Calibration techniques for imaging devices

a color imaging and calibration technology, applied in the field of color imaging, can solve the problems that the accuracy of the calibration process can substantially affect the color accuracy, and achieve the effect of improving color accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

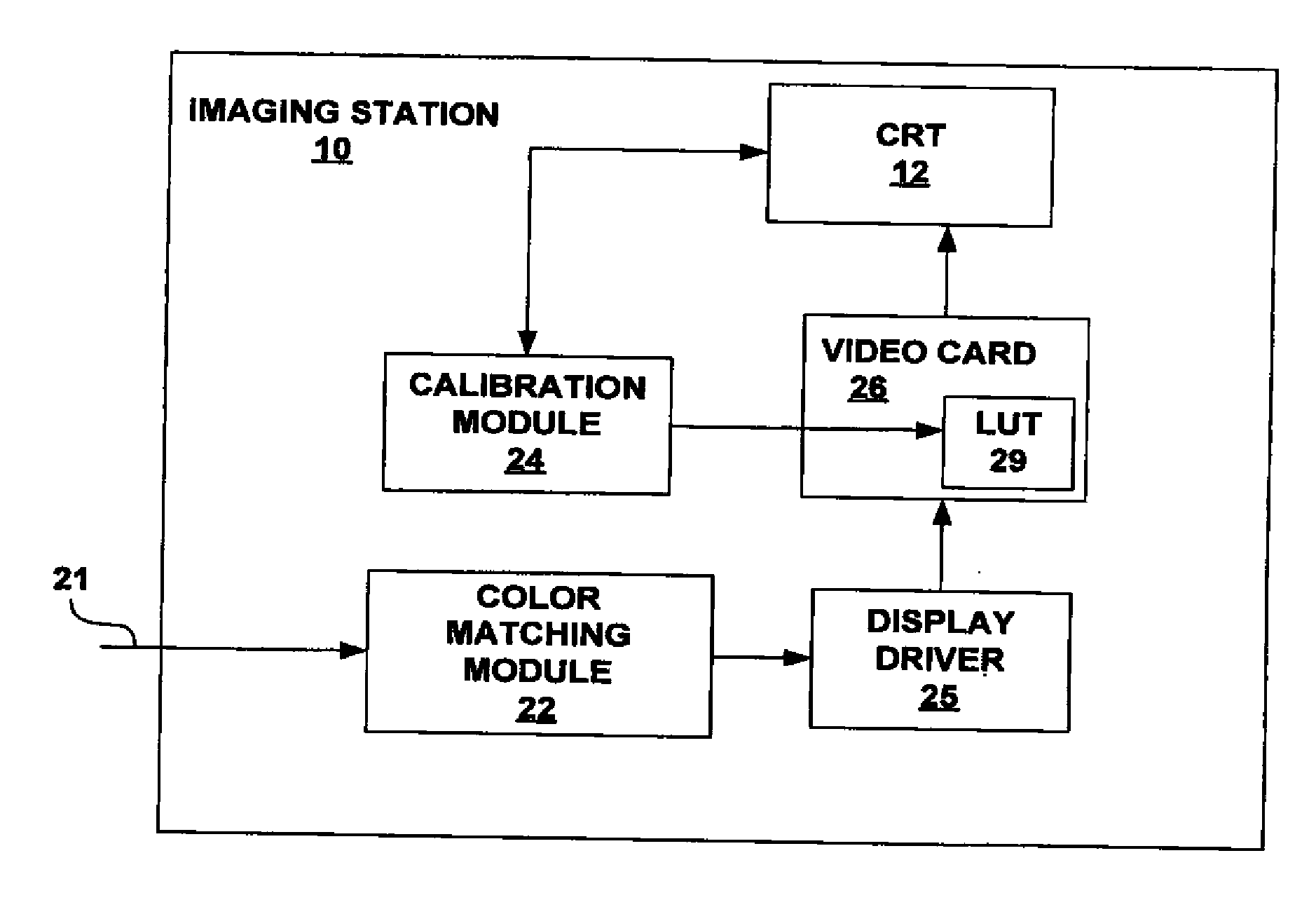

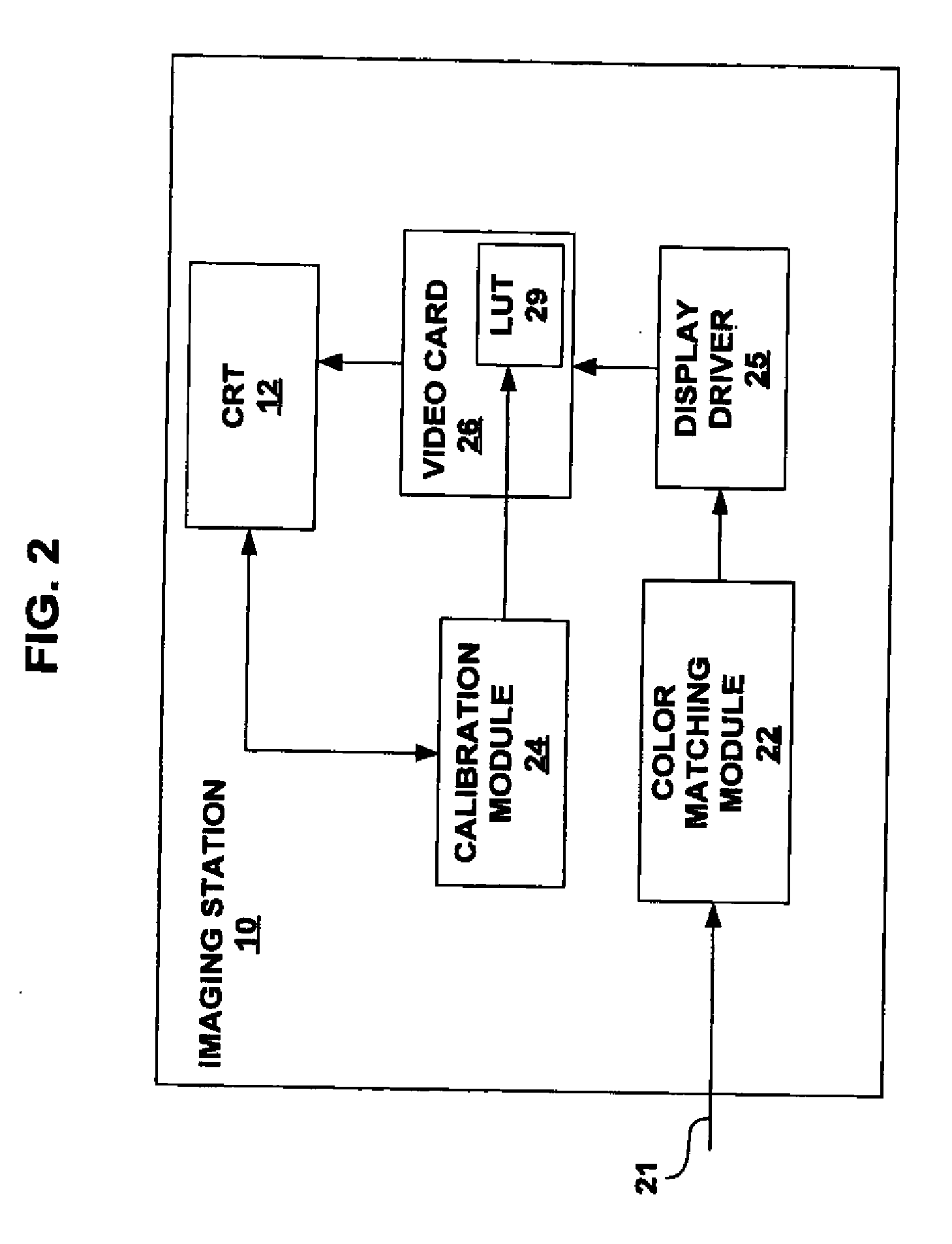

Embodiment Construction

[0023]In the discussion that follows, many aspects of the invention are described with reference to the calibration of an imaging device in the form of a cathode ray tube (CRT). However the invention is not necessarily limited in that respect. For example, techniques according to the principles of the invention may be readily applicable to other imaging devices, including other display devices such as liquid crystal displays, plasma displays, projection displays, and the like; printing devices such as printing presses, laser printers, ink-jet printers, dot-matrix printers, or any other printing device; and other imaging devices such as scanners. Accordingly, the detailed discussion is meant to be an exemplary description of one detailed embodiment in accordance with the invention.

[0024]FIG. 1 is a front view of an exemplary imaging station 10. Imaging station 10 includes an imaging device in the form of a cathode ray tube (CRT) 12. In addition, imaging station 10 includes a computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com