Upsetting method and upsetting apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0161]Next, concrete Examples and Comparative Examples of the present invention will be shown below. However, it should be noted that the present invention is not limited to the following examples.

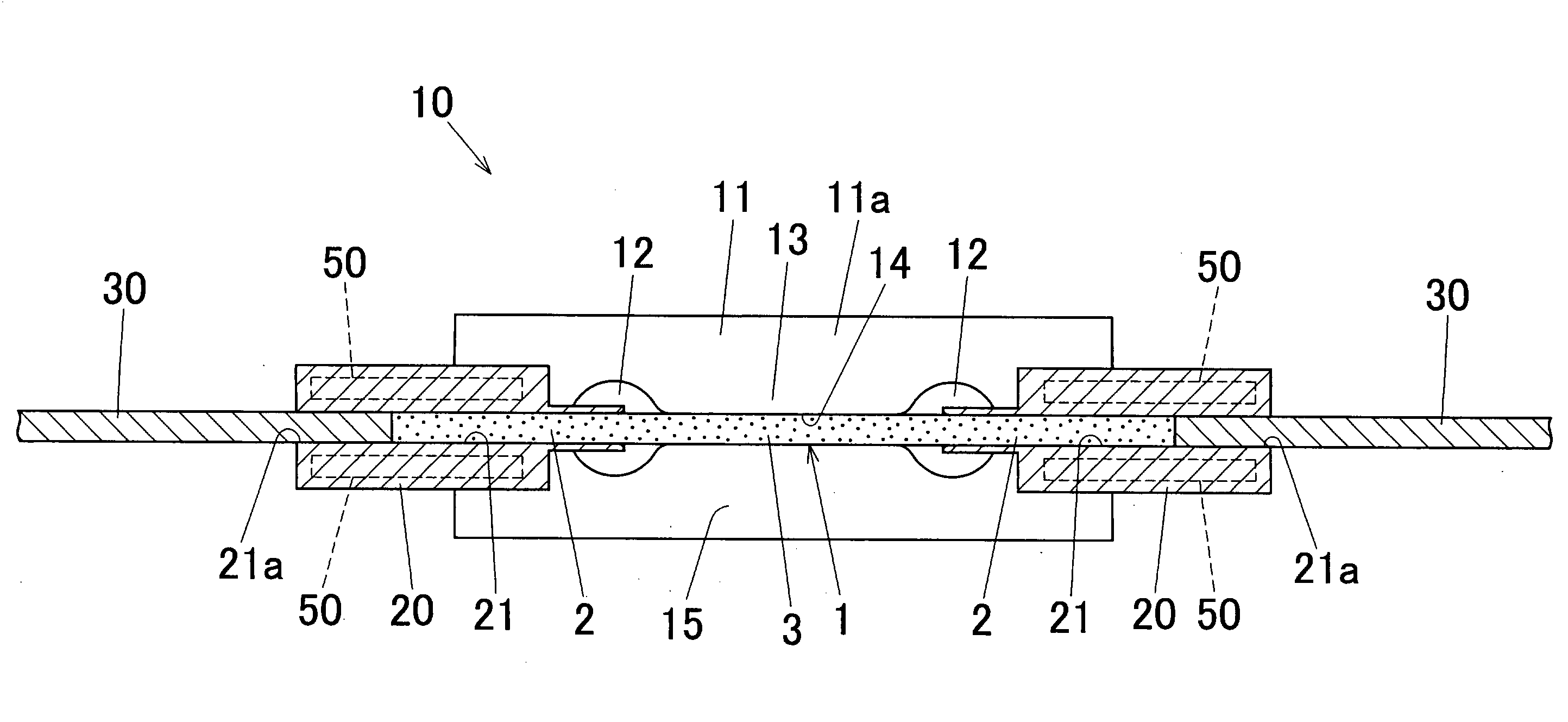

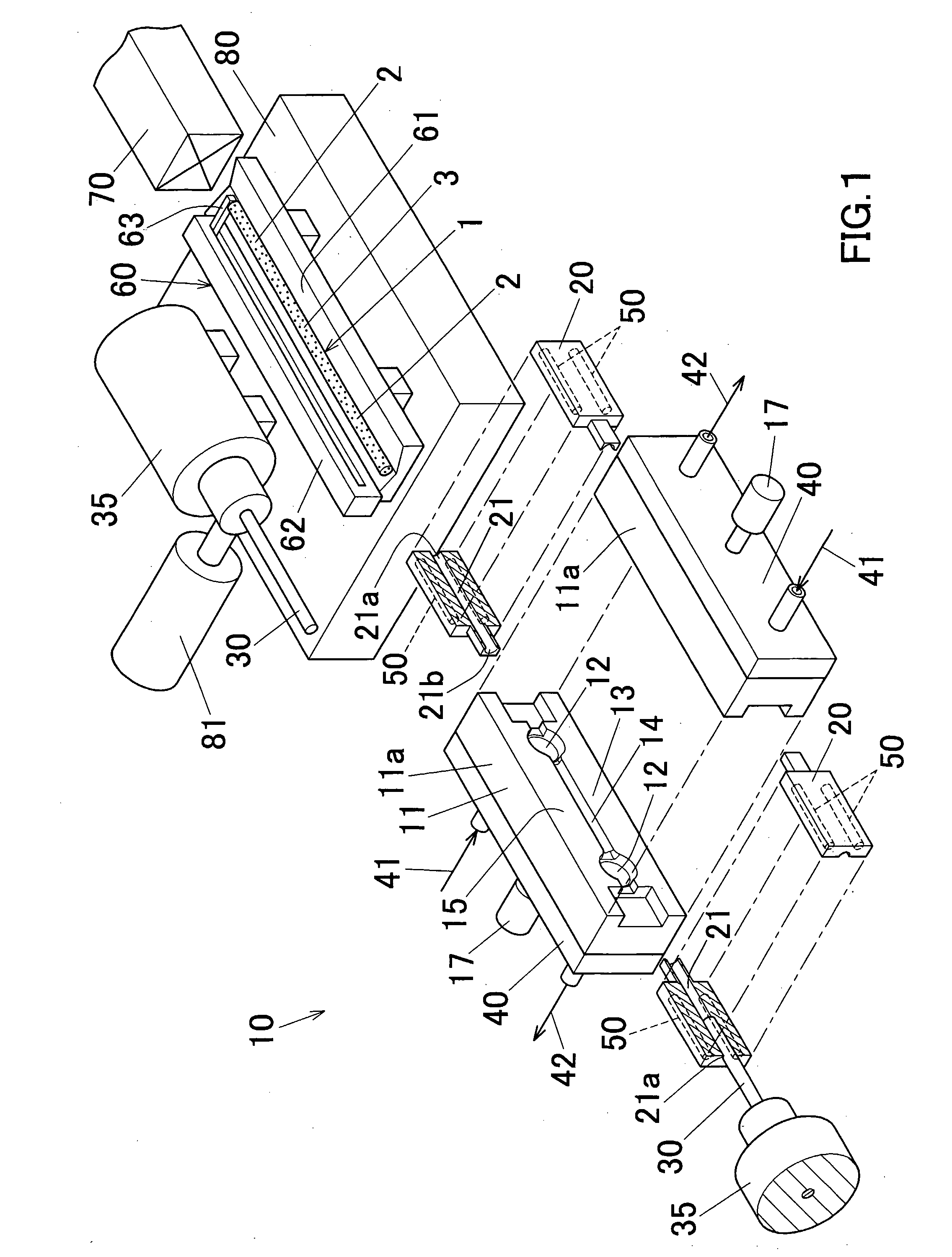

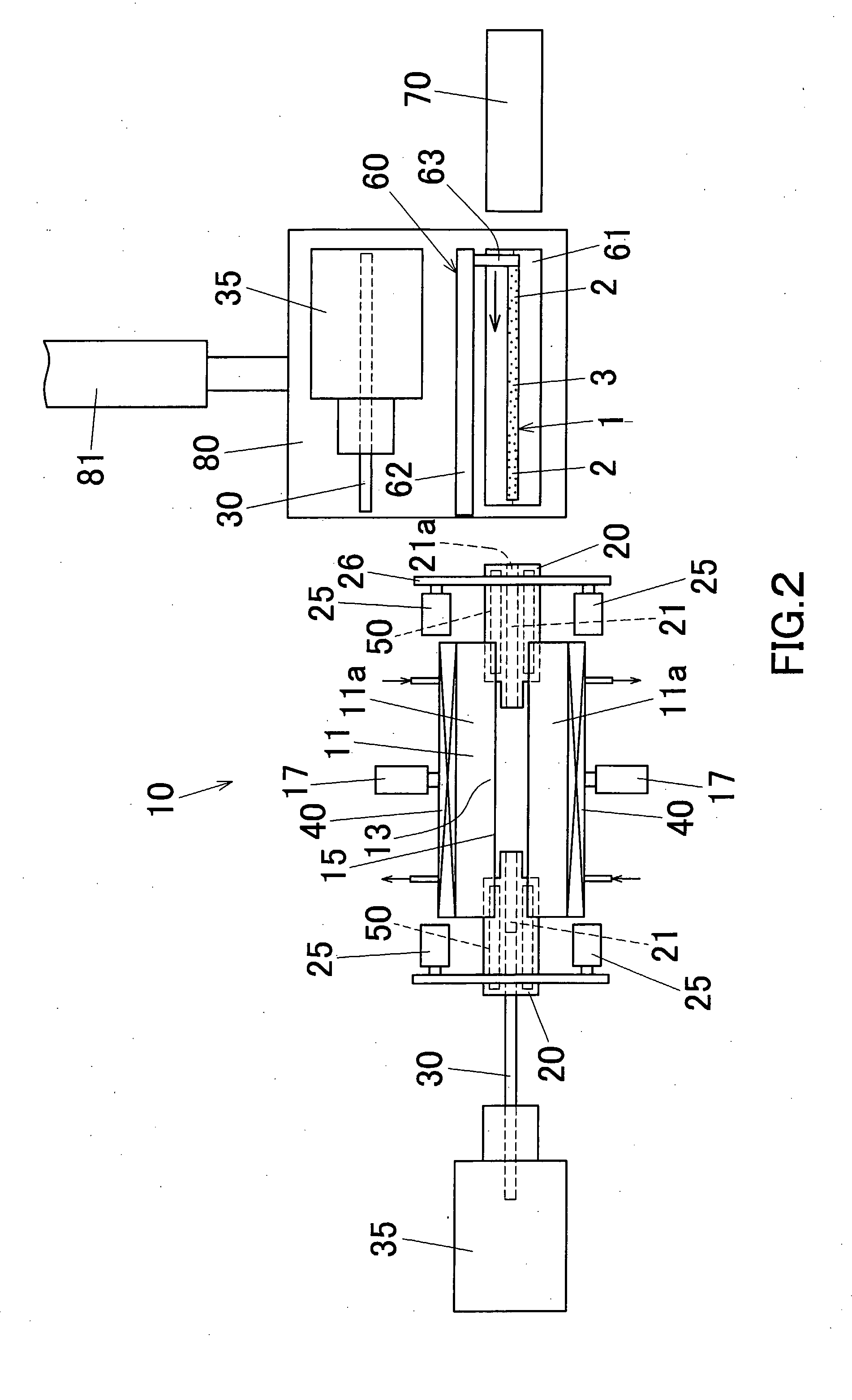

[0162]As raw materials 1, a plurality of heat-treatment type aluminum alloy extruded materials whose alloy number is 6061 according to JIS (Japanese Industrial Standards) were prepared. The diameter of the raw material 1 was 16 mm. Each raw material 1 was subjected to the upsetting method shown in the aforementioned embodiment. At this time, the heating temperature of the raw material 1, the heating temperature of both the guides 20 and 20, the temperature of the forming die 11, the setting method of the raw material 1, and the heat treatment after the upsetting were variously changed as explained below.

[0163]Subsequently, the warpage “a” and the bend “b” of the obtained upsetting manufactured product 5 were measured (see FIG. 10A and FIG. 10B). Moreover, as the mechanical strength of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com