Friction-Joining Steel Plate and Friction-Joining Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0100]Hereinafter, a description will be made of an example experimentally verified for the friction-joining structure of the embodiment.

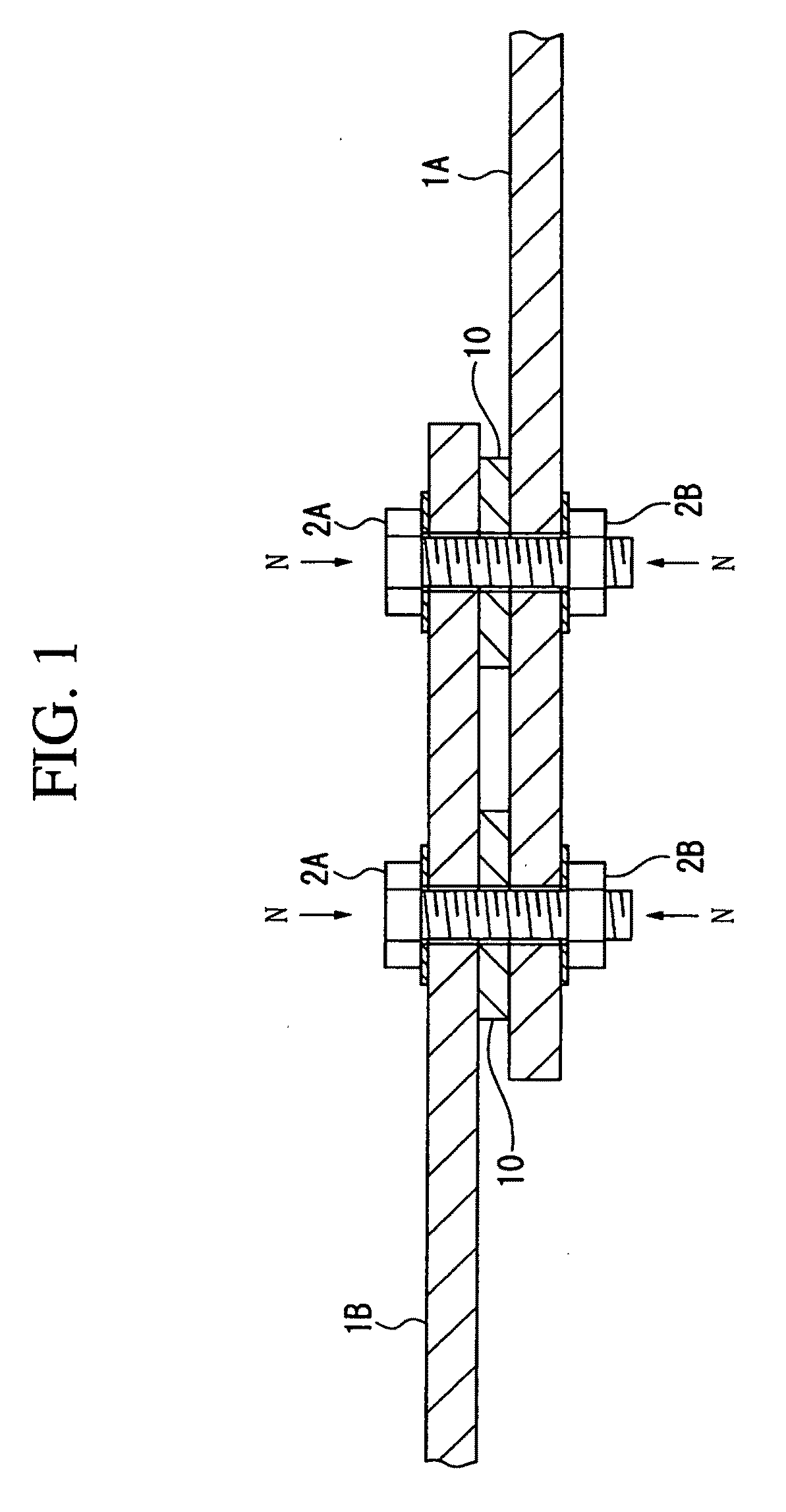

[0101]In the following embodiment, a tensile strength test is conducted in which the friction-joining steel plate 10 and the steel plates 1A and 1B are fastened by using high strength bolts 2A and nuts 2B as illustrated in FIG. 1.

[0102]In this instance, the Vickers hardness ratio (rh) is given as a first parameter, the tip angle (θ) of the projected streaks 11 is given as a second parameter, and the stress intensity ratio (σ / σmb) is given as a third parameter. Then, the tensile strength test is conducted by allowing the three parameters to change, and the thus obtained friction coefficient (slip coefficient) μF is measured

(First Parameter: Vickers Hardness Ratio rh)

[0103]The Vickers hardness ratio rh is a ratio (rh=Hvh / Hvm) of the Vickers hardness (Hvh) at a portion of the projected streaks 11 on the friction-joining steel plate 10 to the Vickers h...

embodiment 1

[0126]FIG. 14 is a photo showing a friction-joining steel plate of Embodiment 1. FIG. 15 is a sectional view illustrating the friction-joining steel plate 10a of Embodiment 1. FIG. 16 is a graph illustrating the test results obtained by using the friction-joining steel plate 10a of Embodiment 1.

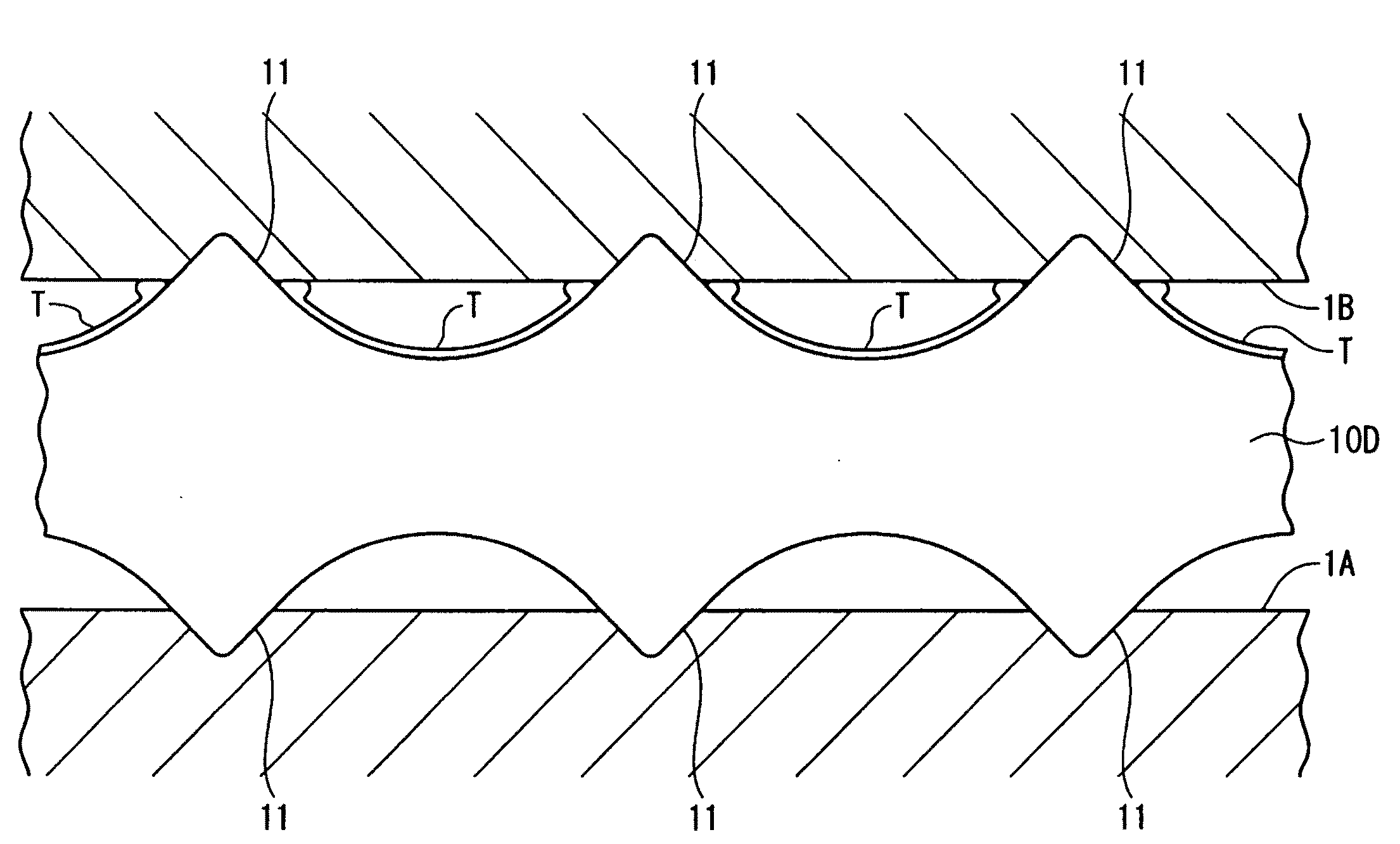

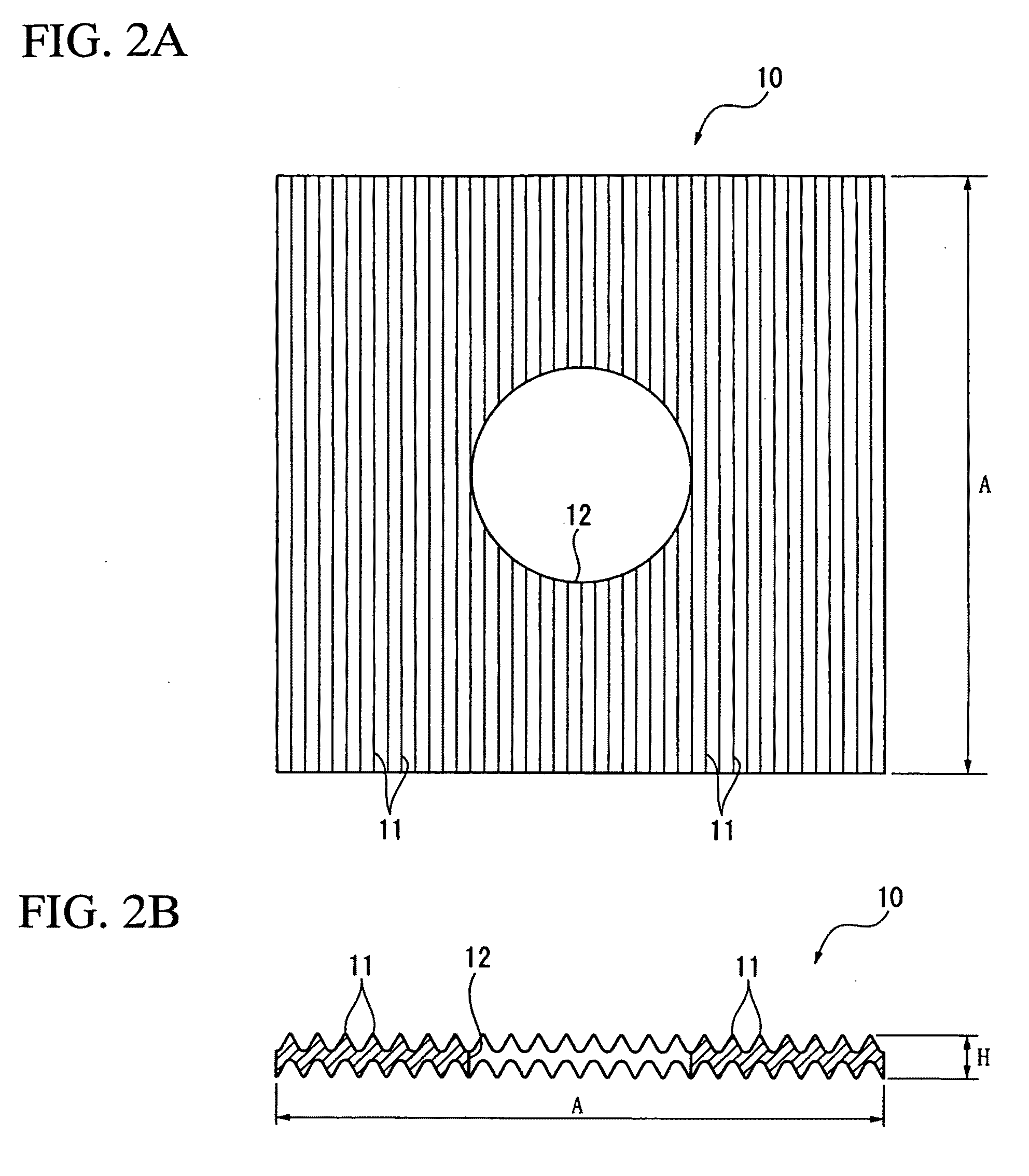

[0127]As illustrated in FIG. 15, the friction-joining steel plate 10A of Embodiment 1 is such that the projected streaks 11 are formed symmetrically on the front face and the back face, a space (S) between adjacent projected streaks 11 is set to be about 1.5 mm, and a distance (H) between the tip ends of the projected streaks 11 on the front face and the back face is set to be about 1.5 mm. Further, in the friction-joining steel plate 10a, a tip angle (θ) of the projected streaks 11 is set to be about 90° and a radius (R1) of the tip end portion of the projected streaks 11 is set to be 0.1 mm or less (about 0.1 mm), and a radius (R2) of a recess between the projected streaks 11 is set to be 0...

embodiment 2

[0129]FIG. 17 is a photo showing a friction-joining steel plate of Embodiment 2. FIG. 18 is a sectional view illustrating the friction-joining steel plate 10B of Embodiment 2. FIG. 19 is a graph illustrating the test results obtained by using the friction-joining steel plate 10B of Embodiment 2.

[0130]As illustrated in FIG. 18, the friction-joining steel plate 10B of Embodiment 2 is such that the projected streaks 11 are formed symmetrically on the front face and the back face, a space (S) between adjacent projected streaks 11 is set to be about 0.8 mm, and a distance (H) between the tip ends of the projected streaks 11 on the front face and the back face is set to be about 1.5 mm. Further, in the friction-joining steel plate 10b, a tip angle (θ) of the projected streaks 11 is set to be about 75° and a radius (R1) of the tip end portion of the projected streaks 11 is set to be 0.1 mm or less (about 0.1 mm), and a radius (R2) of a recess between the projected streaks 11 is set to be 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com