Blade and gas turbine

a gas turbine and blade technology, applied in the field of blades, to achieve the effect of reducing weight, reducing weight, and influencing the strength properties of segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Turbomachines use blade stages, which comprise adjacent rotor blades and guide vanes, to convert flow energy into rotary energy and vice versa. The guide vanes are arranged on the machine housing, while the rotor blades are directly connected to the rotor.

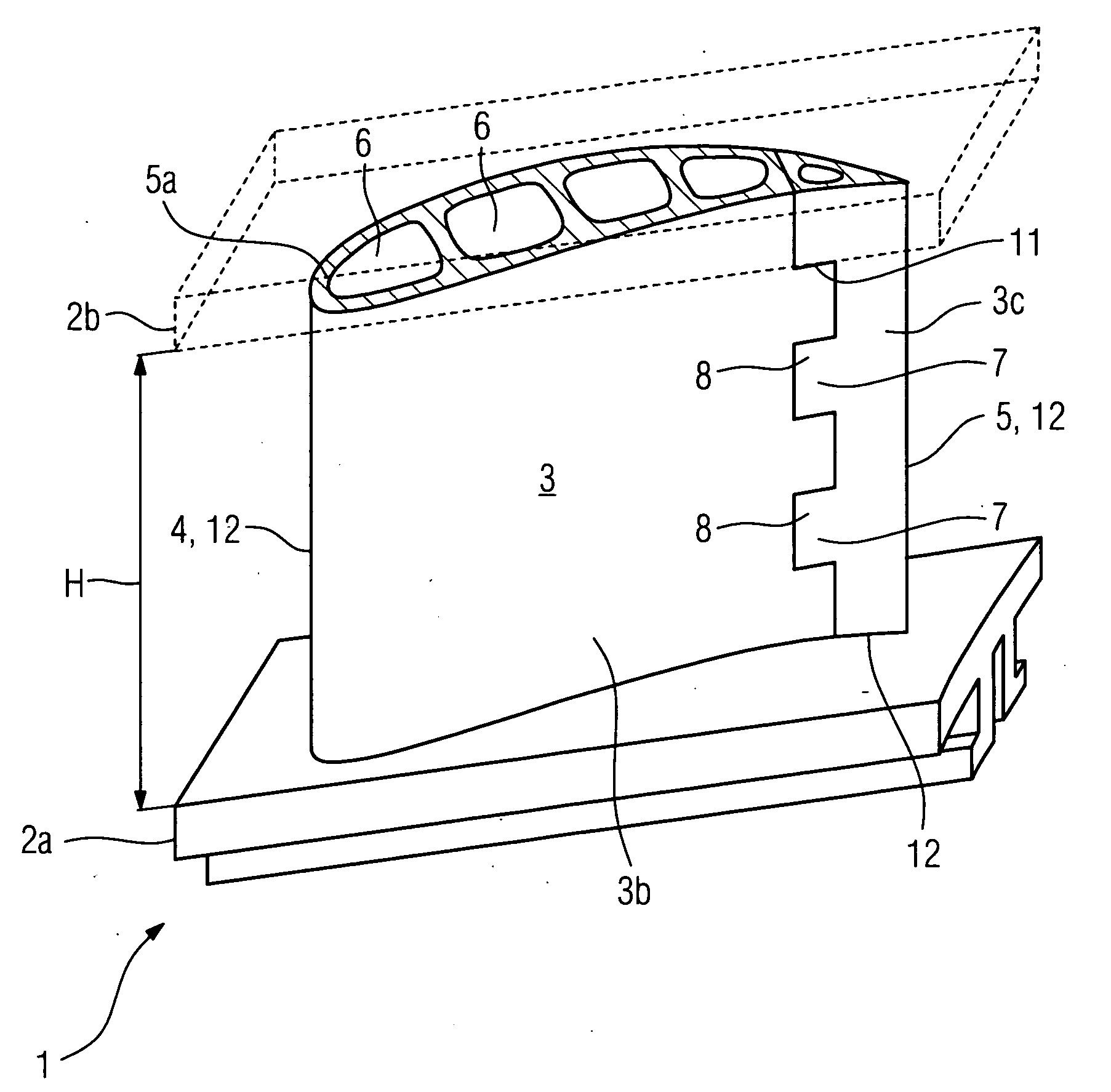

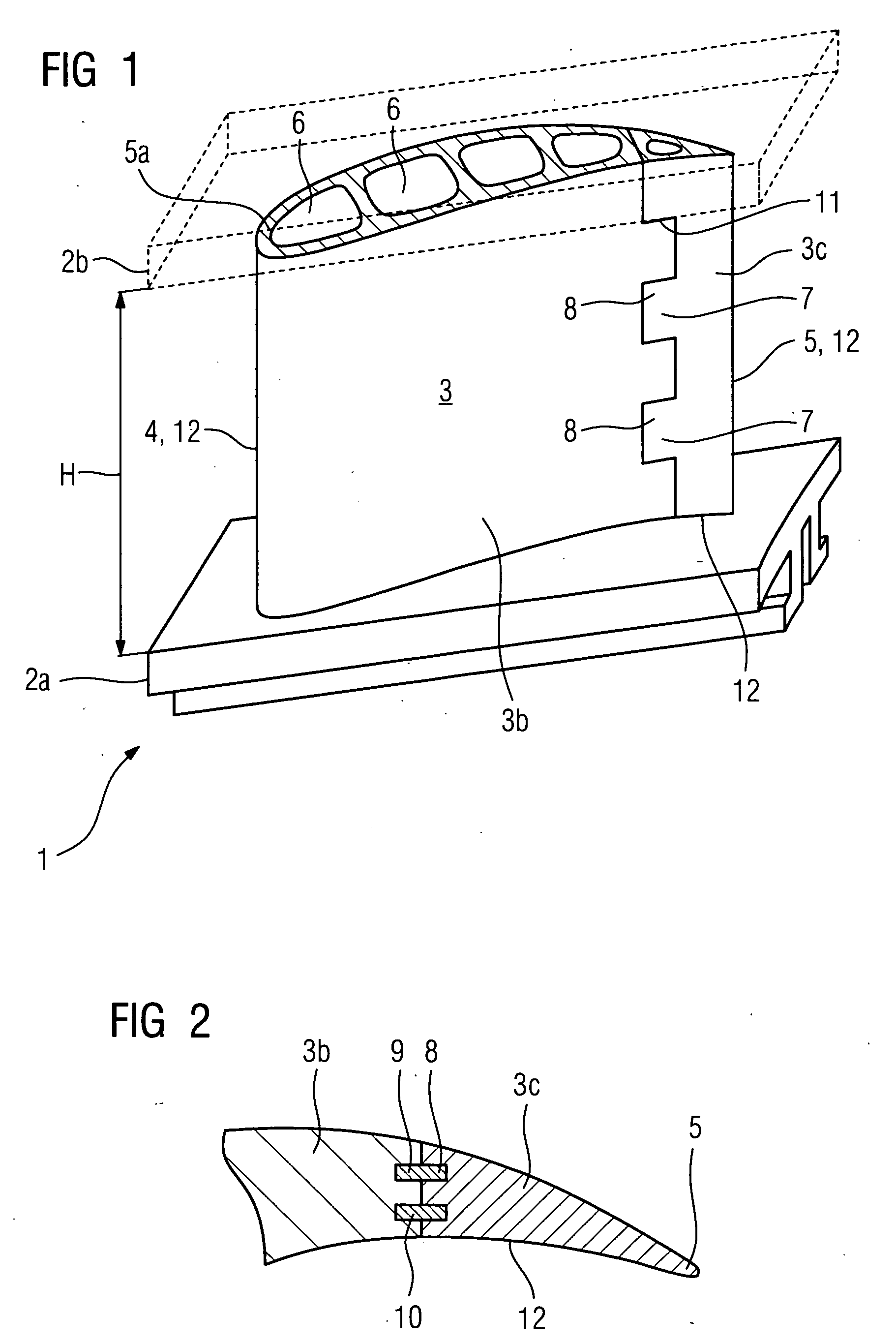

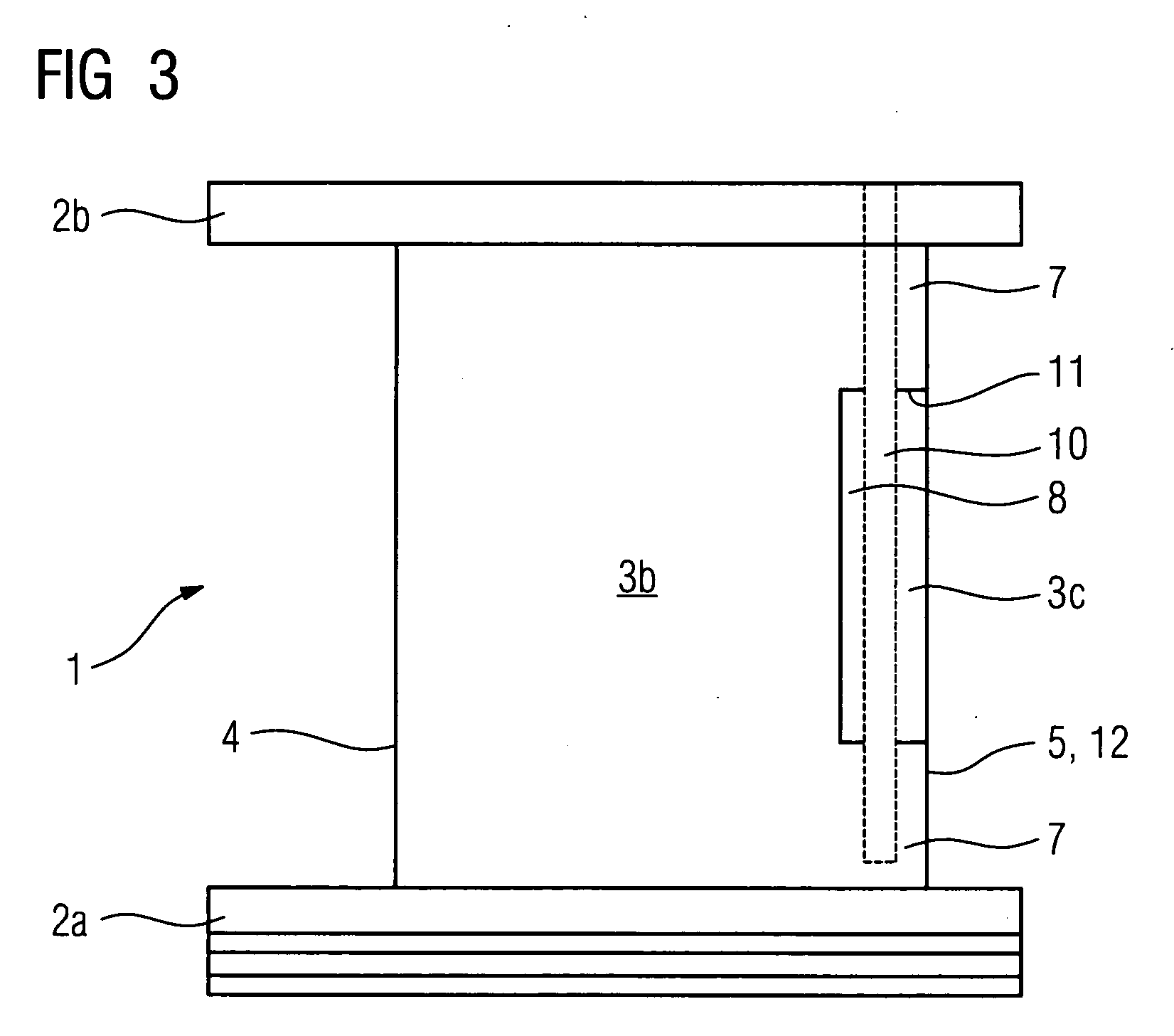

[0023]A blade 1 according to the invention with a segmented trailing edge is illustrated in FIGS. 1 to 3. The blade 1 itself has a platform 2a and a main blade part 3 with a blade leading edge 4 and a blade trailing edge 5. A second platform 2b, which is formed integrally at the upper end 5a of the main blade part 3, is illustrated by dashed lines. The main blade part 3 is composed of a base body segment 3b and a trailing edge segment 3c. As can be seen at the upper end 5a of the main blade part 3, the base body segment 3b has a plurality of cavities 6 which, given sufficient strength, are used to reduce the blade mass in order to lower the mechanical and thermal stresses in operation. One or more cavities 6 may be filled wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| relative movements | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com