Packer for Repairing Crack in Concrete Body

a concrete body and crack technology, applied in the field of concrete body crack repair packaging, can solve the problems of increasing labor costs due to post-process, elongating construction time, and cracks in concrete bodies, and achieves the effects of shortening the time for crack repair, reducing labor costs, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

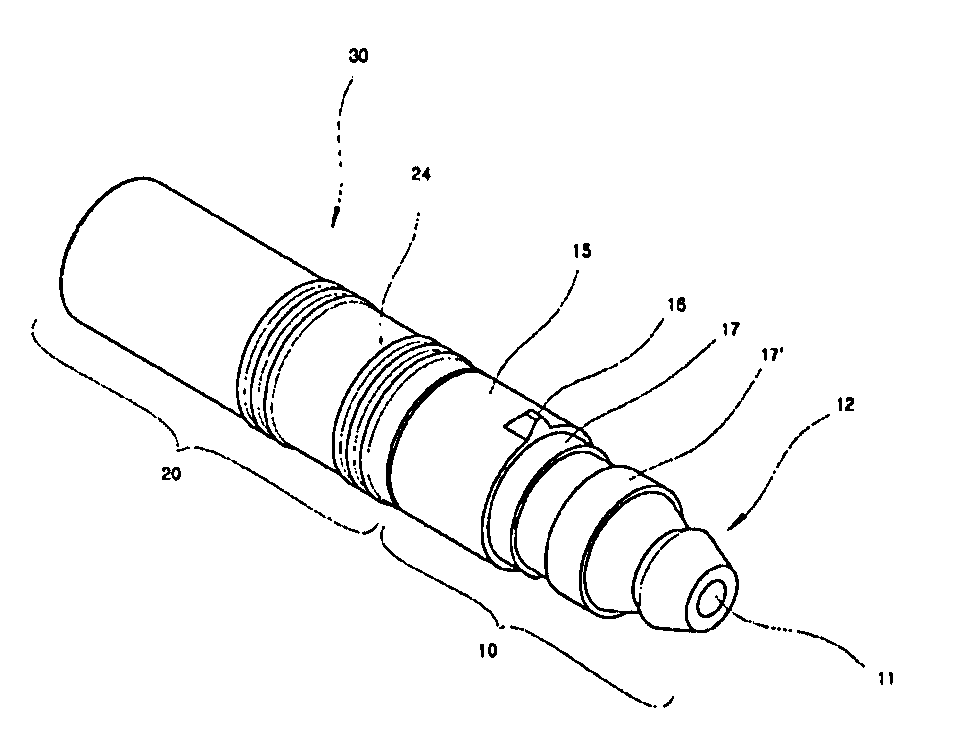

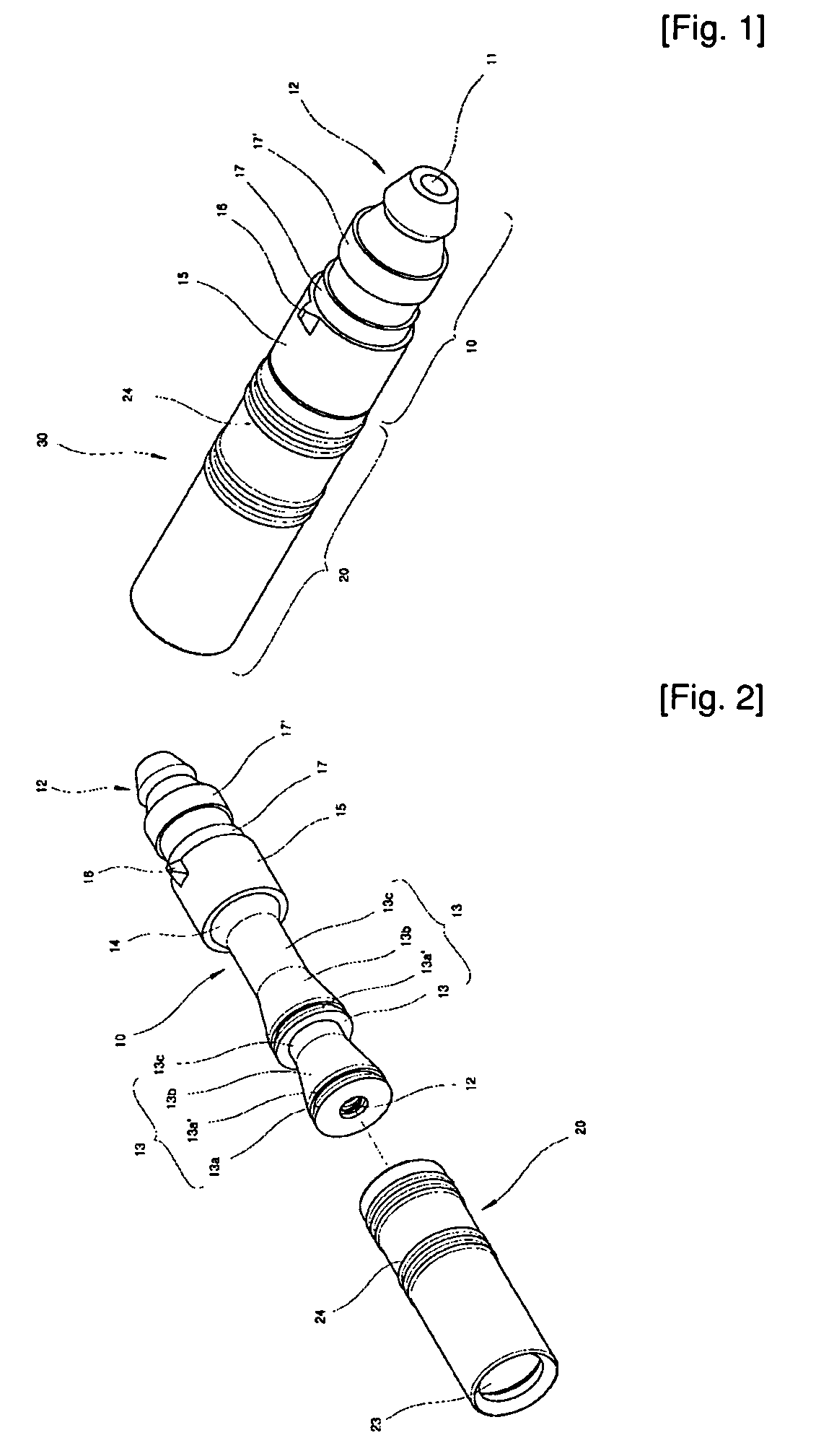

[0020]A packer 30 of the present invention comprises an injection main body 10 and a soft sleeve 20, which are assembled. An inflow route 11 is formed through the injection main body 10 in the longitudinal direction. A nipple part 12 is formed at one end of the injection main body 10, and a plurality of extension units 13, each of which has a trapezoidal section such that its diameter is increased from the front end to the rear end, are consecutively formed at the other end of the injection main body 10. A backward flow prevention groove 11′ having a diameter larger than that of the inflow route 11 is formed in the end of the inflow route 11 opposite to the nipple part 12, and a backward flow prevention unit 17 including a check ball 17a having a spherical shape and a compressed spring 17b, which are sequentially assembled, is formed at the backward flow prevention groove 11′. The soft sleeve 20 has a cylindrical structure having a hollow formed therethrough in the longitudinal dire...

second embodiment

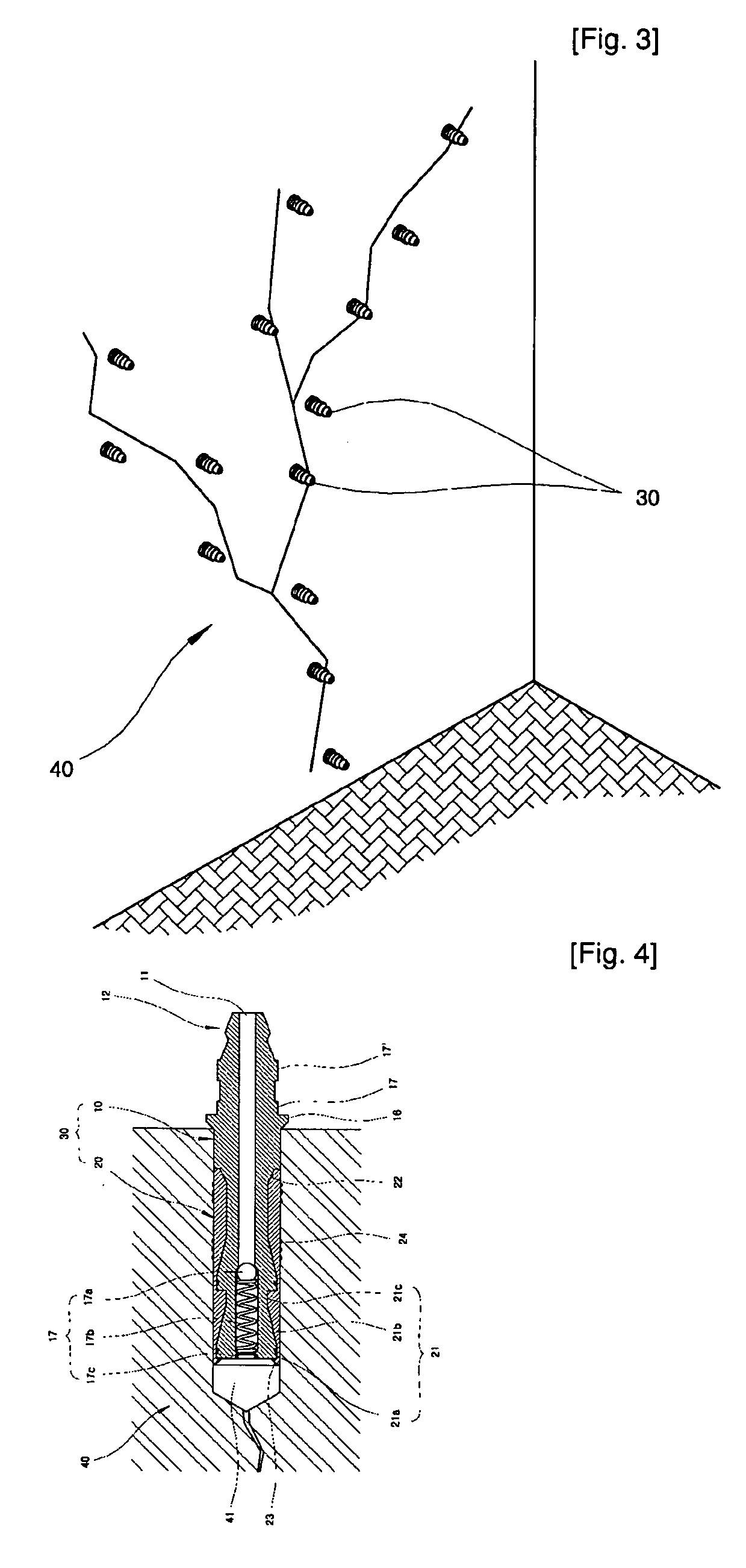

[0032]Hereinafter, with reference to FIGS. 3 to 7, a method for repairing a crack in a concrete body using packers of the present invention will be described.

[0033]In a drilling and blowing step (S1), the fixing holes 41 having a designated depth are formed in the concrete body 40 along a crack using an electric drill, and scraps of foreign substances generated thereby are removed by wind. The fixing holes 41 are formed at an angle of 45 degrees by drilling such that the external surfaces of the fixing holes 41 are spaced from the crack by a designated distance and the internal portions of the fixing holes 41 are connected to the internal portion of the crack. A plurality of the fixing holes 41 are formed along the crack in zigzag.

[0034]Thereafter, in a packer-installing step (S2), as shown in FIGS. 3 and 4, the packer 30 is inserted into each of the fixing holes 41. Here, the soft sleeve 20 is completely inserted into the fixing hole 41, and the injection main body 10 is partially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com