Self-adjusting container

a self-adjusting, container technology, applied in the direction of tray containers, transportation and packaging, manufacturing tools, etc., can solve the problems of wasting countless hours in organizing and storing items for the future, frequently searching for particular items, and wasting time in organizing and storing materials, etc., to facilitate the safe storage and removal of materials, convenient access, and constant and secure separation of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

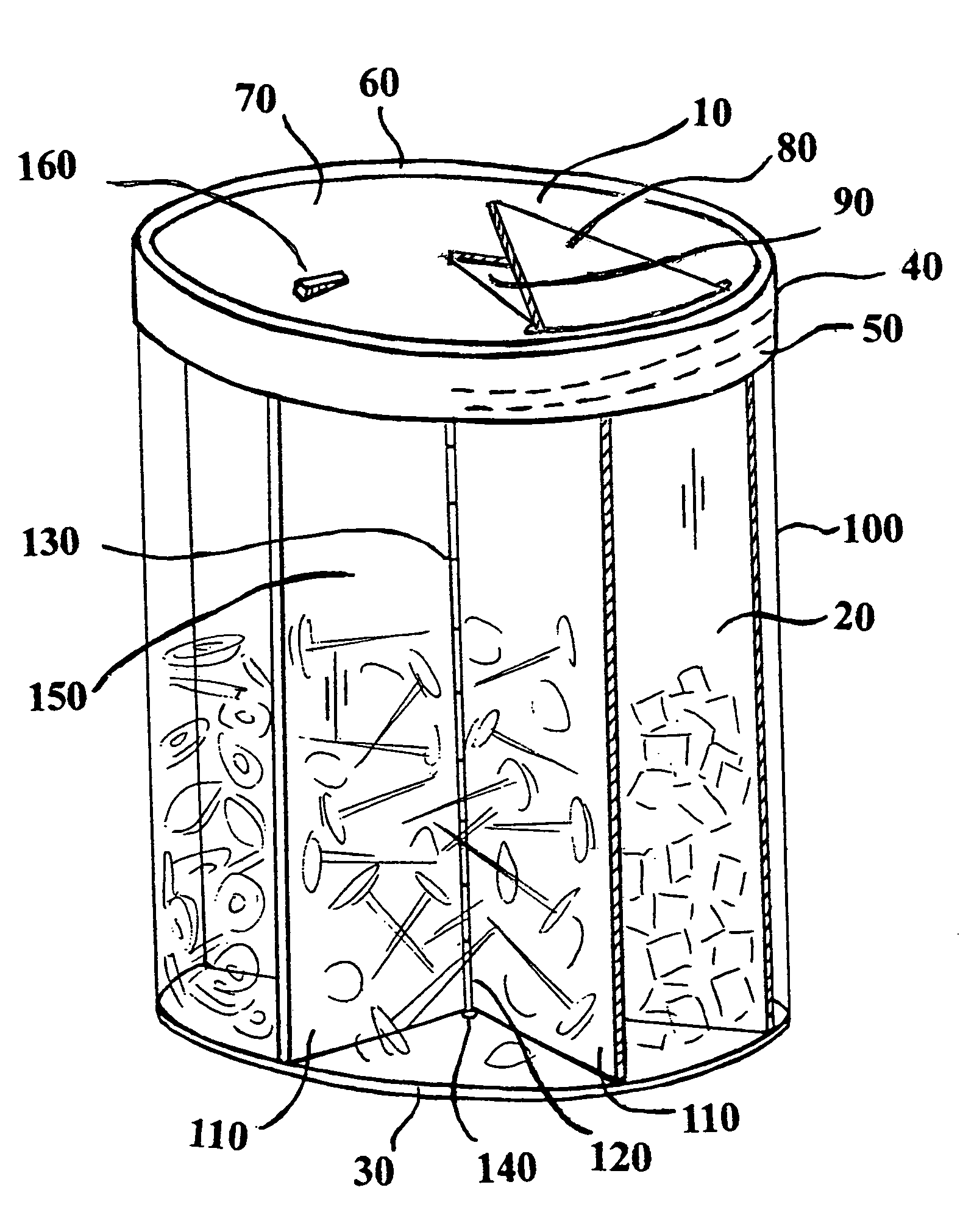

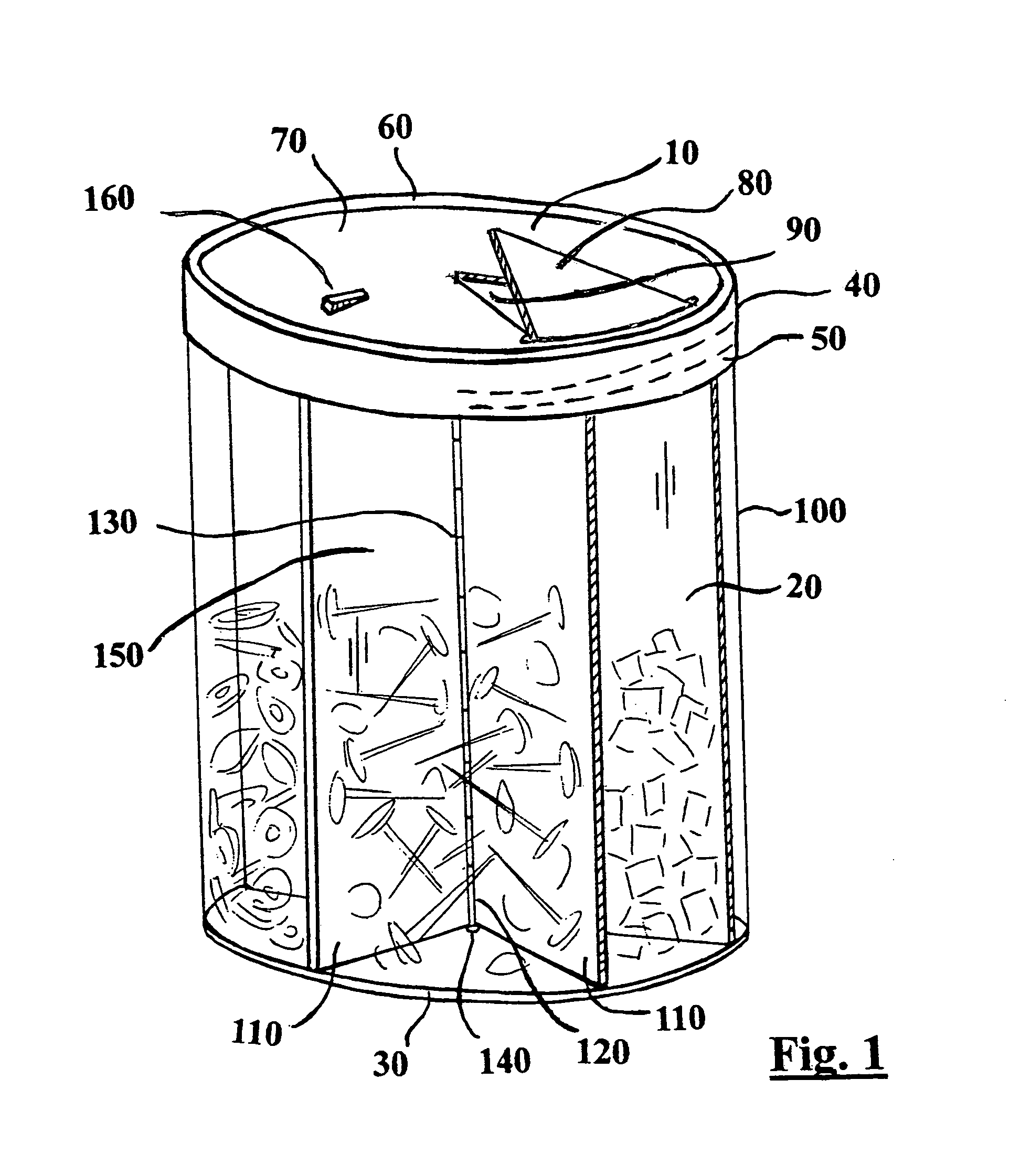

[0041]FIG. 1 illustrates a preferred embodiment of the device. Top 10, tubular cylindrical body 20 and base 30 form a secure container, whereby enclosed materials are prevented from escaping to the exterior.

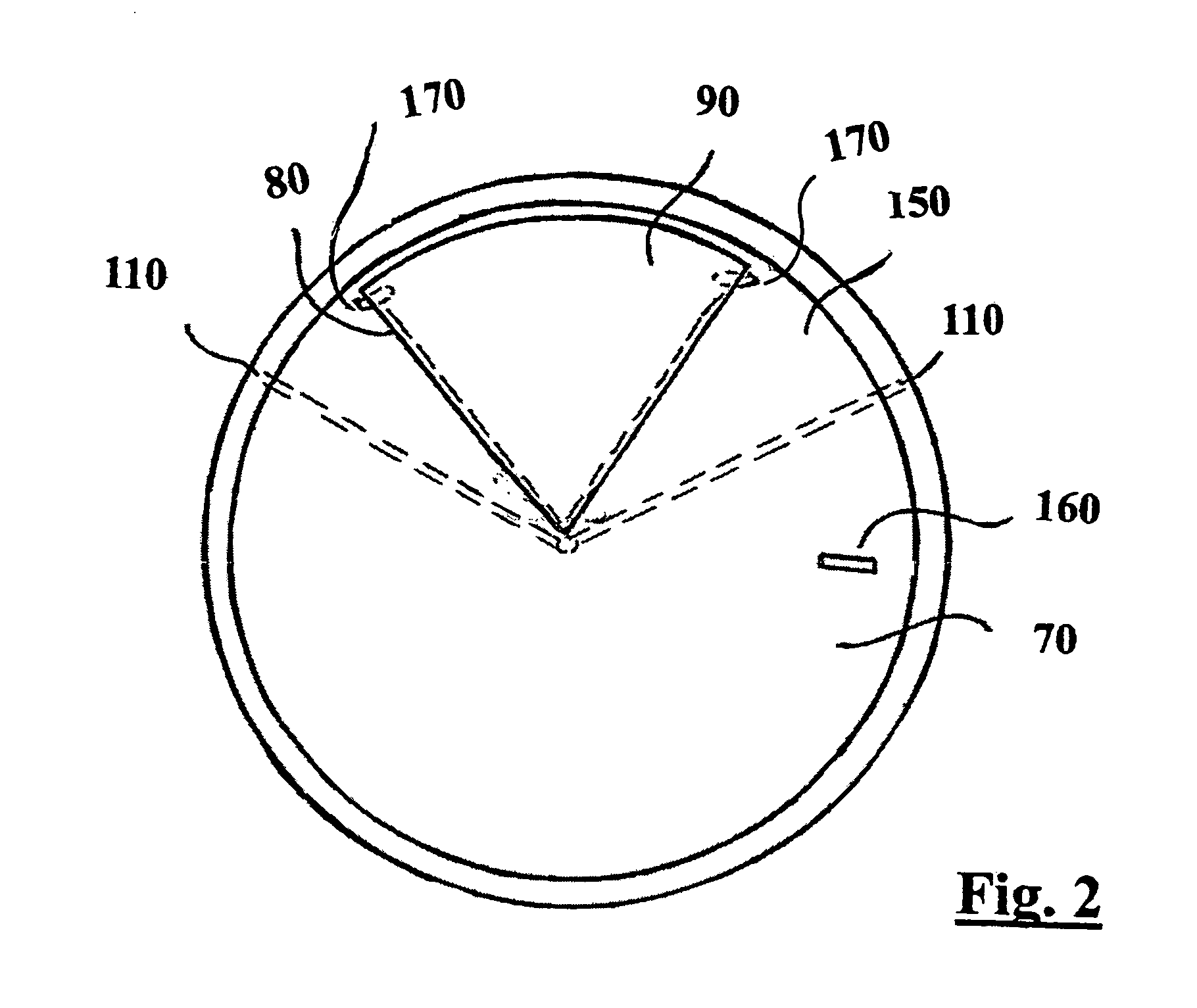

[0042]Top 10 is comprised of a threaded retaining rim 40 having threads 50 matching those threads on cylindrical body 20 so it may be screwed on in a manner similar to a common jar. Holding lip 60 allows movement of rotatable disk 70 when retaining rim 40 is loosened, similar to the design of common mason jars. Flap 80 covers access hole 90 in rotatable disk 70, which may be rotated to a desired position when rotatable disk 70 is turned. Flap 80 snaps securely into access hole 90, and unsnaps to provide access through access hole 90. Sidewalls 100 of tubular cylindrical body 20 are transparent and may be constructed from a variety of materials, including plastic or glass.

[0043]Internally, pivotable separators 110 having hinges 120 are rotatably communicated with axle 130, which l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com