A multi-vehicle storage and delivery system for urban rail transit

An urban rail transit, multi-vehicle technology, applied in the system field of the multi-vehicle storage and delivery system of urban rail transit, to achieve the effect of improving comprehensive production capacity, reducing floor space and solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

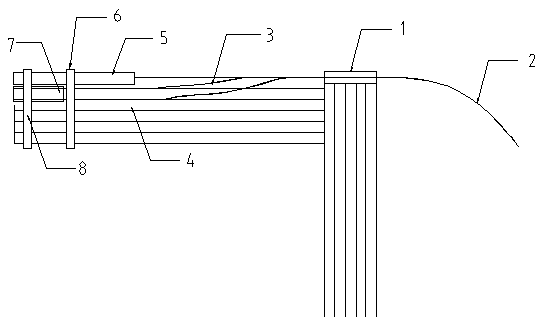

[0041] Such as figure 1 As shown, the present invention provides a multi-model storage and delivery system for urban rail transit, which includes a wagon transfer station 1, a transfer line 2, a switch 3, a car storage line 4, a delivery trench 5, a mobile crane 6, and a disassembly trench 7. , Fixed crane 8;

[0042] Car transfer platform 1: A device similar to a bridge, its main function is to connect the vehicle with the moving line outside the workshop after the vehicle body is welded, painted, assembled and statically adjusted, followed by the completion of the vehicle on the moving line After the dynamic adjustment test, it can be transferred to the storage and dispatch line through the transfer platform;

[0043] Transfer line 2: The track line arranged according to the company's overall plan and process layout, mainly used for vehicle transfer;

[0044] Turnout 3: The standard No. 7 turnout is adopted, and its main function is to meet the reversing between the parking lanes ...

Embodiment 2

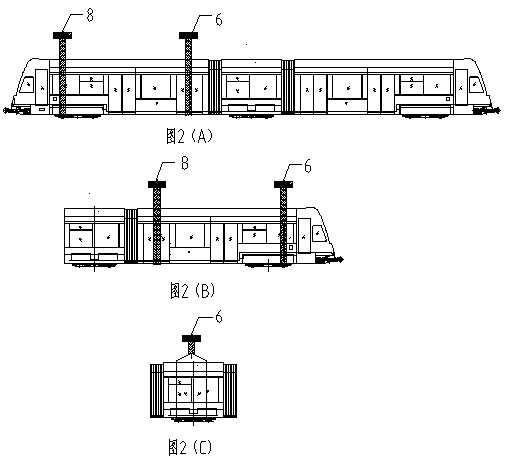

[0060] Such as figure 2 As shown, a three-module and five-module tram delivery method: The most obvious feature of this tram 9 and subway car is that the three-module tram 9 has 2 bogies, and the five-module tram 9 has only There are 3 bogies, and each subway train has 2 bogies. According to the process requirements of the tram 9, the tram 9 cannot be hoisted as a whole car, and can only be hoisted in a single train after disassembly. After the subway disassembly, each train can run independently, but some modules of the tram 9 cannot be independently supported after the disassembly. And walking, the following detailed description of the vehicle delivery steps with a 3-module tram 9.

[0061] The shipping method of the three-module tram 9 includes the following steps:

[0062] Such as figure 2 As shown in (A), the first step: 1. Move the tram 9 below the crane, the fixed crane 8 and the mobile crane 6 directly act on the position of the vehicle lifting point through the spreader...

Embodiment 3

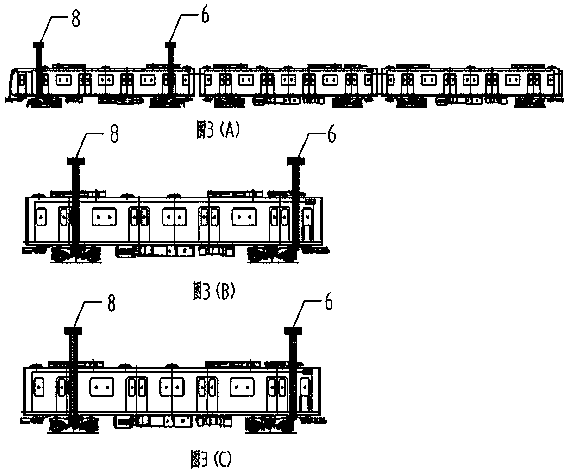

[0066] Such as image 3 As shown, a method for the delivery of subway vehicles: the subway structure is generally four or six marshalling modules, each module has basically the same shape and size, and its hanging point positions are basically the same, and there is no need to break up trenches when unpacking. Therefore, the delivery of subway vehicles is relatively simple; the subway vehicles stored on the storage lane 4 are decomposed and directly pushed to the vehicle hoisting area under the two cranes, and the mobile crane 6 is adjusted to ensure that the distance between the two cranes is exactly the same. The hoisting point location of the subway vehicle to complete the hoisting and delivery; the method of subway vehicle hoisting includes the following steps:

[0067] Such as image 3 As shown in (A), in the first step, when the main vehicle of the industry is ready for shipment, the craftsman can directly decompose the vehicle. After decompilation, each train can travel alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com