Netting framework of a fiber-made racket

a fiber-made racket and netting technology, applied in the field of netting framework of fiber-made rackets, can solve the problems of slow weaving with the threads, inconvenience, etc., and achieve the effects of reducing contact area, facilitating thread passing, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0023]With reference to FIG. 6 as a sectional view illustrating the supporting part integrated into the racket frame in this invention, the structure and function is approximately the same as that in the preferred embodiment of this invention, and what is different is in that the supporting part 20 is a cylindrical rod made of the metallic material, of which a middle annular portion that shrinks is formed with an arc-shaped shift limit concave 24. The supporting parts 20 are stationary separately at concave portions 25 and 26 that are formed at two adequate intervals around the upper and lower ends of the upper and lower racket frames 11 and 12. The concave portions 25 and 26 may be dots or rings. In the embodiment, the concave portions 25 and 26 are rings so that the supporting parts 20 may be placed in a formed model, and then the protruding portions 231 may be used as a basic level to fix the upper racket frame 11 with the lower racket frame 12 and enhance the intensity of format...

third embodiment

[0024]With reference to FIG. 7 as a view illustrating the appearance of partial structure where the supporting part is integrated into the racket frame in this invention, the structure and function is approximately the same as that in the preferred embodiment of this invention, and what is different is in that the supporting part 20 is a cylindrical rod made of a composite material, around which a damper sheath 40 made of a rubber wraps. A lengthwise cut groove 41 is formed axially at a side of the damper sheath 40 and gradually shrinks towards the radial center of annular damper sheath 40 to form an arc-shaped shift limit groove 42 so that the net thread 30 may get into the shift limit groove 42 to be fixed, and thus the damper sheath 40 is tightened to enhance the intensity of support to the hit area 31.

fourth embodiment

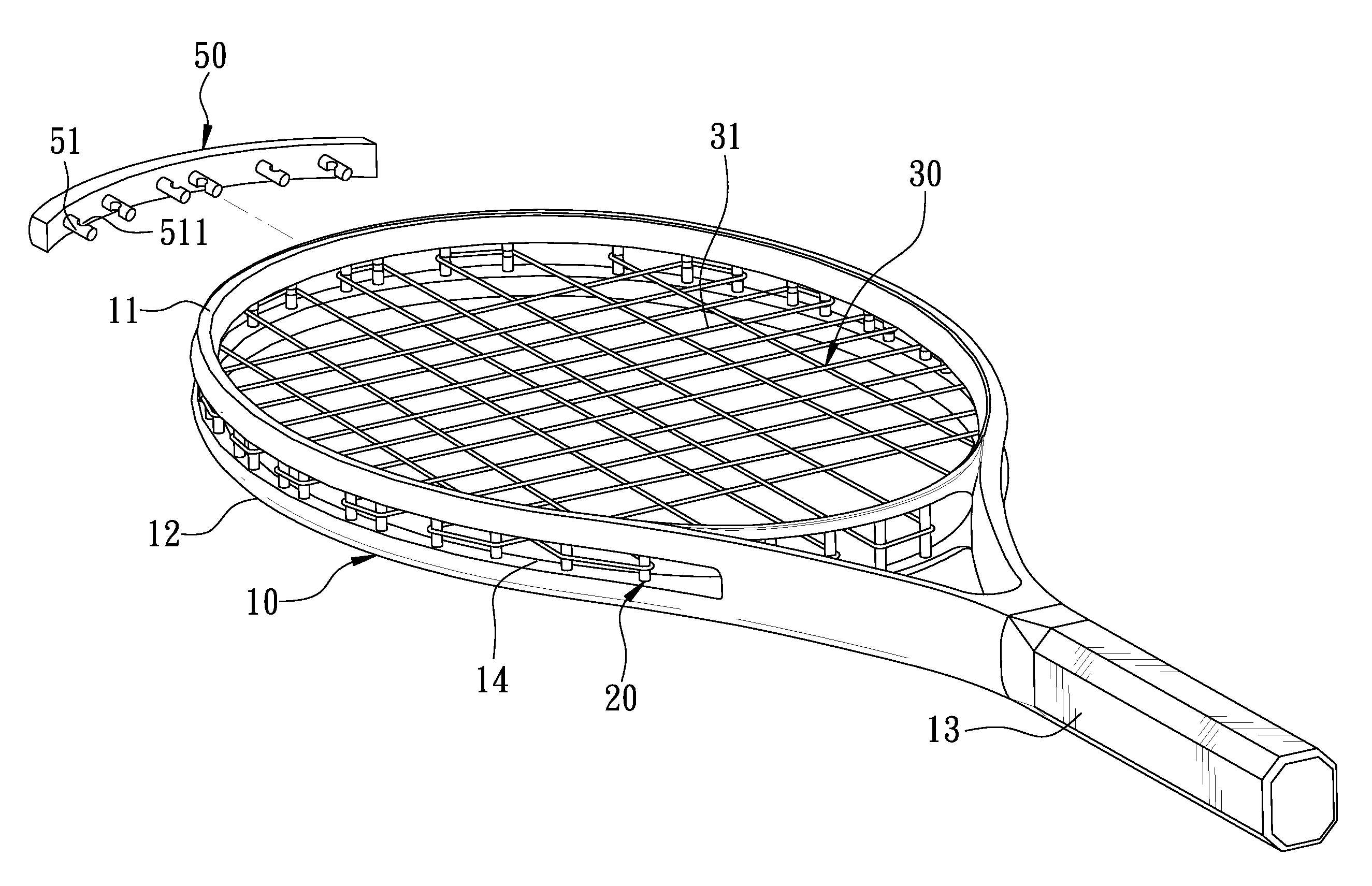

[0025]With reference to FIG. 8 illustrating this invention, the structure and function is approximately the same as that in the preferred embodiment of this invention, and what is different is in that an all-in-one ornament strip 50 made of plastics are formed at a top side of the grasp portion 13 opposite to the netting area 14 of the racket frame 10. Several clamping strips 51 are provided at a side of the supporting parts 20 corresponding to the ornament strip 40. The clamping strips 51 are cylindrical sleeve, and a notch 511 is formed corresponding to each of the sides of supporting parts 20 for the clamping strips 51 to wedge the supporting parts 20. The other side of the ornament strip 40 is exposed to an outside of the netting area 14, where an advertisement typeface character or pattern blueprint may be printed.

[0026]Here, the features and attainable expected effects of this invention are described again below:[0027]1. The racket frame and supporting parts according to this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com