High temperature cathode for plasma etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

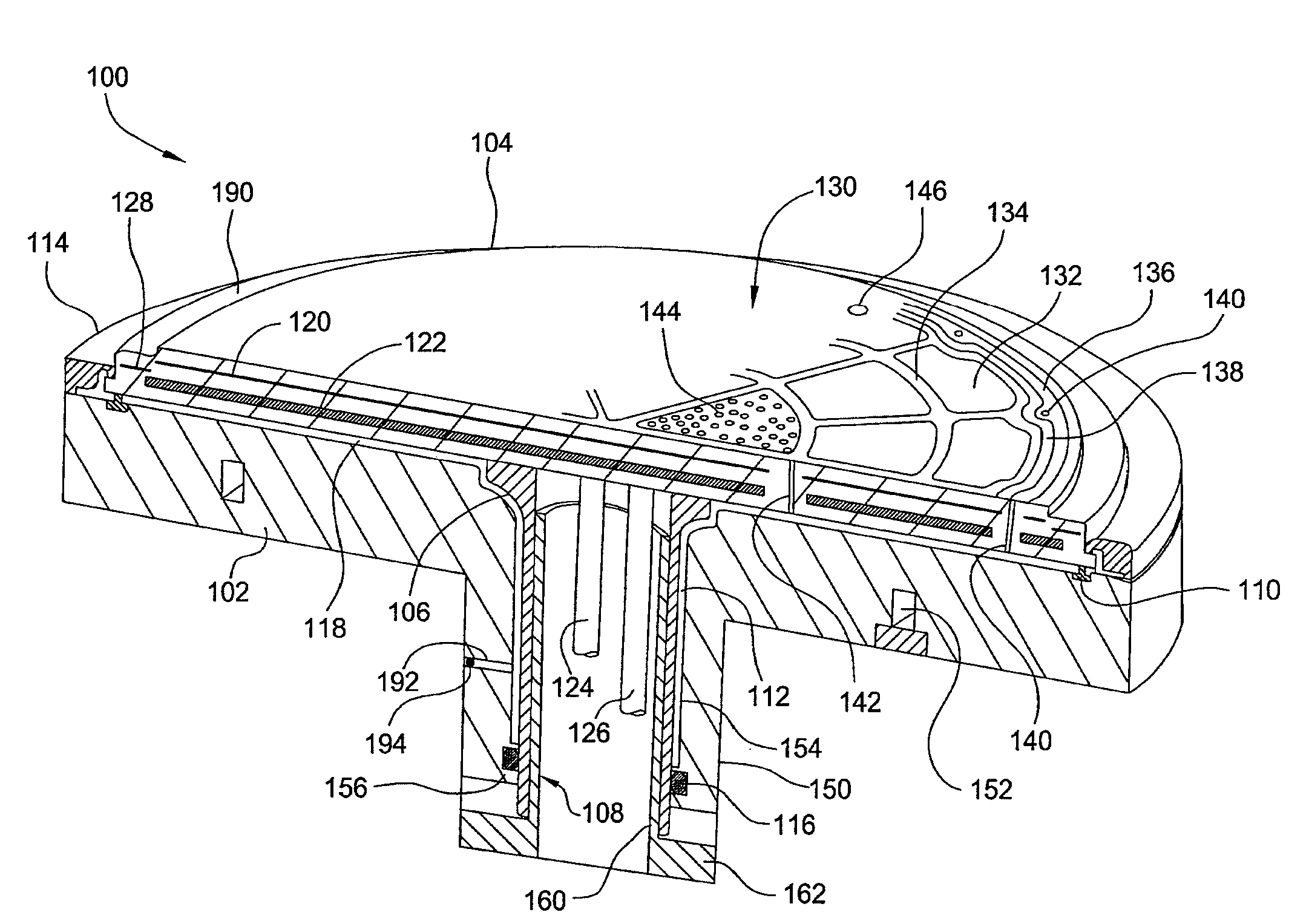

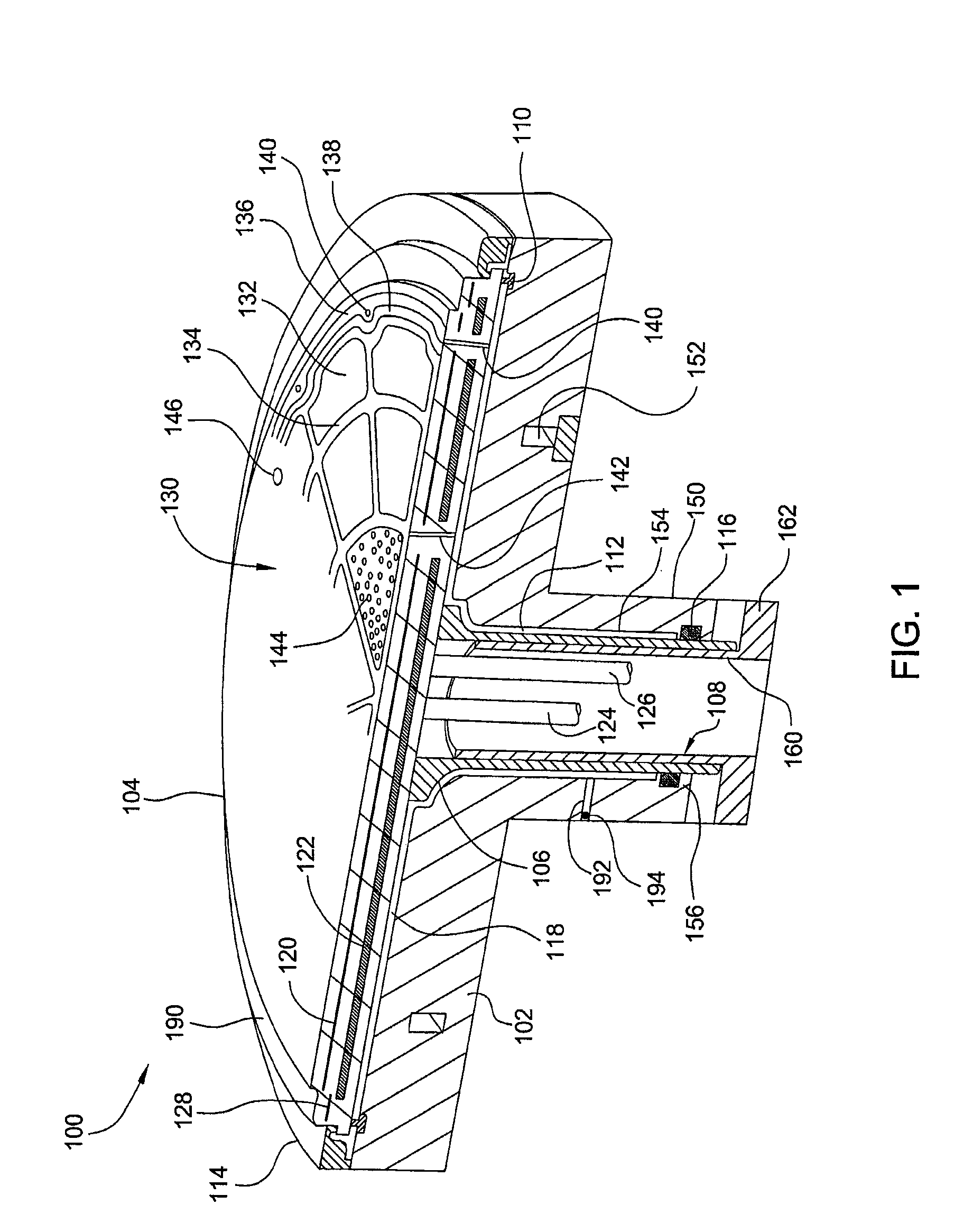

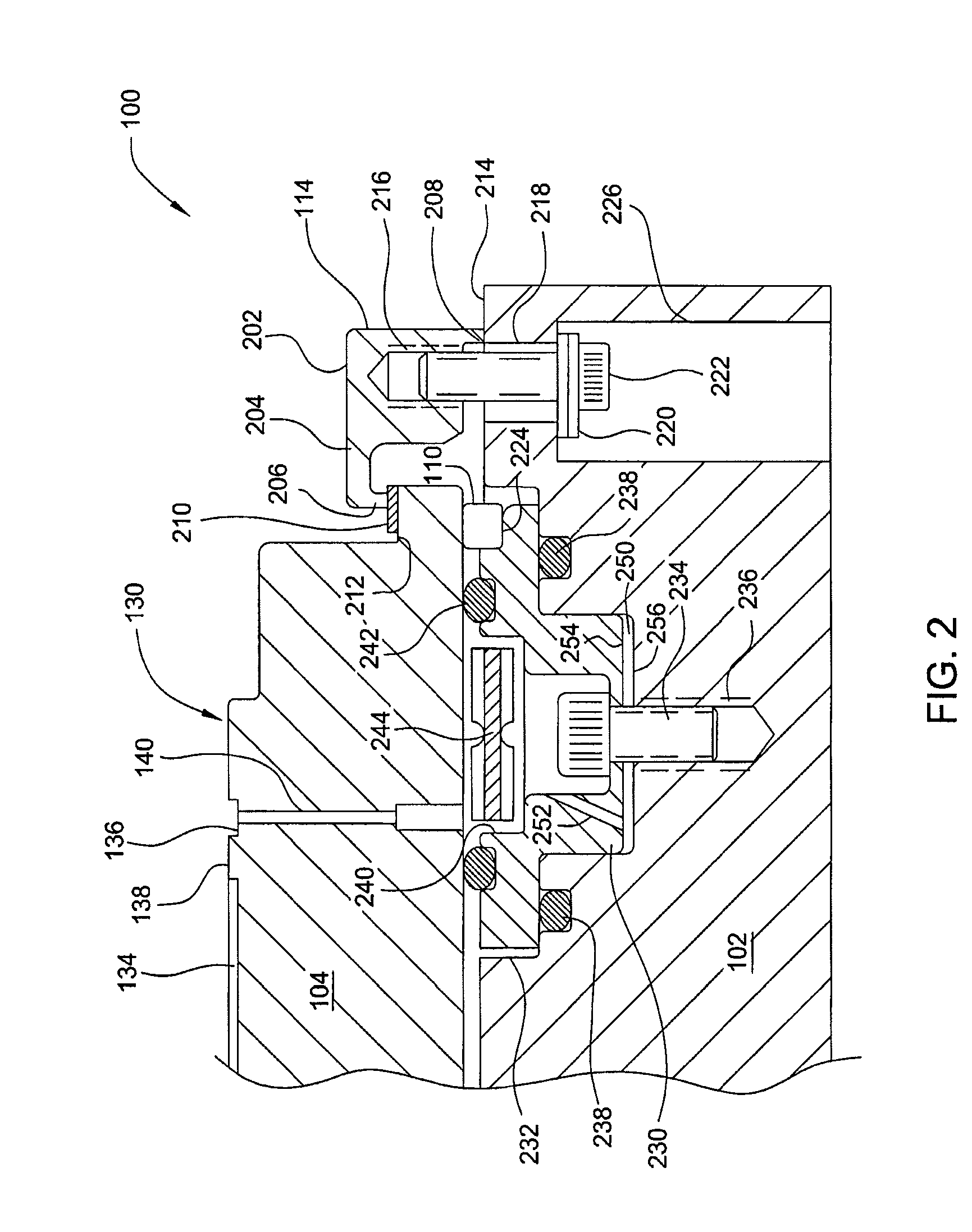

[0030]FIG. 1 is a sectional isometric view of one embodiment of a high temperature cathode 100 suitable for plasma etching. The cathode 100 may be advantageously utilized in plasma etch reactors, such as the AdvantEdge™ Etch reactor, available from Applied Materials, Inc., of Santa Clara, Calif., among other etch reactors, including suitable reactors available from other manufacturers.

[0031]FIG. 1 is one embodiment of a cathode 100. The cathode 100 generally includes an electrostatic chuck 104 secured to a cooling base 102. A stem 106 extends from a bottom of the electrostatic chuck 104. The stem 106 may be coupled to the electrostatic chuck 104 by braising or other suitable method. The stem 106 is generally fabricated from a conductive material such as stainless steel.

[0032]The electrostatic chuck 104 is supported above the cooling base 102 in a spaced-apart relation. In the embodiment depicted in FIG. 1, a support ring 110 is provided between the cooling base 102 and electrostatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com