System performance correction by modifying refrigerant composition in a refrigerant system

a refrigerant system and composition technology, applied in refrigeration components, liquefaction, light and heating equipment, etc., can solve the problems of reducing the leakage of refrigerant components in the mixture more than the others, so as to reduce the amount of cycling, reduce the current, and reduce the unit capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

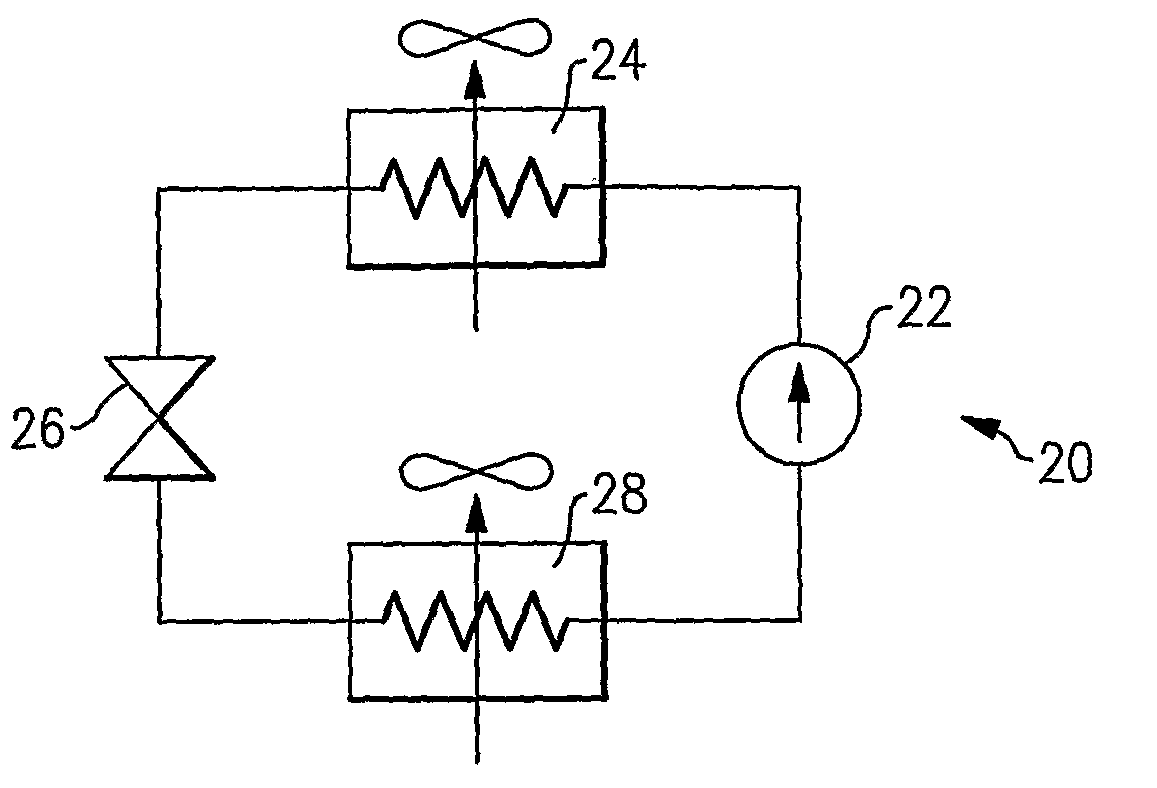

[0015]As shown in FIG. 1, a refrigerant system 20 includes a compressor 22 compressing a refrigerant and delivering it downstream to a condenser 24. Refrigerant passes from the condenser 24 to an expansion device 26, and then to an evaporator 28. As is known, the condenser in a conventional air conditioning system is typically located outdoors, and delivers heat to the ambient environment. The evaporator is typically positioned indoors, and conditions air to be delivered into a building. As also known, refrigerant circulates between the four basic components, 22, 24, 26 and 28 interconnected in a closed-loop arrangement. Many other subsystems and components are often included in refrigerant systems. However, for purposes of explaining this invention, all that is necessary is to understand the basic refrigerant system schematic and operation.

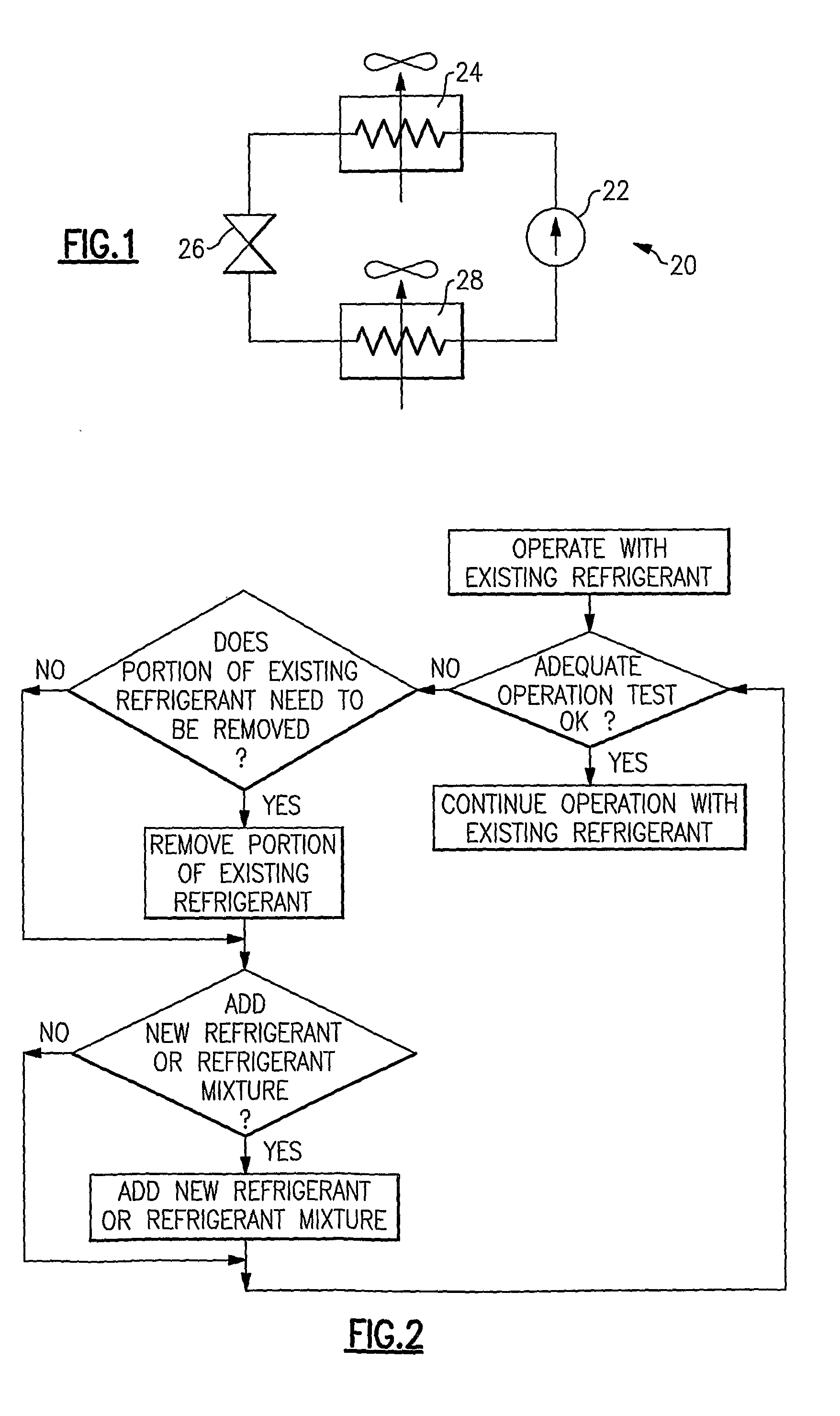

[0016]When it has been determined that the refrigerant system 20 is operating less than optimally, a decision can be made to partially or fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com