Apparatus for Packing Leafy Produce into a Tray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0012]FIG. 6 is side view of a plunger assembly comprising two plungers per transfer chute, wherein at least one plunger is disposed outside a transfer chute and a funnel, shown without a mounting bracket and without the support frame for clarity only, in accordance with the present invention.

second embodiment

[0013]FIG. 7 is side view of a plunger assembly comprising two plungers per transfer chute, wherein at least one plunger is disposed inside a product transfer chute and a funnel, shown without a mounting bracket and without the support frame for clarity only, in accordance with the present invention.

[0014]FIG. 8 is a front view of an automated packing machine, being serially disposed in an assembly line, in accordance with an embodiment of the present invention.

[0015]FIG. 9 is an upward perspective view of an automated packing machine, in accordance with the present invention, with a plunger assembly comprising one plunger per transfer chute.

[0016]FIG. 10 is a downward perspective view of the automated packing machine, as shown in FIG. 9, in accordance with the present invention, with a plunger assembly comprising one plunger per transfer chute.

[0017]FIG. 11 is an upward perspective view of an automated packing machine, shown without the support frame for clarity only, in accordance...

fifth embodiment

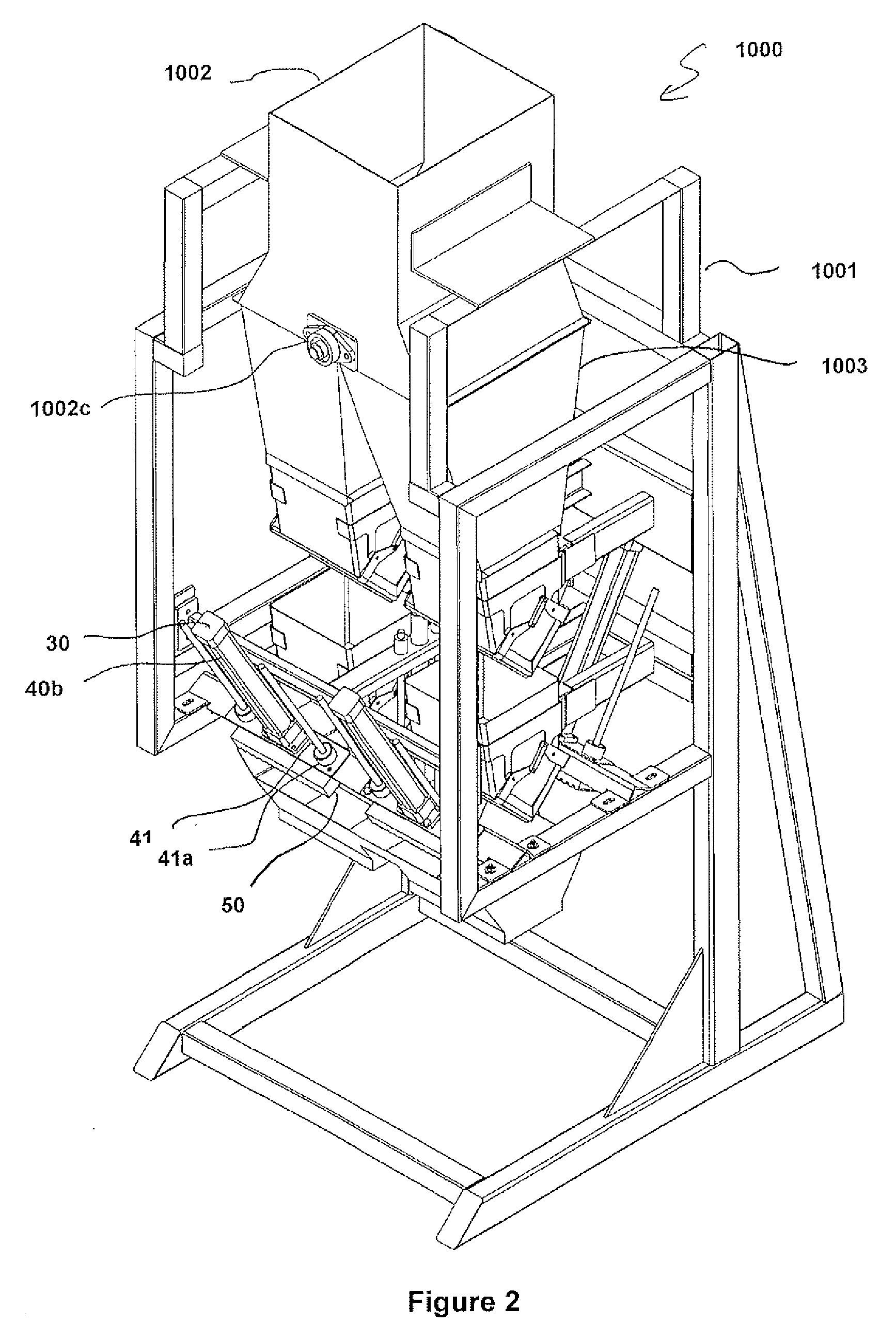

[0031]FIG. 8 illustrates, in a front view, an automated packing machine 1000, comprising automated plunger assemblies 100, 100′, being serially disposed in an assembly line, wherein the second apparatus 100′ acts as a secondary set of plungers, in accordance with the present invention. The primary chute 1002 comprises a flop gate 1002a, a flop gate actuator 1002b, and a flop gate control device 1002c, such as a solenoid switch, for controlling the flop gate actuator 1002b. The flop gate 1002a limits the amount of leafy produce 10 which is packed at a given packing interval.

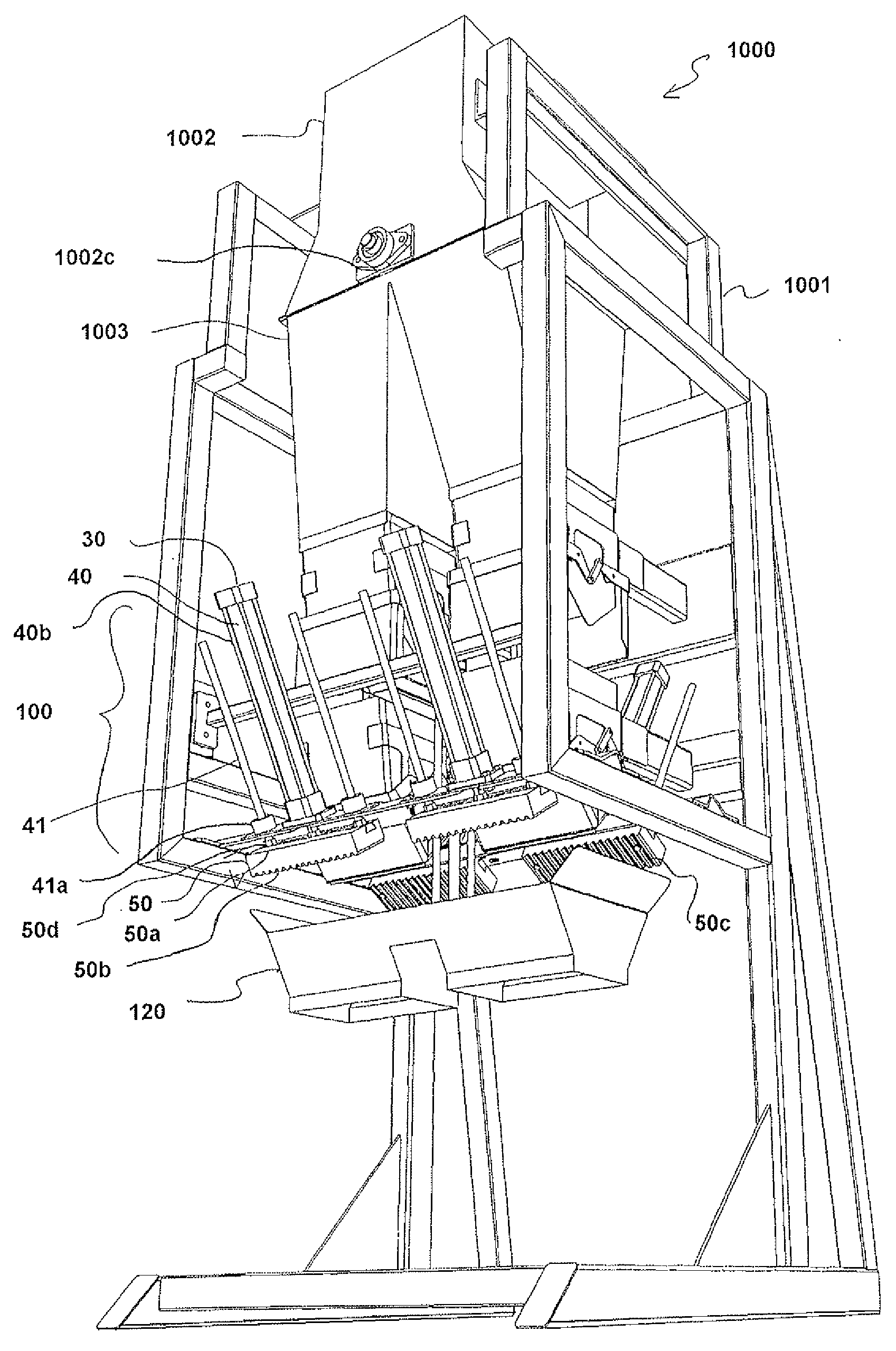

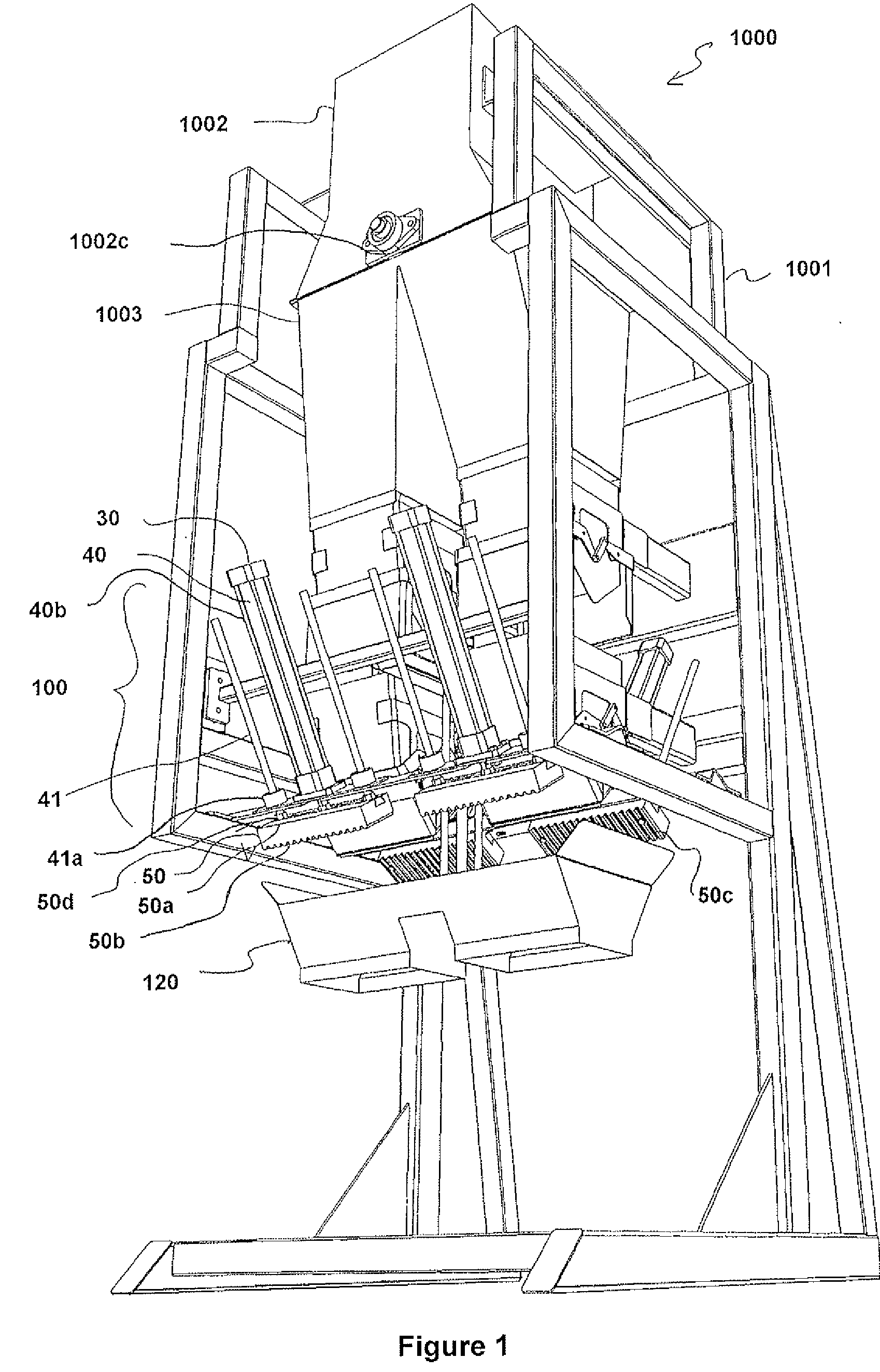

[0032]Referring to both FIGS. 1 and 8, the automated machine 1000 for packing leafy produce 10 into a tray 20, comprises a conveyor 60 having a stepper 70 for accommodating and moving at least one tray 20, a tray filler generally comprising a hopper 80 for channeling the leafy produce 10 and a feeder 90 for receiving the channeled leafy produce 10 and for filling the leafy produce 10 into the at least one tray 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com