Fire, acoustic, and thermal resistant construction

a technology of acoustic and thermal insulation and construction, applied in the field of structure, can solve the problems of labor-intensive, time-consuming, and high cost of the process, and achieve the effects of improving fire, thermal and sound resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In the following description, like reference characters designate like or corresponding parts throughout the several views. Also in the following description, it is to be understood that such terms as “forward,”“rearward,”“left,”“right,”“upwardly,”“downwardly,” and the like are words of convenience and are not to be construed as limiting terms.

[0026]As used herein “improved” fire, sound or thermal resistance refers to a measurable increase in fire resistance, sound resistance or thermal resistance when comparing the present invention with only outer membranes to a conventional area separation walls as described herein. Moreover, “low-conductivity”, “thermally resistive”, “acoustically transmission resistant”, “electrically non-conductive”, and the like are relative to conventional area separation walls which are composed of more than outer membranes.

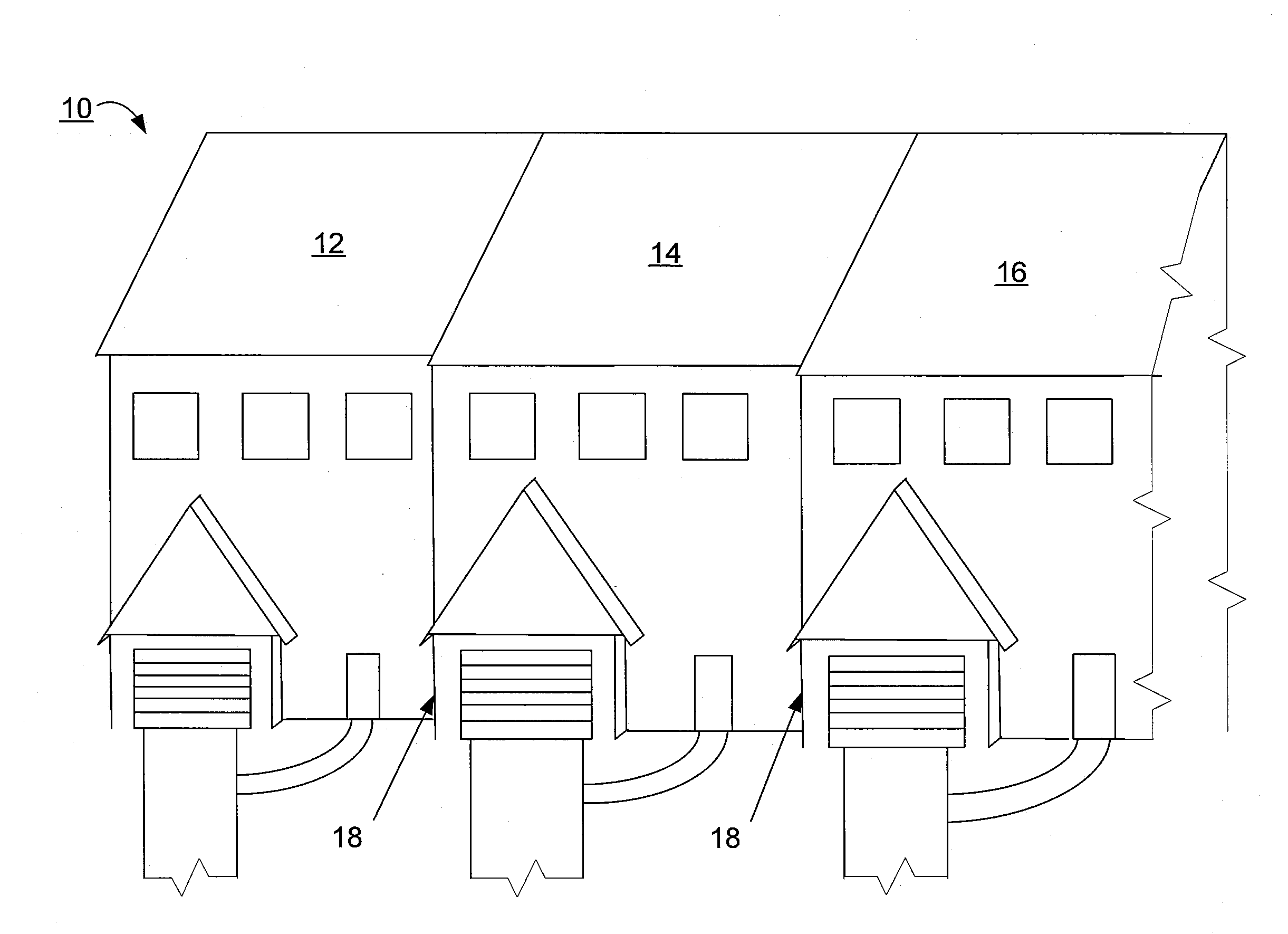

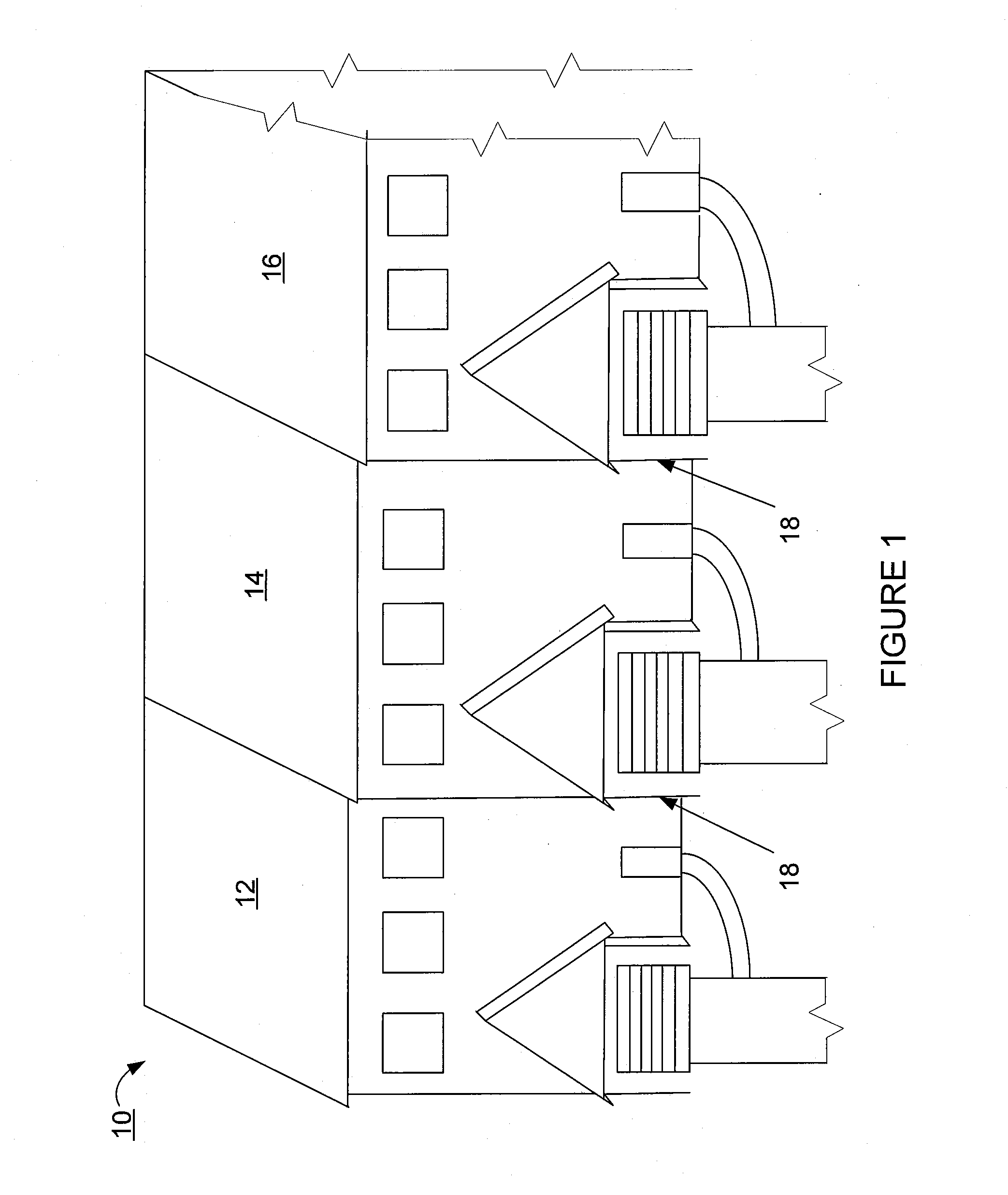

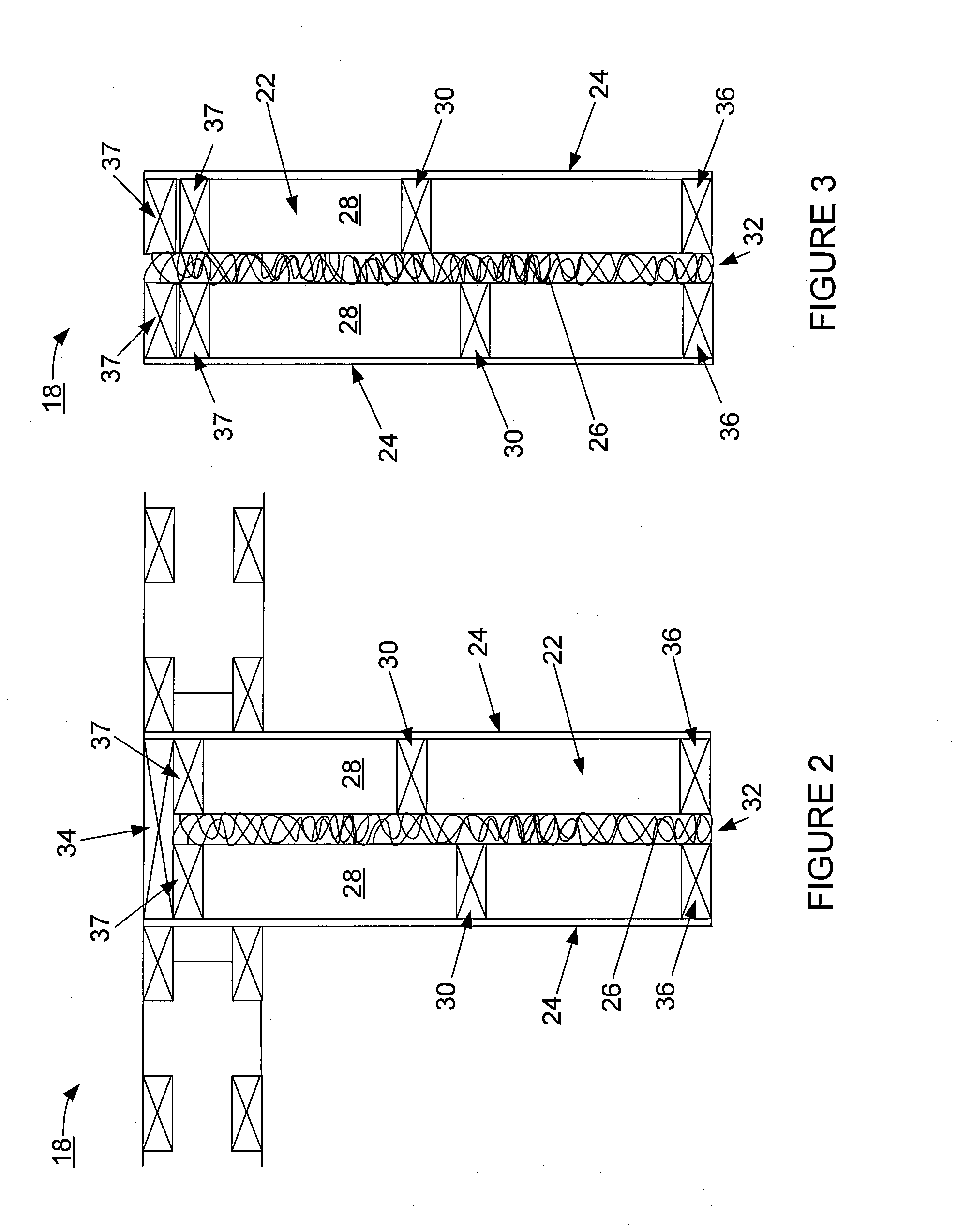

[0027]Referring now to the drawings in general and FIG. 1 in particular, it will be understood that the illustrations are for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com