Oil strainer for transmission

a technology of oil strainer and transmission tube, which is applied in the direction of filtration separation, lubricant mounting/connection, and separation process, etc., can solve the problems of affecting the aeration effect of the upper case and the lower case, so as to reduce the total amount of oil and reduce the structure. simple, the effect of restrainting the aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

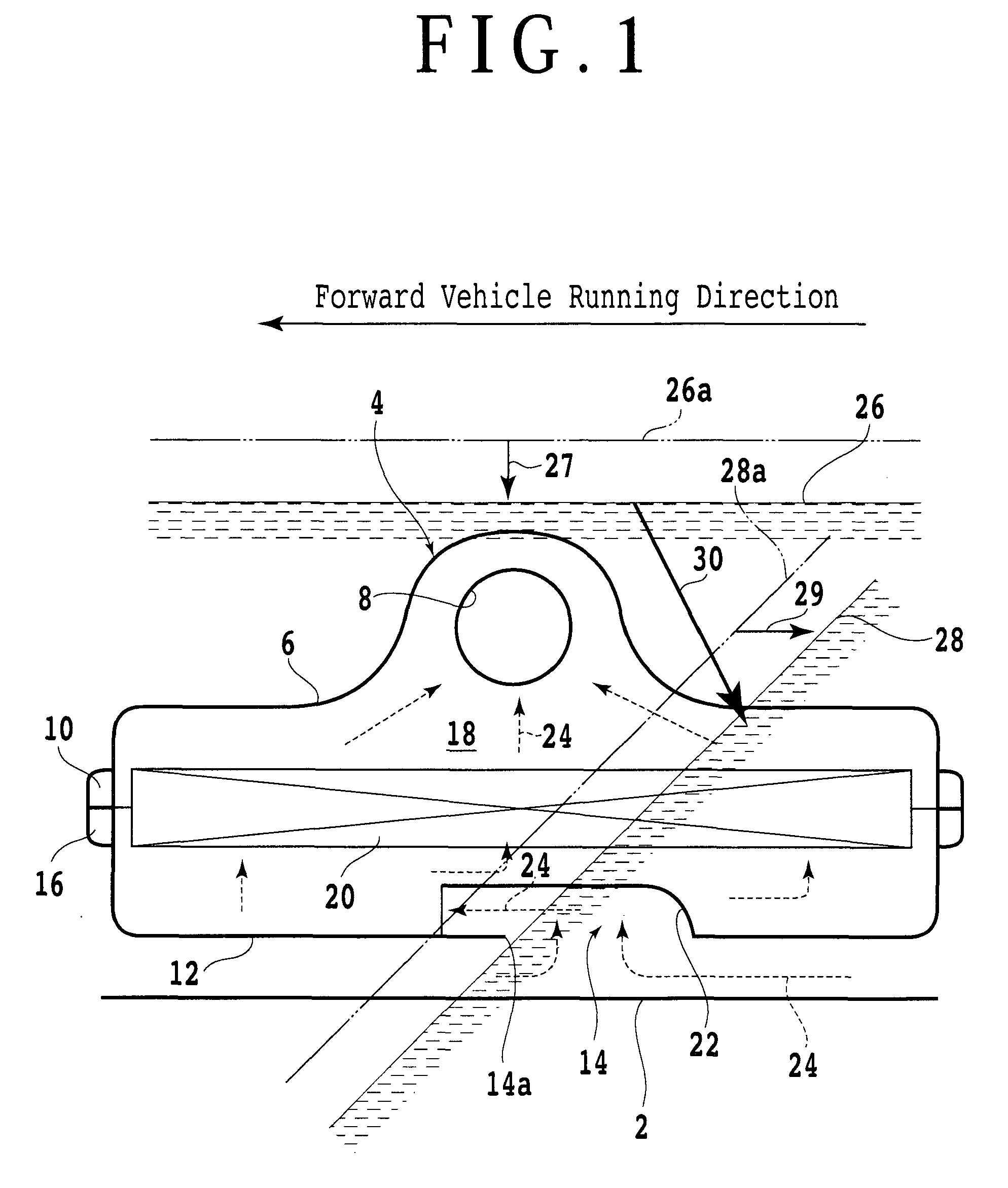

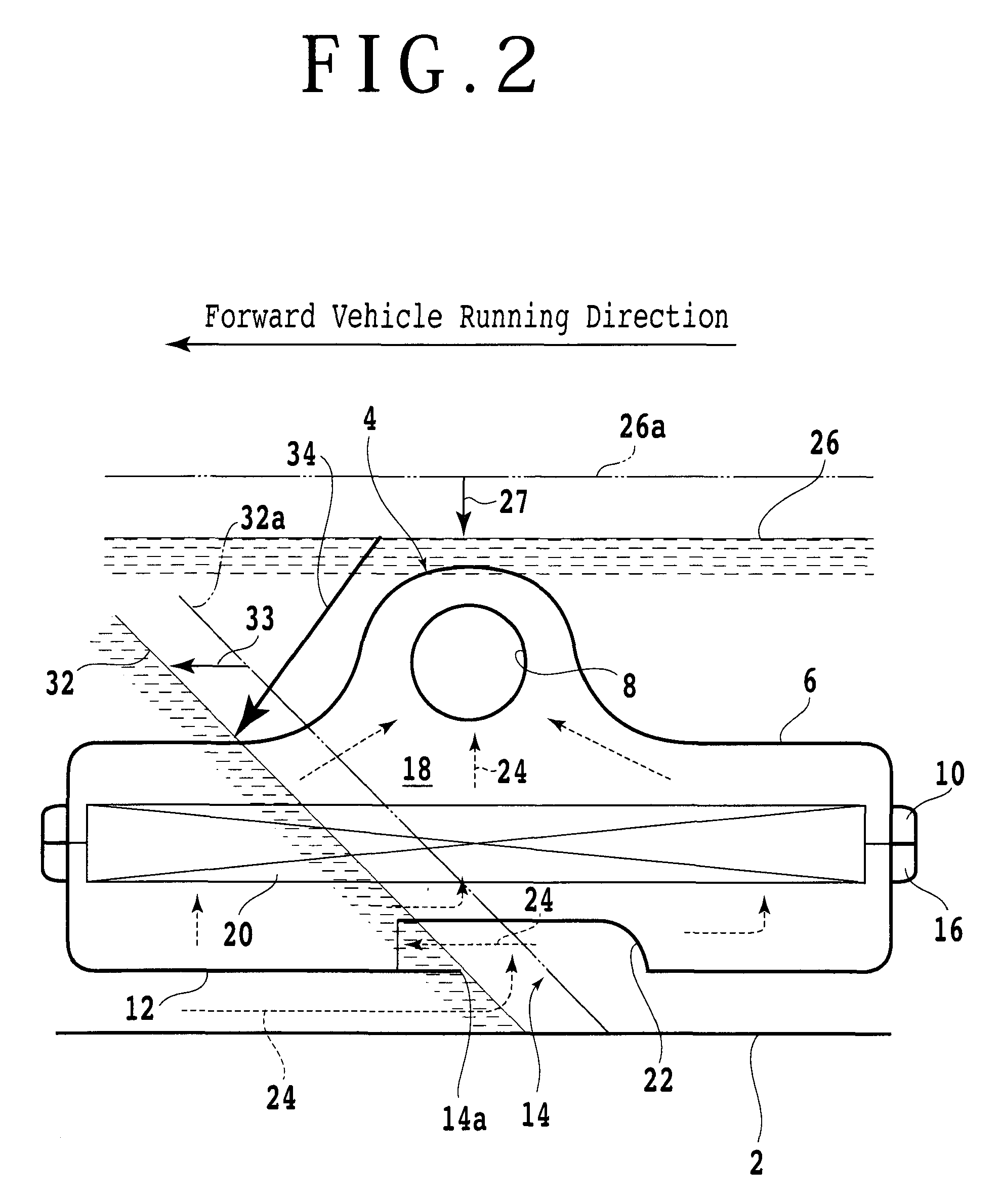

[0030]Now, an oil strainer for a transmission according to an embodiment of the present invention will be described in detail below, referring to the drawings. Referring to FIG. 1, a schematic sectional view of the oil strainer according to one embodiment of the present invention is shown, together with changes of an oil surface at the time of standstill of the vehicle and at the time of an acceleration of the vehicle.

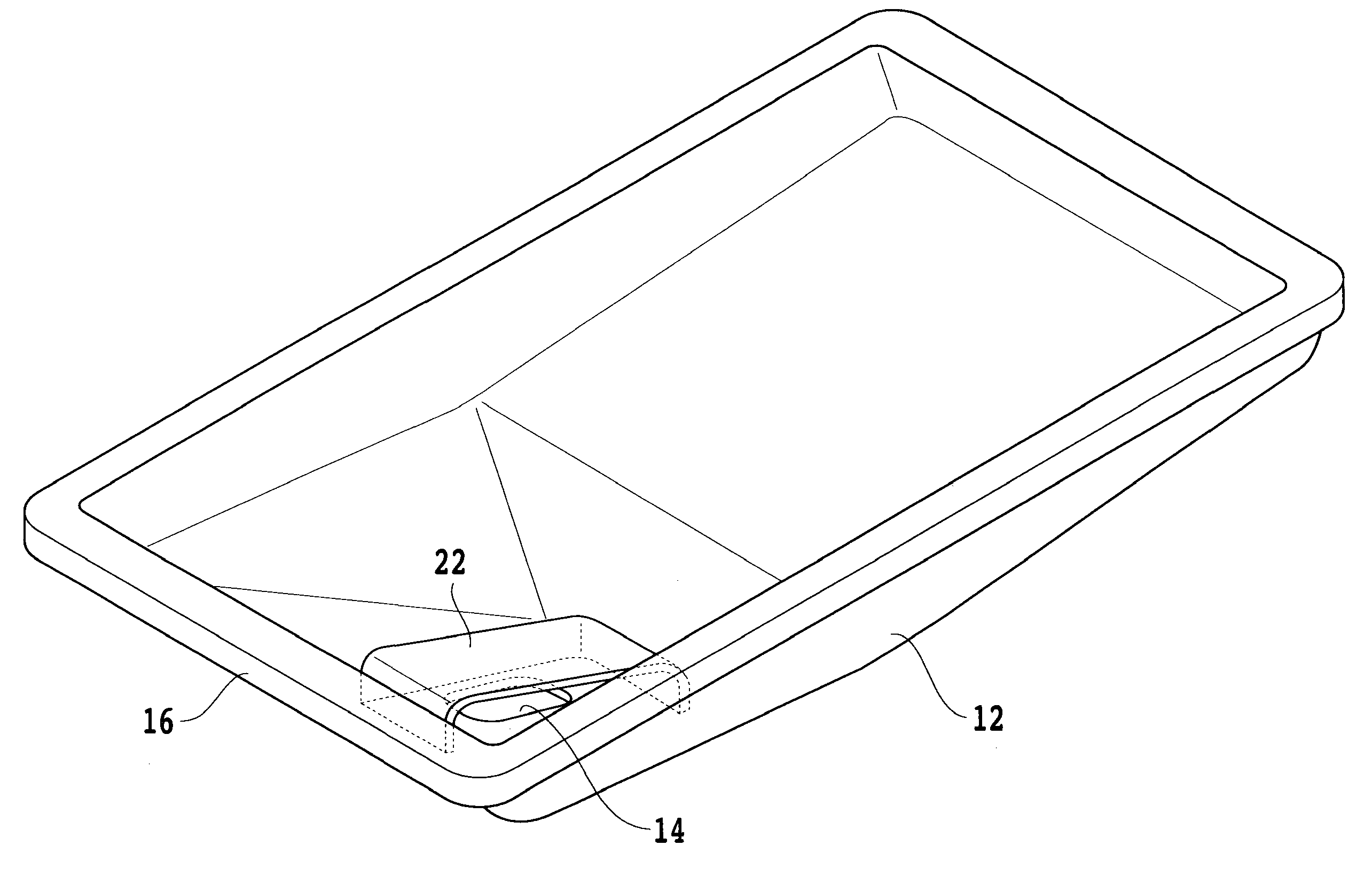

[0031]Reference numeral 2 denotes a bottom surface of a transmission case, and the oil strainer 4 is disposed in the transmission case. The oil strainer 4 includes an upper case 6 provided with a communication port 8 for communication with an oil pump in a side surface of an upper part thereof, a lower case 12 which is provided with an oil suction port 14 in its lower surface and which is joined to the upper case 6, and a filter member 20 which is disposed in a space 18 formed by joining the upper and lower cases 6 and 12 and which is provided for filtering an oil flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Acceleration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com