Modular Element With Photovoltaic Module

a technology of photovoltaic modules and modules, applied in photovoltaics, solar heat collectors for particular environments, heat collector mounting/support, etc., can solve the problems of difficult sealing and thermal protection of the roof in its entirety, complex construction of such a structure, and complex integration of solar panels on such a structure. achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

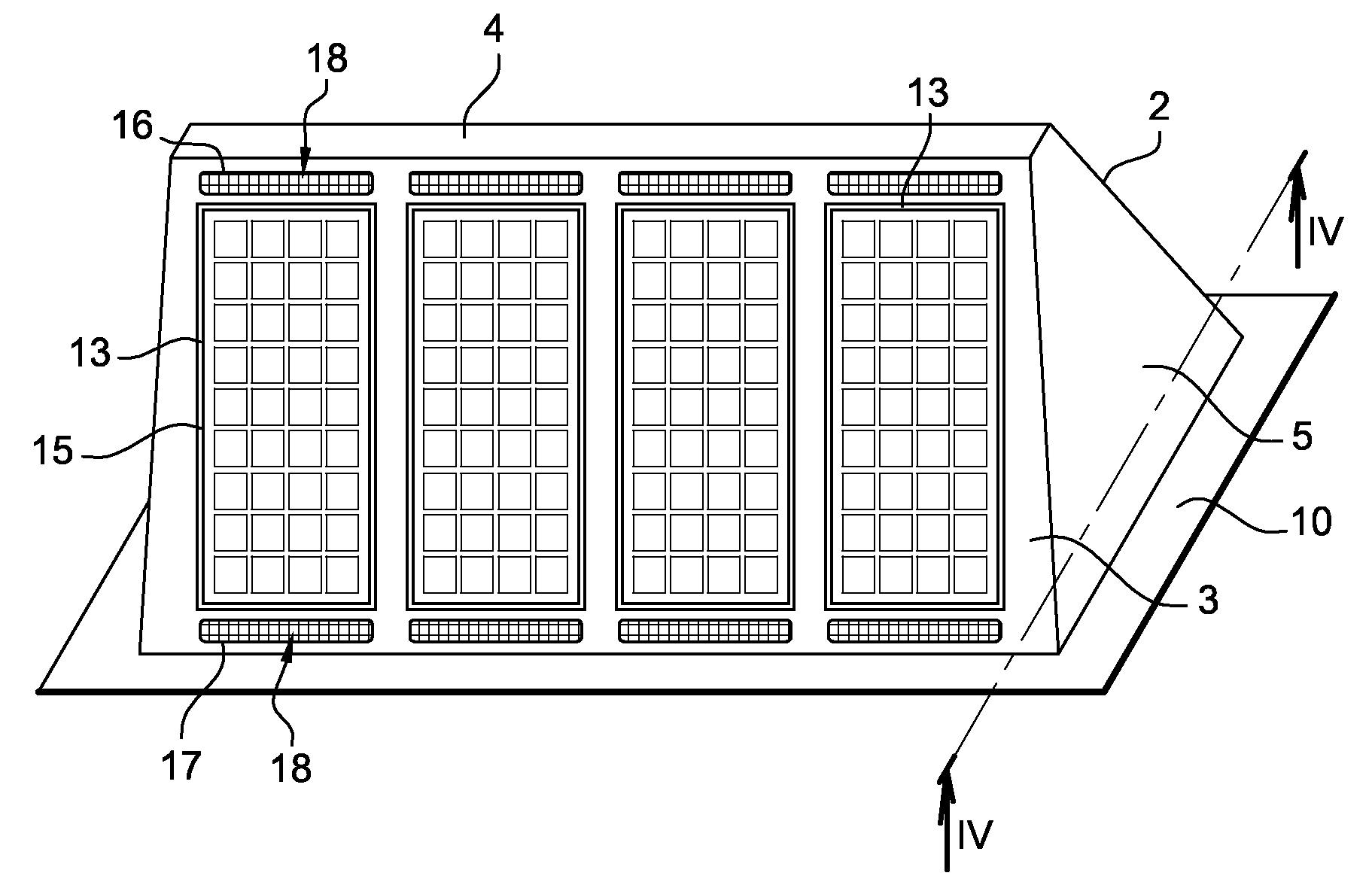

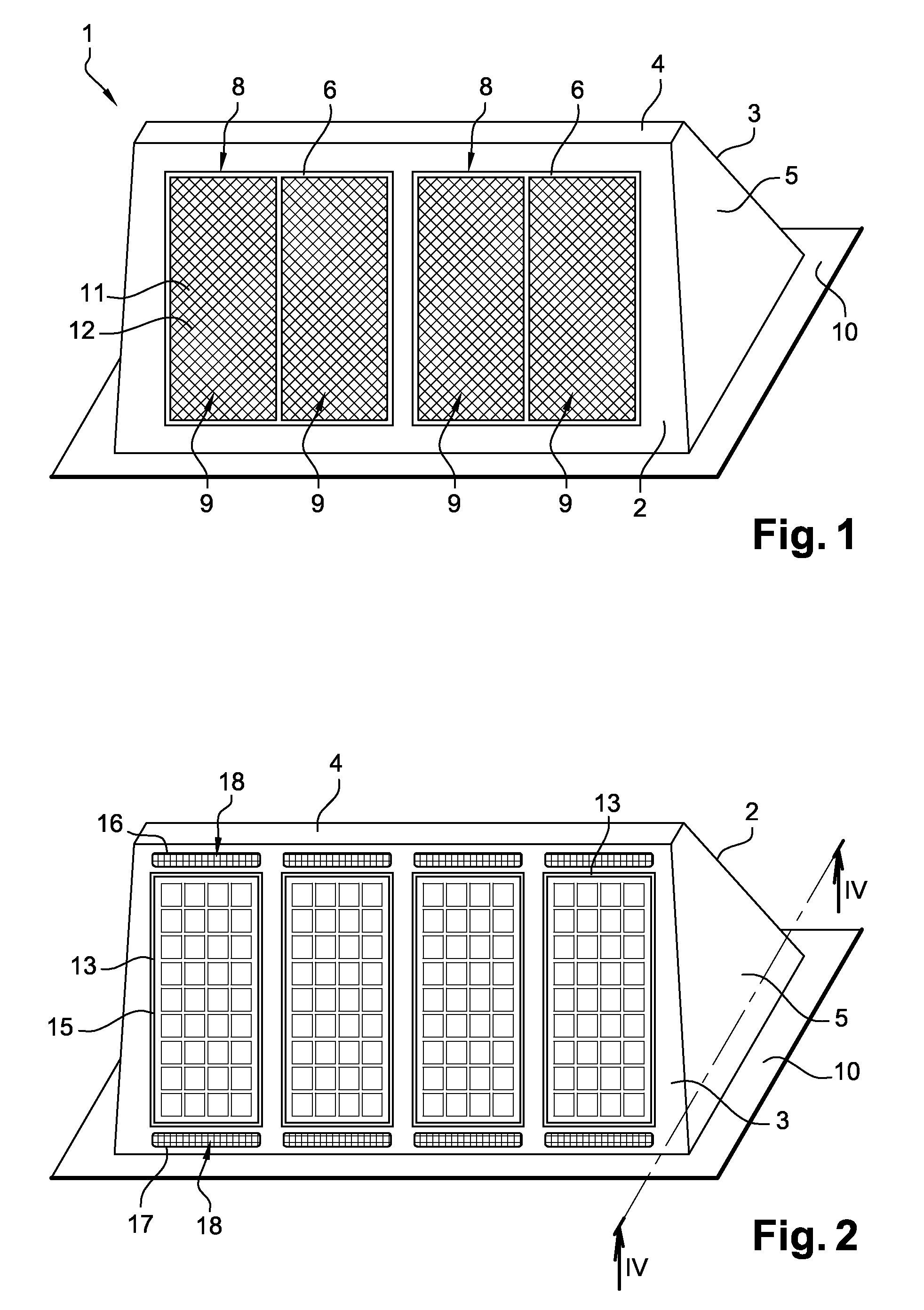

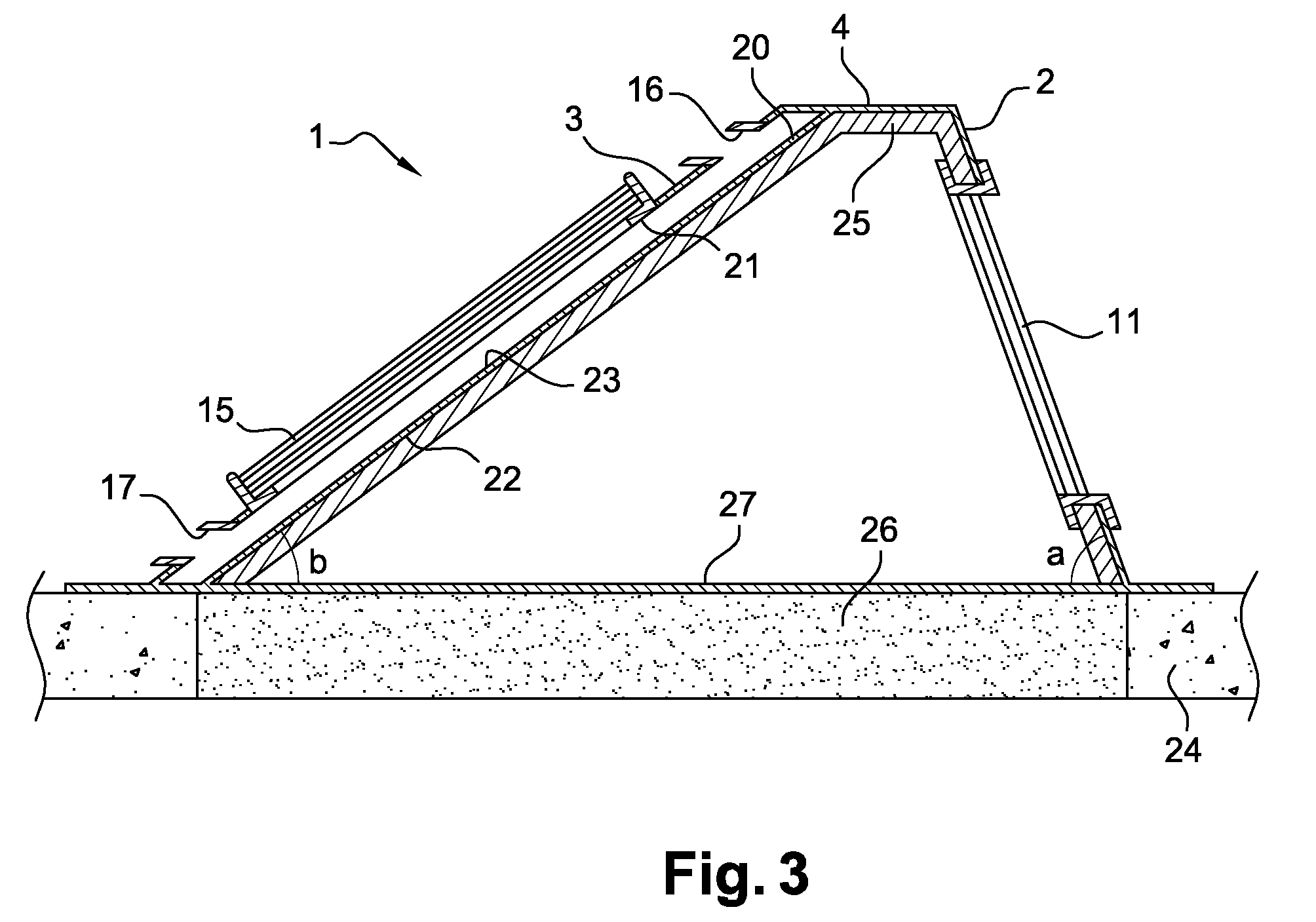

[0027]As shown in FIGS. 1 to 3, a modular construction element 1 according to the invention comprises a body having a wall formed by a first face 2 inclined to a horizontal plane, a second face 3 inclined to a horizontal plane and a strip 4. The orientation of the second face 3 is opposite that of the first face 2 so that the two faces 2, 3 have substantially the shape of an inverted V, seen in cross section perpendicular to the plane of the faces. The apex of this inverted V is truncated, the two faces being joined by the flat horizontal strip 4.

[0028]The modular element 1 also includes two lateral faces 5 placed transversely with respect to the first and second faces 2, 3 and to the strip 4.

[0029]This wall defines a downwardly open space, the edge of the downward-facing opening consisting of the lower edges of the first and second faces 2, 3 and of the lateral faces 5. The edge of the opening is surrounded by a flat outer rim 10.

[0030]As illustrated in FIG. 3, the second face 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com