Multi-purpose panels with a modular edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In the following description, similar features in the drawings have been given identical reference numerals where appropriate. All dimensions described herein are intended solely to illustrate an embodiment. These dimensions are not intended to limit the scope of the wafer described herein, which can depart from these dimensions.

[0047]An embodiment is illustrated and described in context of providing a modular edge system for temporary surface used to distribute the load of workers, equipment and vehicles over a large surface area. However, it is contemplated that the modular edge system may be applied to any surface panel or wafer such as wall panels, ceiling panels, roofing, flooring, walkways or the like.

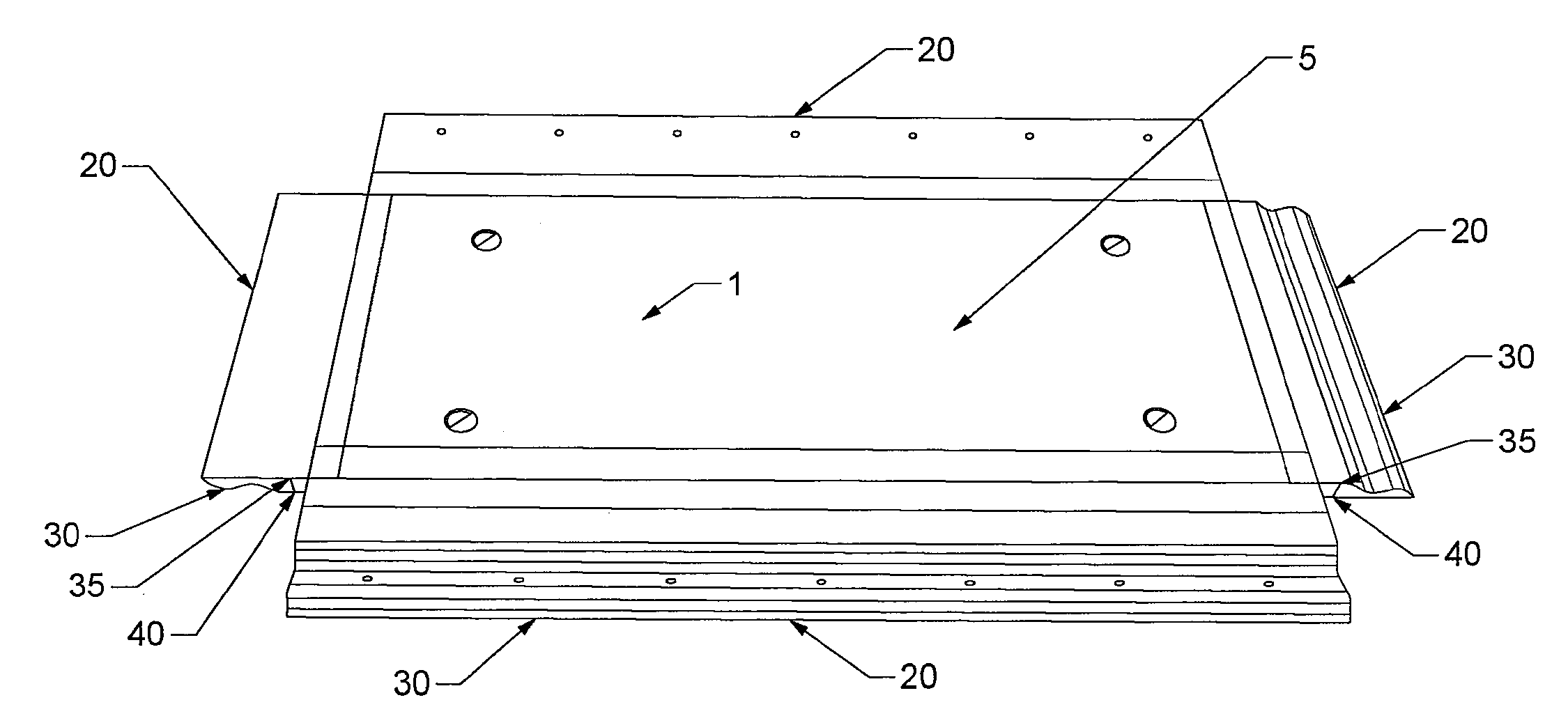

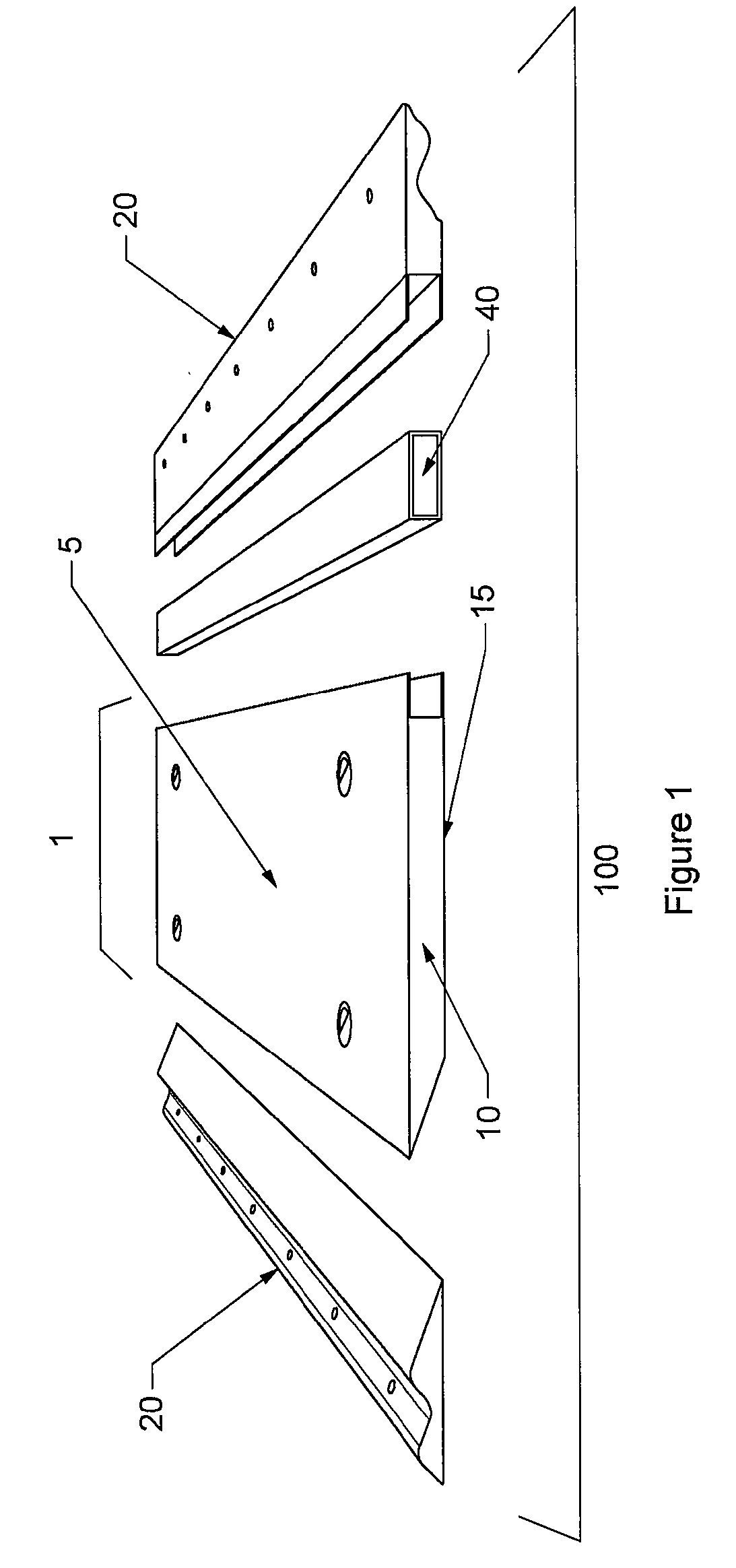

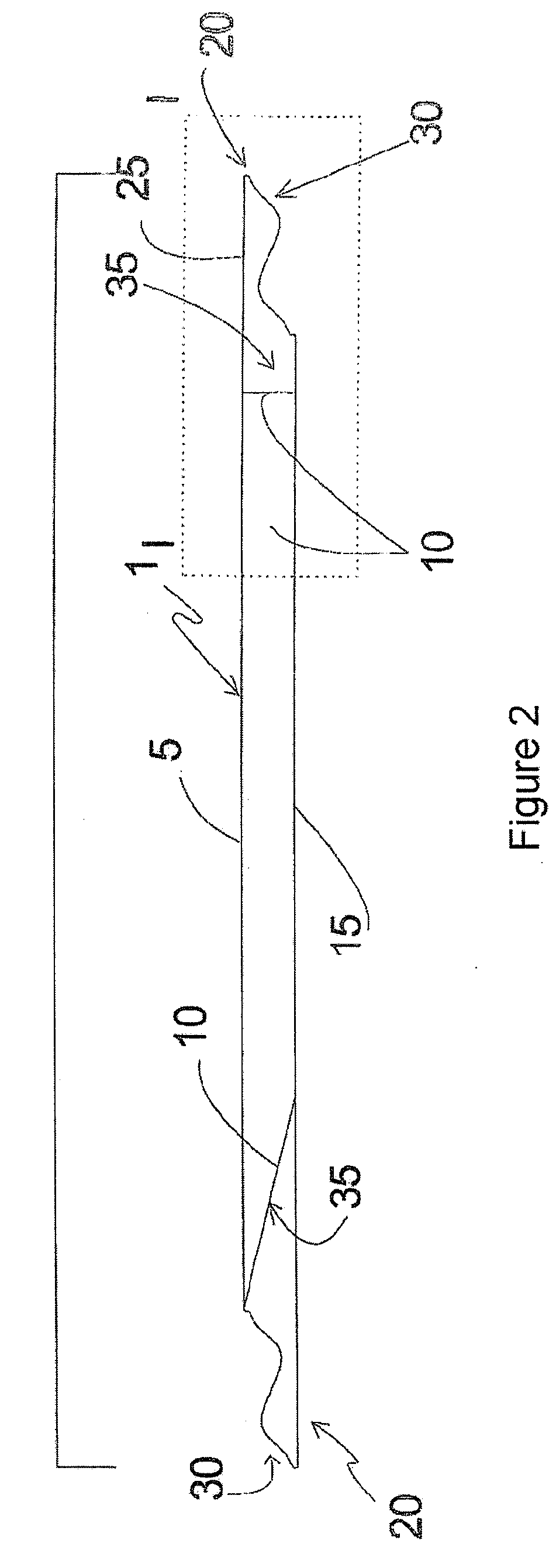

[0048]Referring to FIG. 1 and FIG. 2, there is illustrated a panel 100 according to one embodiment of the present invention having, a wafer 1, an upper wafer skin 5 and an opposing bottom wafer skin 15. Referring to FIG. 3 and FIG. 4, the wafer has at least three sides 10 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com