Sliding mechanism apparatus and appliance integrated with the same

a technology of sliding mechanism and sliding device, which is applied in the direction of electrical apparatus, substation equipment, telephone set construction, etc., can solve the problems of increasing the manufacturing cost of sliding device, extending the assembly time therefor, and not having any means of providing moving force, so as to reduce noise, smooth and stable sliding motion of slider, effect of alleviating contact impa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

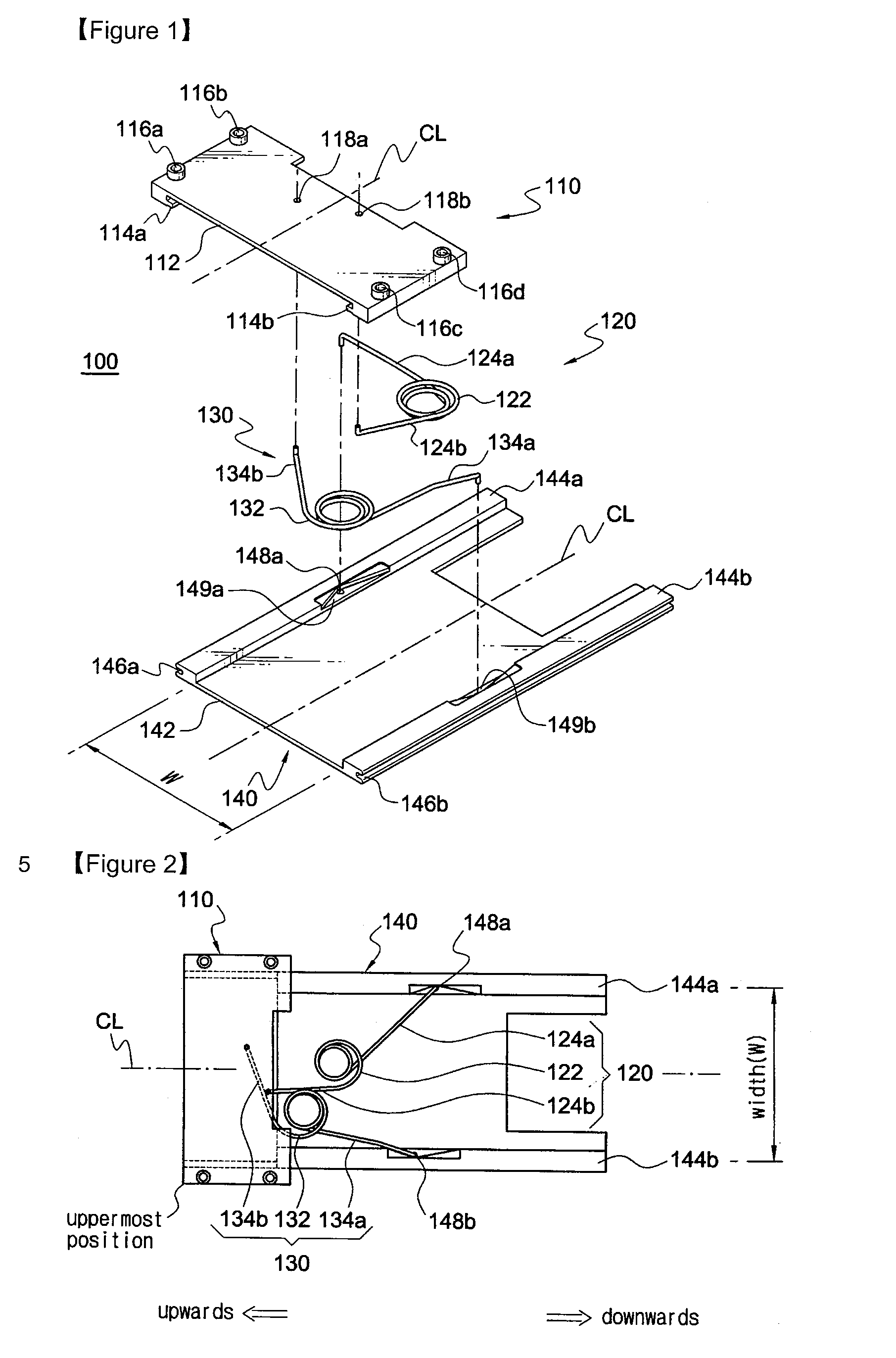

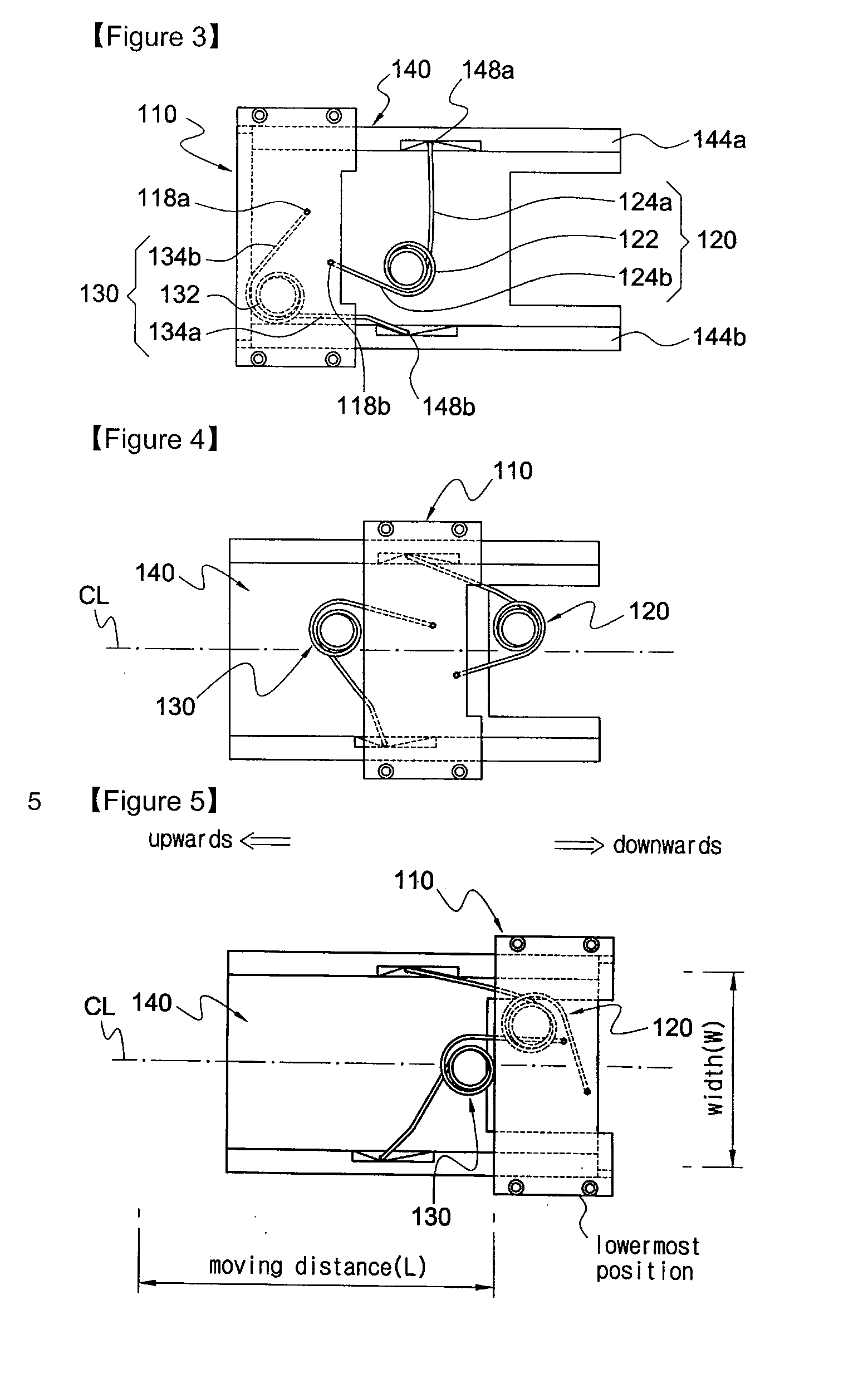

[0089]FIG. 1 is an exploded perspective view of a sliding mechanism apparatus according to the invention, where the sliding mechanism apparatus of the invention is denoted at 100. The sliding mechanism apparatus 100 of this embodiment includes a slider member 110, a first torsion spring 120, a second torsion spring 130, and a guide member 140.

[0090]The guide member 140 is comprised of a rectangular plate 142 and a first and second guide rails 144a and 144b elongated along both opposing parallel edges thereof. The first and second guide rails have a desired width and height respectively. In the outer face of the first guide rail 144a and the second guide rail 144b is formed respectively a first and second guide rail groove 146a, 146b in the longitudinal direction thereof. In addition, approximately in the middle of the first guide rail 144a is formed a V-shape groove 149a, and a connection hole 148a is formed at the apex of the V-shape groove 149a. Similarly, in the second guide rail...

fifth embodiment

[0130]On the other hand, the fifth embodiment as described above may be slightly modified into those constructions shown in FIGS. 22 and 23.

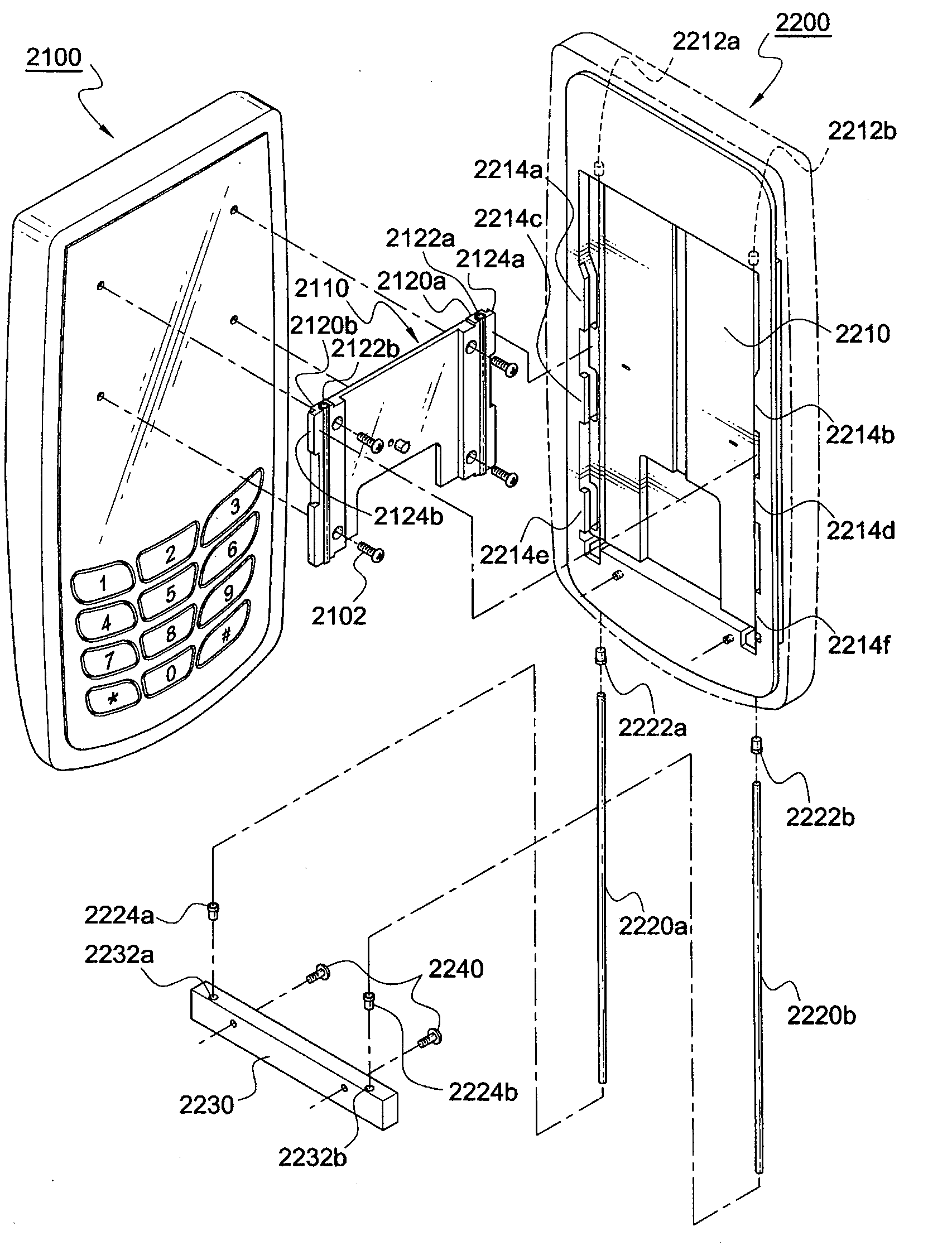

[0131]FIGS. 22 and 23 are respectively an exploded perspective view and an assembled cross-section of a sliding mechanism apparatus according to a sixth embodiment of the invention. As illustrated in FIGS. 22 and 23, a first and second slide-coupling hand 624a, 624b, which is provided in both sides of a rectangular base plate 622 in a slider member 620, is formed so as to be shorter than the length of the rectangular base plate 622, not over the entire length thereof. Thus, when in the uppermost or lowermost position, the rectangular base plate 622 of the slider member 620 can run beyond an upper and lower finishing crossbar 614, 618, thus extending the sliding distance of a slider-type cellular phone. That is, if the rectangular base plate 622 of the slider member 620 and the guide bar 650a, 650b of the guide member 610 have the same length as ...

eighth embodiment

[0135]FIG. 28 is an assembled perspective view of a sliding mechanism apparatus 800 according to the invention, and FIG. 29 is a cross-section taken along the line F-F in FIG. 28. In this embodiment, the guide dam and guide rail structures are removed, and the relative sliding of a guide member 810 and a slider member 820 is guided through the engaging structure of guide bars 850a, 850b and guide holes 826a, 826b. In this sliding and guiding structure, the stability therefor is slightly inferior to the previous embodiments, but the slider member can be slid and guided without any hitch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com