Connecting System For Surface Coverings

a technology of connecting system and surface covering, which is applied in the field of surface covering, can solve the problems of affecting the installation and use of the floor system, so as to achieve convenient and fast installation and flexibility, improve the ease of installation, and facilitate the connection to other planks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

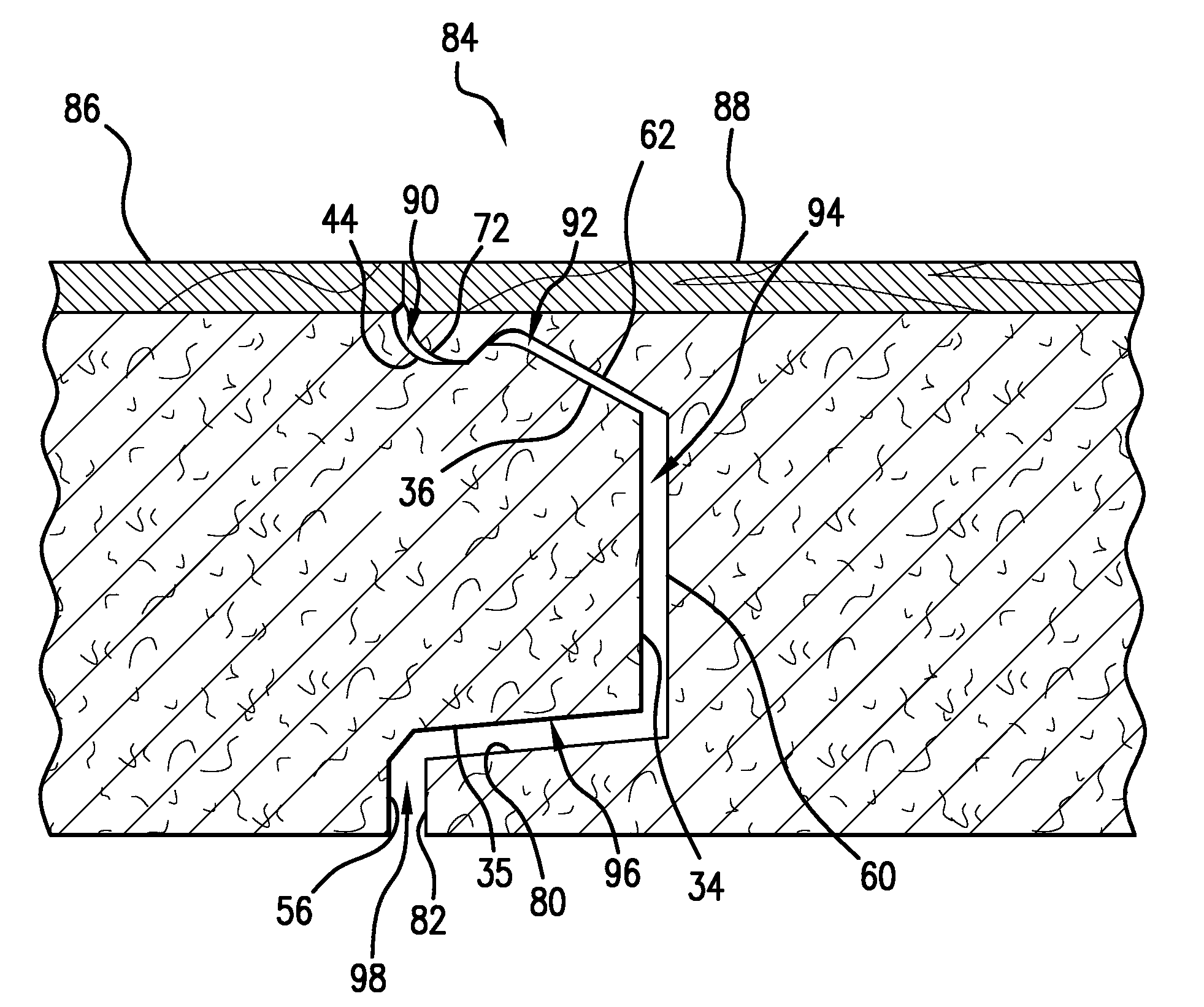

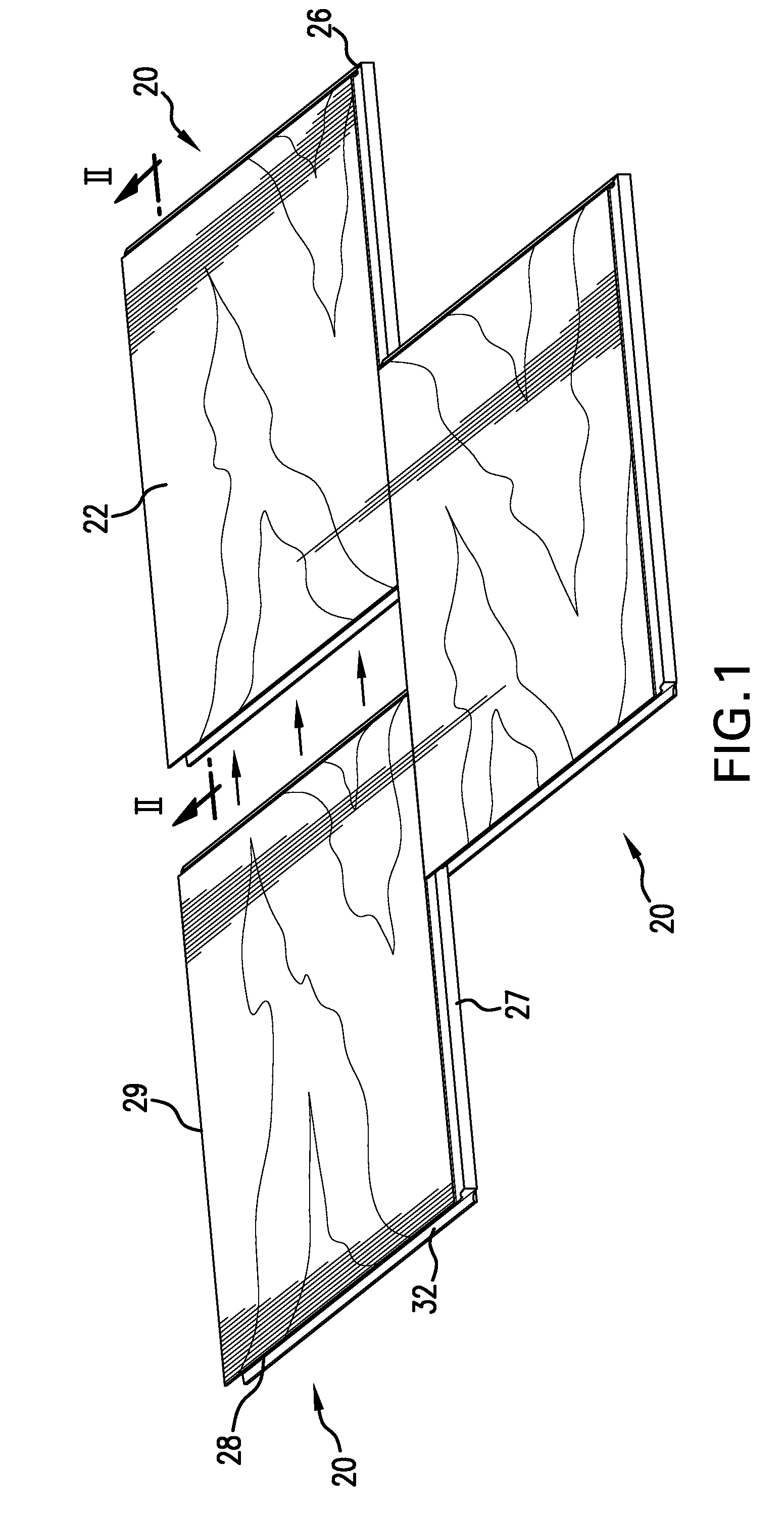

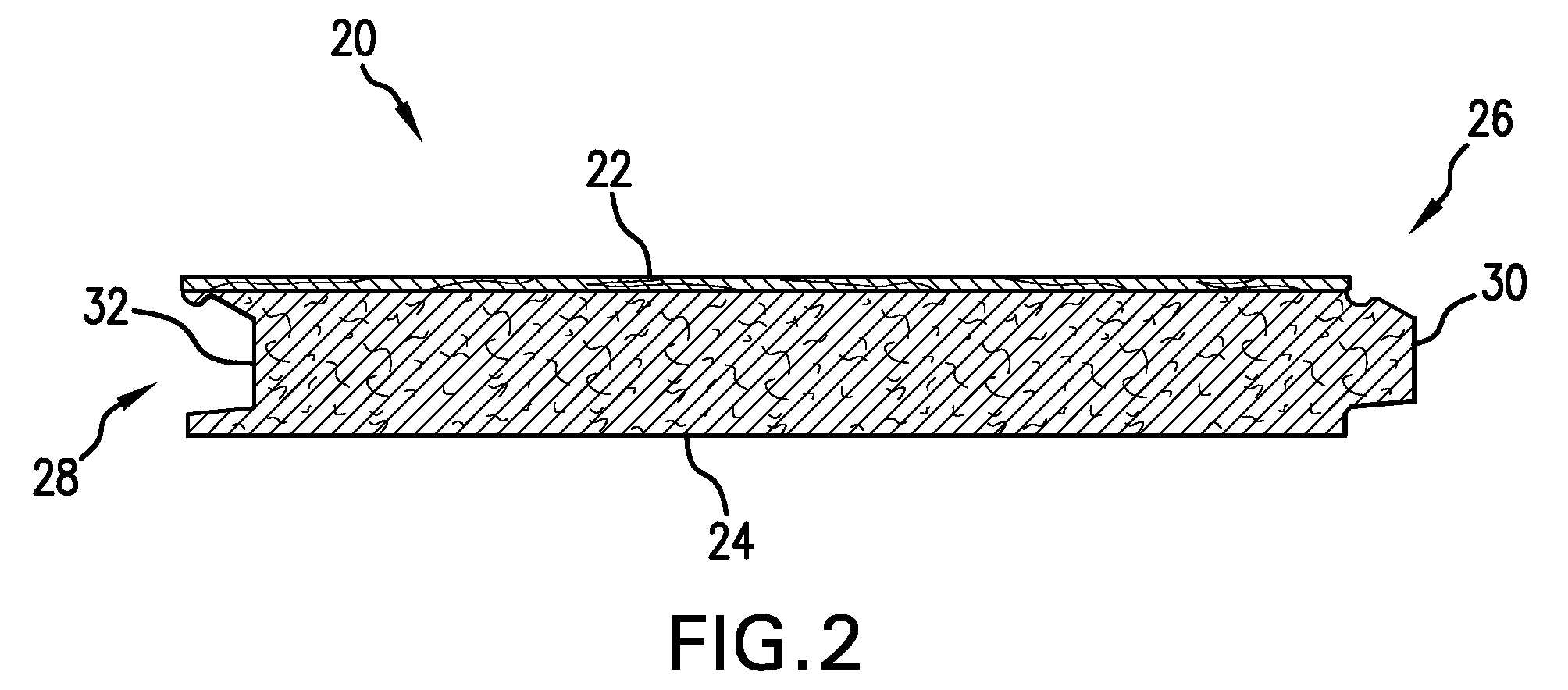

[0037]According to various embodiments, the plank can comprise a generally rectangular shape, having opposing first and second ends extending along the width of the plank, opposing first and second longitudinal sides extending along the length of the plank, and opposing top and bottom surfaces. In some embodiments, the plank comprises a tongue edge at a first end of the floor plank and a groove edge at an opposing second end of the floor plank. The tongue edge can be defined, at least partially, by a vertical distal surface that is substantially vertical with respect to the top and bottom surfaces, and a top planar slanted surface extending away from the vertical distal surface toward the top surface of the plank. A vertical lip can be included that extends downwardly from the top surface of the plank, and a slanted tongue bottom extending away from the vertical distal surface towards the bottom surface. A channel can be disposed substantially between the top planar slanted surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com