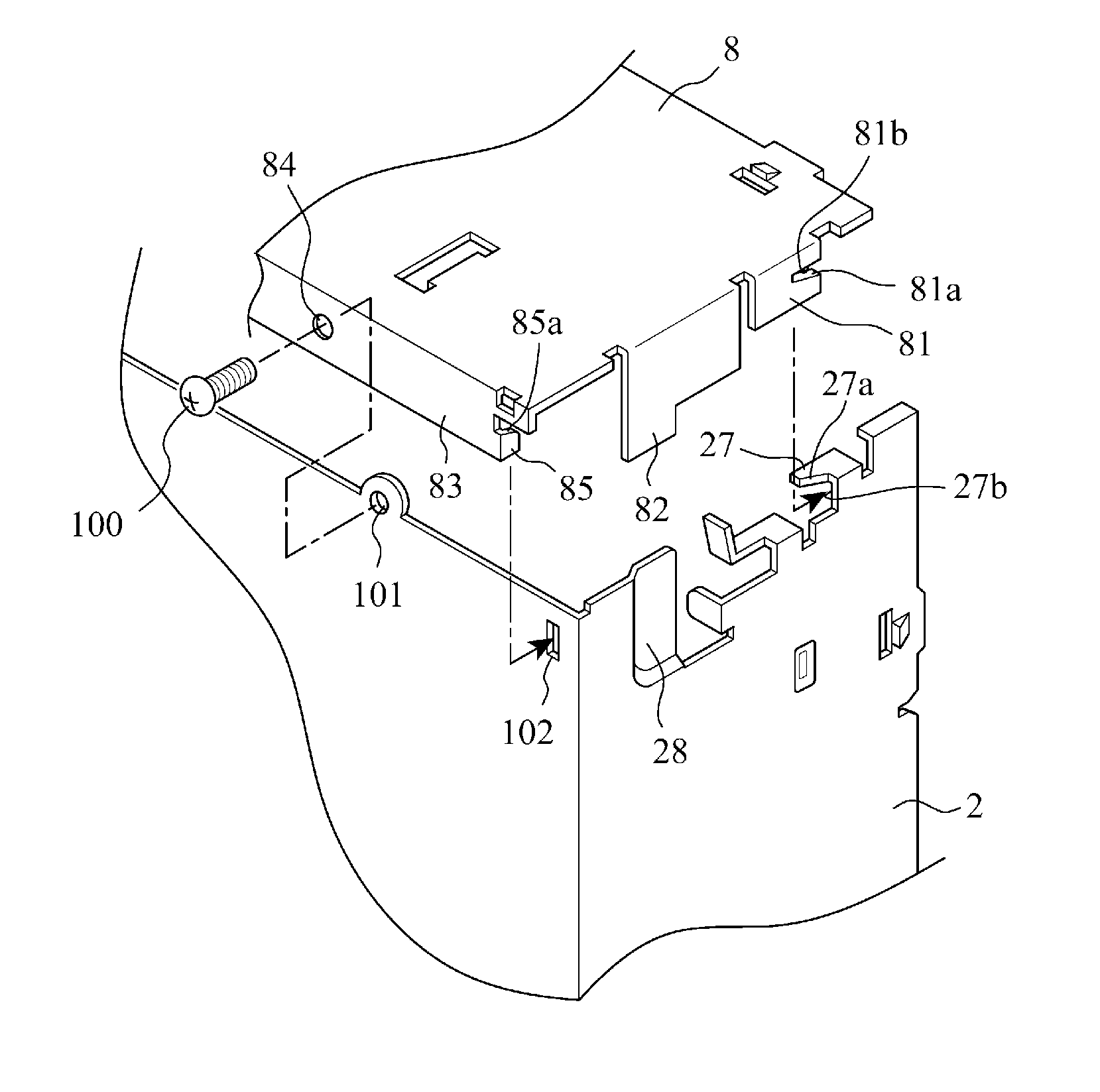

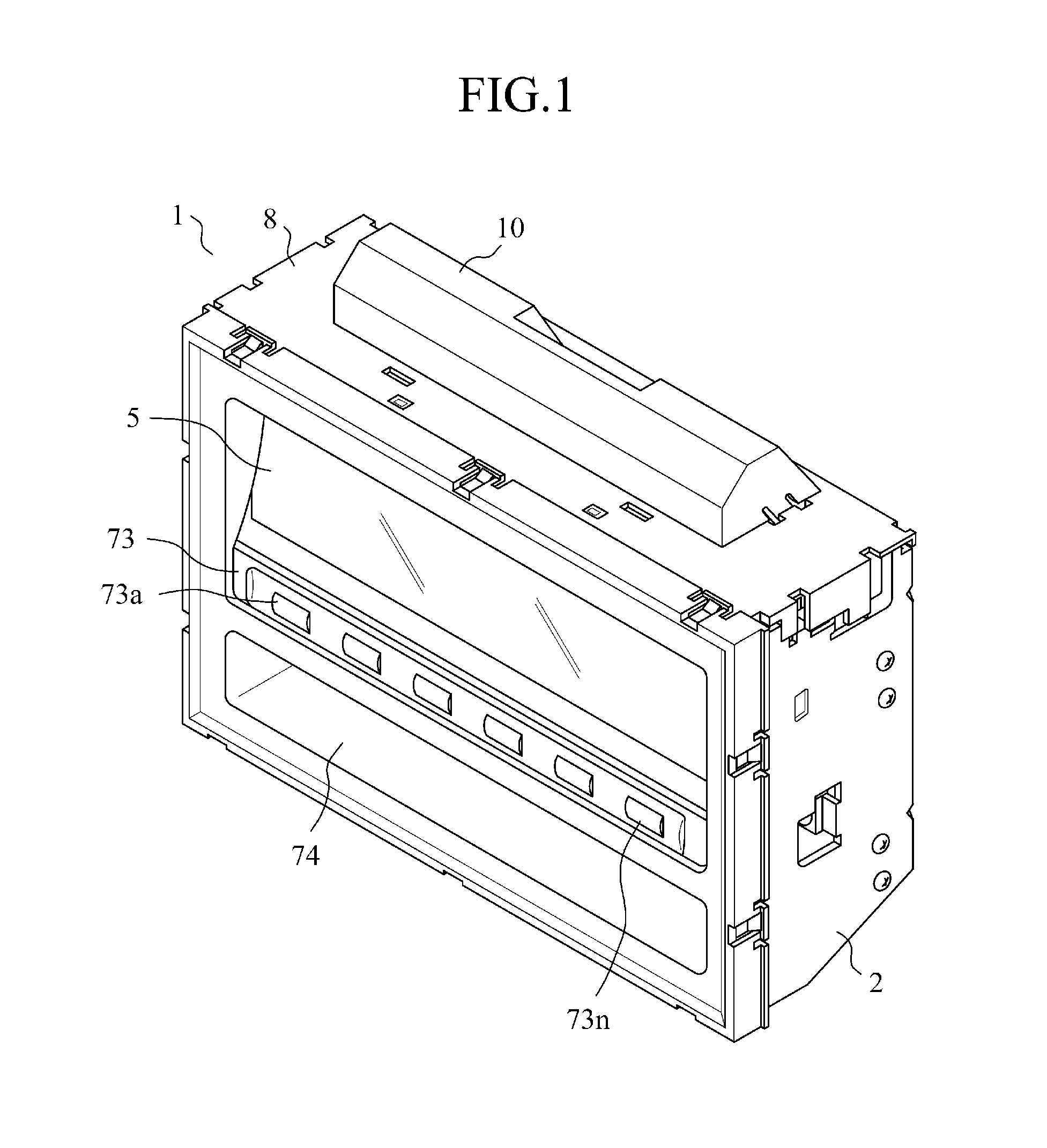

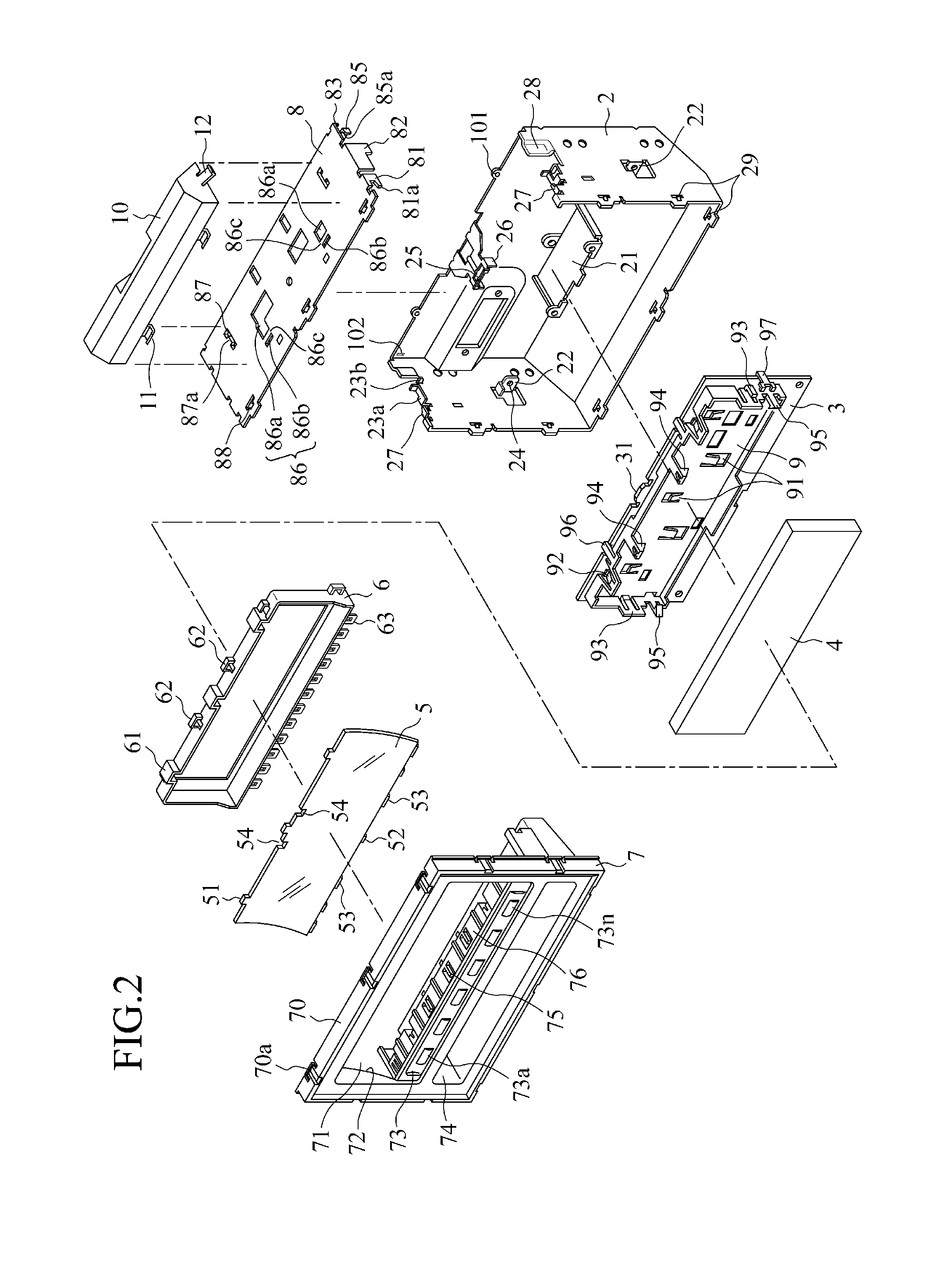

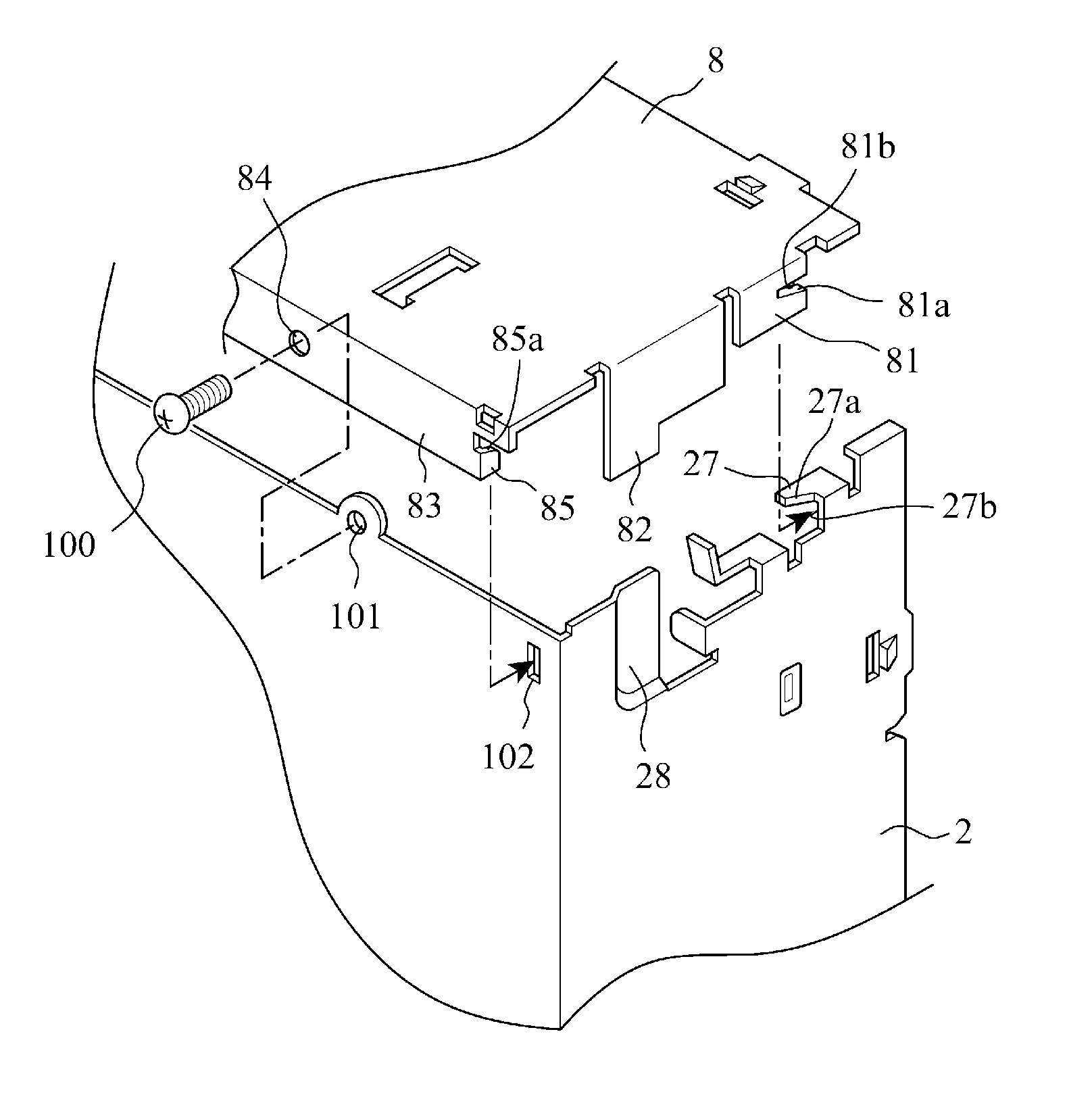

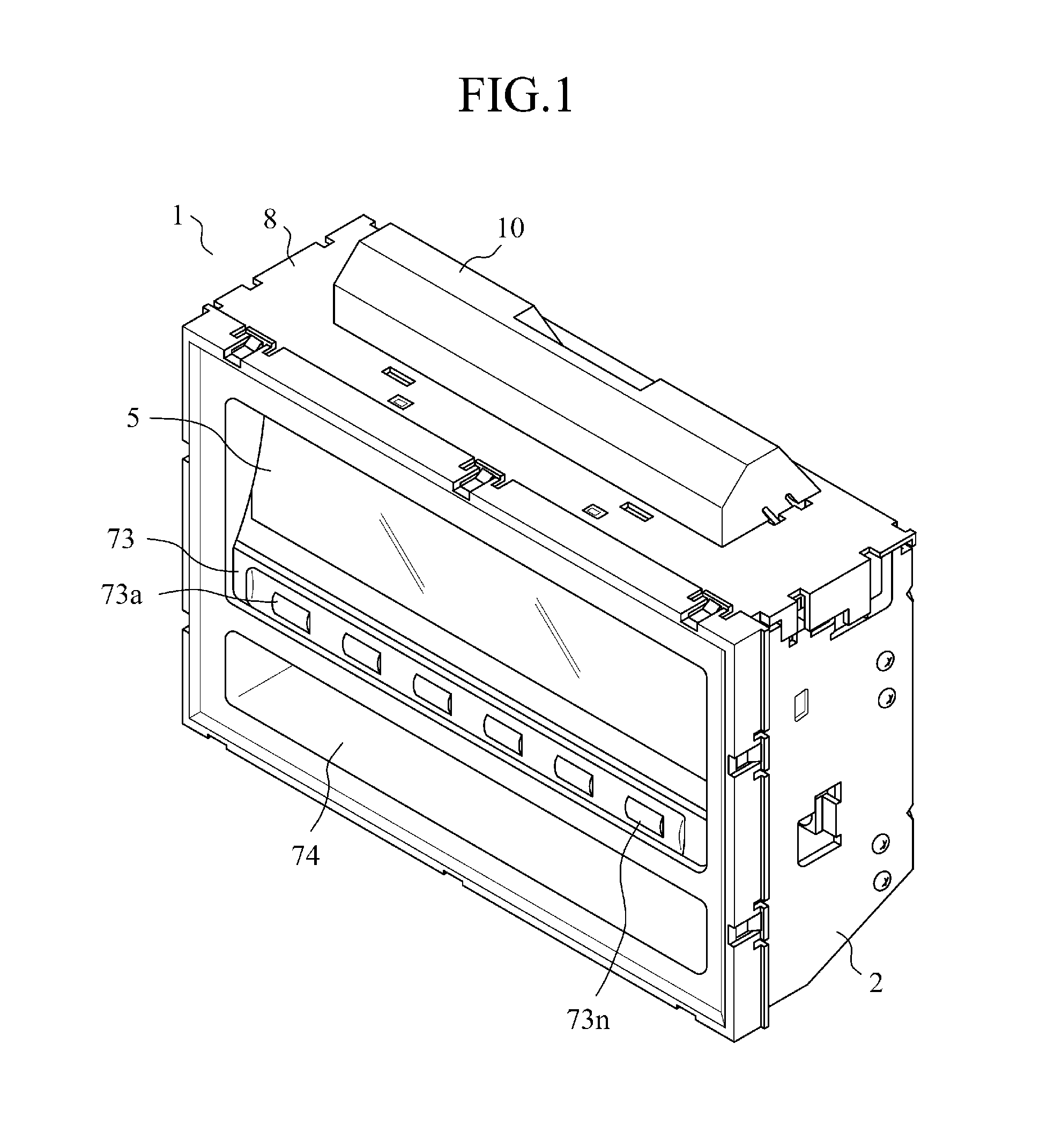

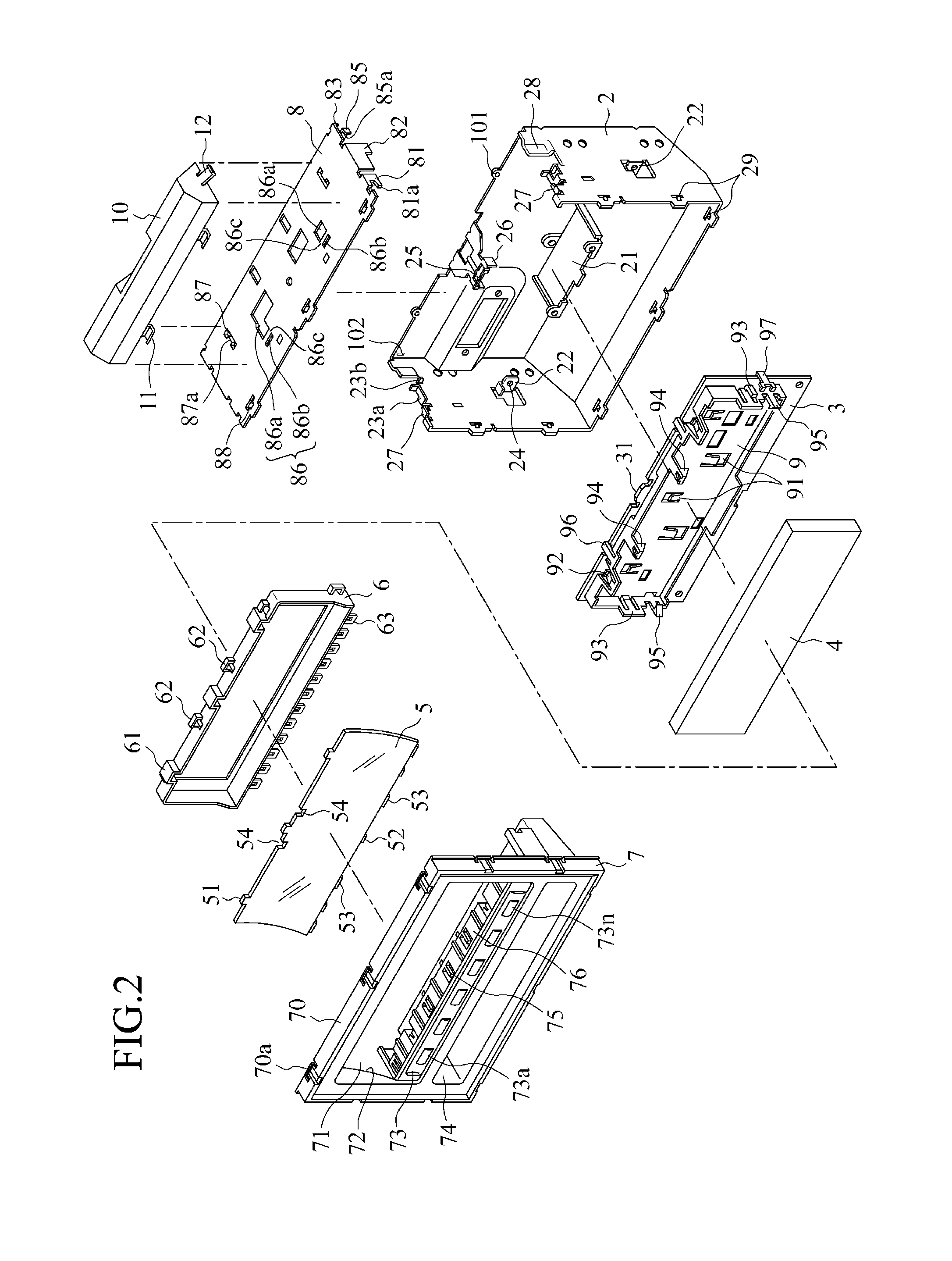

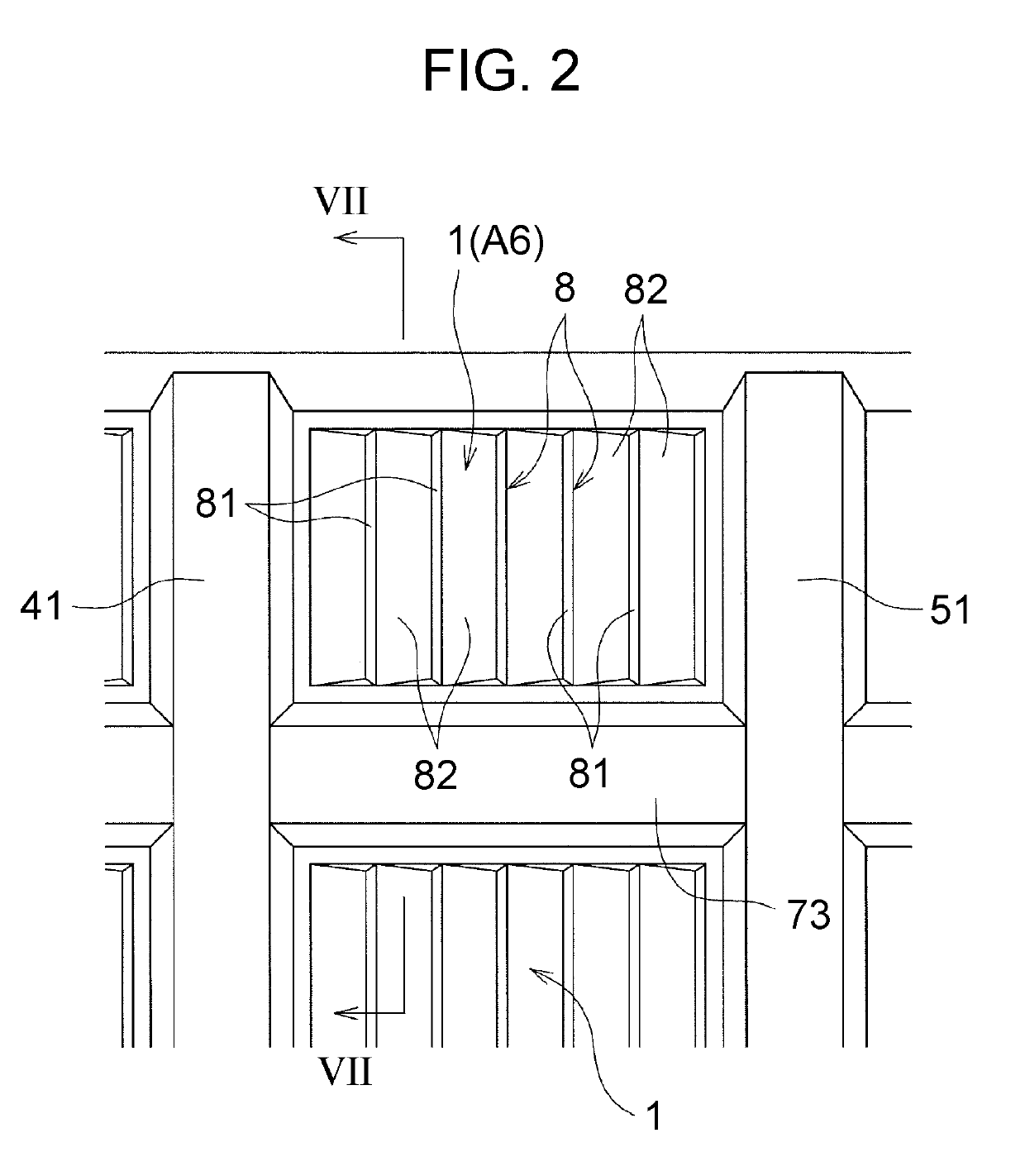

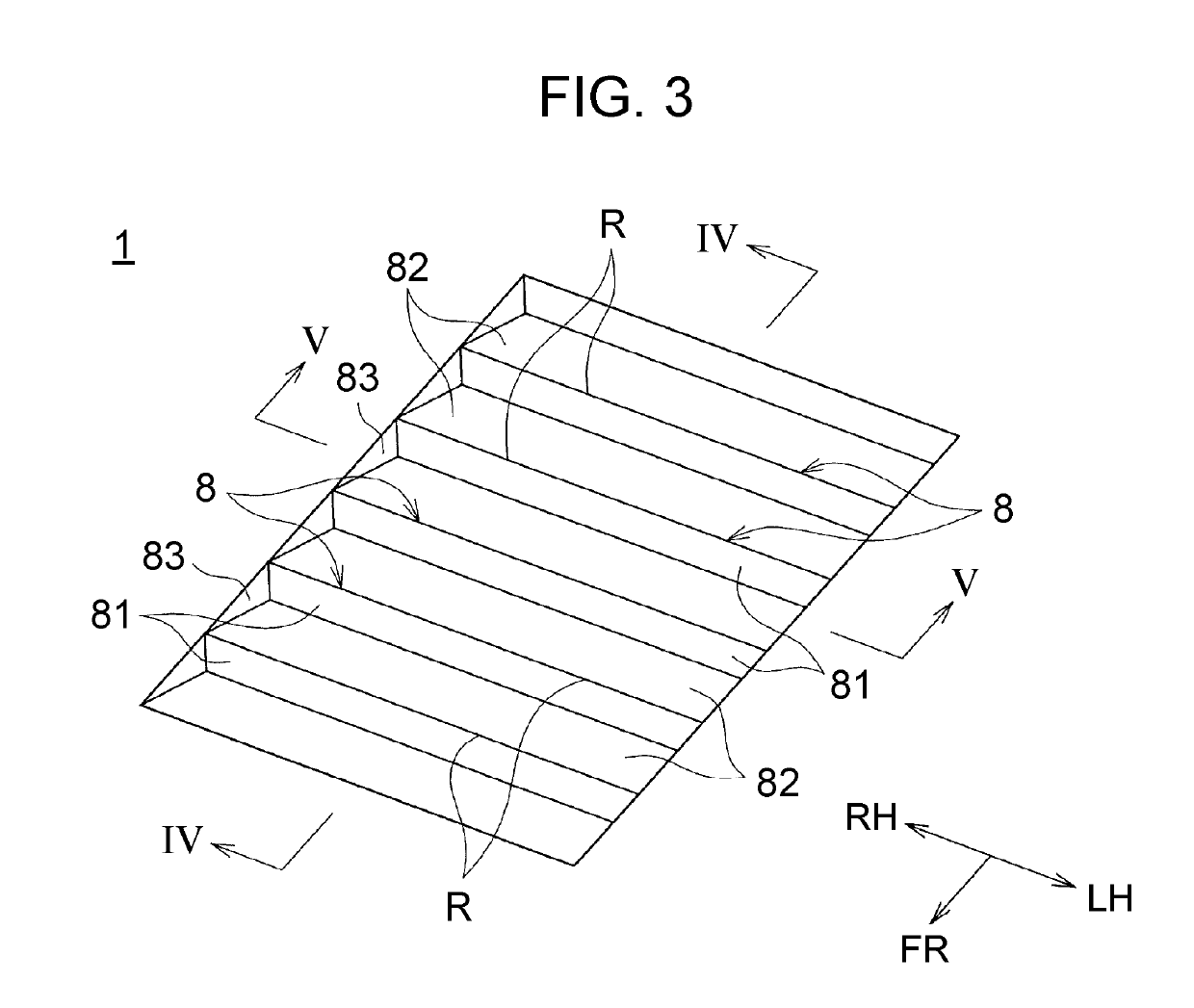

Structure for fastening metallic plate parts together

ActiveUS8273999B2Avoid generatingImprove abilitiesClosed casingsRopes and cables for vehicles/pulleyClassical mechanicsScrew thread

A chassis 2 as a first sheet-metal part has an L-shaped hooking section 27 formed at a cover mounting opening end of each side plate thereof, and an assembly guide section 28 dimpling inwardly the opening end of the chassis 2 by the thickness of a cover 8; the cover 8 as a second sheet-metal part has a hooking claw 81 extending from each side edge of the cover to the mounting side thereof and engaging with the L-shaped hooking section 27, and a guide lug 82 engaging with the assembly guide section 28, wherein an engaging claw 85 and an engaging hole 102, and a tapped hole 101 and a screw passing-through hole 84 are relatively provided on the abutment faces between the chassis 2 and the cover 8, respectively.

Owner:MITSUBISHI ELECTRIC CORP

Structure for fastening metallic plate parts together

ActiveUS20110229258A1Avoid generatingPrevent looseningClosed casingsCouplings for rigid shaftsEngineeringHooking

A chassis 2 as a first sheet-metal part has an L-shaped hooking section 27 formed at a cover mounting opening end of each side plate thereof, and an assembly guide section 28 dimpling inwardly the opening end of the chassis 2 by the thickness of a cover 8; the cover 8 as a second sheet-metal part has a hooking claw 81 extending from each side edge of the cover to the mounting side thereof and engaging with the L-shaped hooking section 27, and a guide lug 82 engaging with the assembly guide section 28, wherein an engaging claw 85 and an engaging hole 102, and a tapped hole 101 and a screw passing-through hole 84 are relatively provided on the abutment faces between the chassis 2 and the cover 8, respectively.

Owner:MITSUBISHI ELECTRIC CORP

Outdoor unit of air conditioner

InactiveUS7963121B2Reduce resistanceWind whistling sound is also reducedEvaporators/condensersNoise suppressionEngineeringHeat exchanger

An outdoor unit of an air conditioner is provided in which a wind whistling sound and a vibration noise due to airflow are reduced. The outdoor unit includes an outdoor heat exchanger, a fan, a motor for driving the fan, and a motor support table for supporting the motor. The fan moves air on the outdoor heat exchanger to promote heat exchange between refrigerant and air. The motor support table (63) is provided with a rectifying member, and the rectifying member deflects air flowing toward the motor support table in a predetermined direction.

Owner:DAIKIN IND LTD

Controller for brushless motor

ActiveUS7112933B1Suppresses the generation of abnormal noiseSuppress increase in calculation loadSingle-phase induction motor startersSynchronous motors startersBrushless motorsEngineering

In a controller for brushless motor which suppresses the generation of abnormal noise when the motor current is controlled by updating voltages applied to the coils, the present values of the applied voltages to the coils are calculated from the d axis target current, the q axis target current, the d axis actual current, the q axis actual current, and the present value of the detected rotational position of the rotor. The updating period of the applied voltages is set as a period that is shorter than this calculation period. The predicted value of the rotational position at a point in time at which the applied voltages are updated until the next calculation of the present values of the applied voltages is determined in accordance with the present value, a past value of the detected rotational position, and the applied voltage updating period. The predicted values of the applied voltages are calculated from the predicted value of the rotational position, the d axis target current, the q axis target current, the d axis actual current, and the q axis actual current. The applied voltages are updated in accordance with the present values and predicted values of the applied voltages.

Owner:JTEKT CORP

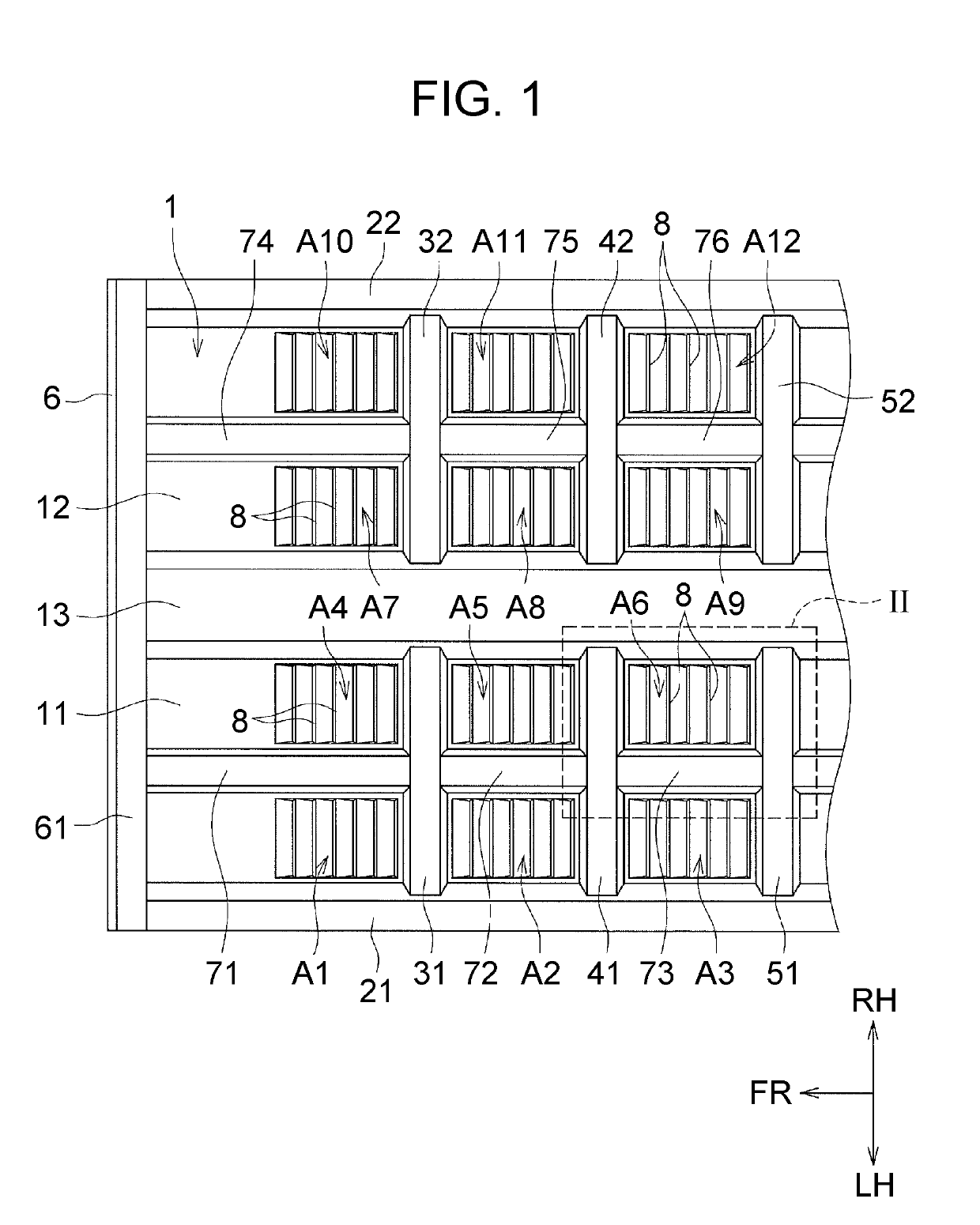

Vehicle body floor structure

ActiveUS20190168690A1Suppresses the generation of abnormal noiseReduce vibrationSuperstructure subunitsMechanical engineeringEngineering

A vehicle body floor structure includes: a plurality of first vehicle body framework members extending along a vehicle body front-rear direction; a plurality of second vehicle body framework members extending along a vehicle width direction; a floor panel to which each of the first vehicle body framework members and the second vehicle body framework members is joined; and a vibration damping material that is applied to a surface of the floor panel. The floor panel includes a plurality of steps having ridge lines extending along a short-side direction of a first region. The first region is surrounded by the first vehicle body framework members and the second vehicle body framework members. The vibration damping material is applied along at least one outer edge portion of the first region.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com