Pre-loading of building sites over compressible strata

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

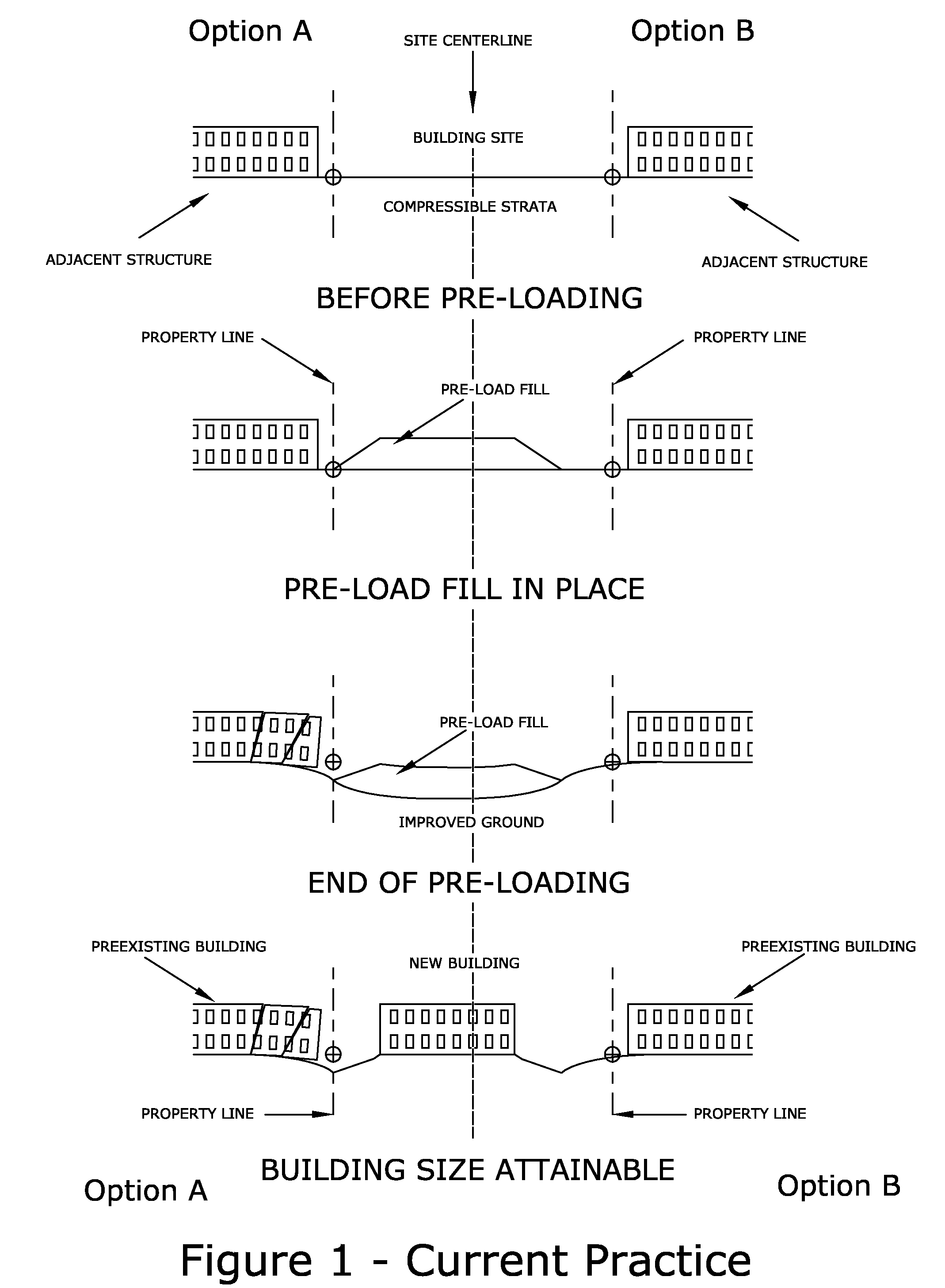

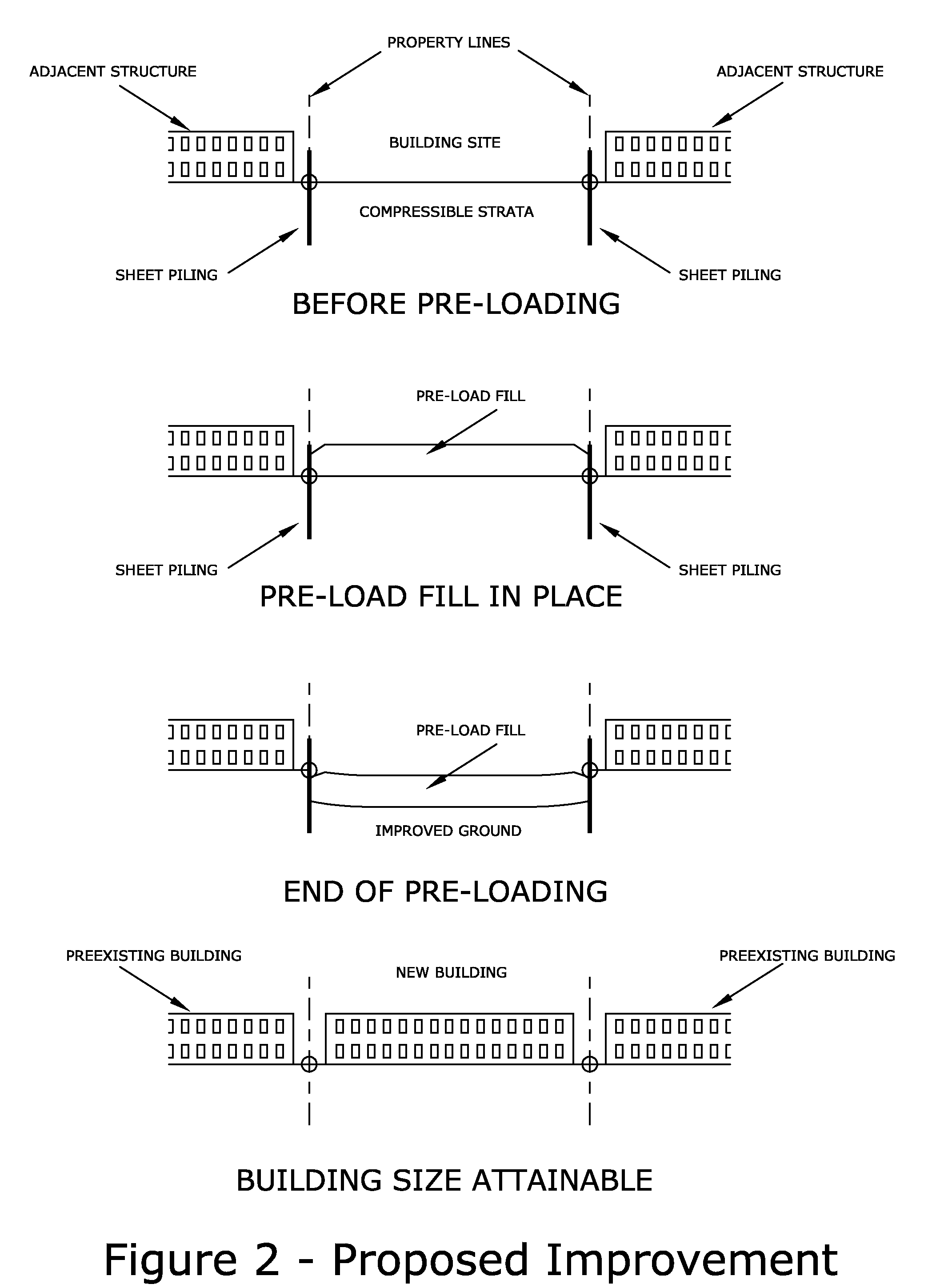

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

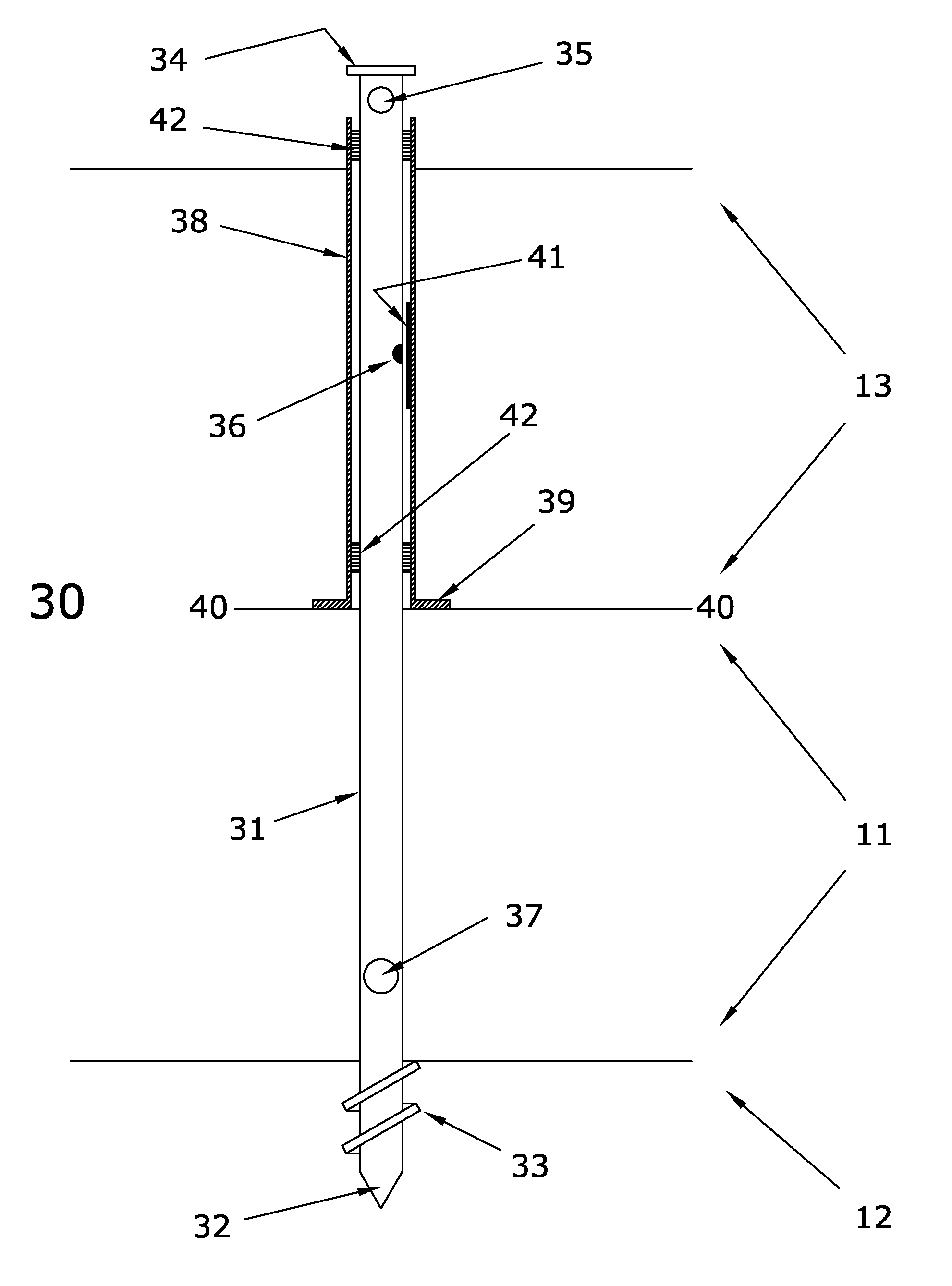

[0047]FIG. 3 shows schematically sheet pile sections 10 required for the isolation wall. These are standard construction items, and are available in plastic as well as steel. The installation of the piles is achieved by driving them thorough the compressible strata 11 and into the upper competent stratum 12 prior to placing the pre-load fill 13 on top of the ground surface 14. A variety of pile driving hammers are available; for the circumstances involved in this application it might be preferable to use vibratory, rather than impact (drop or diesel) pile driving hammers. Such pile driving equipment involve no novelty. To make this system function optimally, two pieces of novel apparatus are preferable, and these are as follows:

Description of the Anchor Assembly

[0048]FIG. 3 shows schematically adjustable passive anchor assembly 20 which includes the following arrangement of parts: A strong relatively rigid plate 21, preferably rectangular. A deformable space 22 is provided behind, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com