Wood Beam System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

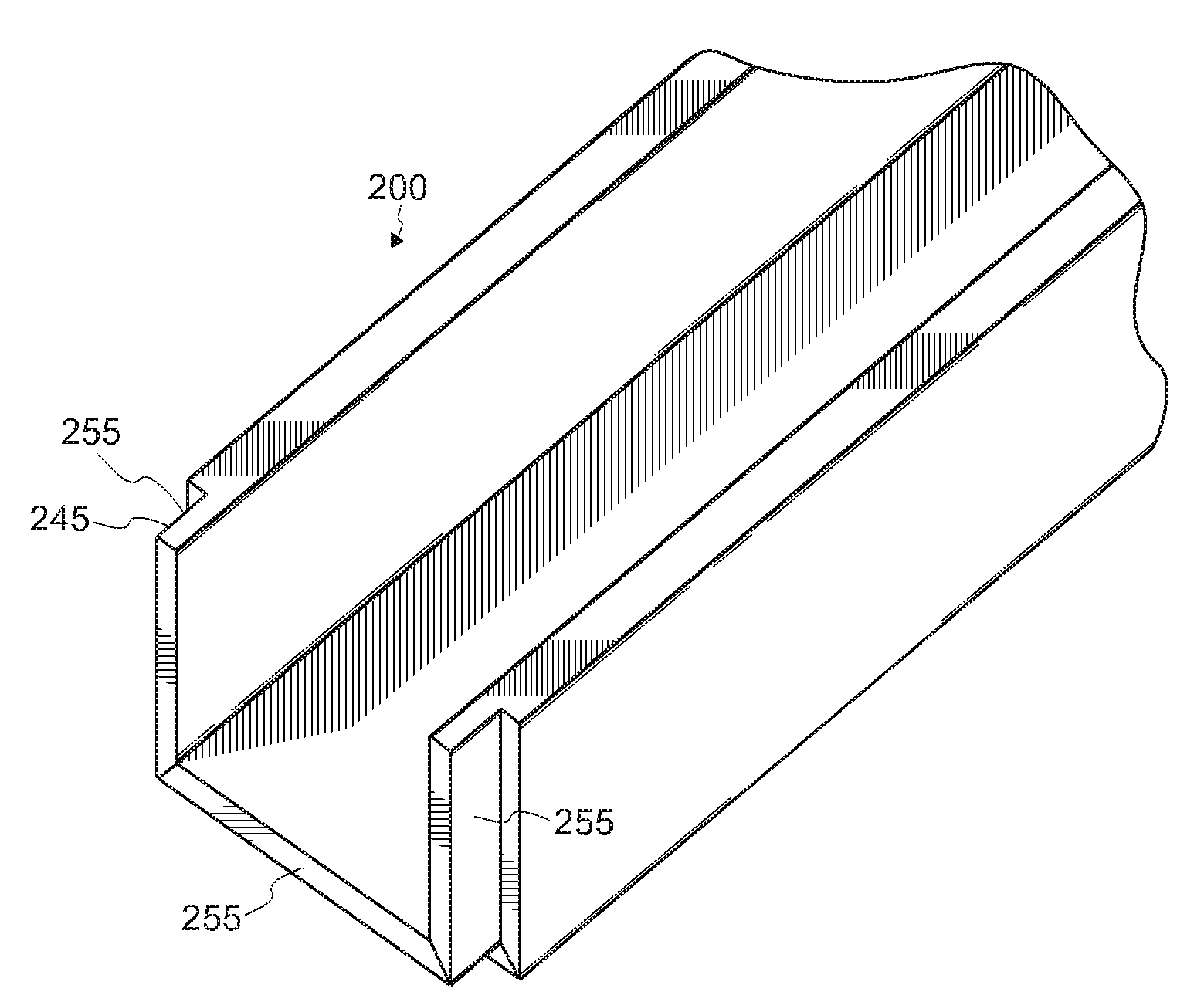

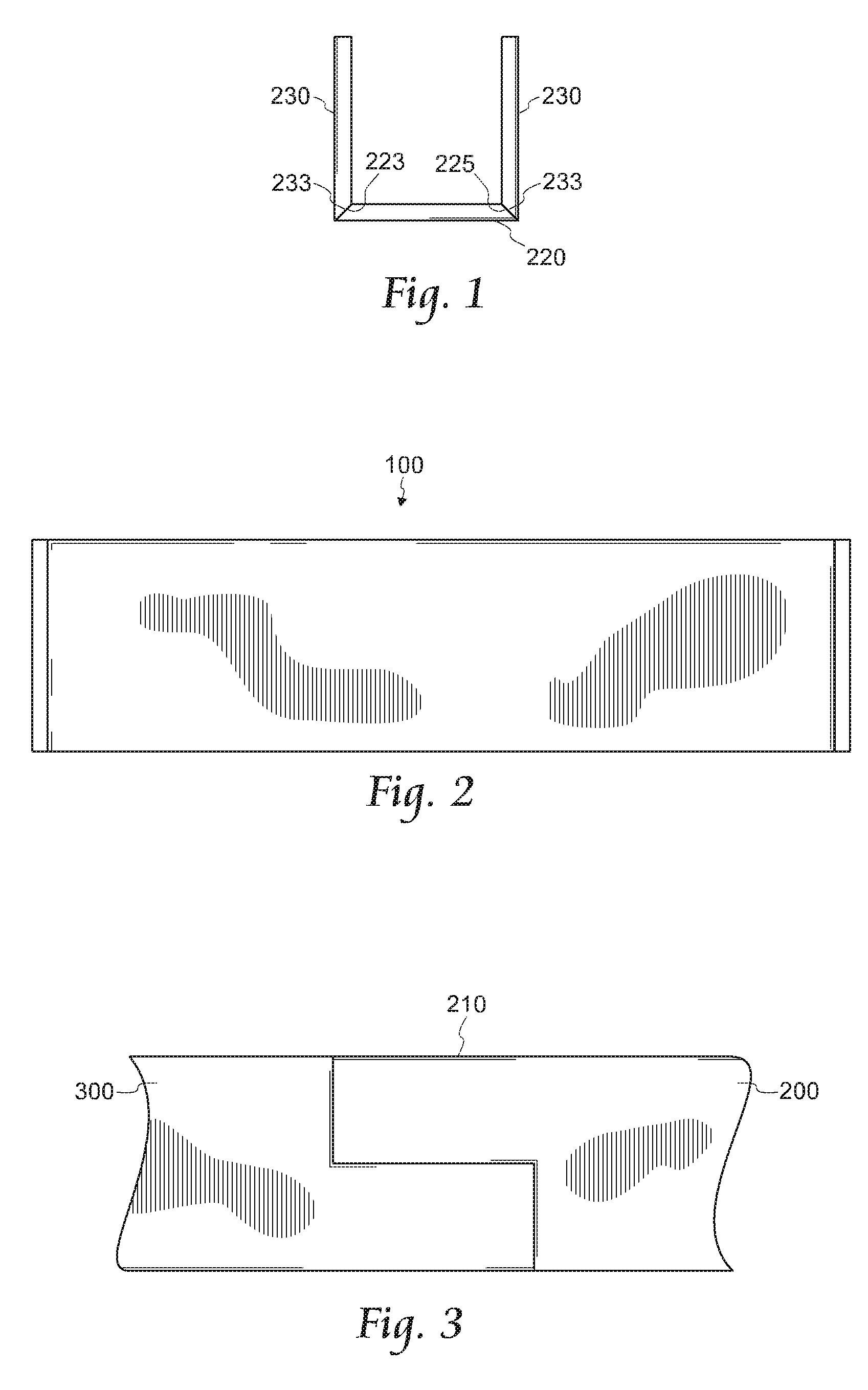

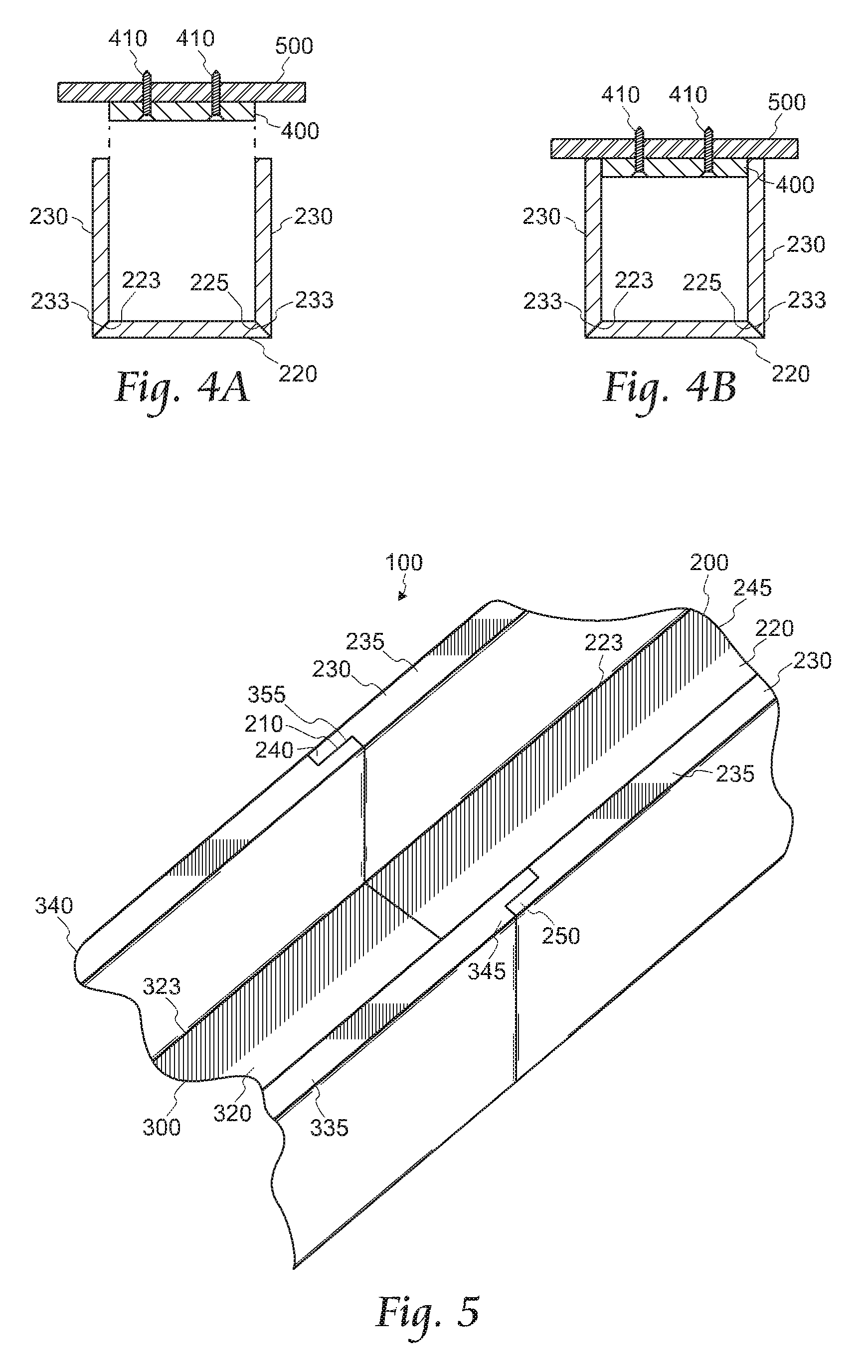

[0022]FIG. 5 shows a top view of the preferred embodiment of the beam system 100. As seen in FIGS. 4A, 4B, and 5, the beam system 100 comprises a first beam piece 200, a second beam piece 300, and an anchor plate 400. These pieces combined together create the beam system 100 disclosed. Preferably, the first beam piece 200 and the second beam piece 300 are made of real wood and are coupled together, as shown in FIG. 3, using a shiplap joint 210 at the connection point.

[0023]In the preferred embodiment of the invention, the first beam piece 200 further comprises a bottom plate 220 and two vertical plates 230, as shown in FIGS. 5 and 7. The bottom plate 220 has a first edge 223 and a second edge 225 that are mitered. The two vertical plates 230 both include a top edge 233 and a bottom edge 235. Only the top edges 233 of the vertical plates 230 are mitered in the preferred embodiment. The first edge 223 of the bottom plate 220 is coupled to the top edge 233 of the first vertical plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com