Exhaust treatment system with an oxidation device for NO2 control

a technology of exhaust treatment system and oxidation device, which is applied in the direction of separation process, machine/engine, mechanical apparatus, etc., can solve the problem of reducing the number of no2 /sub>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

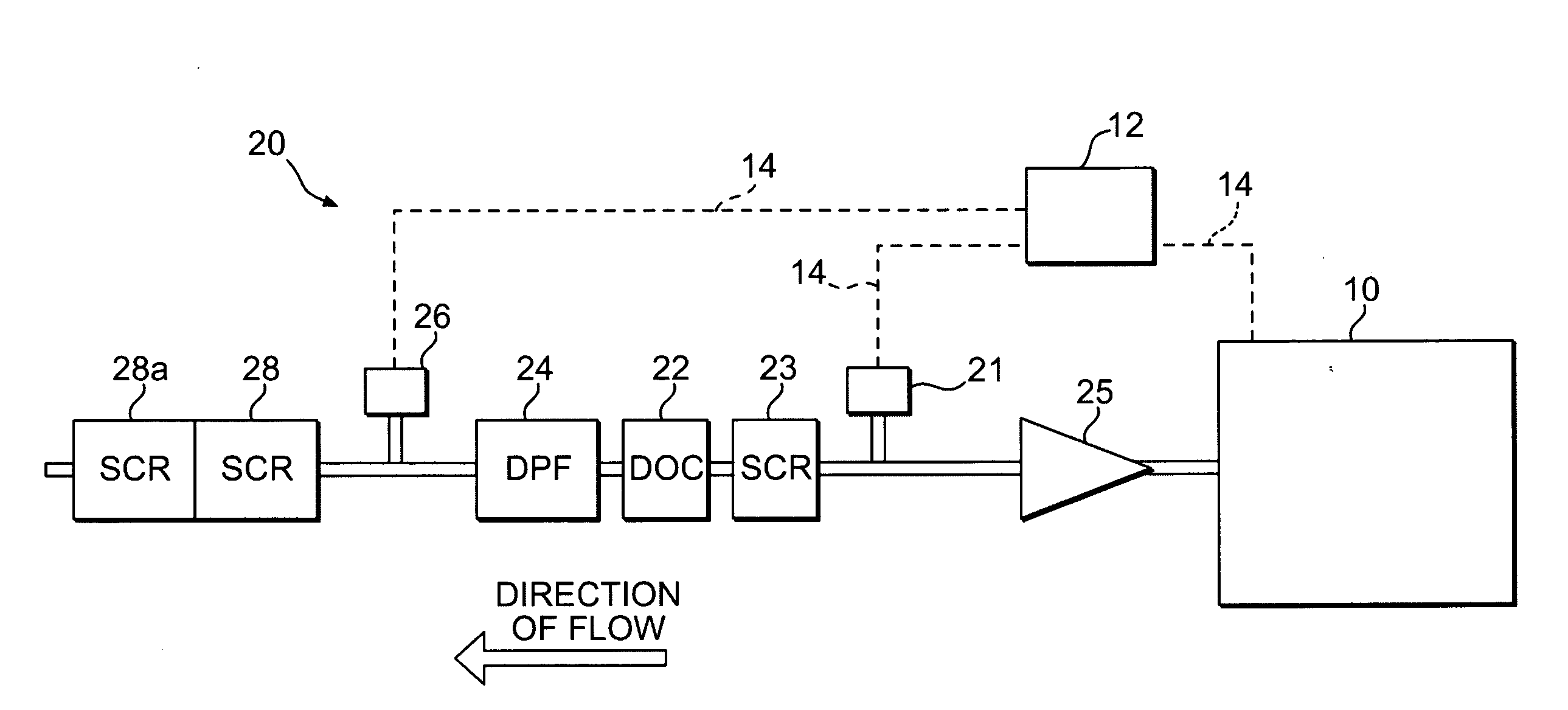

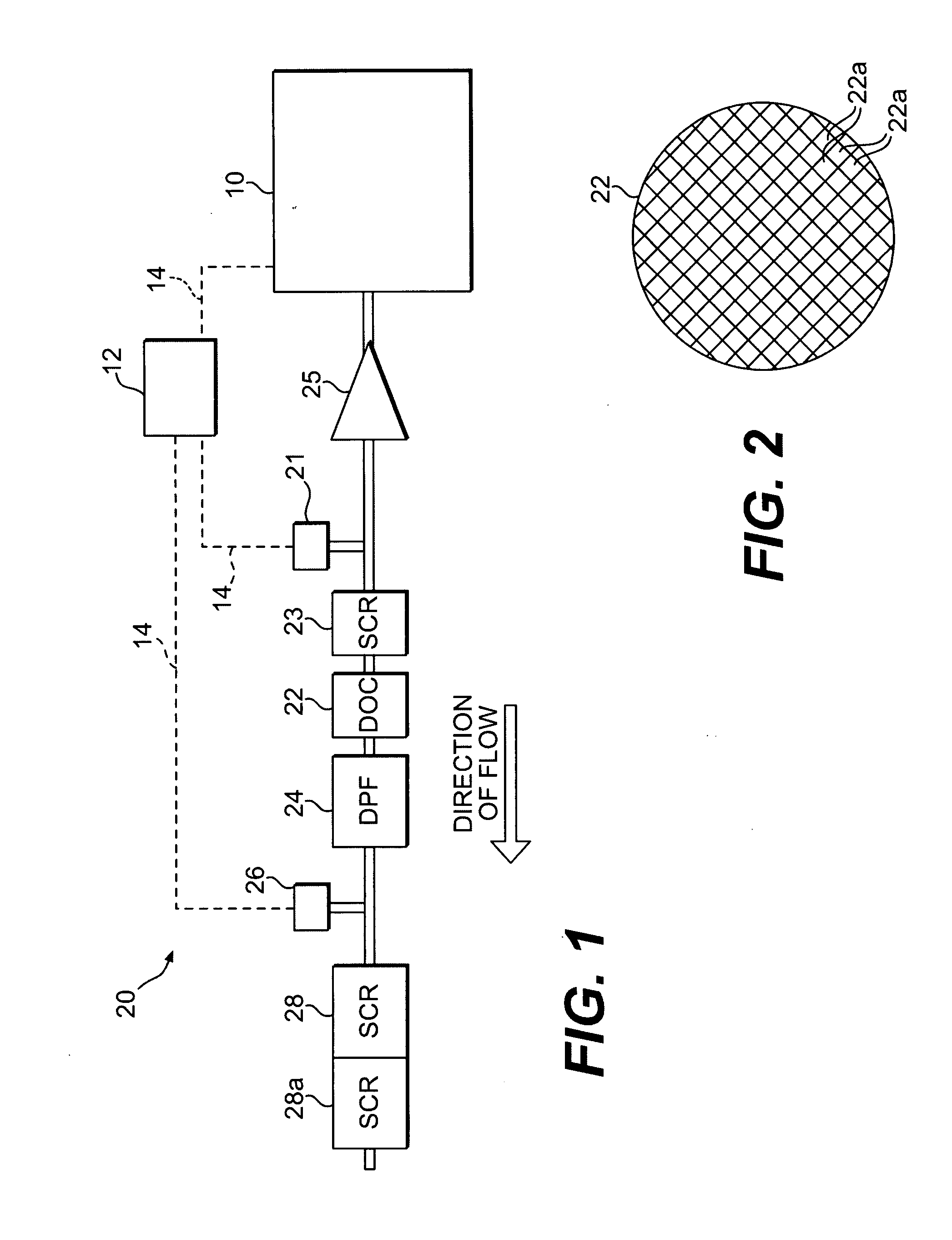

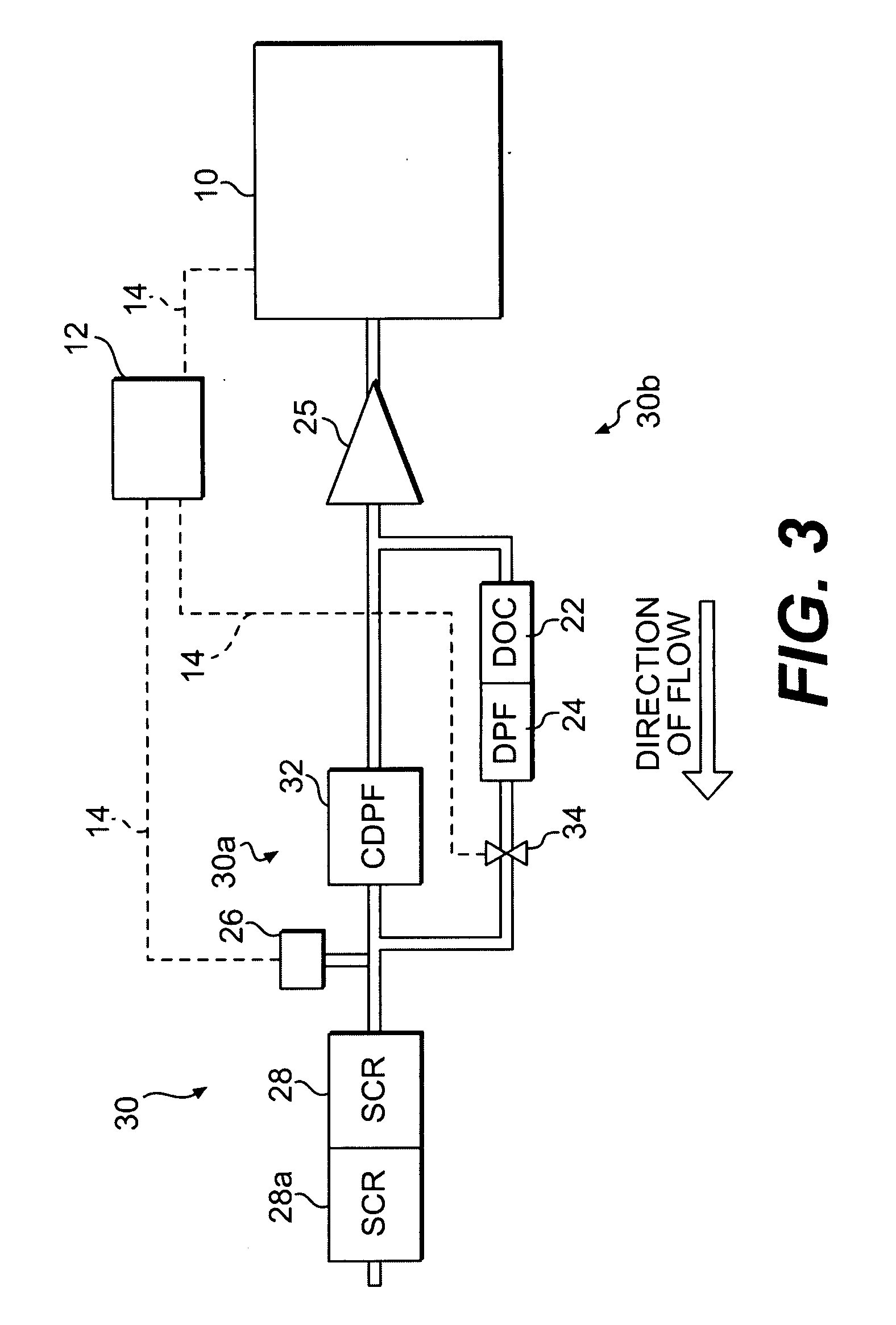

[0020]Reference will now be made in detail to exemplary embodiments, which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0021]As shown in FIG. 1, a power source, such as an engine 10, of a machine is provided. The disclosed embodiment may be applicable to various types of machines such as, for example, a fixed or mobile machine that performs some type of operation associated with an industry such as mining, construction, farming, transportation, power generation, tree harvesting, forestry, or any other industry known in the art. The engine 10 may be an internal combustion engine, such as, for example, a diesel engine, a gasoline engine, a gaseous fuel-powered engine, or any other engine apparent to one skilled in the art. The engine 10 may alternatively be another source of power such as a furnace or any other suitable source of power for a powered system such as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com