Male urinal

a urinal and male technology, applied in the field of urinals, can solve the problems of affecting reducing the service life of the urinal, so as to increase the strength of the urinal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

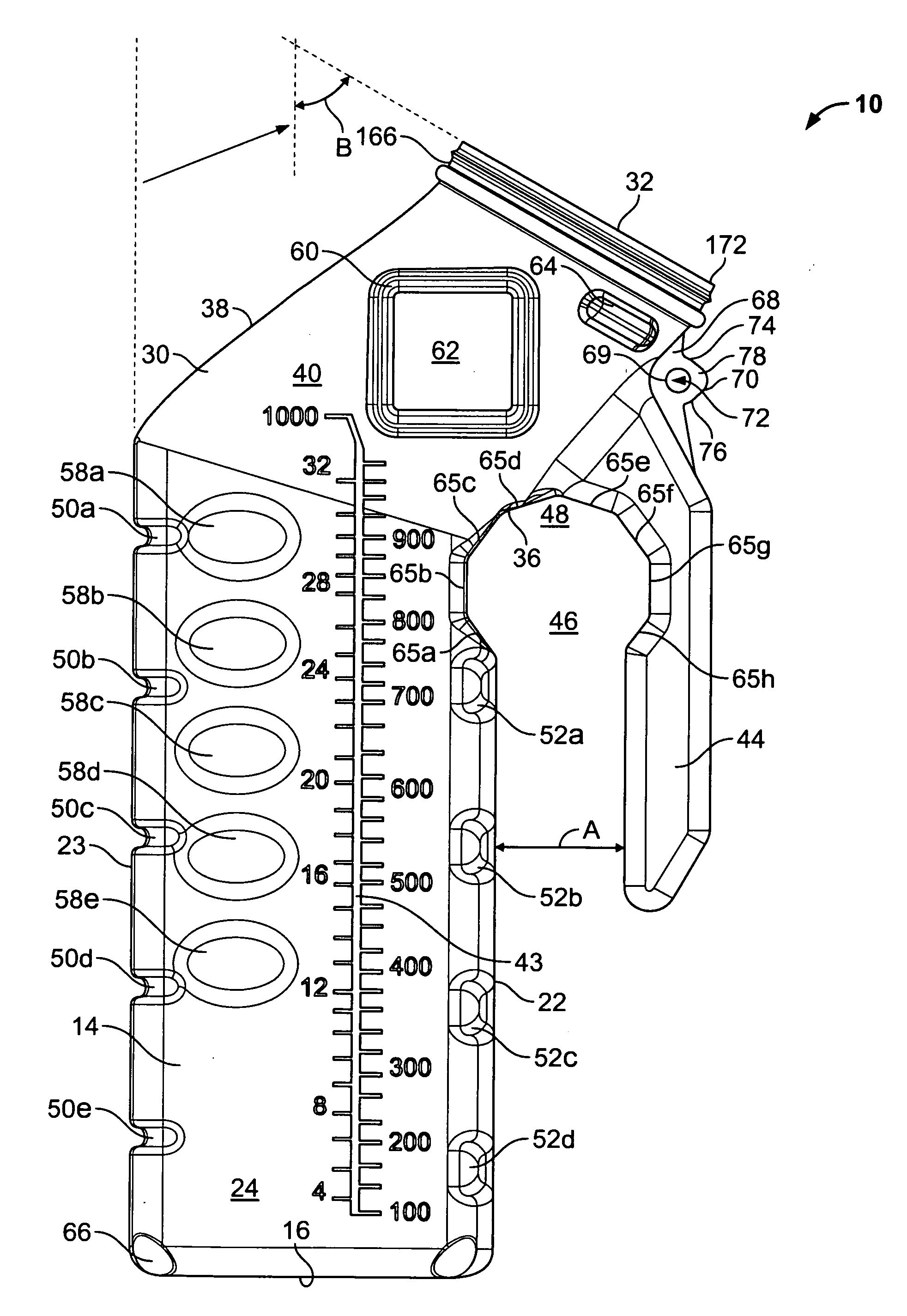

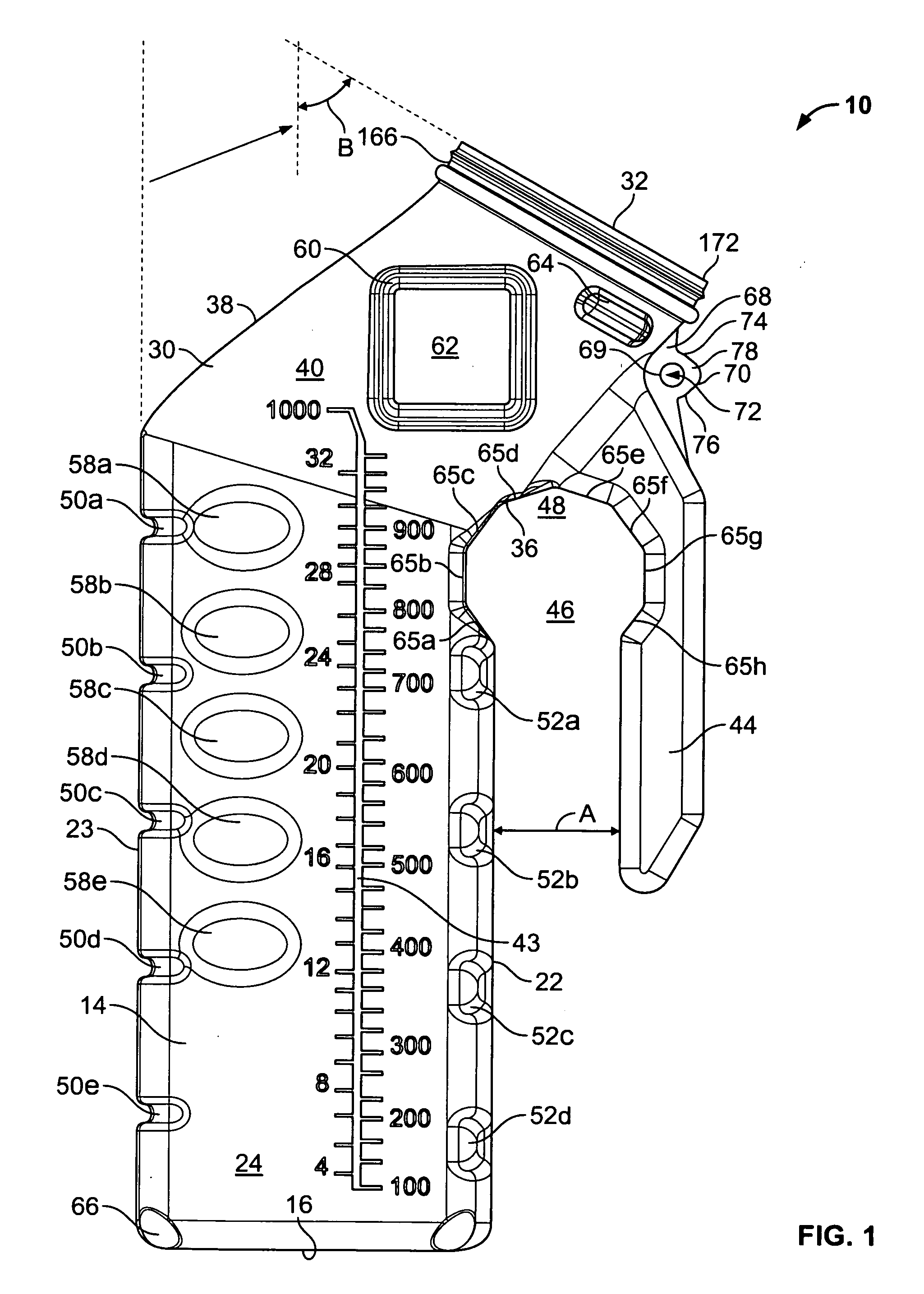

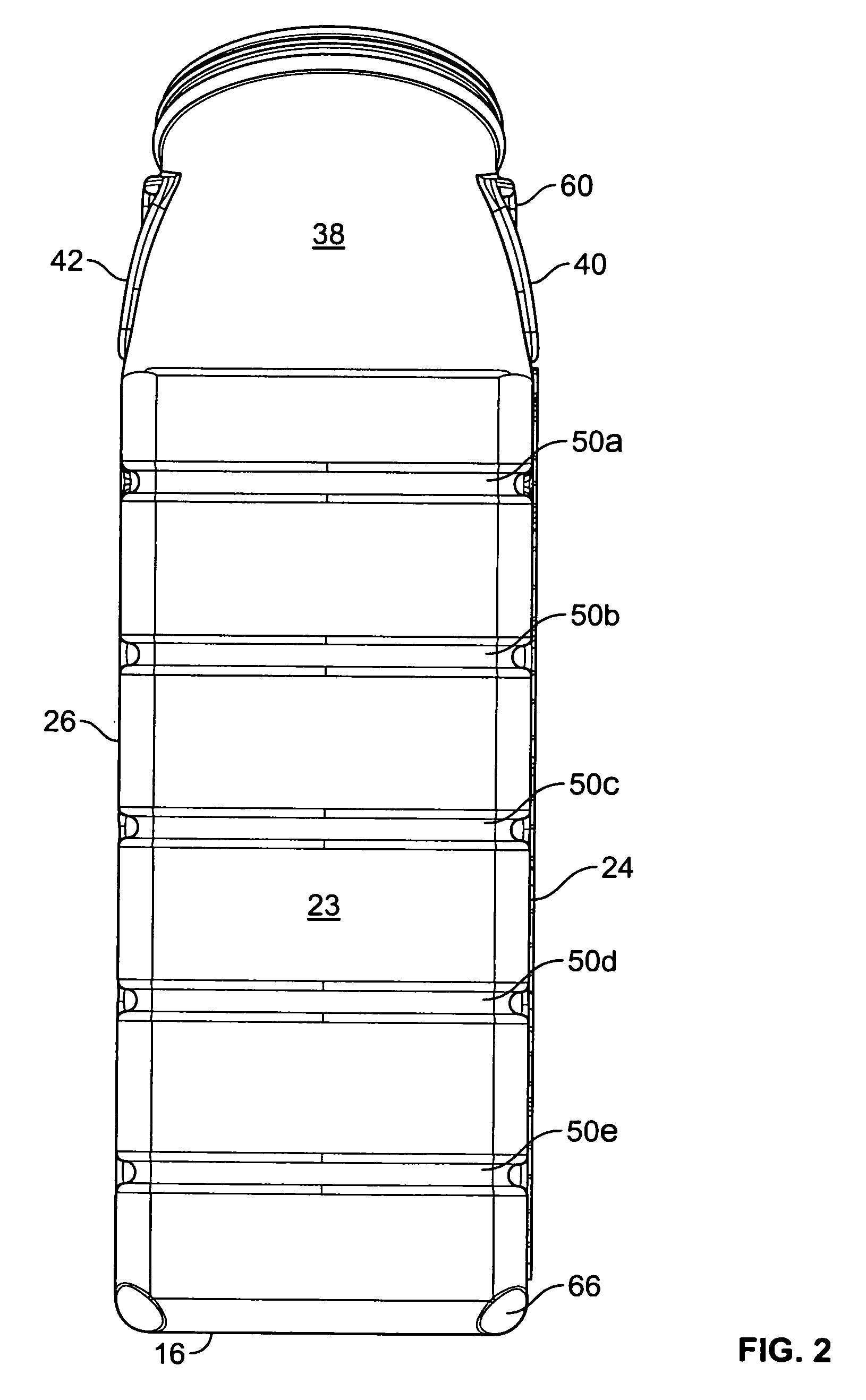

[0031]FIG. 1 illustrates a male urinal 10 according to one embodiment. The urinal 10 may be blow-molded from a suitable polymer, such as polyurethane, polypropylene, polyethylene, PET polyester, polyvinyl chloride, another type of thermoplastic polymer, or a suitable combination of polymers so as to have a body 14 having a bottom wall 16, a lower front wall 22, a lower back wall 23 positioned generally opposite the lower front wall 22, and first and second lower side walls 24, 26 (see FIG. 2) bridging the lower front and lower back walls 22, 23. The body 14 includes curved edges where the respective walls join one another. The lower front wall 22 is generally curved, which provides for ease of manufacture and strength. Thus, the bottom wall 16 has a custom shape. In one embodiment, the bottom wall 16 has a generally rectangular custom shape.

[0032]The urinal 10 further includes a neck 30 that is angled relative to the body 14. The neck 30 includes an open mouth 32 having a generally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com