Bracing and spacing apparatus for hip trusses

a technology for bracing and spacing, which is applied in the direction of load-supporting braces, building roofs, building components, etc., can solve the problems of not being able to brace adjacent hip trusses, requiring a bit more complex trusses, and being more difficult to construct hip roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

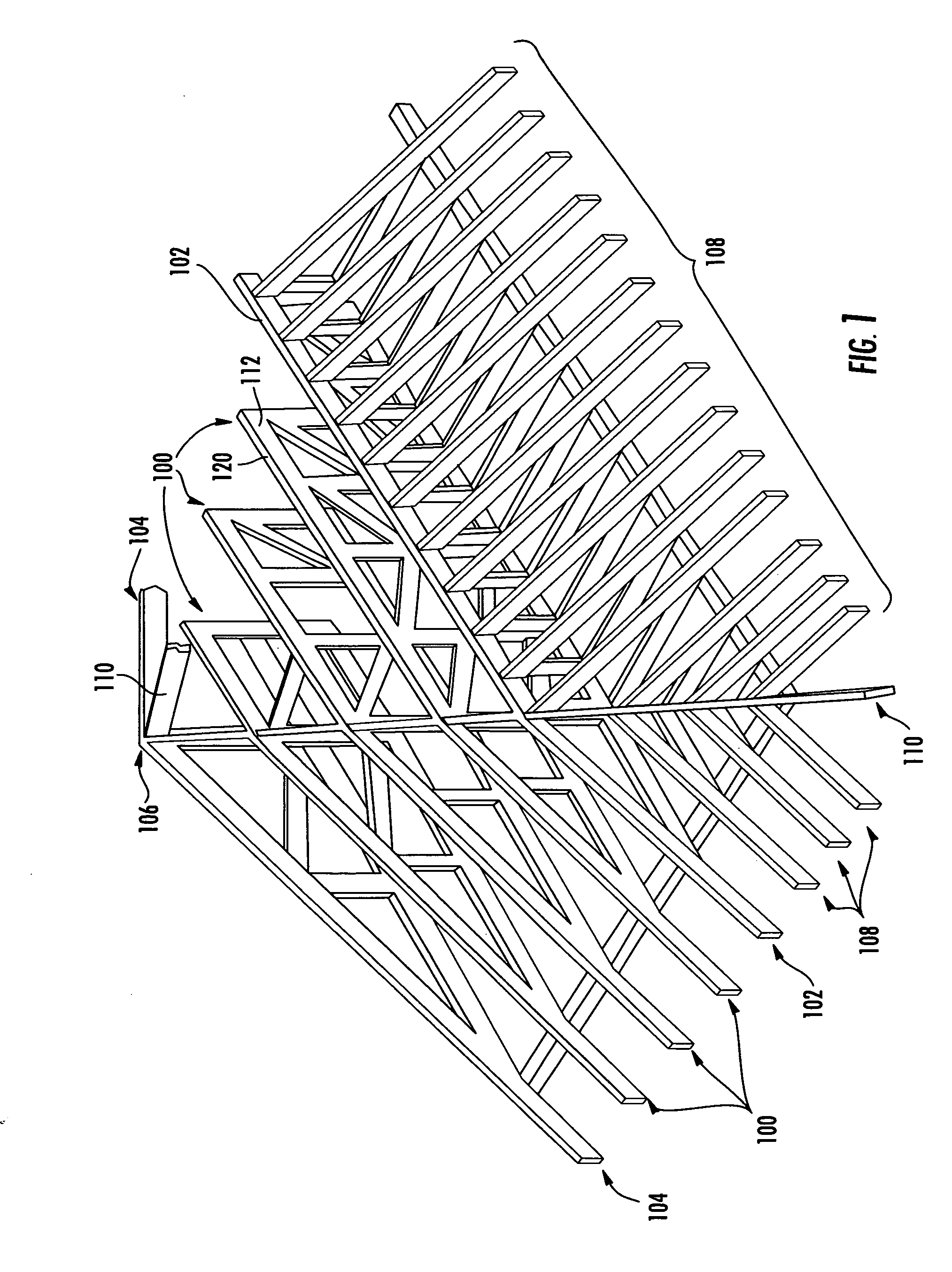

[0025]In order that the construction and benefits of the subject invention may be fully appreciated it is first necessary to understand the environment within which it is installed, namely a framed hip roof system. Reference first being made to FIG. 1, a typical hip roof end is built up of flat top hip trusses 100 arranged in a stepped up sequence beginning with a hip girder 102 and terminating in a common truss 104 the apex 106 of which serves as the peak of the hip. The truncated girder truss 102 is there to give extra strength to the hip areas. They are usually double the thickness of the ordinary trusses (two trusses of the same thickness nailed together). A plurality of hip jack trusses 108 complete the framing system some of which are attached to hip girder 102 while others are attached to diagonal hip rafter 110 as shown. Note that the hip rafters 110 form the “hip” of the roof.

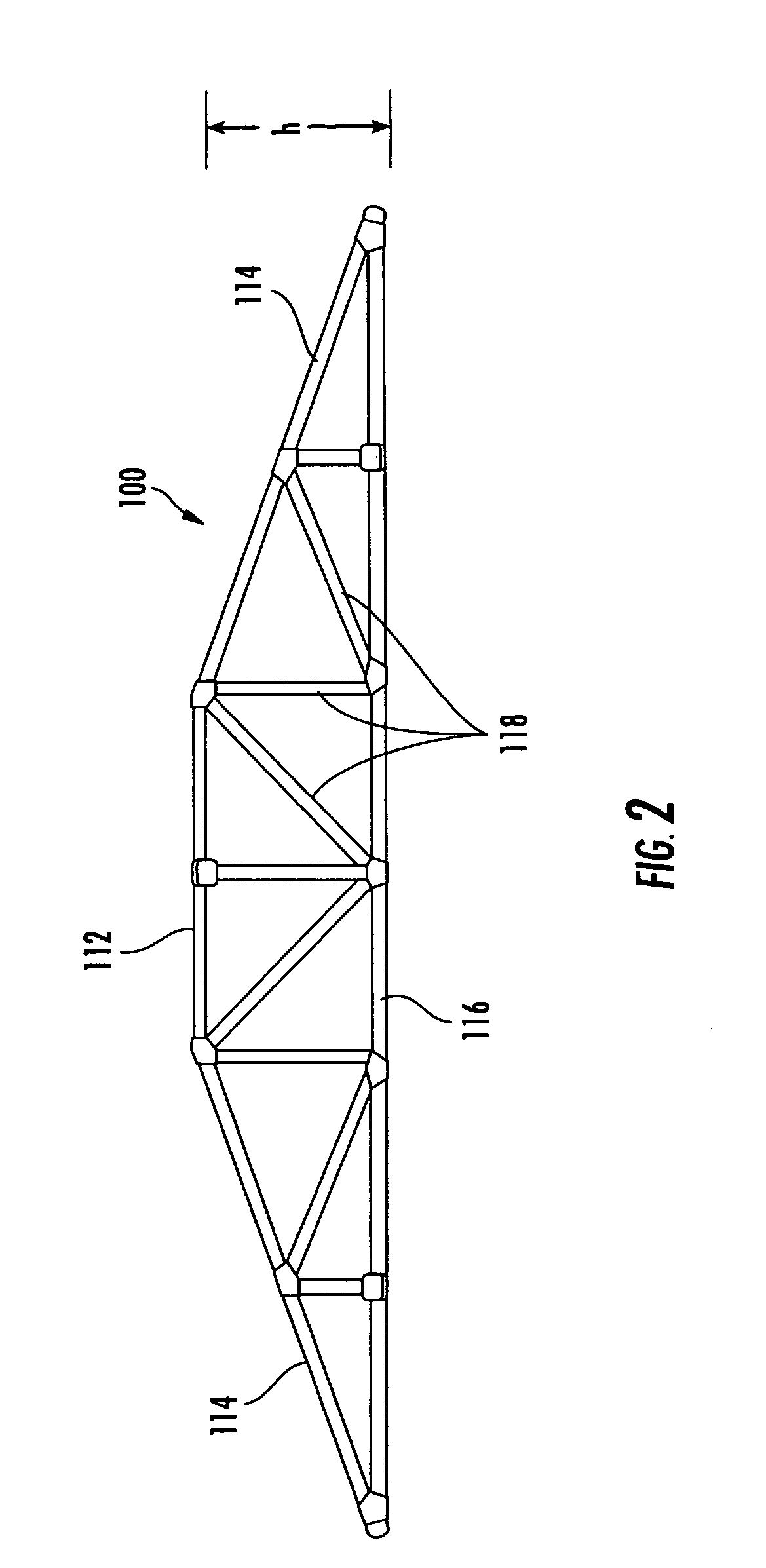

[0026]Referring next to FIG. 2, a typical hip truss 100 is comprised of a horizontal top chord memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com