Method and apparatus for filling beverage bottles, in a beverage bottling plant, with a beverage material comprising a carbonated water component and a liquid flavoring component, and method and apparatus for filling containers, in a container filling plant, with a material comprising a first ingredient and a second ingredient

a beverage and bottling plant technology, applied in the direction of liquid transferring devices, packaging goods types, liquid handling, etc., can solve the problems of significant construction effort, inability to achieve constant fill levels, and inability to meet the needs of consumers, so as to achieve the effect of reducing construction costs and increasing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

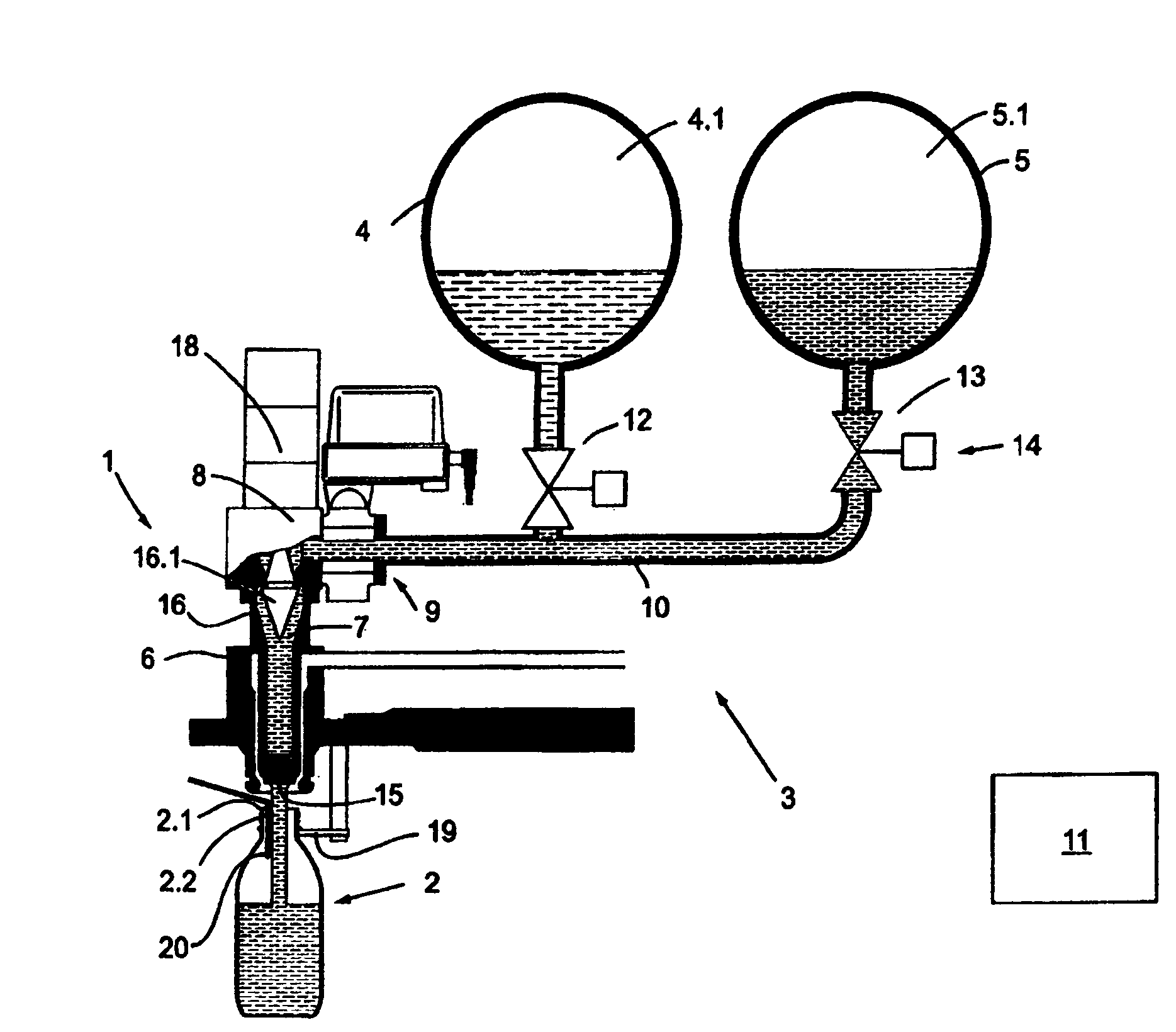

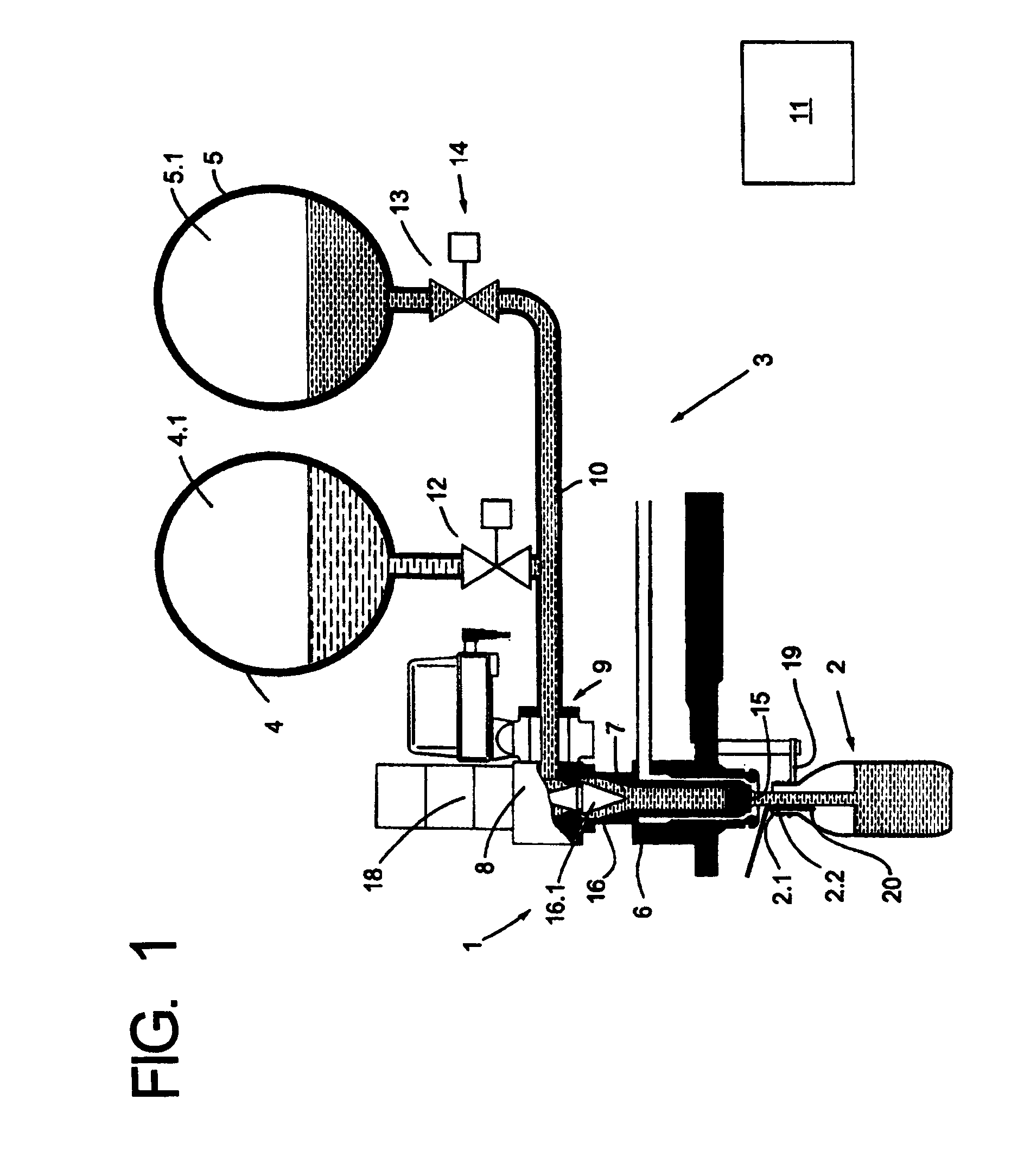

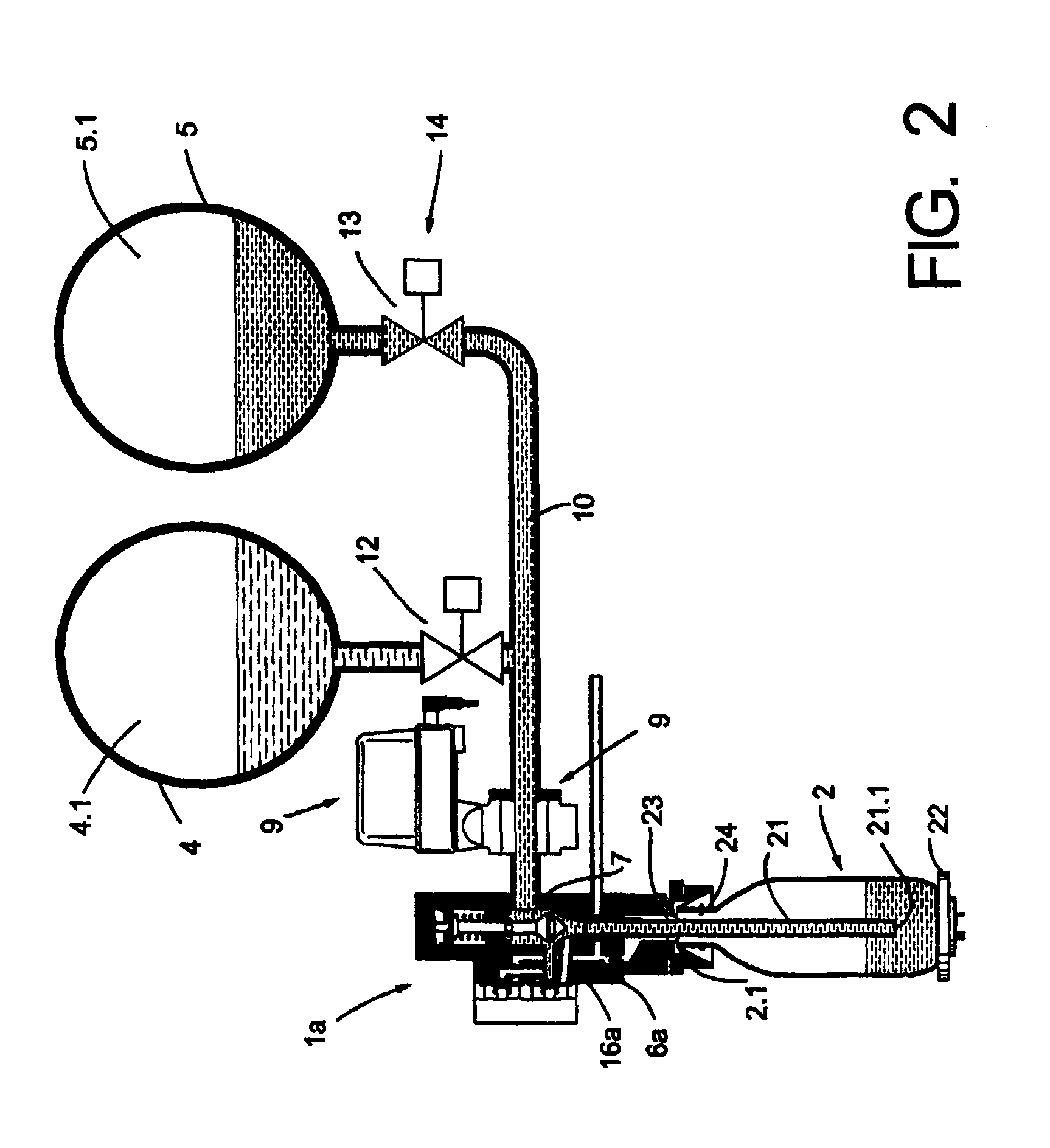

[0026]FIG. 1 shows a filling element 1 of a filling system of a machine that employs a rotary construction and is used to fill bottles 2 or similar containers with a liquid which is composed of two ingredients which are mixed with each other only in the individual bottle 2. One ingredient can be, for example, an additive in the form of a liquid flavoring such as syrup, and the other ingredient can be the basic ingredient such as carbonated water, e.g. mineral water. The filling element 1 is provided with a plurality of identical or similar filling elements 1 on the periphery of a rotor 3 which is driven in rotation around a vertical machine axis and on which there are, among other things, two bowls 4 and 5 that serve all the filling elements in common, whereby each bowl contains one ingredient of the liquid being bottled, for example the bowl 4 for the additive and the bowl 5 for the basic ingredient.

[0027]In a filling element housing 6 of each filling element, a liquid duct 7 is re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com