Apparatus and method to control and adjust water consumption by a toilet during refill of the bowl and reservior

a technology for toilets and toilets, applied in the direction of diaphragm valves, engine diaphragms, operating means/releasing devices of valves, etc., can solve the problems of sewage discharge, high construction and maintenance costs of sewage delivery systems and treatment plants, and foregoing traditional toilets wasteful and inefficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

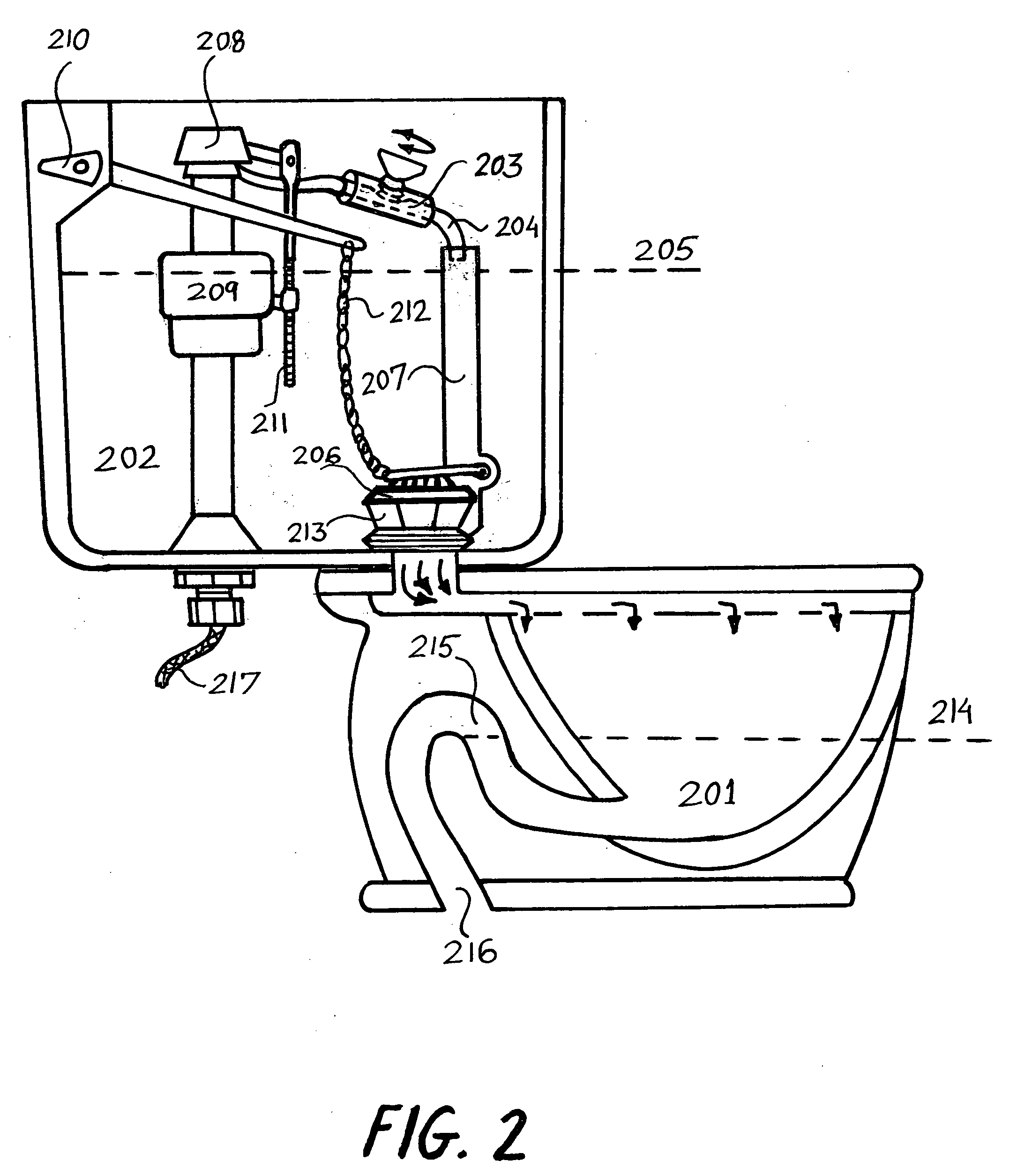

[0032]FIG. 2 illustrates a toilet bowl 201 and reservoir 202 in accordance with an example embodiment of the present invention. The example embodiment employs an adjustable valve 203 as a component of refill tube 204.

[0033]Toilet includes a reservoir 202, designed to hold a first predetermined amount of water, indicated by reservoir water level 205. The water in the reservoir 202 may be held in place by a flush valve 206. The first predetermined amount of water in reservoir 202 may be determined based on the design of the toilet and the necessary amount of water for flushing the toilet bowl 201. The reservoir also includes an overflow tube 207, a fill valve 208, having a float 209, a refill tube 204, having an adjustable valve 203, a flush handle 210, a rod 211, a flapper chain 212, and a flush valve 206, (a “flapper”).

[0034]The overflow tube 204 may be set at a height slightly above the first water level 205. The overflow tube 207 is connected to the connection tube 213. Water ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com