Pressure hood with removable seal assembly

a technology of sealing assembly and pressure hood, which is applied in the direction of papermaking, drying machines with progressive movements, textiles and paper, etc., can solve the problems of not only high cost, but also considerable assembly work directly at the machine, so as to simplify the replacement of seals, reduce machine down time, and improve machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

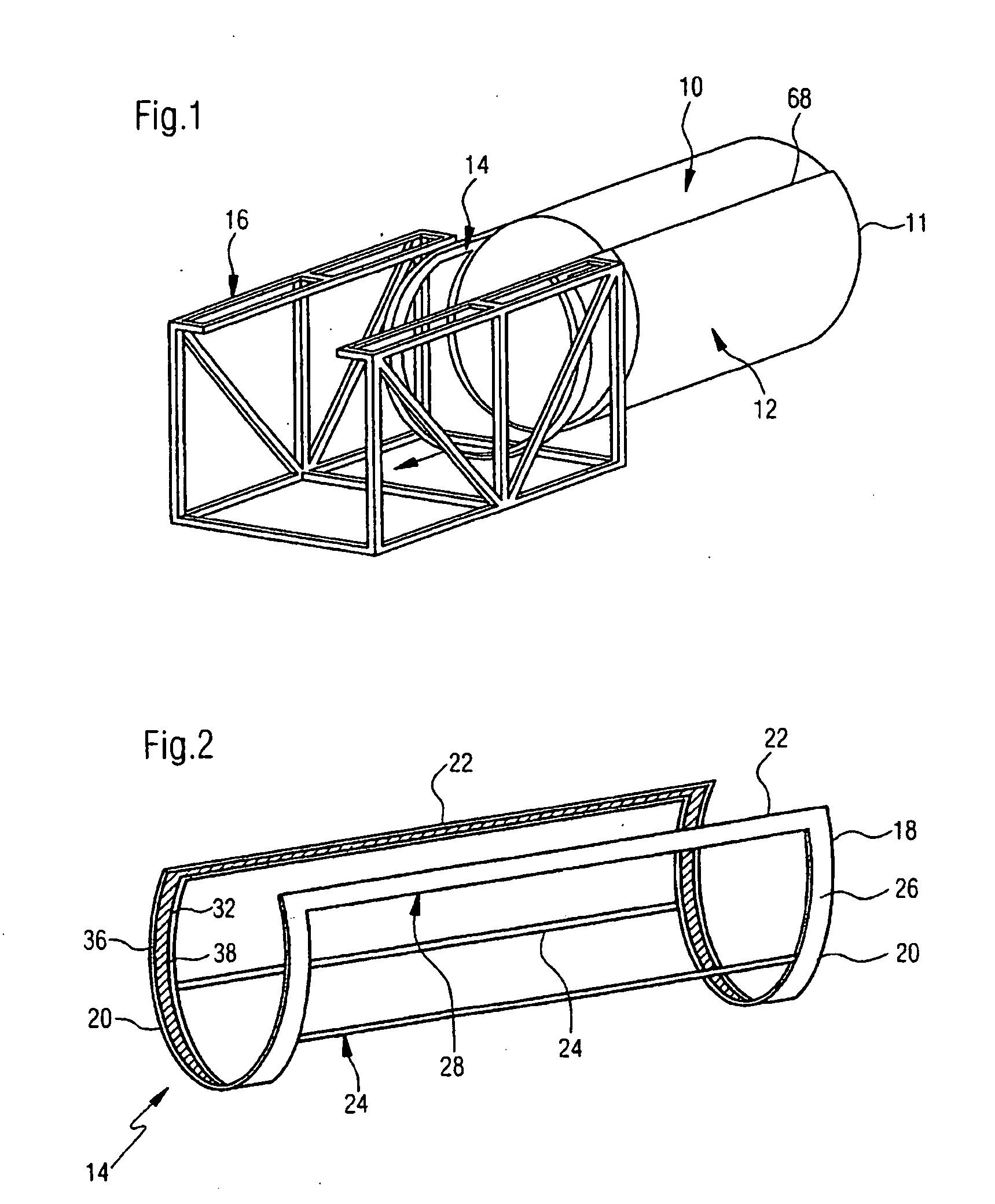

[0053]Referring now to the drawings, and more particularly to FIG. 1, there is shown a heated cylinder, as used in paper production for example for continuous drying of a fibrous web which is not illustrated here, for example a paper, cardboard or tissue web and which for this purpose runs at least partially over the circumferential surface of the cylinder.

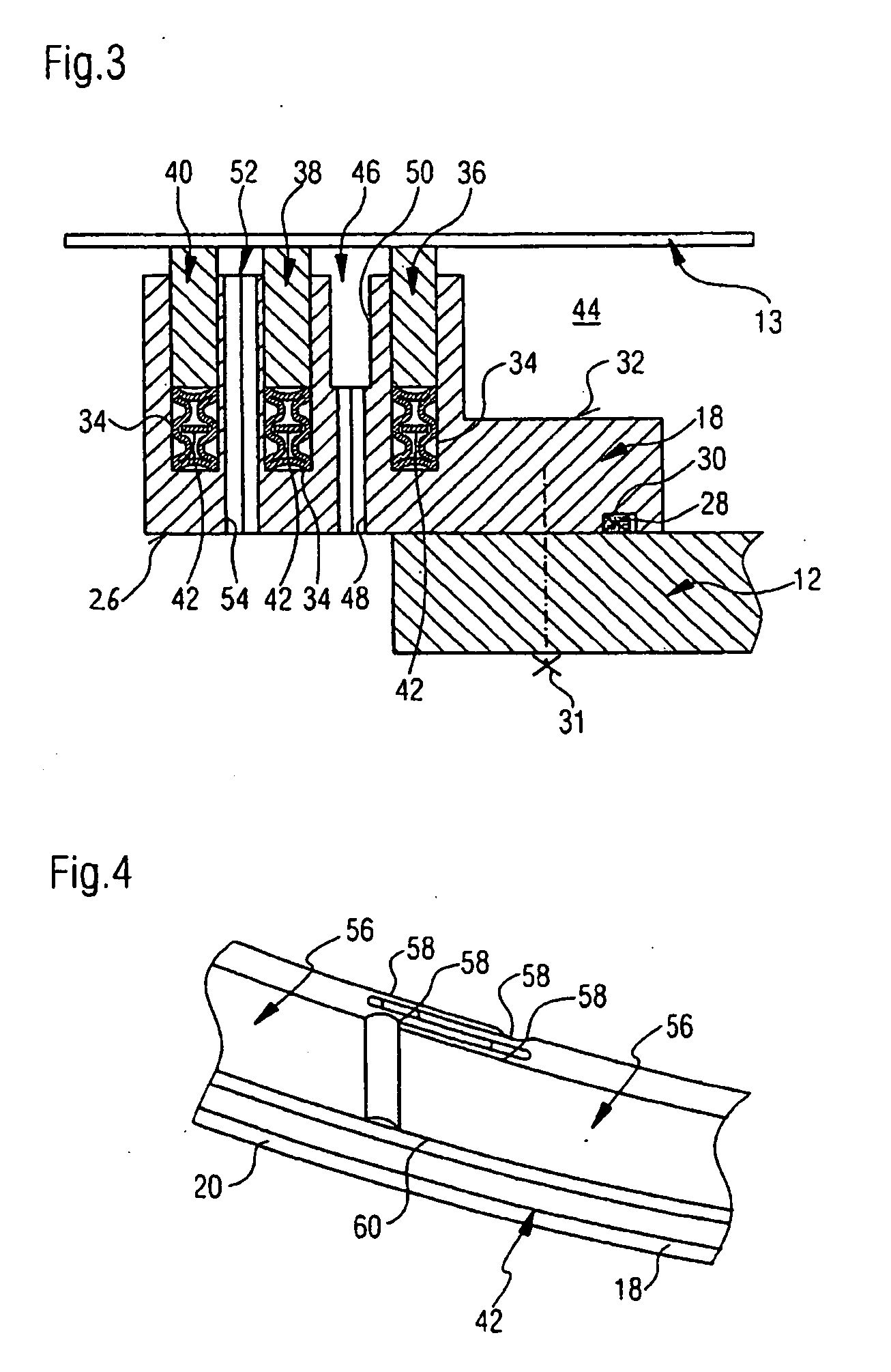

[0054]A pressure hood 11 with a pressure hood body 12 is mounted on the cylinder. Viewed in axial direction the pressure hood body envelopes the circumferential surface of the cylinder 10 essentially over the entire width and viewed in circumferential direction to approximately three quarters of the cylinder circumference. The interior of the pressure hood 11 can be filled with a pressure medium, for example with water which can have an overpressure of several bar relative to the surroundings in order to press against the cylinder 10 a moisture impermeable belt 13 (FIG. 3) which runs between the pressure hood 11 and the fibrous we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com