Gearbox Noise Reduction By Electrical Drive Control

a technology of electrical drive and noise reduction, applied in the direction of underwater vessels, amplifier modifications, non-deflectable wheel steering, etc., can solve the problems of difficulty in accurately pinpointing the exact source of audible noise, and various forms of passive and active noise cancellation schemes have been used to reduce or eliminate low frequency noise with limited success. , to achieve the effect of reducing the audible nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

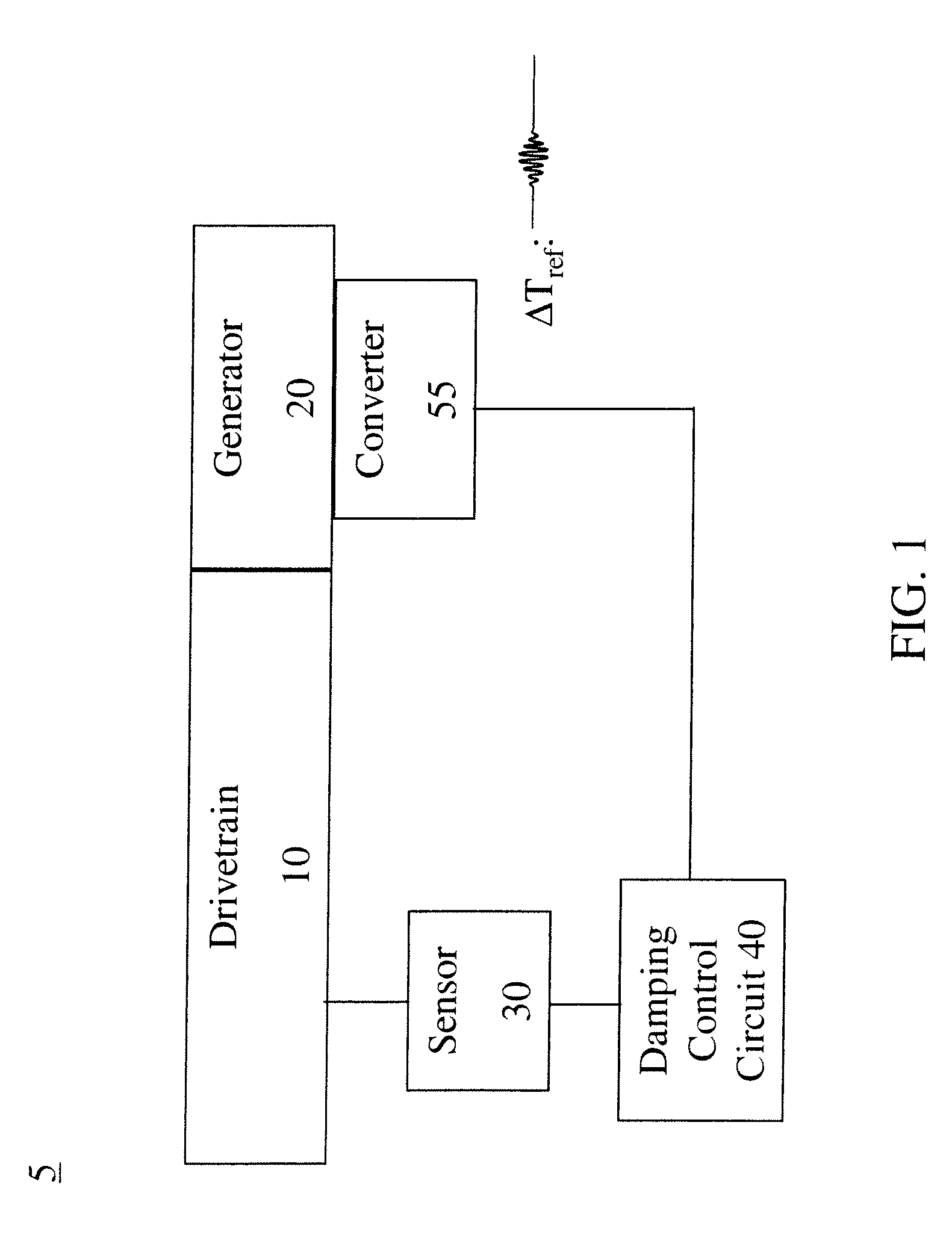

[0027]In general, certain embodiments of the invention provide for a reduction of noise issues with systems employing drive trains. An example of a drive train refers to those systems using gearboxes. As used herein, gearboxes shall include the various forms of transmissions and drive trains that experience noise and vibration issues.

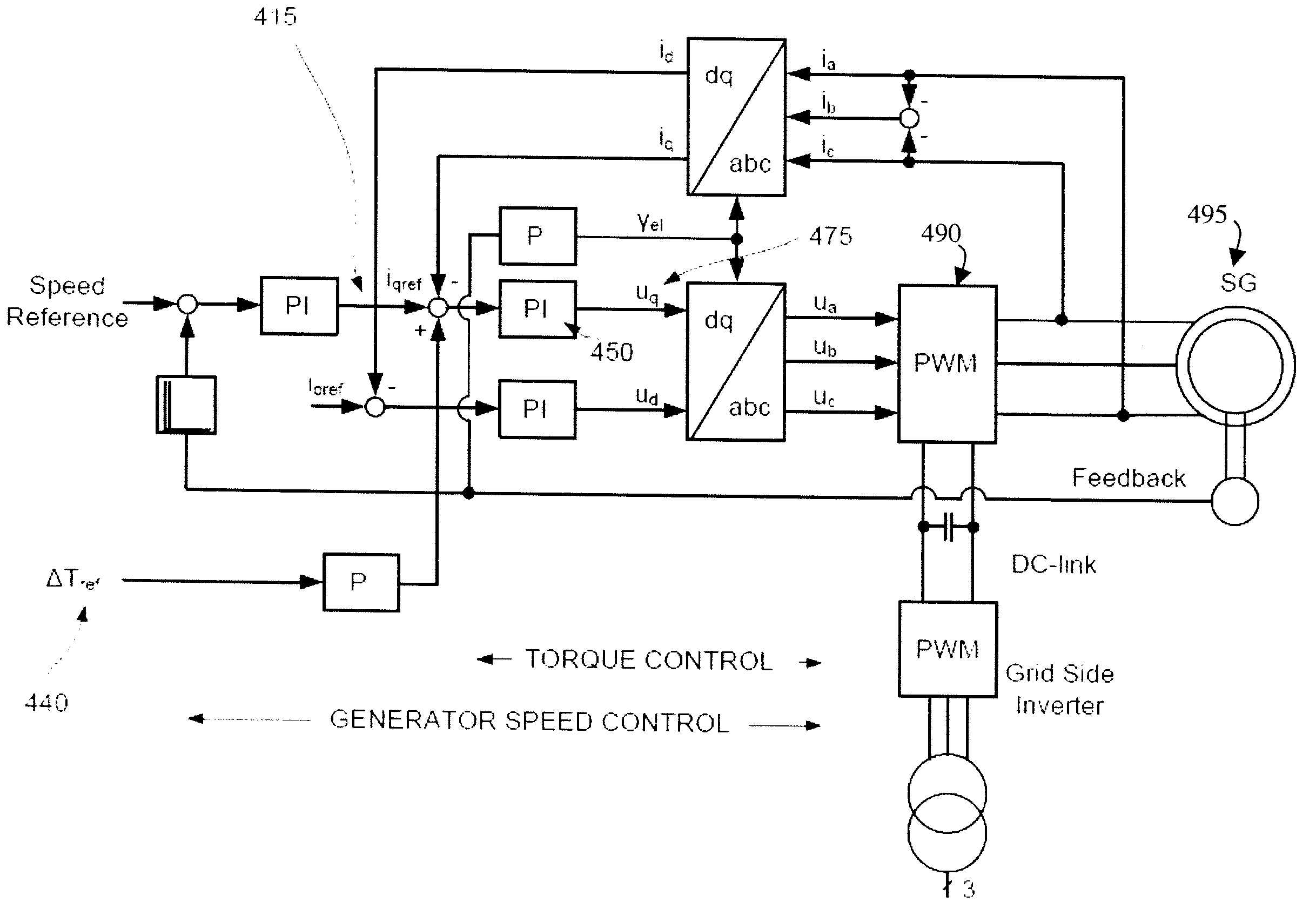

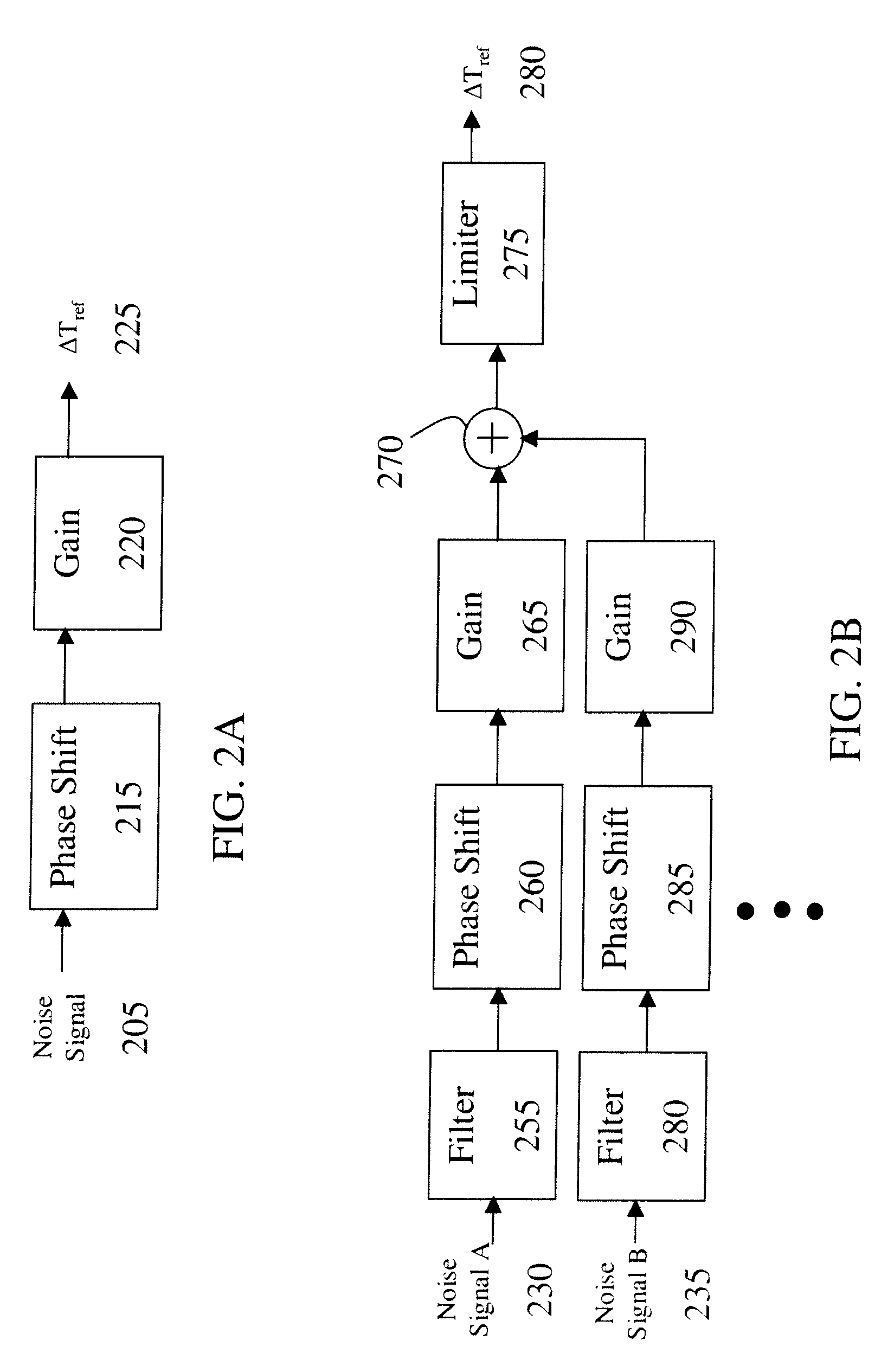

[0028]According to one embodiment, the noise reduction is achieved by suppressing the effect of the noise excitation, such as the gear-mesh excitation, by using a noise reduction control circuit for the drive system. The noise reduction circuit generates a dynamic torque feedback signal with the same frequency as the noise signal but at a different phase, wherein the feedback signal is fed back to the air-gap torque of the system, such as electric motor or generator. As used herein, electric machine shall refer to the various motors and generators that can be coupled to a drive train.

[0029]Many electrical drives are operated at variable frequency, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com