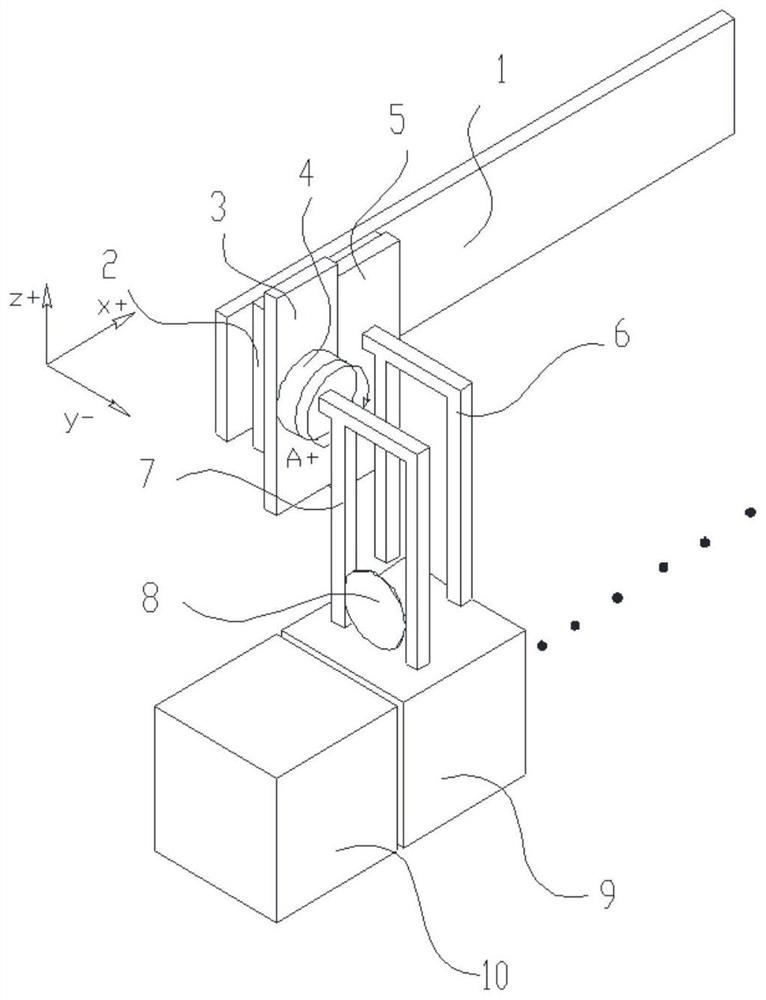

A wafer transfer manipulator and wafer flipping method thereof

A technology of manipulators and wafers, applied in conveyor objects, transportation and packaging, electrical components, etc., can solve problems such as the impact of transmission efficiency, reduce wafer cleanliness, etc., and achieve the effect of high space utilization and compact travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

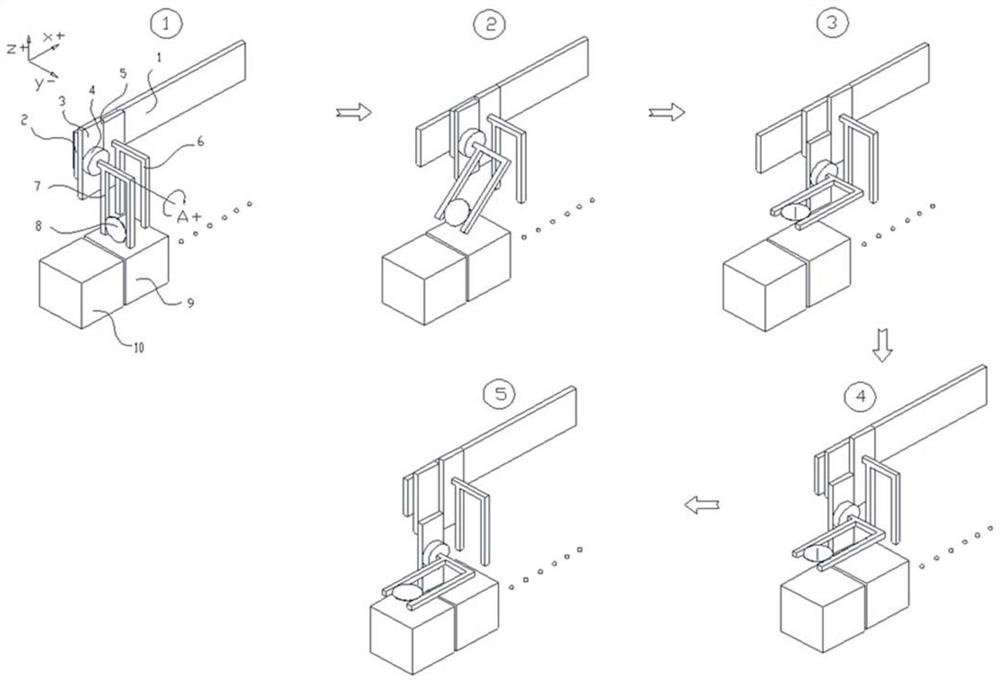

[0049] After the first jaw holding arm 7 moves along the Z-axis direction and takes out the wafer 8 from the pre-drying unit 9 (such as figure 2 as shown in part ①), such as figure 2 As shown in part ②, the horizontal transfer carriage 2 moves in the X+ direction, and at the same time, the rotary table 4 drives the wafer 8 to rotate clockwise along A+, and the first vertical lifting axis 3 carries the first jaw clamping arm 7 in the Z- direction Moving downward, the first jaw clamping arm 7 carries the wafer 8 to move together in the three directions of X+, A+, and Z-, and coordinates to complete the state transition process of the wafer 8 from vertical to horizontal, such as figure 2 As shown in part ③ of , the wafer 8 has reached a horizontal state. During the flipping of the wafer 8 , the designated mechanism inside the drying unit 10 is ready to put the wafer 8 into it. Then the horizontal transfer carriage 2 drives the first claw clamping arm 7 to move to the X-direc...

Embodiment 2

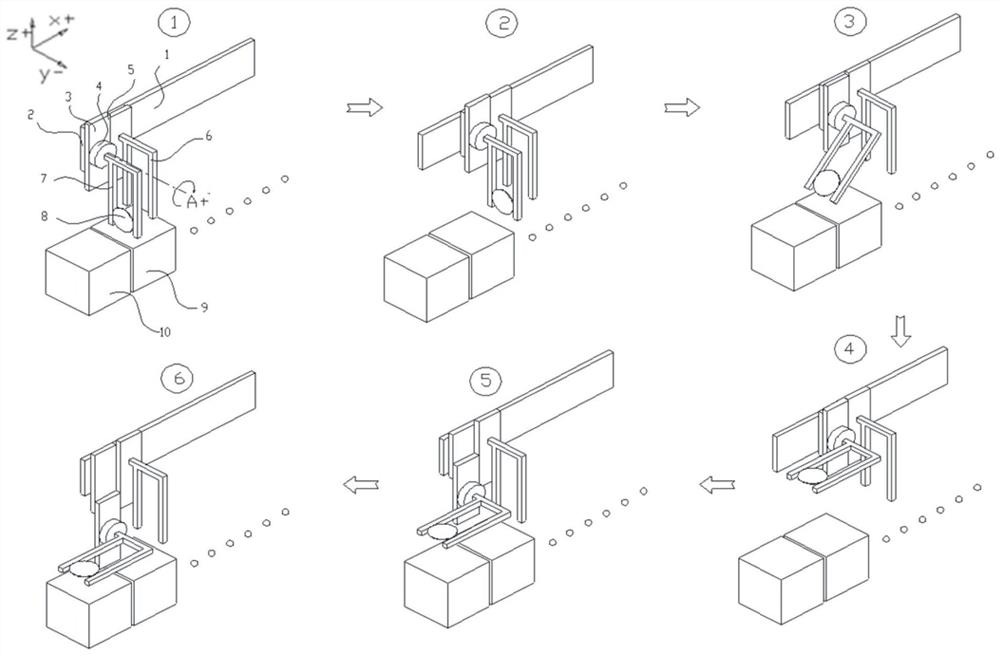

[0051] After the first jaw holding arm 7 moves along the Z-axis direction and takes out the wafer 8 from the pre-drying unit 9 (such as image 3 as shown in part ①), such as image 3 As shown in part ②, the horizontal transfer carriage 2 moves a certain distance in the X+ direction, and then the rotary table 4 drives the first claw clamping arm 7 to rotate clockwise along A+ to a certain angle to make the wafer 8 reach a horizontal state (such as image 3 ③ and ④ part shown). Then the first vertical lifting shaft 3 and the first claw clamping arm 7 move downward to a certain position in the Z-direction. During the flipping of the wafer 8 , the designated mechanism inside the drying unit 10 is ready to put the wafer 8 into it. Then the horizontal transfer carriage 2 drives the first claw clamping arm 7 to move to the X-direction until the wafer 8 is located above the drying unit 10 (such as image 3 shown in part ⑤). The first claw clamping arm 7 moves downward in the Z-dir...

Embodiment 3

[0053] After the first jaw holding arm 7 moves along the Z-axis direction and takes out the wafer 8 from the pre-drying unit 9 (such as Figure 4 as shown in part ①), such as Figure 4 As shown in part ②, the horizontal transfer carriage 2 moves a certain distance in the X+ direction, and then the rotary table 4 drives the first claw clamping arm 7 to rotate clockwise along A+ to a certain angle to make the wafer 8 reach a horizontal state (such as Figure 4 ③ and ④ part shown). Then the horizontal transfer carriage 2 drives the first claw clamping arm 7 to move in the X-direction (as Figure 4 ⑤), and then the first vertical lifting shaft 3 and the first claw clamping arm 7 move down in the Z-direction until the wafer 8 is located in the designated mechanism inside the drying unit 10 (such as Figure 4 shown in part ⑥). Finally, the first clamping arm 7 releases the wafer 8 , and the wafer 8 is located on the designated mechanism inside the drying unit 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com