Hose Clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

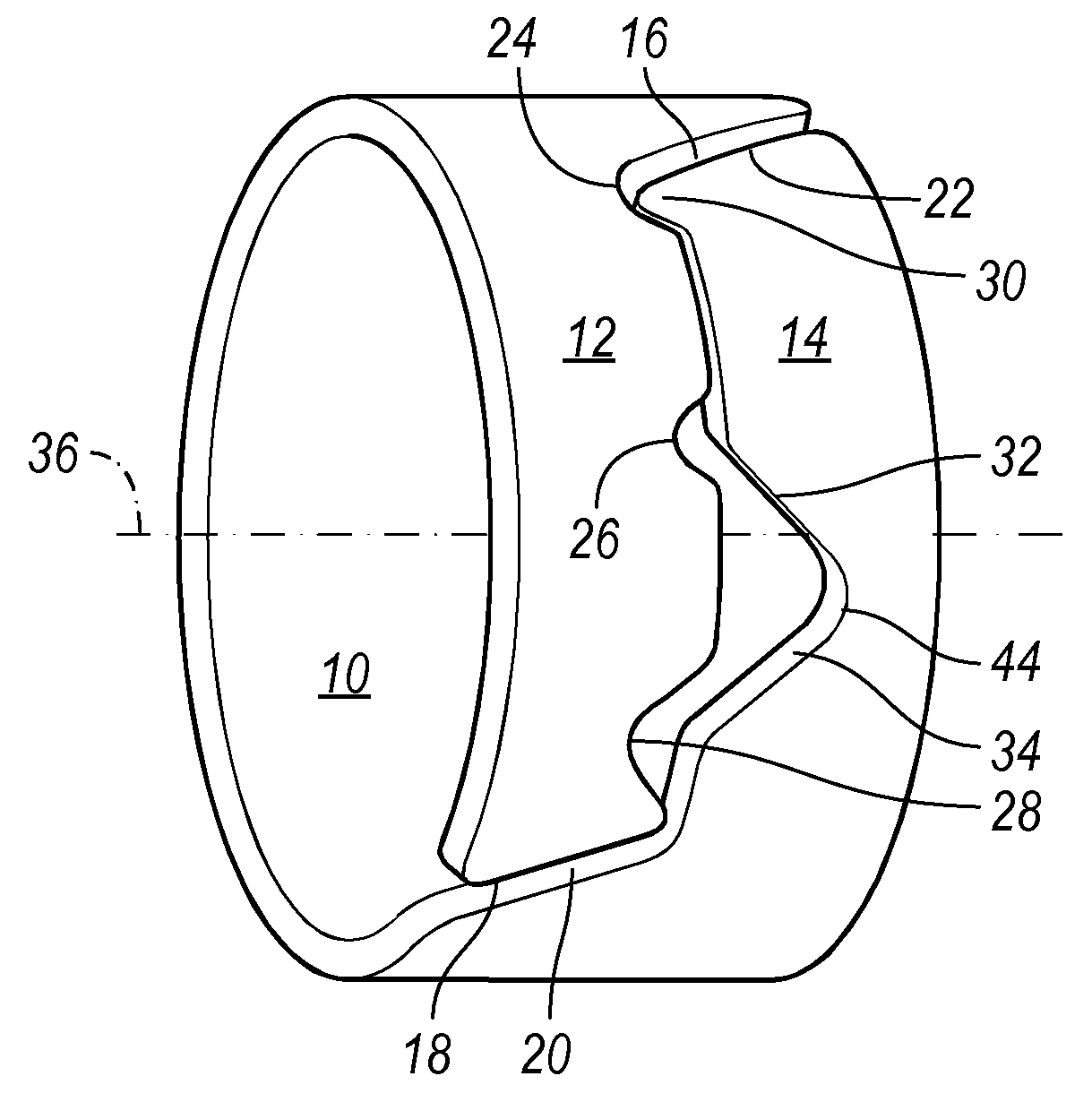

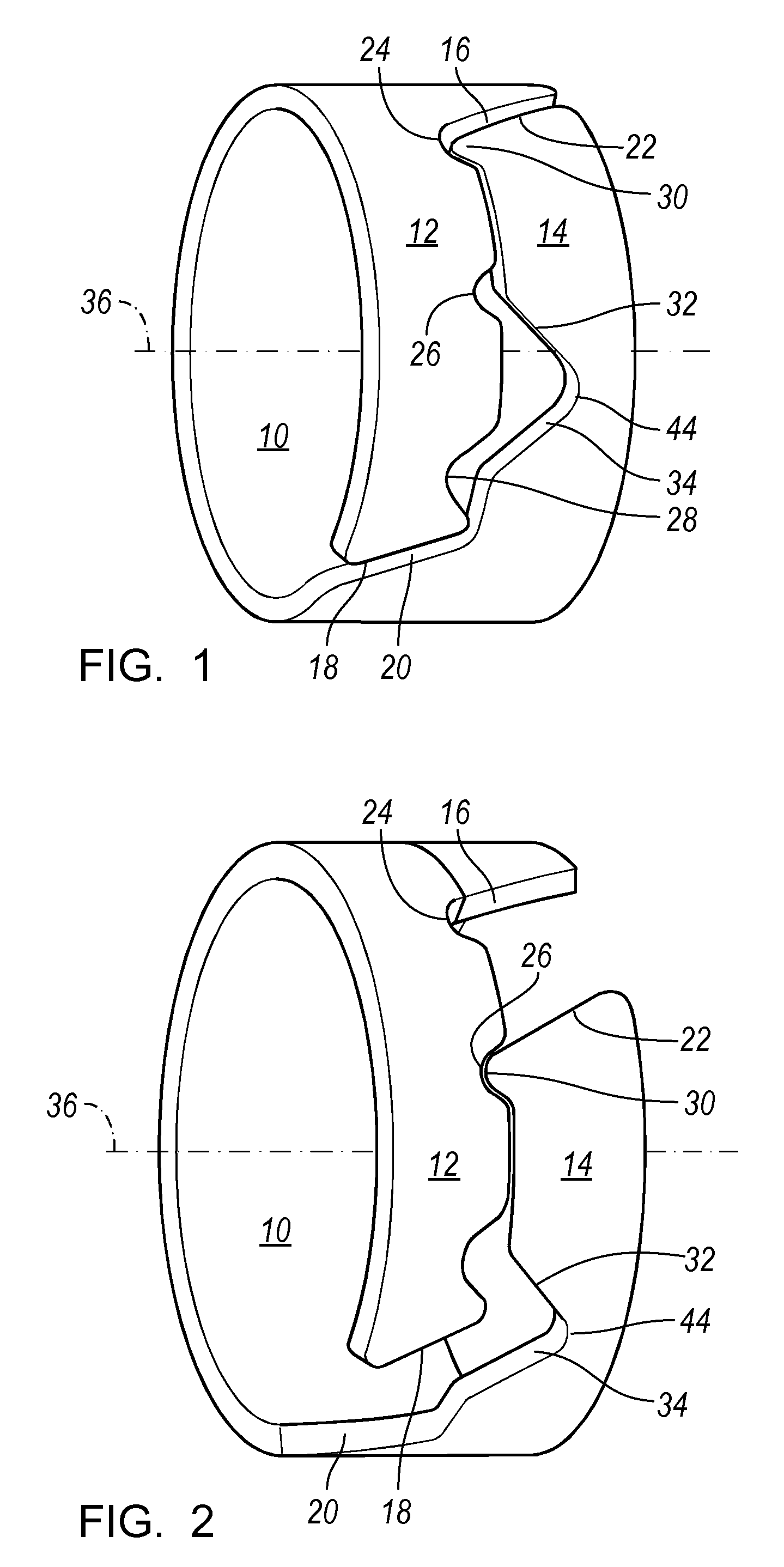

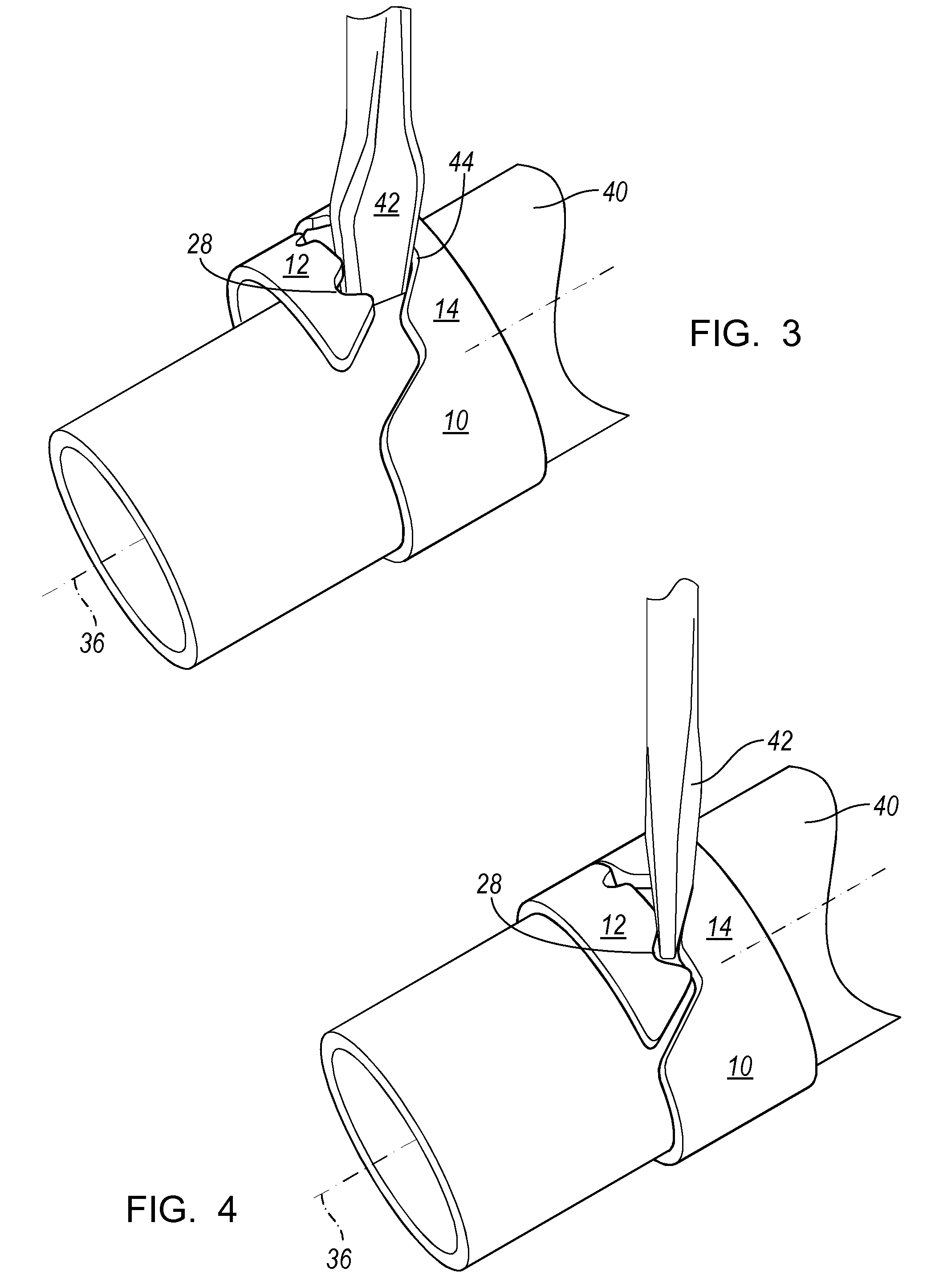

[0022]Referring first to FIG. 1, a first hose clamp 10 is formed in a circular, open-ended hoop of uniform thickness from elastically resilient material, preferably steel. FIG. 1 illustrates clamp 10 in its closed state. FIG. 2 illustrates clamp 10 in its open state, in which the clamp develops and maintains an elastic, resilient preload tending to restore the clamp to the closed state.

[0023]Clamp 10 includes first and second mutually parallel bands 12, 14 that extend along the circumference of the clamp, each band extending axially across a portion of the width of the clamp 10. A first transition surface 16 leads to band 12 and to its open end 18. A second transition surface 20 leads to band 14 and to its open end 22, which faces and is spaced from surface 16. Similarly, end 18 faces and is spaced from transition surface 20.

[0024]Band 12 is formed with recesses 24, 26, 28, which are spaced mutually along the circumference. Band 14 is formed with a projection 30, which can engage ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com