Erecting a wind powerplant

a technology of wind power and rotor, which is applied in the manufacture of machines/engines, hoisting equipment, and final product manufacturing, etc., can solve the problems of cumbersome and expensive removal, high labor cost, and low design cost, and achieve the effect of reducing the complexity of removing the hoisting means and minimizing design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

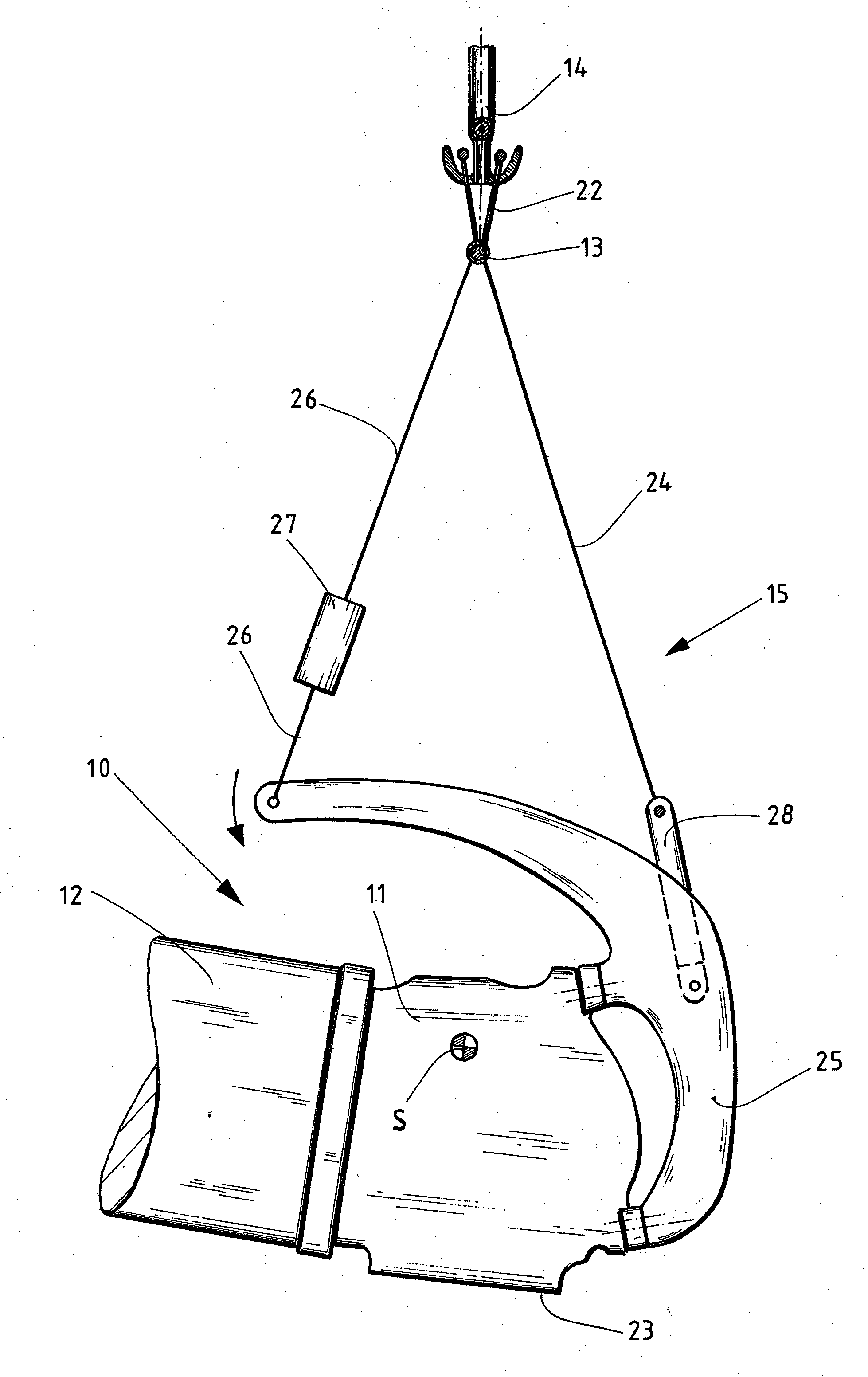

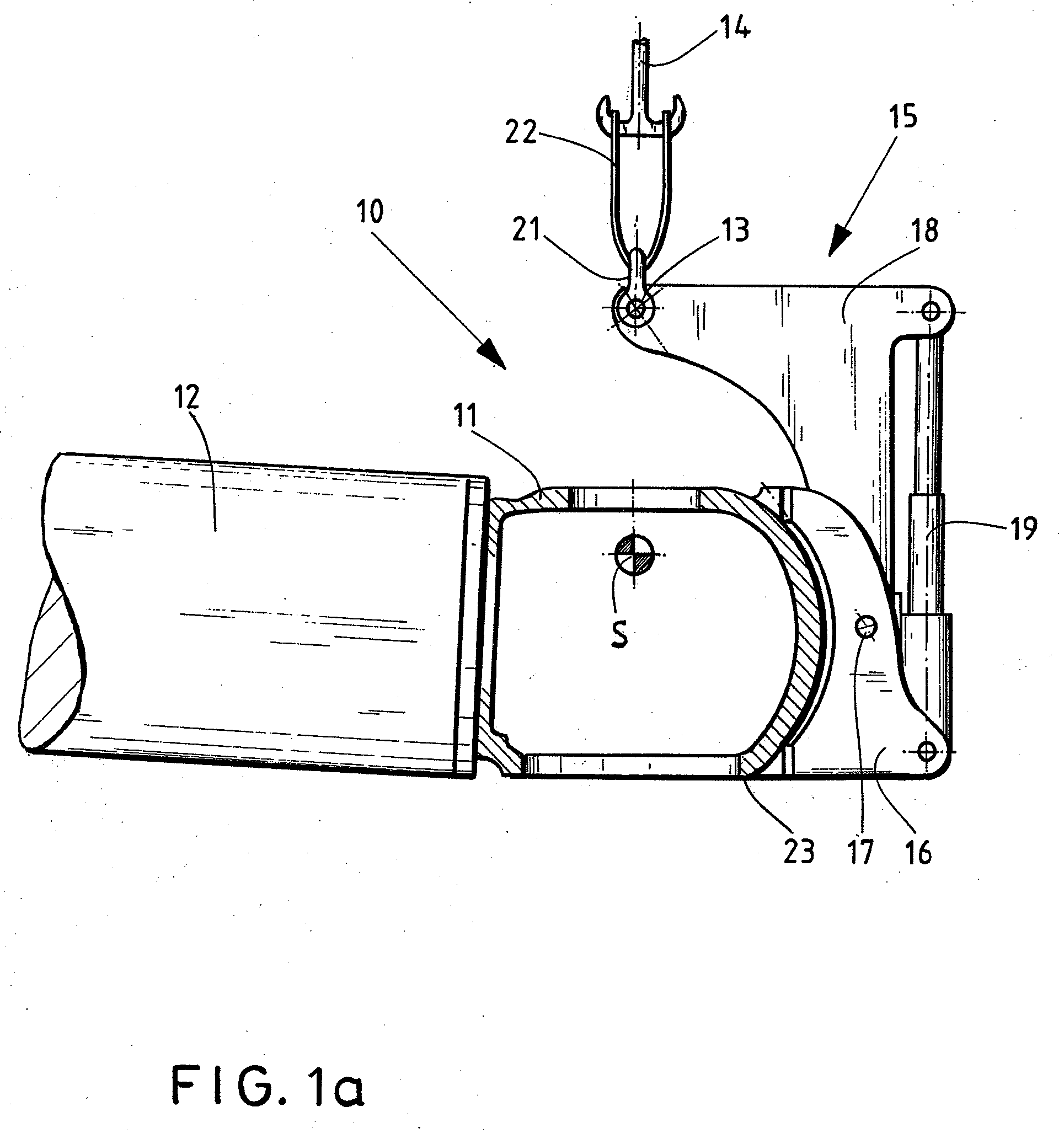

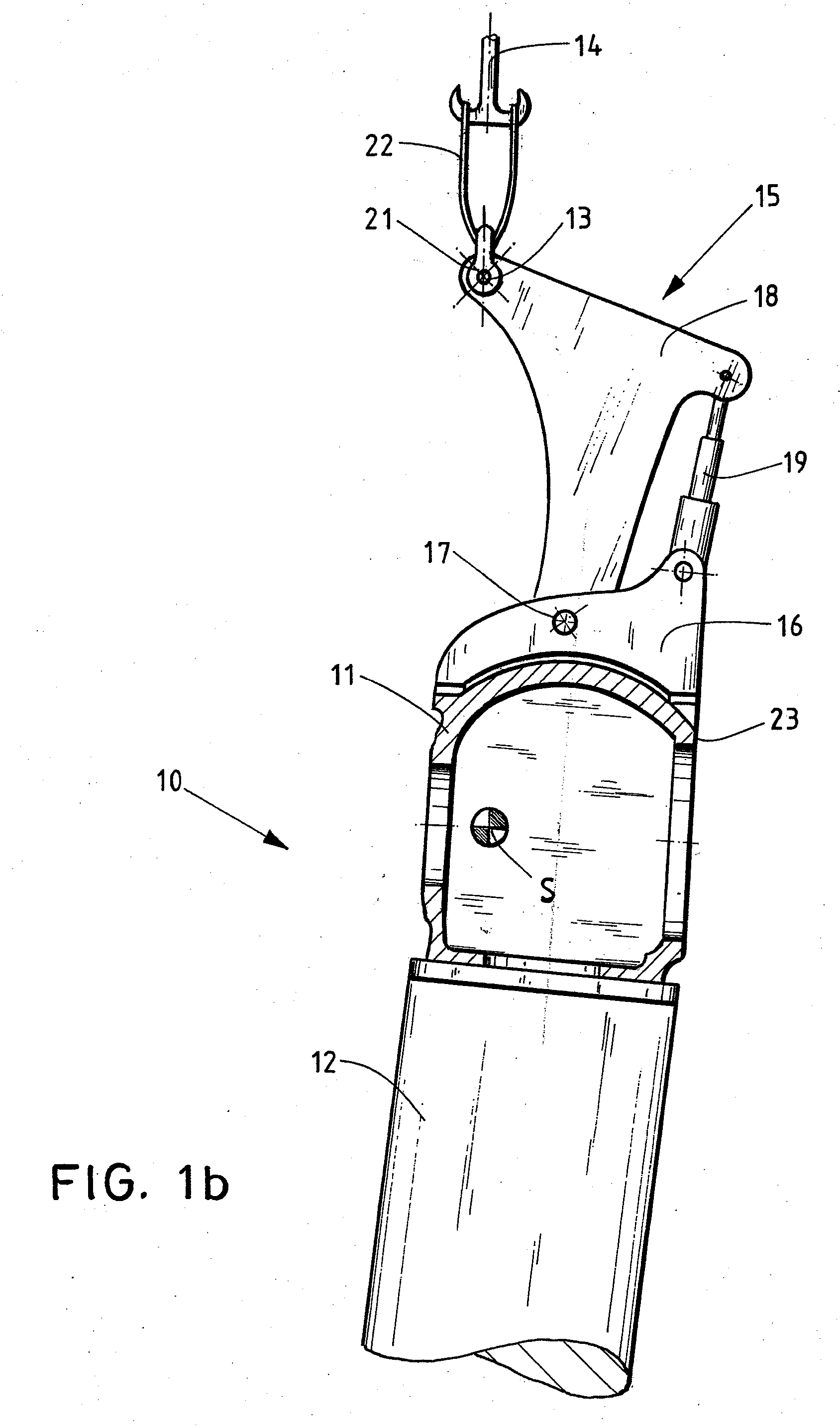

[0055]FIG. 1a is a schematic sideview of a wind powerplant rotor 10 in its raised state, where this rotor 10 comprises a schematic cross-sectionally shown rotor hub 11 and shows a rotor blade 12 mounted on the rotor hub 11.

[0056]In particular, the rotor hub 11 is fitted with several, preferably three equidistant, rotor blades 12 that are joined by flanges to it. Only one rotor blade is shown for clarity.

[0057]The rotor 10 was mounted in its horizontal state on a free, planar surface. Such assembly, for example, may be carried out at a wind powerplant erection site. In case the wind powerplants are erected offshore, the rotors 10 may be finished on land in their horizontal state and then be moved by a floating body to the erection site. At this erection site, the rotors 10 are raised out of their initial horizontal position by means of a crane provided with a boom and with a lifting cable in a manner that said rotor is suspended in a horizontal position from a hook 14 or a grappling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com