Etching process apparatus and member for etching process chamber

a technology of etching process chamber and process apparatus, which is applied in the field of etching, can solve the problems of chemically damaged to produce fine sio, the inner wall materials of the etching process container are notable to be depleted, and the damage of each member in the container is more severe, so as to achieve the effect of diminishing pores and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

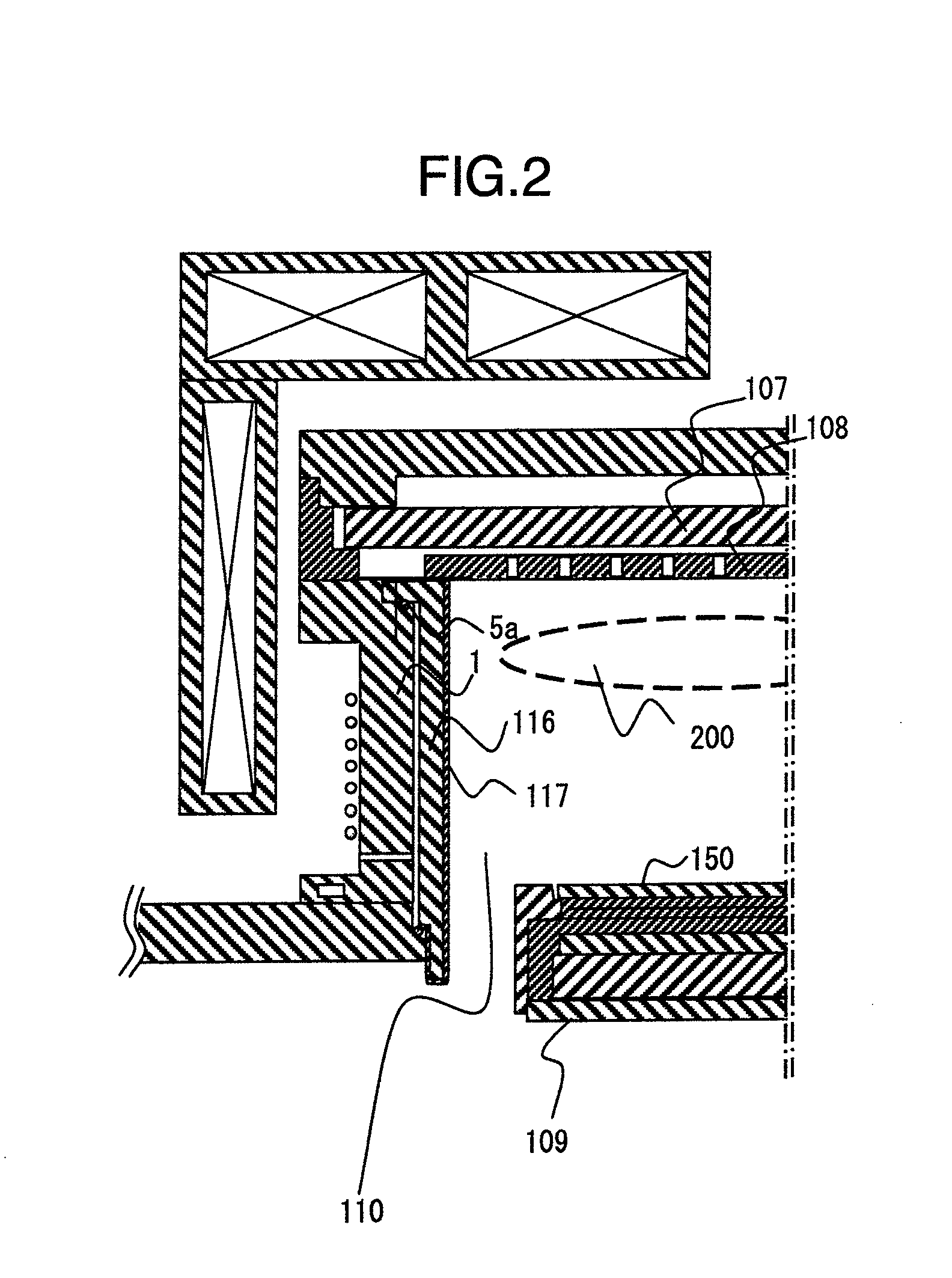

[0037]One example of the present invention is described by referring to FIGS. 1, 2, 3 and 4.

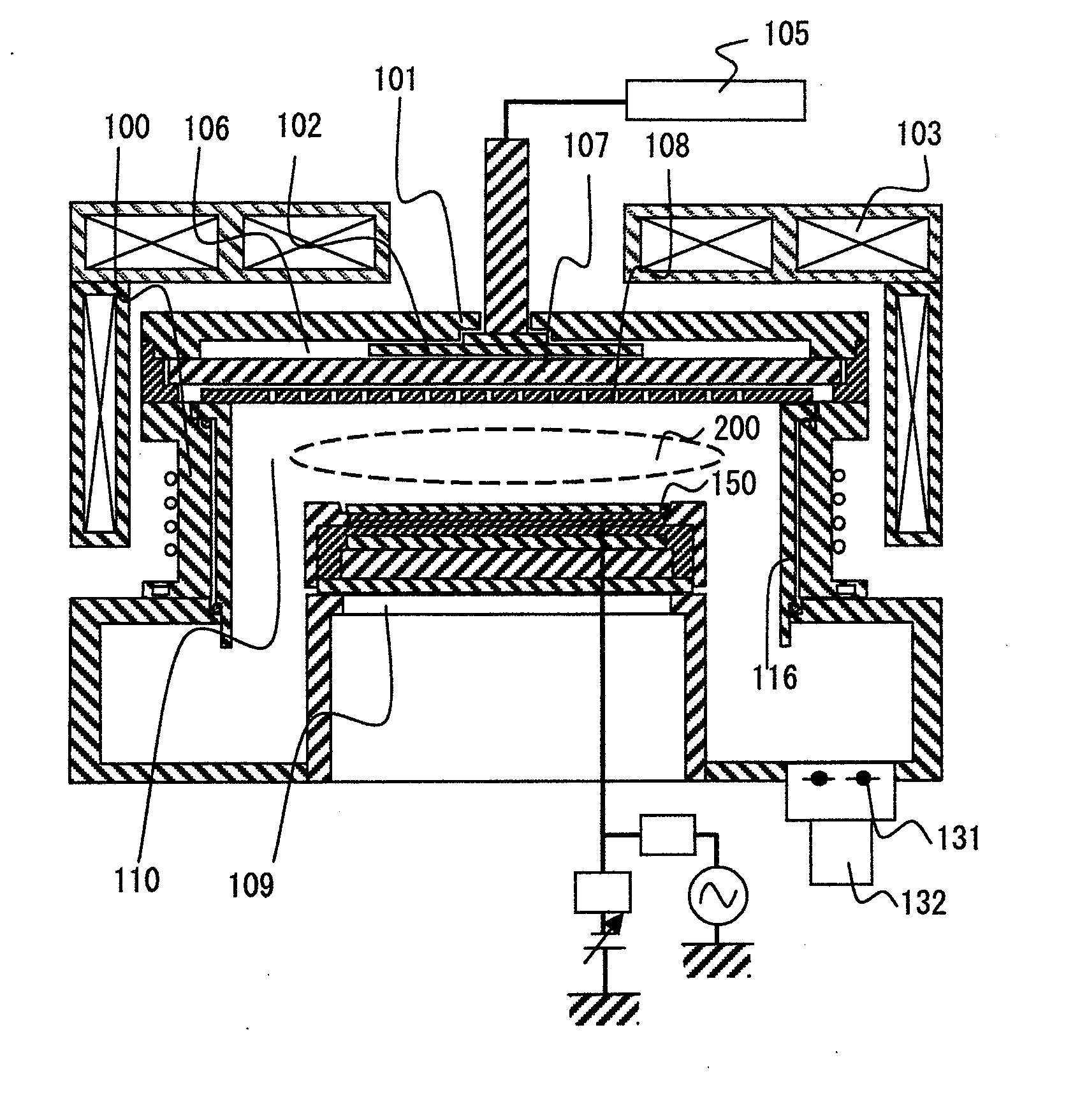

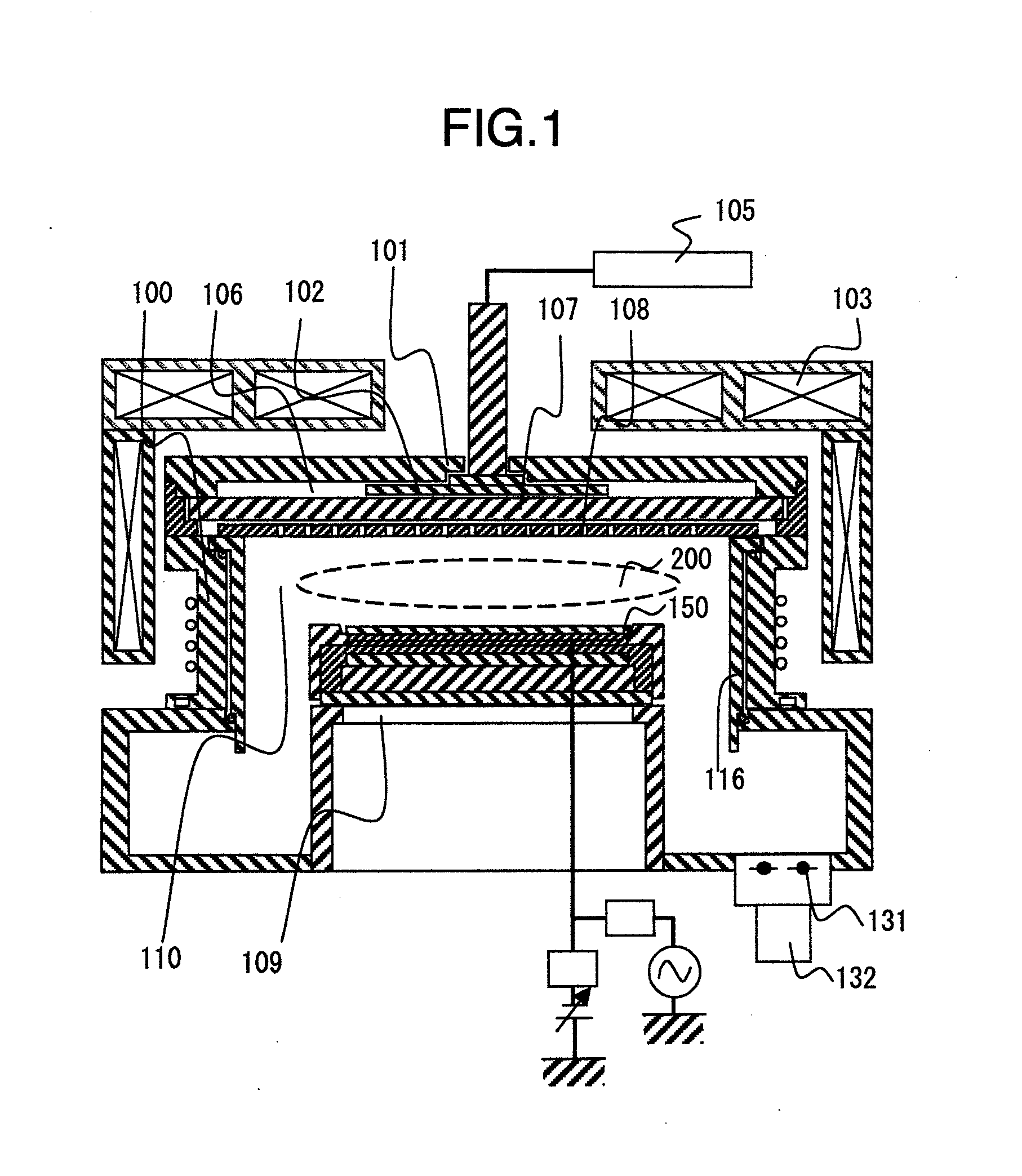

[0038]FIG. 1 shows a cross-sectional view, cut in the longitudinal direction, outlining an etching process apparatus structure of this example of the present invention. As illustrated, the etching process apparatus of this example comprises a process chamber 100 which is a vacuum container containing an etching process chamber 110, and means for supplying an electrical and magnetic fields into the etching process chamber 110 to produce a plasma therein and means for supplying a treat gas into the etching process chamber 110, both means disposed above the chamber 110. It also equipped with an exhaust valve 131 and exhaust pump 132 disposed below, and in communication with, the etching process chamber 110, to exhaust the chamber.

[0039]The etching process chamber, capped by a lid member 101, comprises an antenna 102 disposed below the lid 101, and magnetic field generating section 103 disposed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com