Expander and heat pump using the expander

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

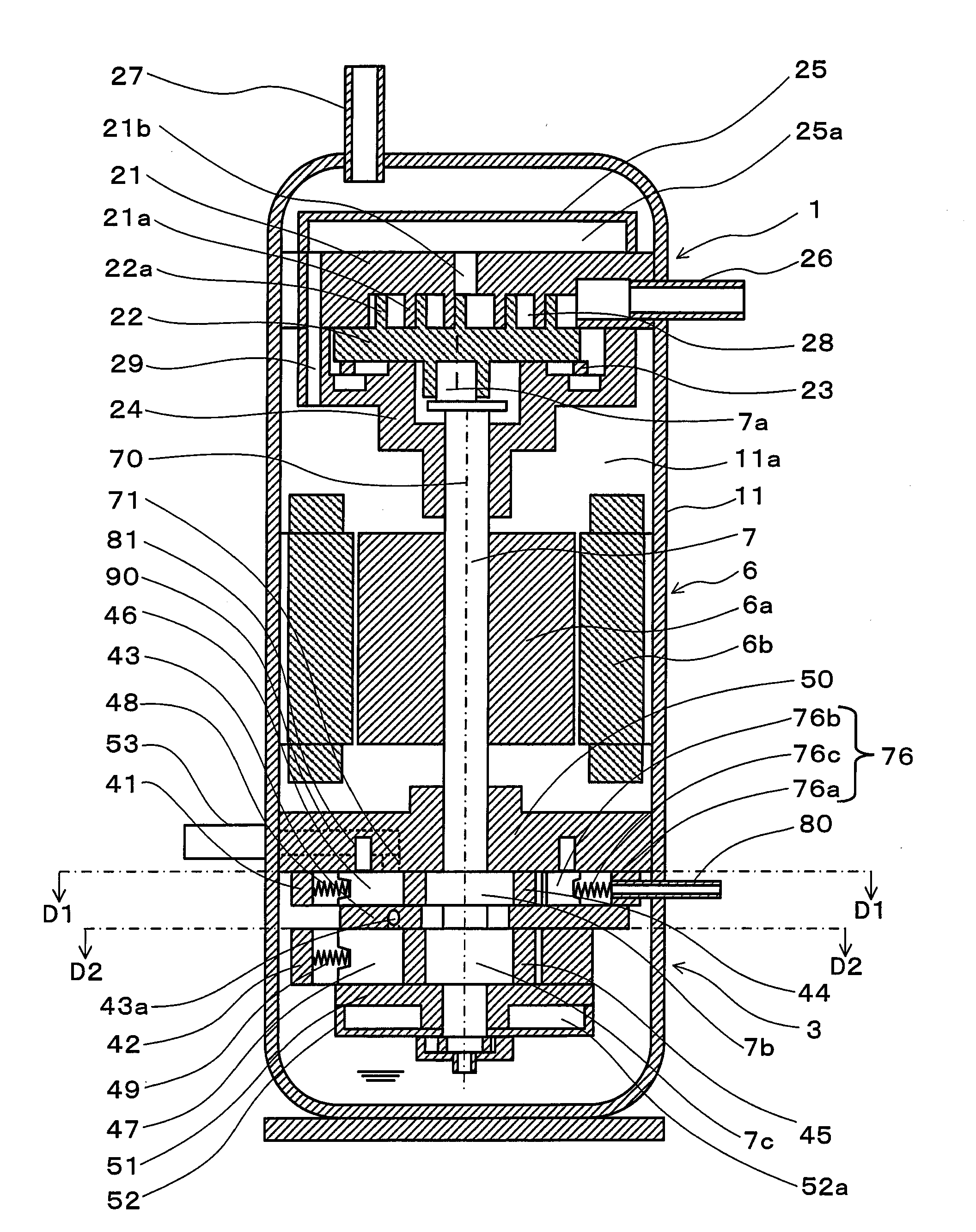

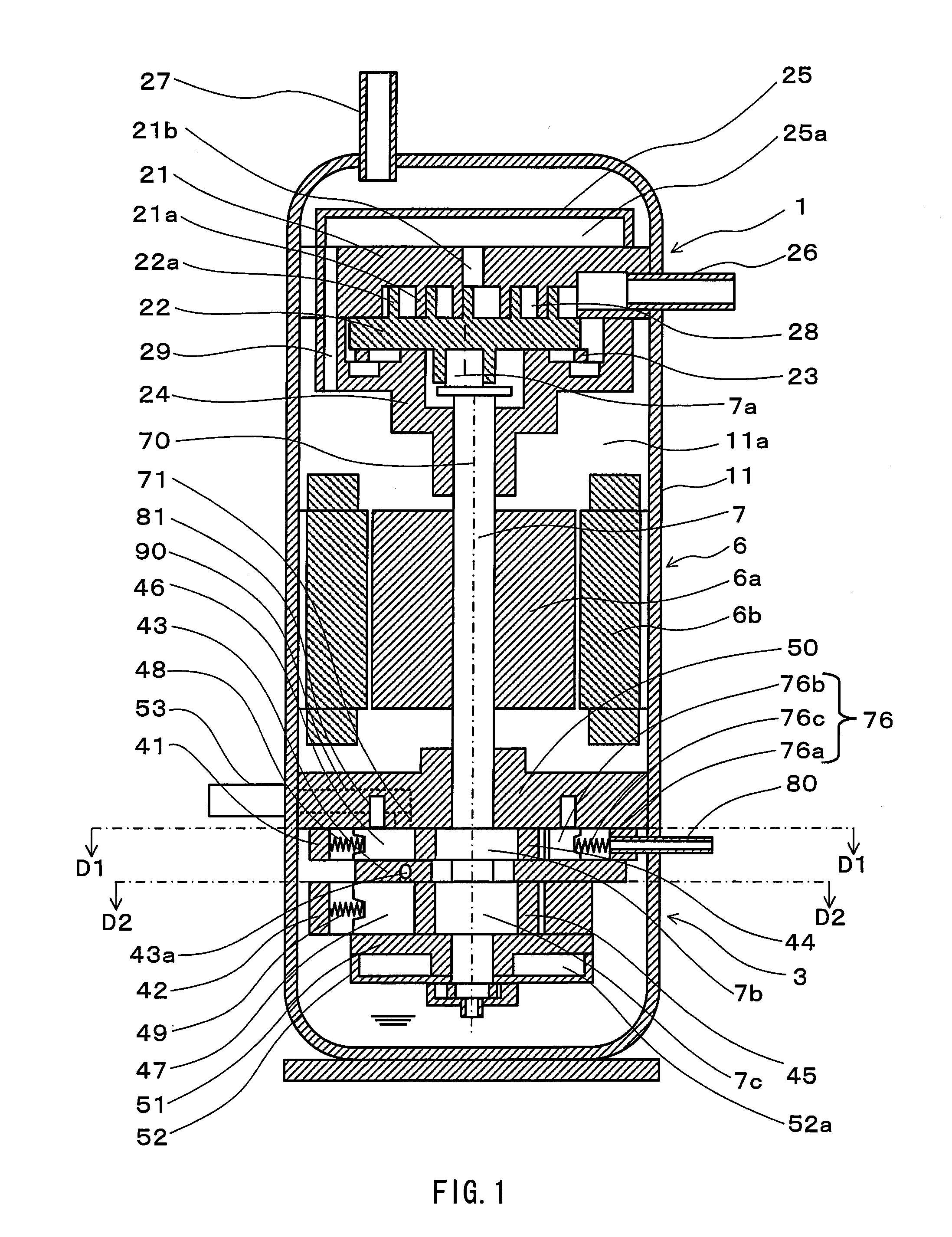

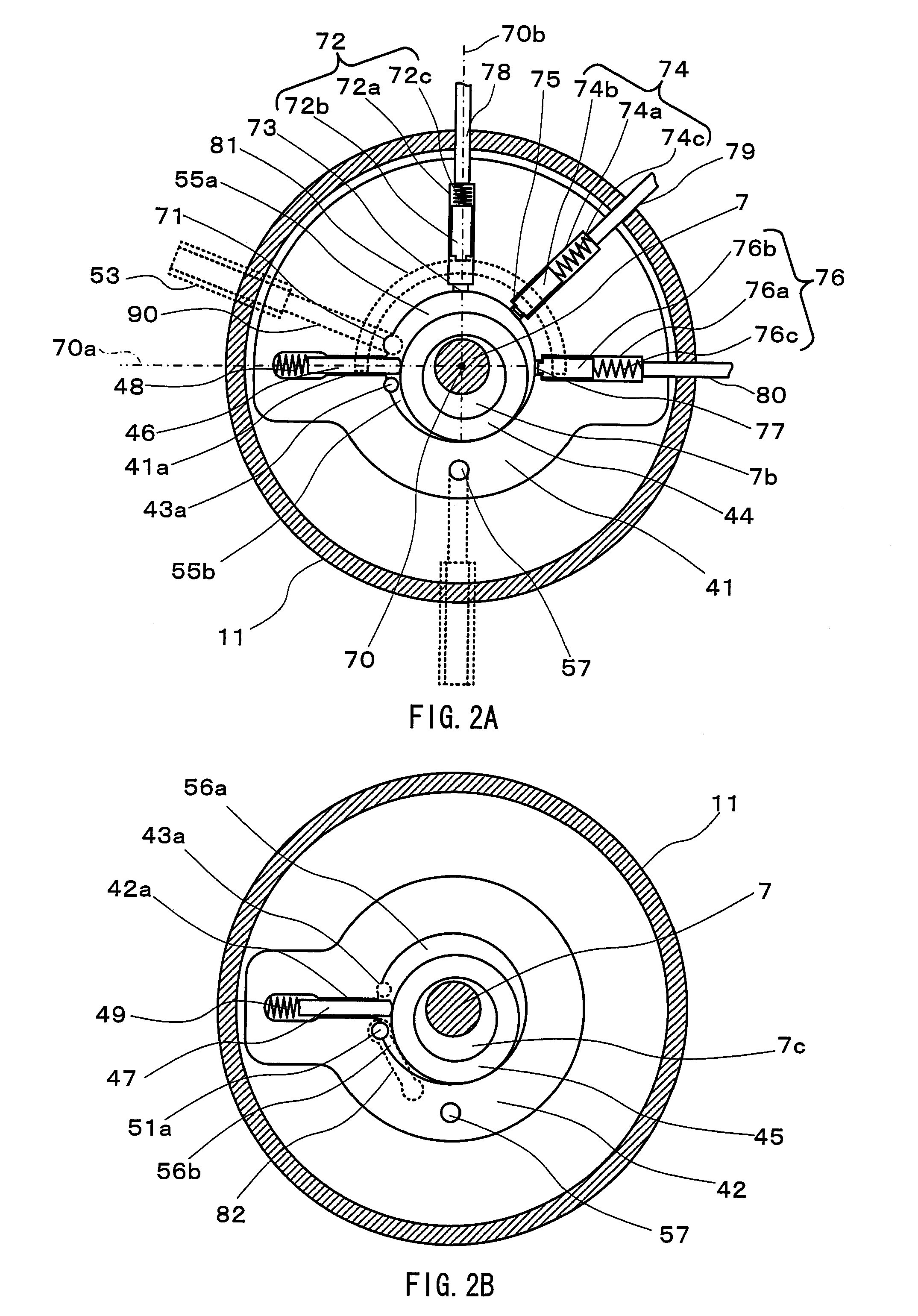

[0044]FIG. 1 is a vertical cross-sectional view illustrating an expander-compressor unit according to a first embodiment of the present invention. FIG. 2A is a horizontal cross-sectional view of an expander section of the expander-compressor unit shown in FIG. 1, taken along line D1-D1 of FIG. 1. FIG. 2B is a horizontal cross-sectional view of the expander section of the expander-compressor unit, taken along line D2-D2.

[0045]An expander-compressor unit according to the present embodiment includes a closed casing 11, a scroll type compressor section 1 disposed in an upper portion of the closed casing, a two-stage rotary expander section 3 disposed in a lower portion of the closed casing, a rotation motor 6 disposed between the compressor section 1 and the expander section 3 and having a rotor 6a and a stator 6b, and a shaft 7 for coupling the compressor section 1, the expander section 3, and the rotation motor 6 to one another.

[0046]The scroll type compressor section 1 has a stationa...

second embodiment

[0101]The first embodiment has described a two-stage rotary expander (expander section 3) that, in addition to the first expansion mechanism, further includes a second expansion mechanism having a working chamber in communication with a working chamber in the first expansion mechanism through a communication port.

[0102]The expander section 3 may be used alone. In other words, it may be used as an expander separate from a compressor. FIG. 9 illustrates the configuration of a power recovery type refrigeration cycle apparatus employing the separate-type expander. This apparatus has a similar configuration to the refrigeration cycle apparatus shown in FIG. 3 (the same members are denoted by the same reference numerals, and the descriptions thereof are omitted). In place of the expander-compressor unit (reference numerals 1, 3, 6, and 7 in FIG. 3), this apparatus includes a compressor 61 and an expander 63, separated from each other, a rotation motor 66 connected to the compressor 61 via...

third embodiment

[0104]The present embodiment provides a refrigeration cycle apparatus that has the configuration shown in FIG. 11, in place of the configuration shown in FIG. 3. This apparatus has a similar configuration to that of the refrigeration cycle apparatus shown in FIG. 3 (the same members are denoted by the same reference numerals, and the descriptions thereof will be omitted), but employs a rotary valve 92 in place of the three-way valves 85, 86, and 87.

[0105]The rotary valve 92 has a cylinder 92a and a piston 92c that is disposed therein and is rotatable with a rotating shaft 92b as the center. The contact surface between the inner wall of the cylinder 92a and the piston 92c is sealed, and the piston 92c can be rotated from outside. The interior space of the cylinder 92a is divided by the piston 92c into a low pressure space 93a in communication with the low pressure pipe 84 and a high pressure space 93b in communication with the high pressure pipe 83.

[0106]The pressure pipes 78, 79, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com