A kind of super-amphiphobic coating and its preparation method and surface wettability conversion method

A conversion method, super-amphiphobic technology, used in coatings, special surfaces, devices for coating liquids on surfaces, etc., to achieve the effect of a wide range of wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

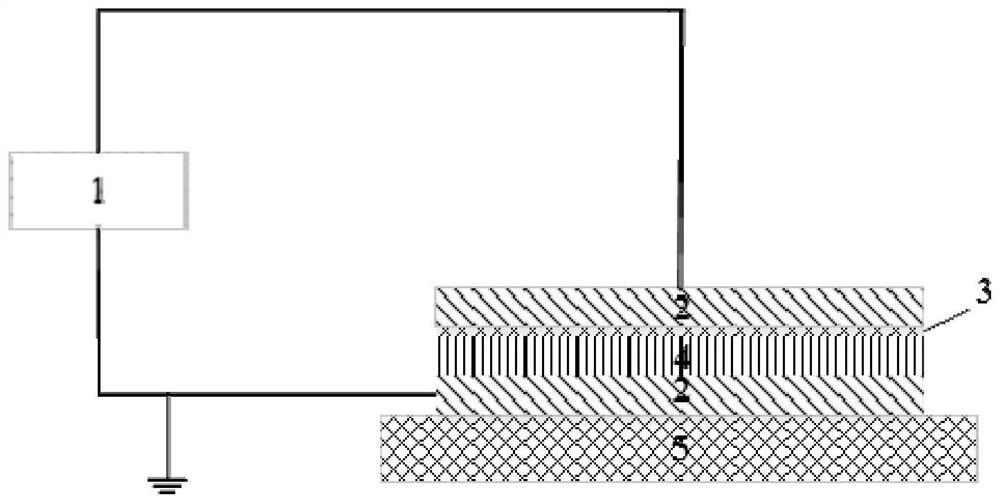

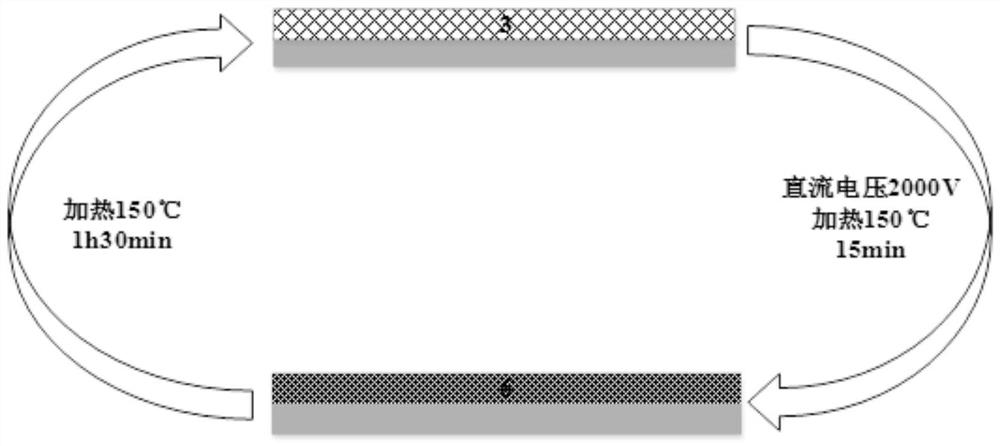

[0035] The invention provides a kind of preparation method of super amphiphobic coating, comprises the following steps:

[0036] Step 1, prepare super amphiphobic coating, specifically:

[0037] Step 11, weigh 0.5-2g of nano-SiO 2 and 0.25-1g of micron SiO 2 , added to 10-100mL of ethanol, stirred to obtain a uniform solution; wherein, nano-SiO 2 Using nano-SiO with a diameter of 16-25nm 2 ; Micron SiO 2 Using micron SiO with a diameter size of 5-50 μm 2 ; The stirring time is 5-20min, and the stirring speed is 200r / min.

[0038] Step 12, take 2-10mL ammonia water and 1-5mL deionized water, add to the homogeneous solution in step 11, stir to obtain a homogeneous mixture; the stirring time is 60-120min, the stirring speed is 200r / min; the concentration of ammonia water is 25 %;

[0039] Step 13, take 0.05-0.5mL tetraethyl orthosilicate, 0.05-1mL perfluorosilyl trimethoxysilane and 1-2mL varnish, add to the homogeneous mixture in step 12, stir until the solution has no ob...

Embodiment 1

[0047] The invention provides a kind of preparation method of super amphiphobic coating, comprises the following steps:

[0048] Step 1, prepare super amphiphobic coating, specifically:

[0049]Step 11, weigh 0.5g of nano-SiO 2 and 0.25g of micron SiO 2 , added to 10mL of ethanol, stirred to obtain a uniform solution; wherein, nano-SiO 2 Using nano-SiO with a diameter of 16-25nm 2 ; Micron SiO 2 Using micron SiO with a diameter size of 5-50μm 2 ; Stirring time is 5min, stirring rate is 300r / min.

[0050] Step 12. Take 2 mL of ammonia water and 1 mL of deionized water, add them to the homogeneous solution in step 11, and stir to obtain a homogeneous mixture; the stirring time is 120 min, and the stirring speed is 100 r / min; the concentration of ammonia water is 25%;

[0051] Step 13, take 0.05mL tetraethyl orthosilicate, 0.05mL perfluorosilyltrimethoxysilane and 1mL varnish, add to the homogeneous mixture in step 12, stir until the solution has no obvious layering and is ...

Embodiment 2

[0060] The invention provides a kind of preparation method of super amphiphobic coating, comprises the following steps:

[0061] Step 1, prepare super amphiphobic coating, specifically:

[0062] Step 11, weigh 1g of nano-SiO 2 and 0.5 g of micron SiO 2 , added to 50mL of ethanol, stirred to obtain a uniform solution; wherein, nano-SiO 2 Using nano-SiO with a diameter of 16-25nm 2 ; Micron SiO 2 Using micron SiO with a diameter size of 25 μm 2 ; Stirring time is 10min, stirring rate is 250r / min.

[0063] Step 12, take 2mL ammonia water and 2.5mL deionized water, add to the homogeneous solution in step 11, stir to obtain a homogeneous mixture; the stirring time is 60min, the stirring speed is 300r / min; the concentration of ammonia water is 25%;

[0064] Step 13, take 0.25mL tetraethyl orthosilicate, 0.5mL perfluorosilyl trimethoxysilane and 1.5mL varnish, add to the homogeneous mixture in step 12, and stir until the solution has no obvious layering and is uniform; stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com