Container seal

a technology for sealing and containers, applied in the field of containers, can solve the problems of difficult to break evenly and consistently around the seal, increase the quantity of particulate materials, and inability to adjust the size of the seal,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

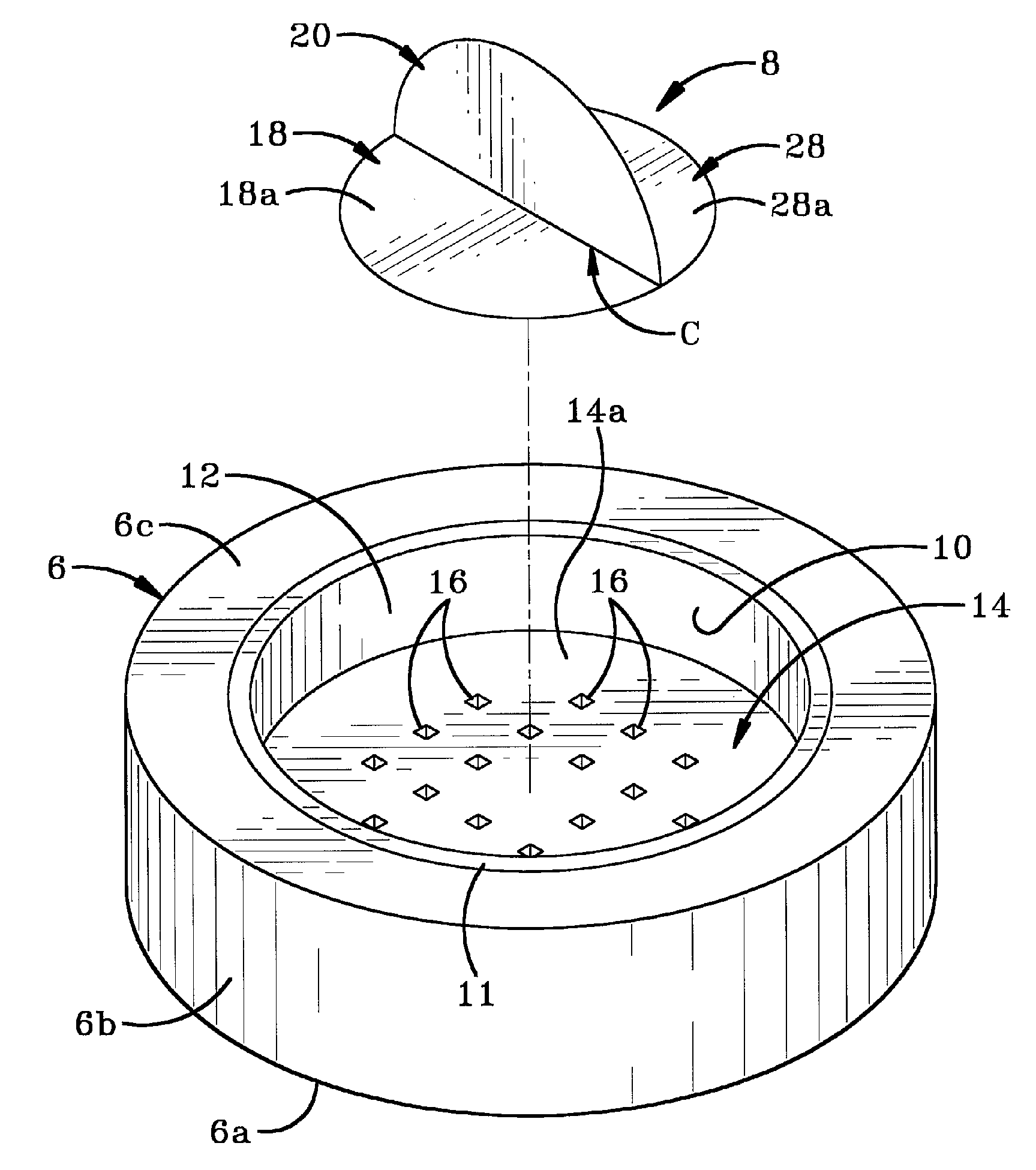

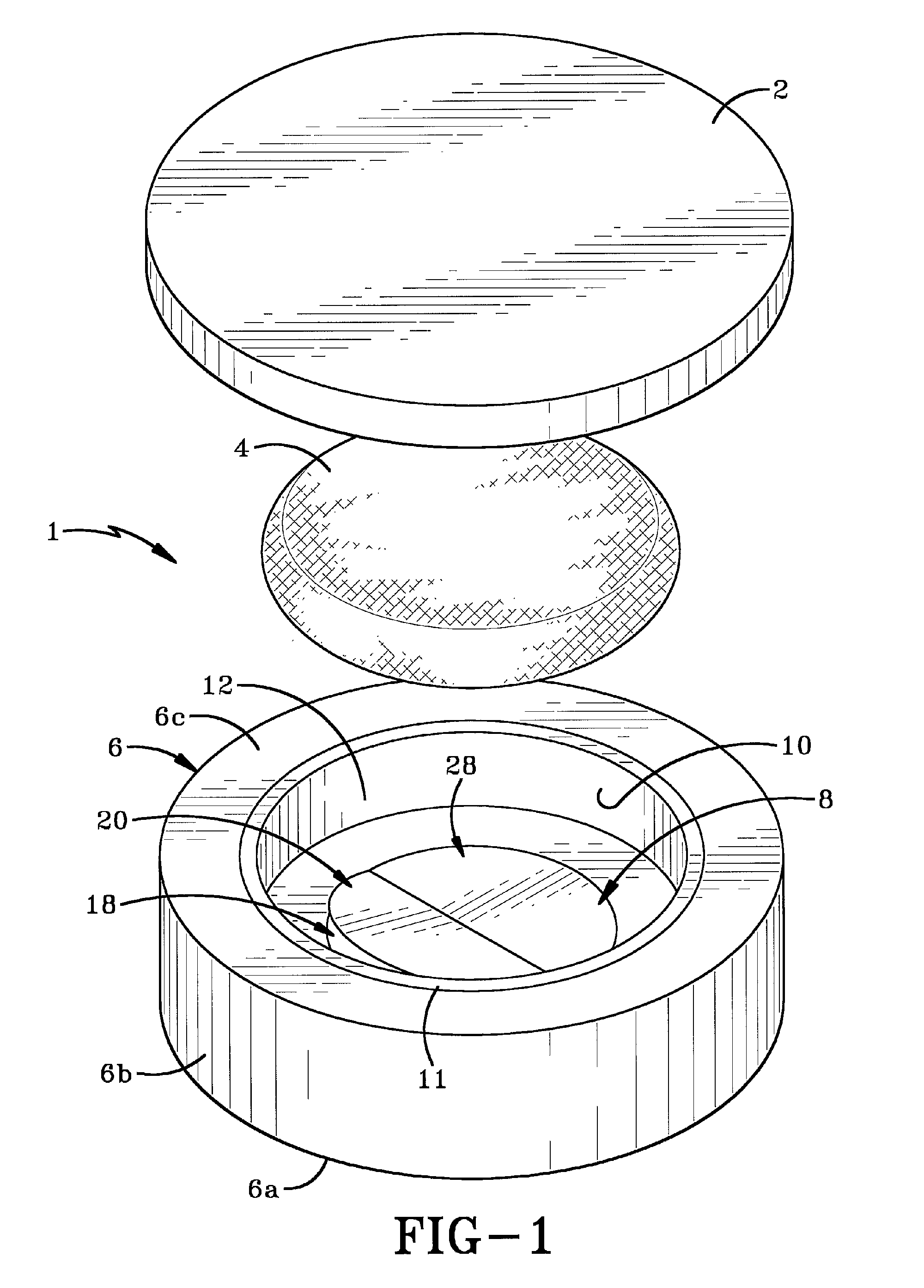

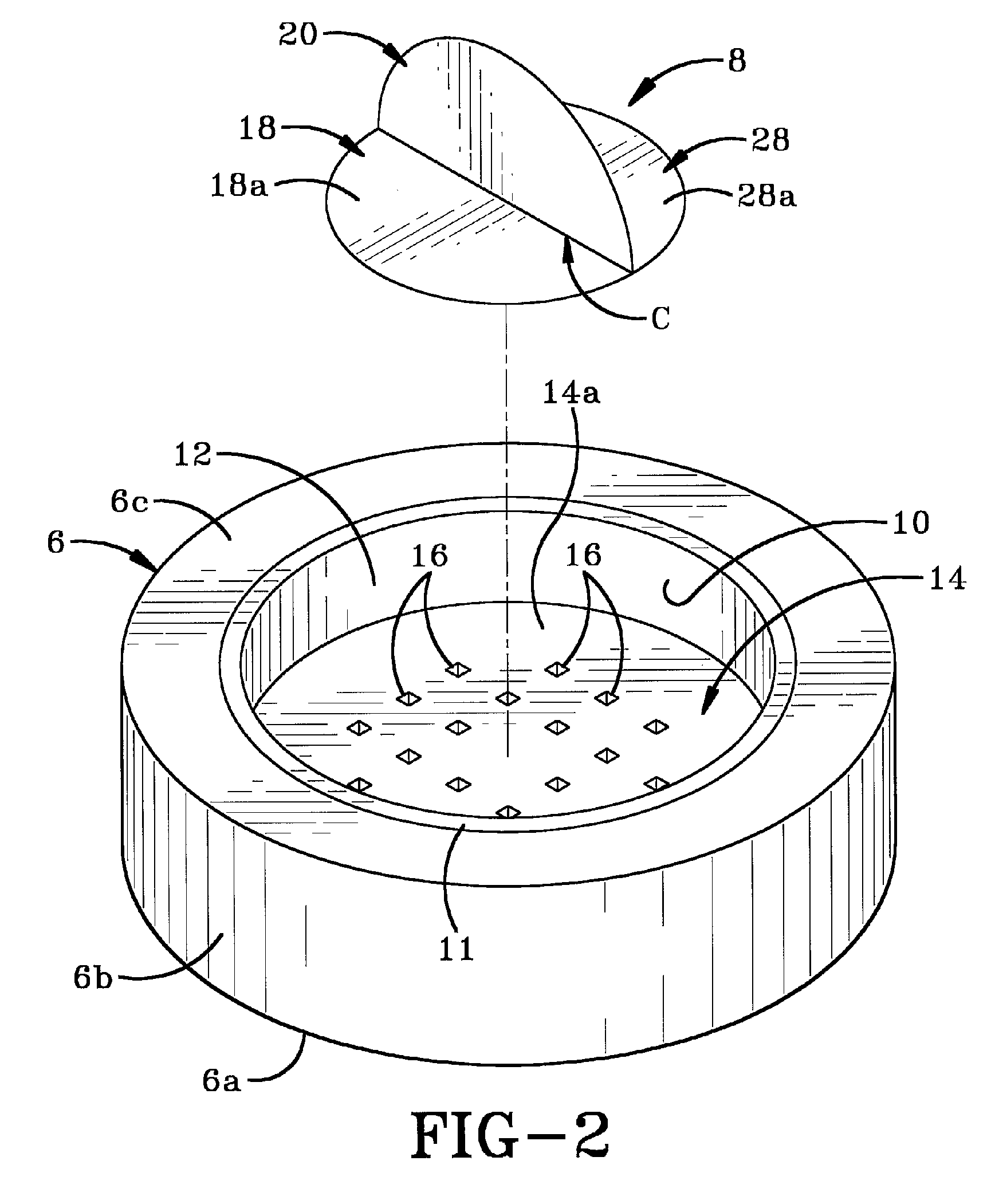

[0018]Referring to FIGS. 1-6, there is shown a container system in accordance with the present invention and generally indicated at 1. Container system 1 is described with reference to a container specifically for a cosmetic powder. It will be understood, however, that system 1 can be any container system that retains a quantity of fine particulate material 22 therein. The particulate material 22 may be talcum powder, paint powder, toner powder etc. It will further be understood that the container and insert can be of any shape, size or configuration, without departing from the spirit of the present invention.

[0019]Container system 1 comprises a container 6, a lid 2, an insert 14, and a cosmetic applicator 4. Container 6 is generally cylindrical in cross-section and includes a bottom wall 6a, a peripheral side wall 6b extending upwardly away from bottom wall 6a, and an upper wall 6c that terminates in a downwardly extending flange 6d and lip 7. Bottom, side and upper walls 6a, 6b, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com