Scaffold connection with concave engagement and gravity lock

a technology of concave engagement and gravity lock, which is applied in the direction of couplings, building scaffolds, mechanical devices, etc., can solve the problems of difficult installation and removal of the wedge connection, and achieve the effect of good engagement and high resistance to accidental disconn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

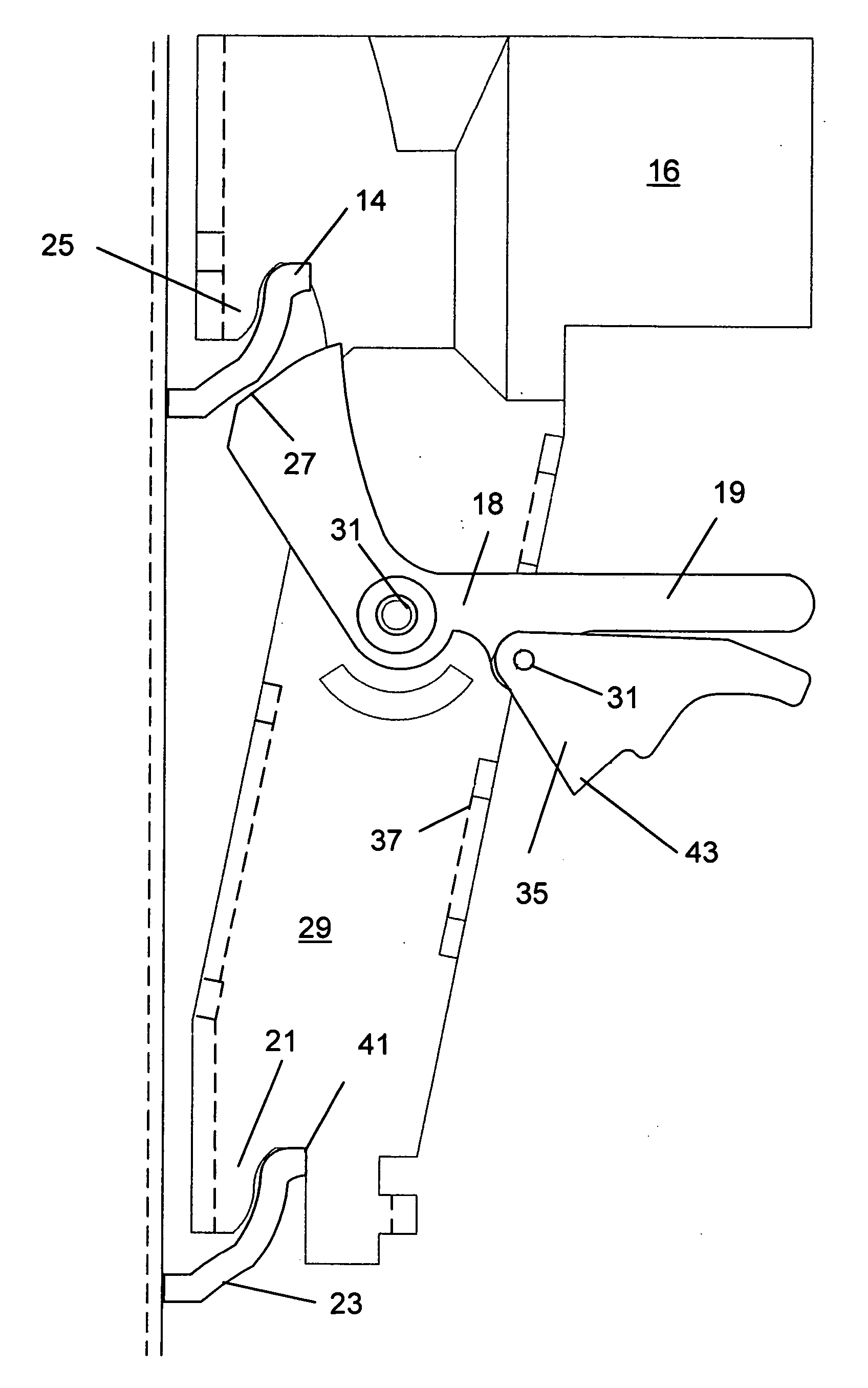

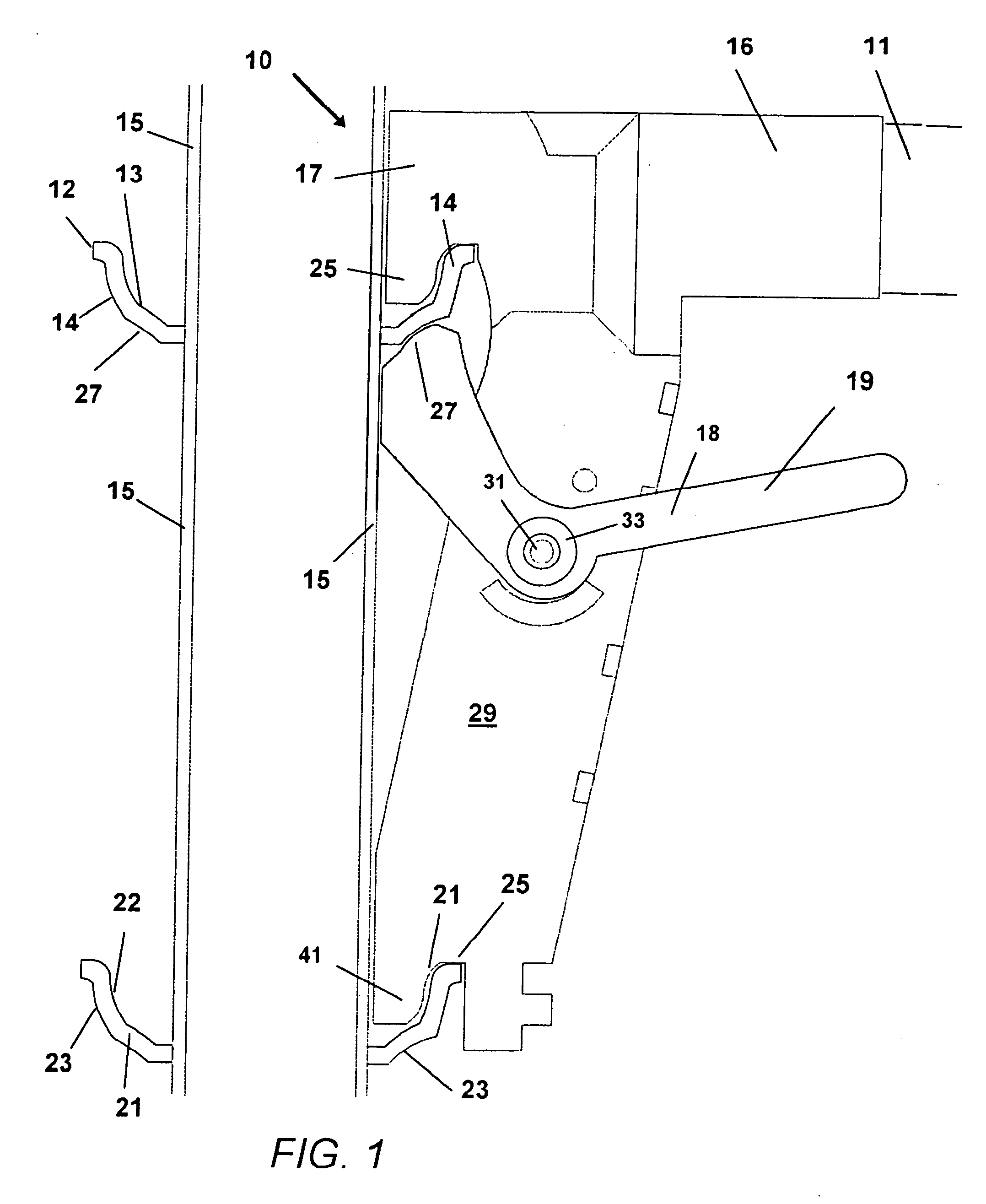

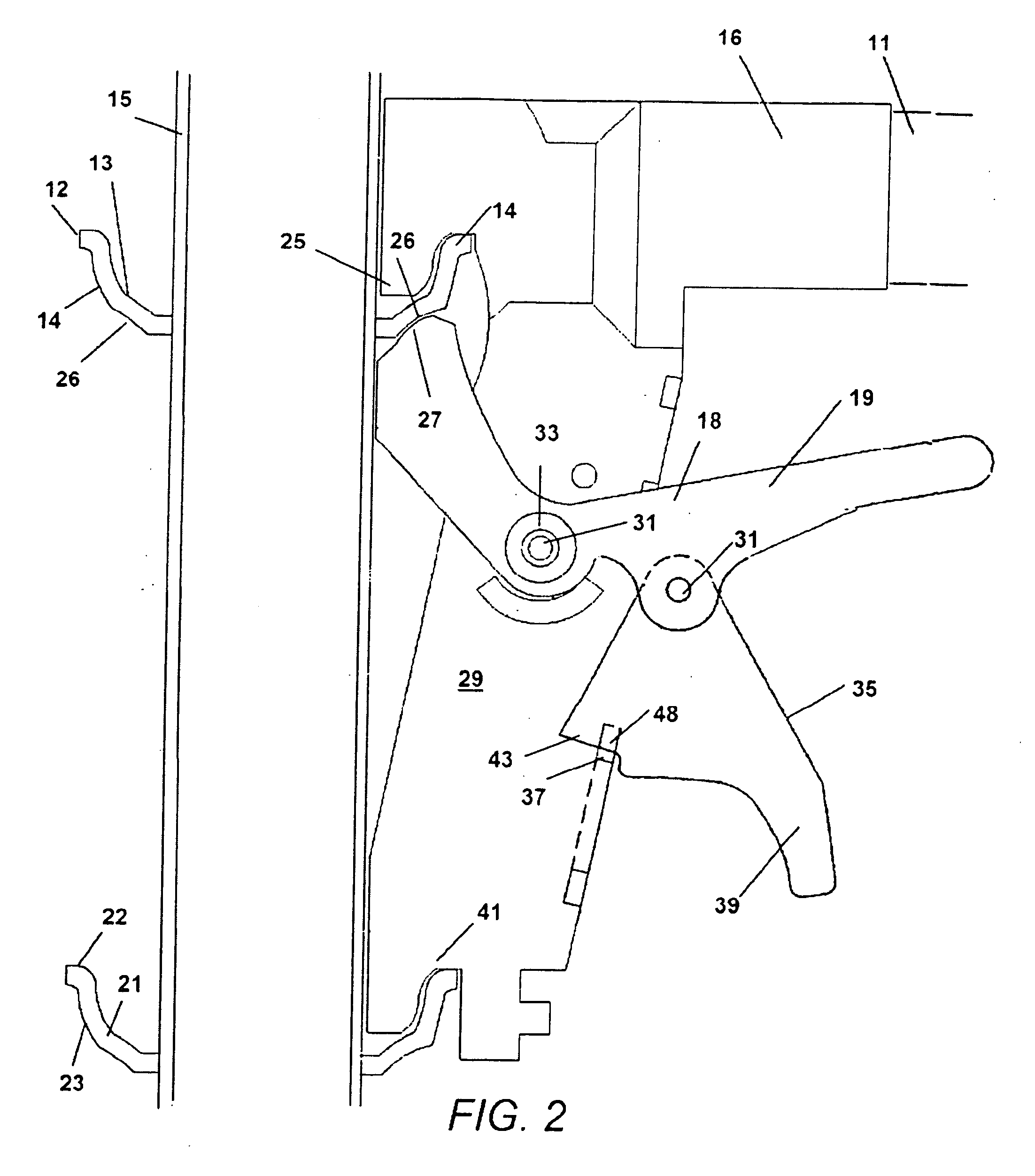

[0016]Referring now to the drawings, FIGS. 1-3 depict various modes of the disclosed device 10 for engagement of scaffold members in construction of scaffolds and similar structures. The Figures depict various embodiments of the improved scaffold connection device 10, all of which incorporate the unique concave engagement of components which yield the increased resistance to disengagement of the components.

[0017]As shown in FIGS. 1-3 all modes of the connection device 10 include a first ring member 12, which is fixedly attached to a vertical scaffold member 15, preferably by welding. The first ring member 12 has an upper side 13 surface and a lower side 14 surface surrounding the member 15 in the curved shape of the ring member 12.

[0018]In the most preferred mode of the device 10 shown in FIGS. 2-3, while not required for the engagement of the scaffold components, additional redundancy and stability of the assembled device 10 to the member 15 can be obtained by the addition of secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com